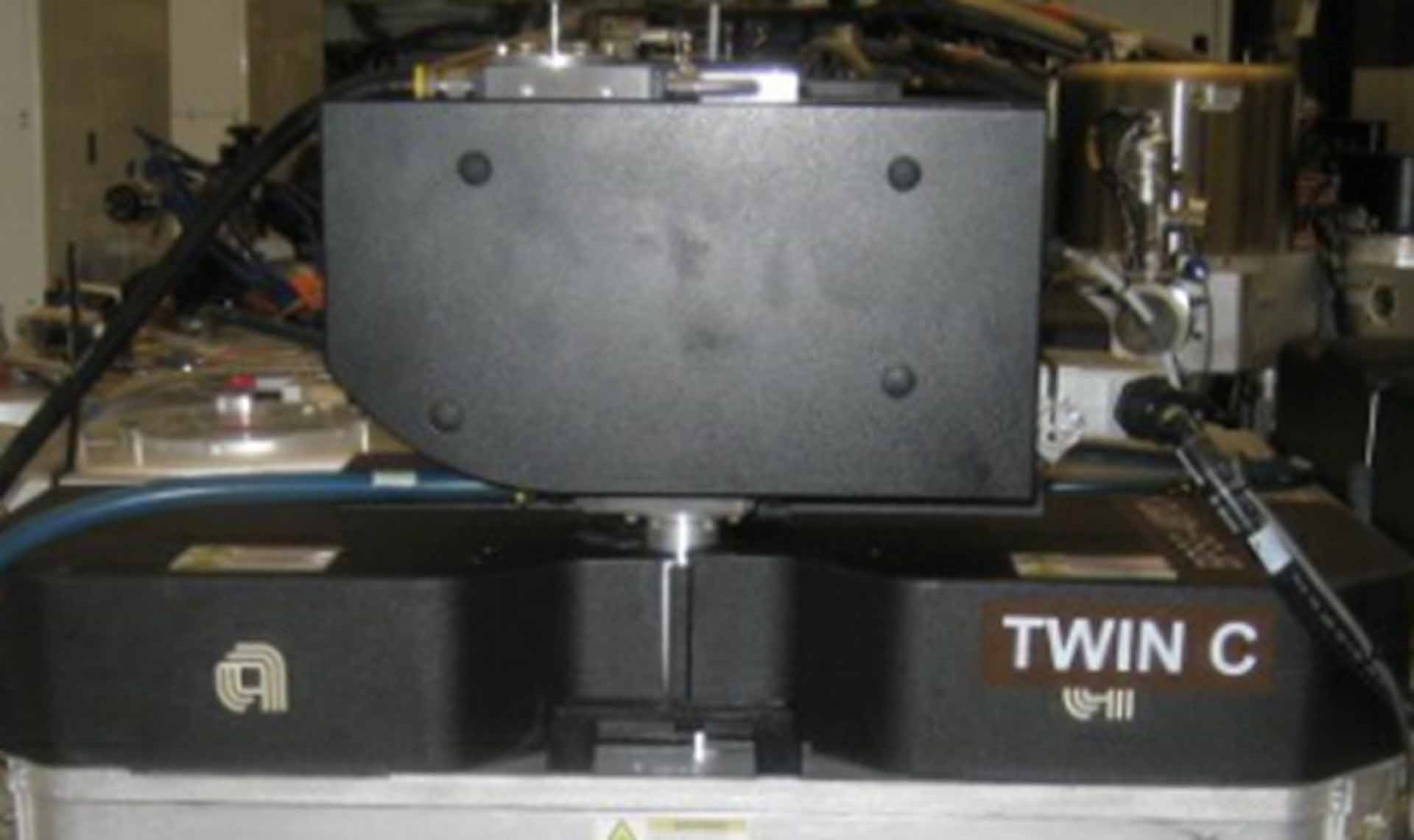

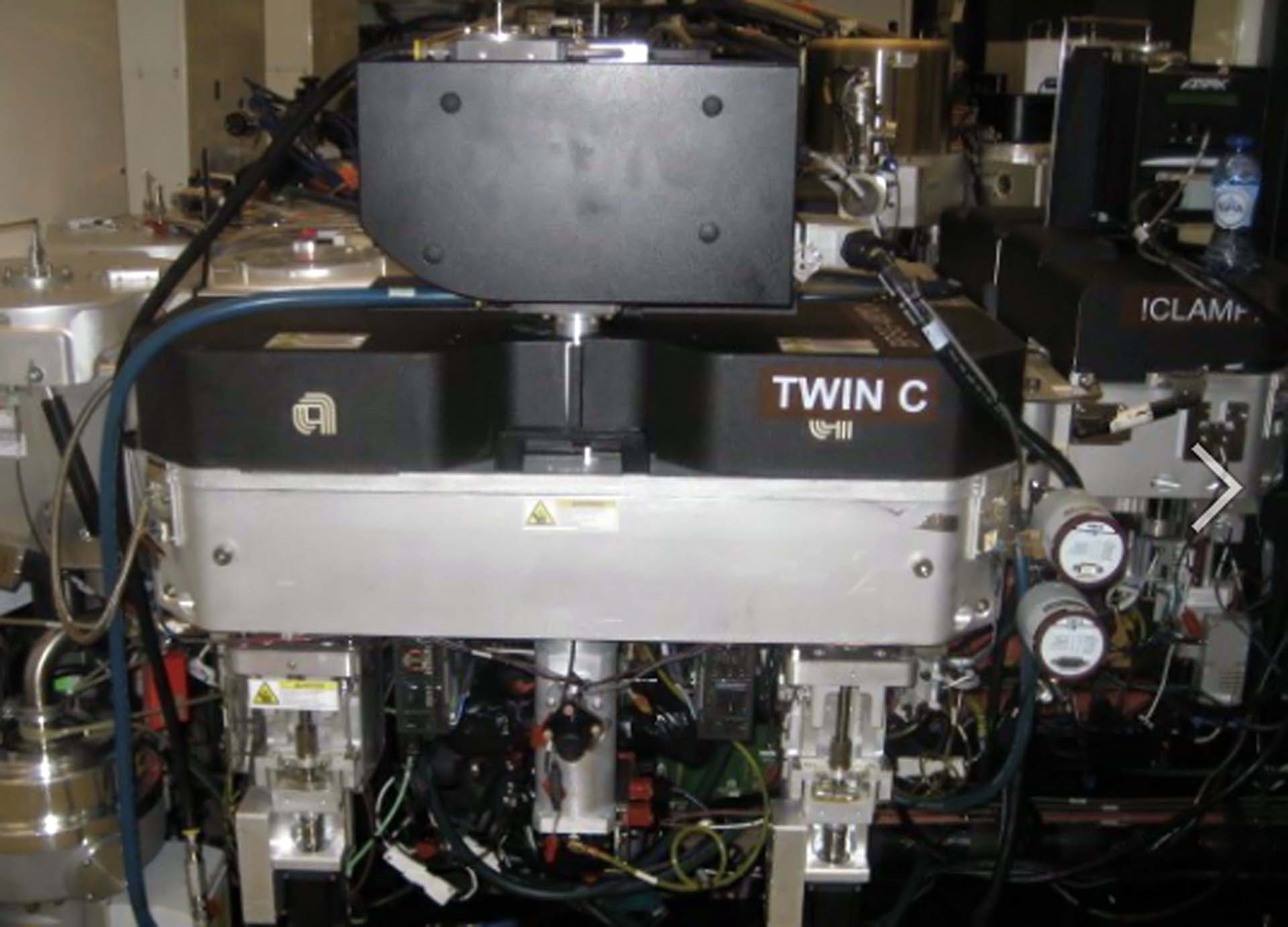

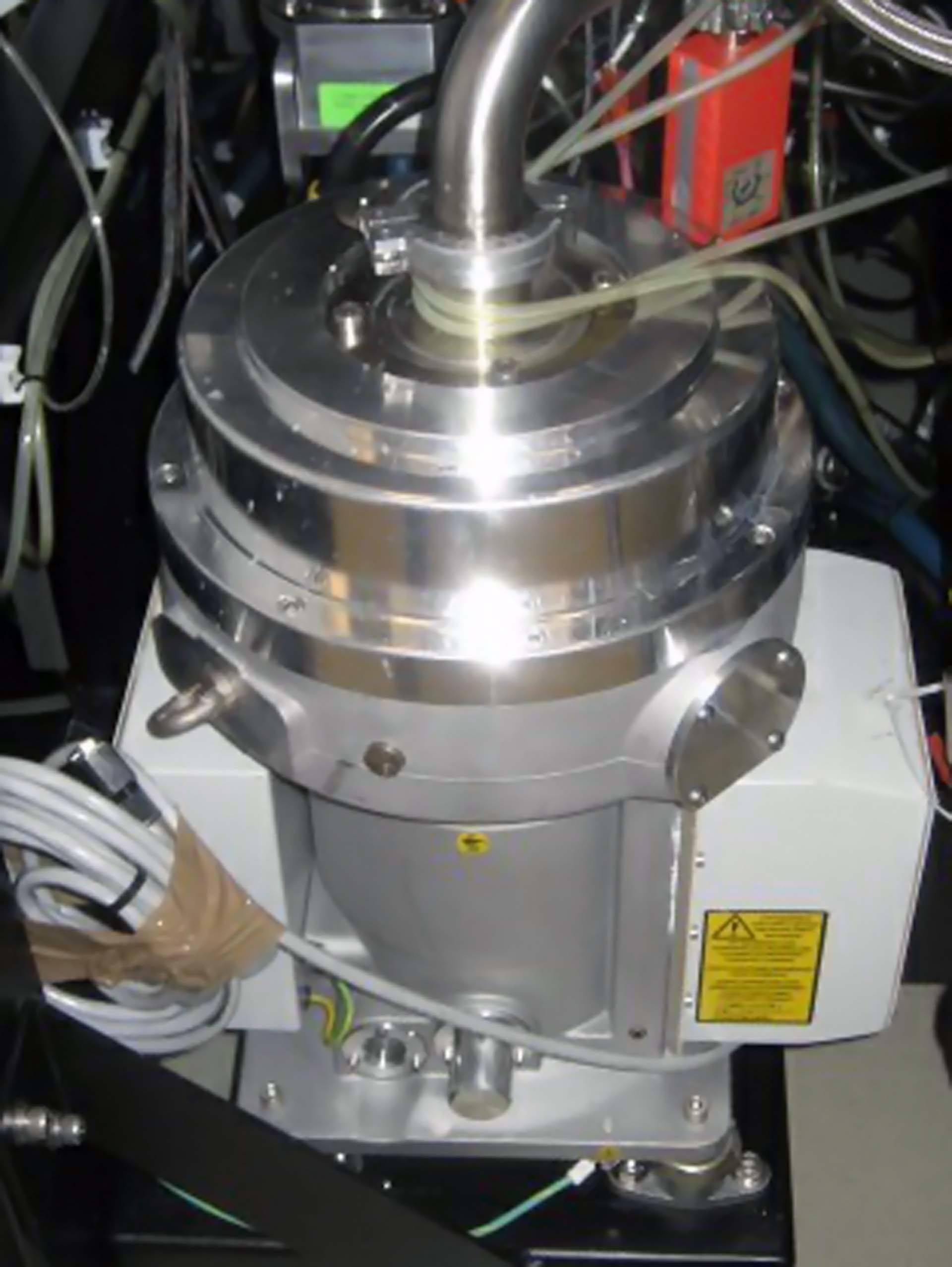

Used AMAT / APPLIED MATERIALS Producer III #9238404 for sale

URL successfully copied!

