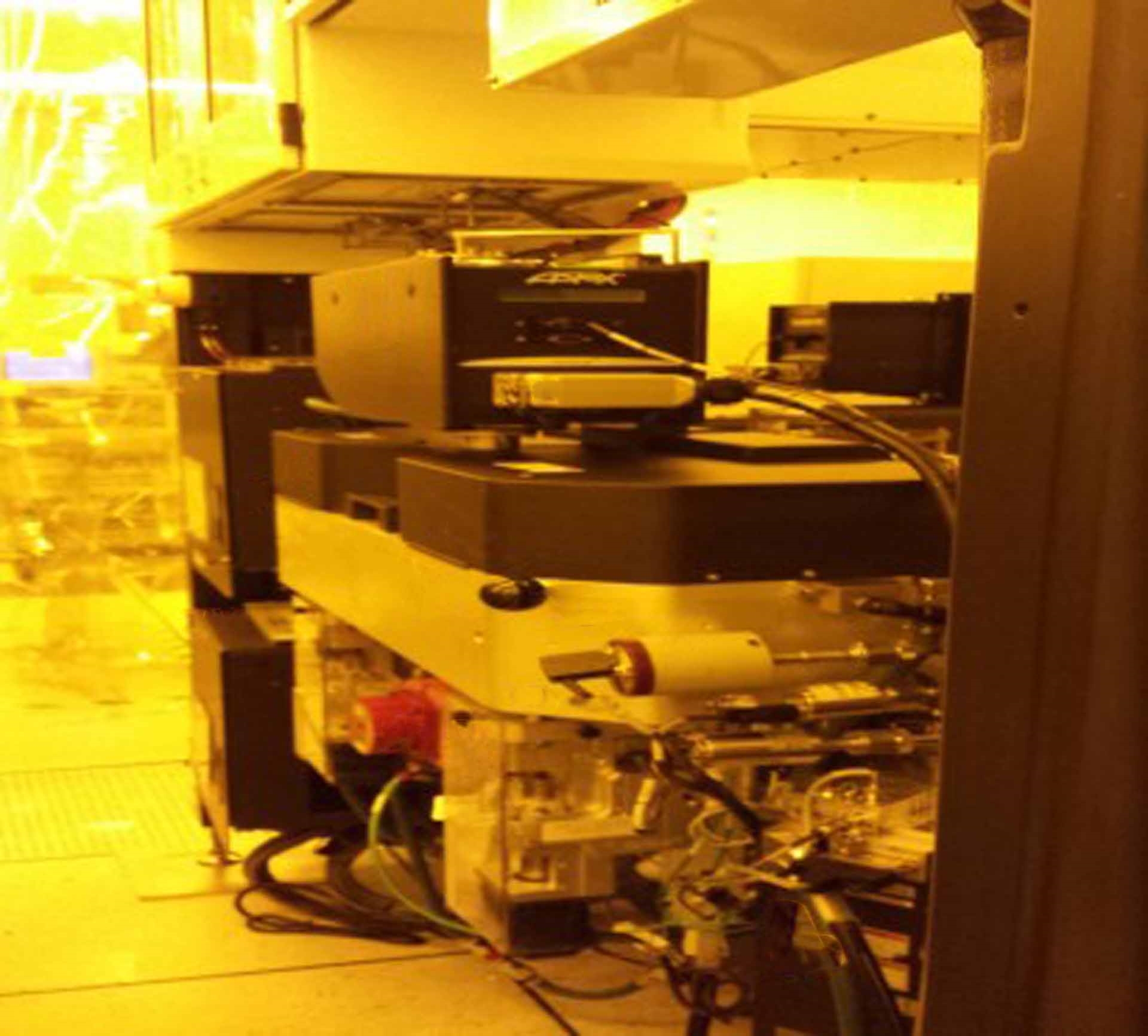

Used AMAT / APPLIED MATERIALS Producer III #9223648 for sale

URL successfully copied!