Tap to zoom

ID: 9238404

Vintage: 2000

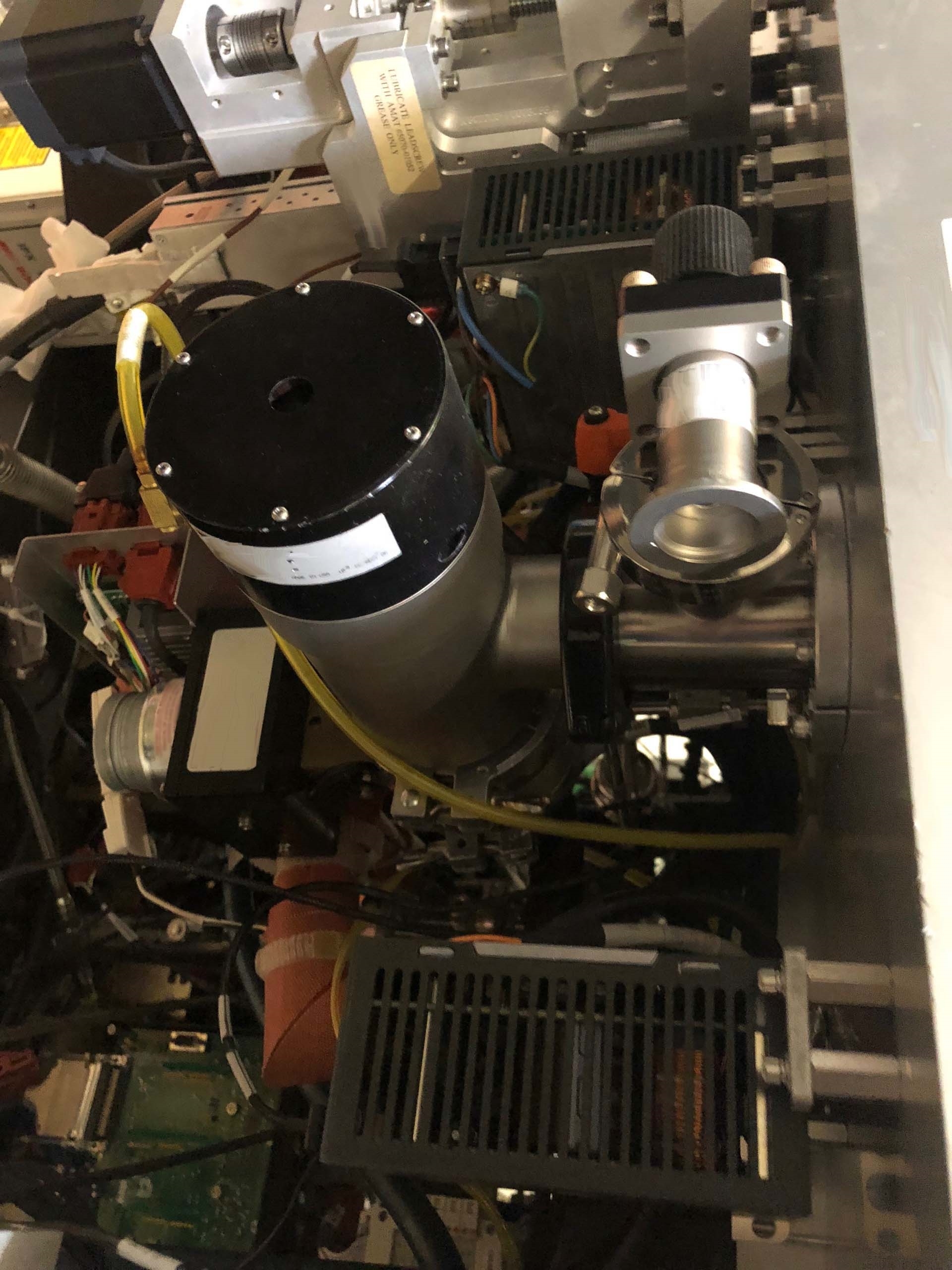

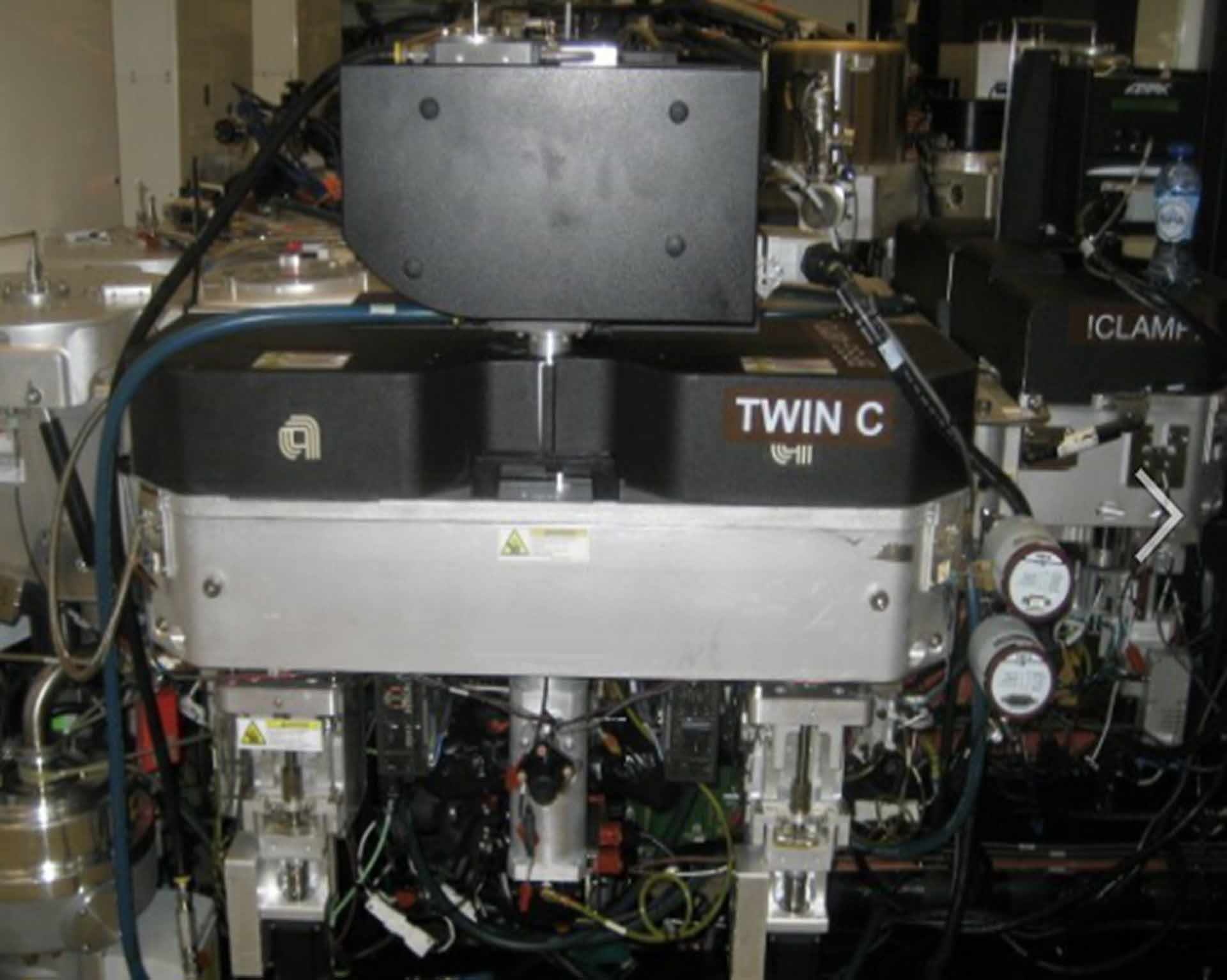

CVD System, 8"