Tap to zoom

ID: 9223648

Wafer Size: 8"

Vintage: 2004

Shrink system, 8"

Process: SILCU

CIM

(3) Twin chambers

Hardware configuration:

SMIF: (4) ASSYST Indexers

Handler system:

SMIF Front end robot

VHP Buffer robot

(3) Process chambers

Heat exchanger: Steelhead

High RF generator: (4) RFG 2000-2V

DPA RF Generator: ENI DPG-10

Platform type: Producer shrink

Chamber A & B & C:

Chamber body effective volume (Syscon):

Chamber A: 12980

Chamber B: 13275

Chamber C: 13300

SiH4_H: 1 SLM

SiH4-L: 300 Sccm

NH3 HI: 1 SLM

N2O HI: 3 SLM

N2O LO: 500 Sccm

N2: 10 SLM

NH3: 500 Sccm

Ar: 5 SLM

He: 10 SLM

Number of gas lines / Name: 10

RF1 & RF2 Generator (Max Power / Brand): 2000 W

Foreline pump (EBARA AAS 100WN): 10000 L/Min

Baratron off-set 626 MKS: 10 T

Lift pin type: Free drop

Lift pin speed (Timing of movement): 3580

Load lock: A & B

Configuration:

Pump capacity (EDWARDS BOC): IPX 100A

Difuser: ENTEGRIS 60 PSIG

Venting N2 flow rate: 10 SLM

Venting time: 57 Sec

Pump time: 65 Sec

Baratron Range / Brand / Off-Set: 325 Moducell MKS

Pressure set point for LL pumping switching: 45 Sec

Time delay for LL door open: 10 Sec

Transfer chamber:

Type of robot / Robot blade: Super blade

Robot speed with wafer / Runrate / Slope:

300000 / 210000

230000 / 120000

Robot speed without wafer (Ext/Rot):

200000 / 325000

230000 / 325000

MFC N2 Flow setting: 10 SLM

Chamber base pressure ( Actual / Alarm): 208 mTorr

Wafer transfer - chamber: 300 mTorr

Buffer pressure transfer chamber - wafer: 320 mTorr

Other periphere:

SiH4 HI: 29.6, 30, 36

NH3 HI 27.6, 27.8, 29

CDA Pressure: 85

HX Temperature / Flow rate: 75

N2 (P): 27

SiH4 LO

NH3 LO

N2O: 30

NF3

2004 vintage.

AMAT / APPLIED MATERIALS Producer III is an advanced plasma reactor for the manufacture of semiconductor chips. AMAT Producer III utilizes an electron cyclotron resonance (ECR) source to create a uniform, high-density plasma, which is critical for depositing thin, precise layers of materials such as polysilicon gate dielectrics and copper interconnects in chip production. APPLIED MATERIALS Producer III design allows for optimal process control over existing systems. Its patented wafer-confined volumes and low-noise technology maintain extremely uniform deposition from each area of the wafer. Producer III is also extremely energy efficient, with reduced power consumption and minimal collateral heat development. All of this combined enables AMAT / APPLIED MATERIALS Producer III to improve the chip production practices of semiconductor manufacturers. AMAT Producer III builds upon the previous AMAT Producers I and II by adding several key features. It provides two separate RF power sources that can independently control deposition from the bottom and top of the wafer, allowing the growth of over 200 layers. It is also equipped with a proprietary UHP (Ultra High Pressure) system that maintains an ultra-uniform gas flow across the wafer and more precisely regulates process conditions. APPLIED MATERIALS Producer III also allows for a high degree of flexibility of the deposition. It can apply a uniform film to the entire wafer or to select zones depending on the application. Each zone has programmable parameters that can be adjusted for individual deposition processes, allowing the user to custom design processes. It also has advanced diagnostics and data logging that enable offline analysis of the process. Producer III is a highly advanced plasma reactor designed to provide the most precise and repeatable deposition results. With improved process control, flexibility and energy efficiency, AMAT / APPLIED MATERIALS Producer III offers unparalleled support for chip manufacturing processes.

There are no reviews yet