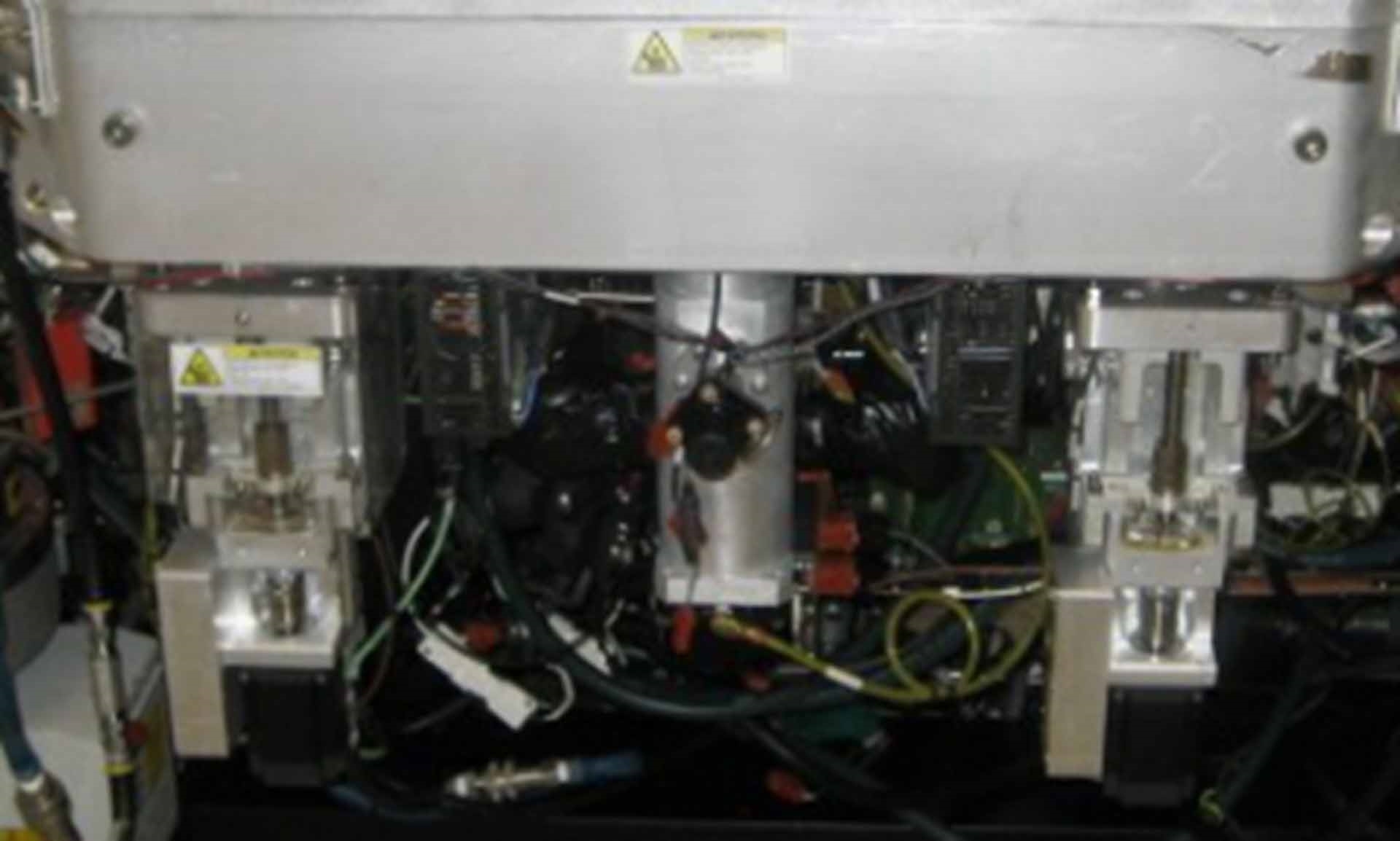

(3) Twin chambers

Platform: Producer S

Wafer shape: SNNF

Mainframe:

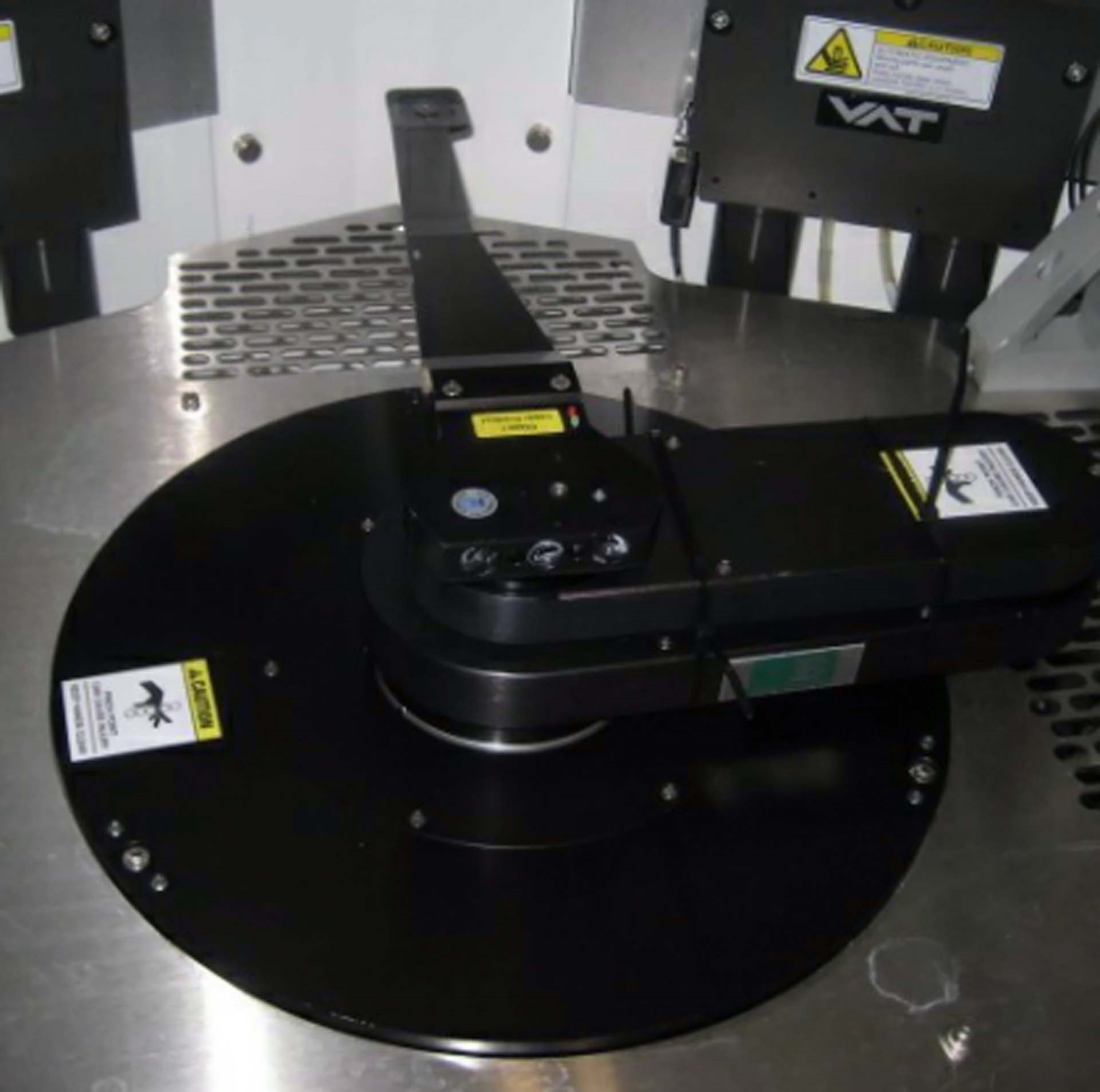

Buffer robot type: VHP

FI Robot type: Manual

Buffer robot blade: Standard blade

RYGB Status light tower

Front end type: Manual type front end

PRI BROOKS ABM407 Front end robot

VHP Buffer robot

Transfer pump: IPX Pump

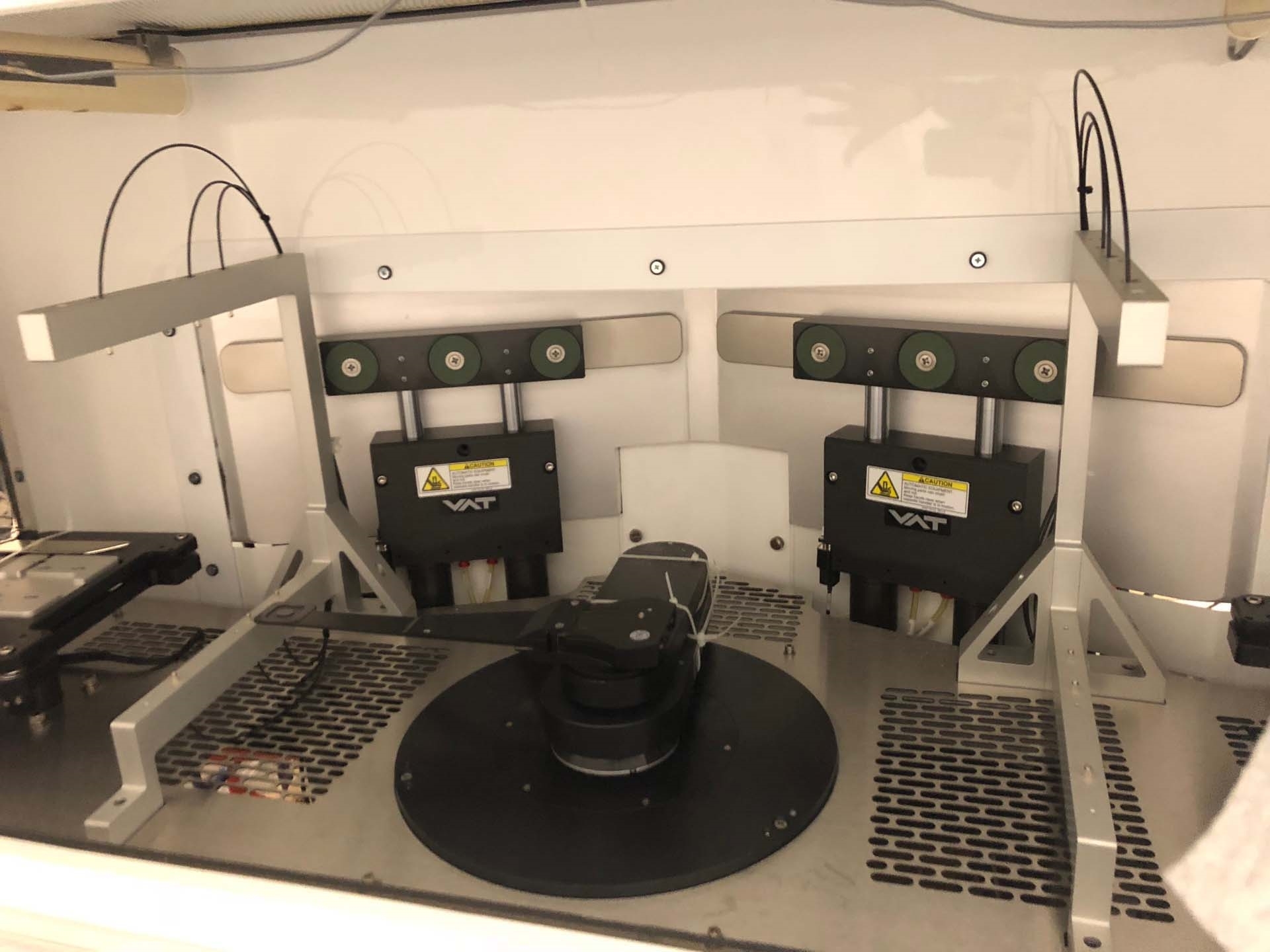

Chamber slit valve / LL Door: VAT

L/L Gauge: MKS Stand

Hard disk: Stand

Floppy disk: 1.44 M

Chamber configuration:

Chamber A, B, C: Producer S BPSG Twin

Chamber parts:

Gas feedthrough assy

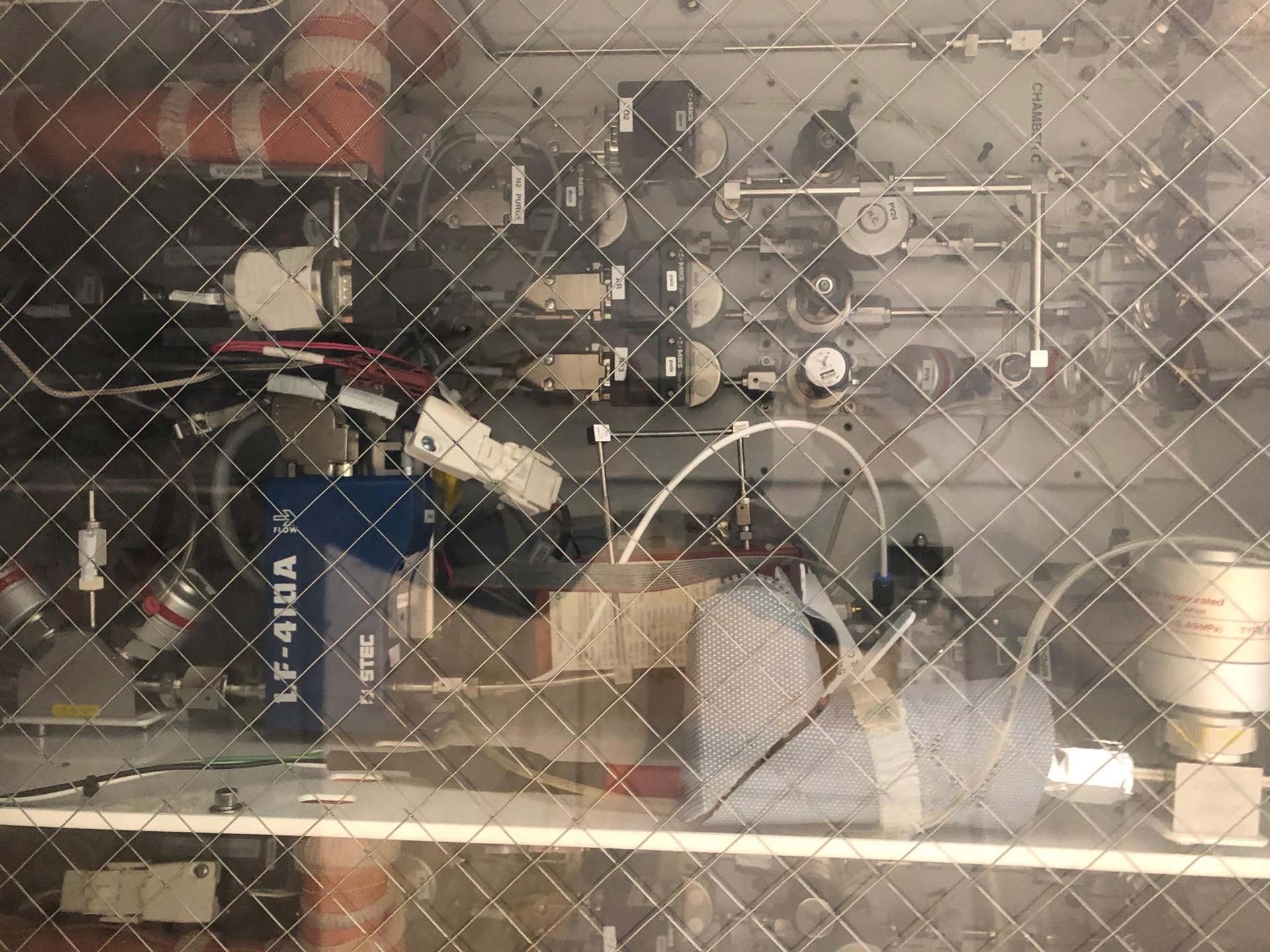

Gas box

Face-plate

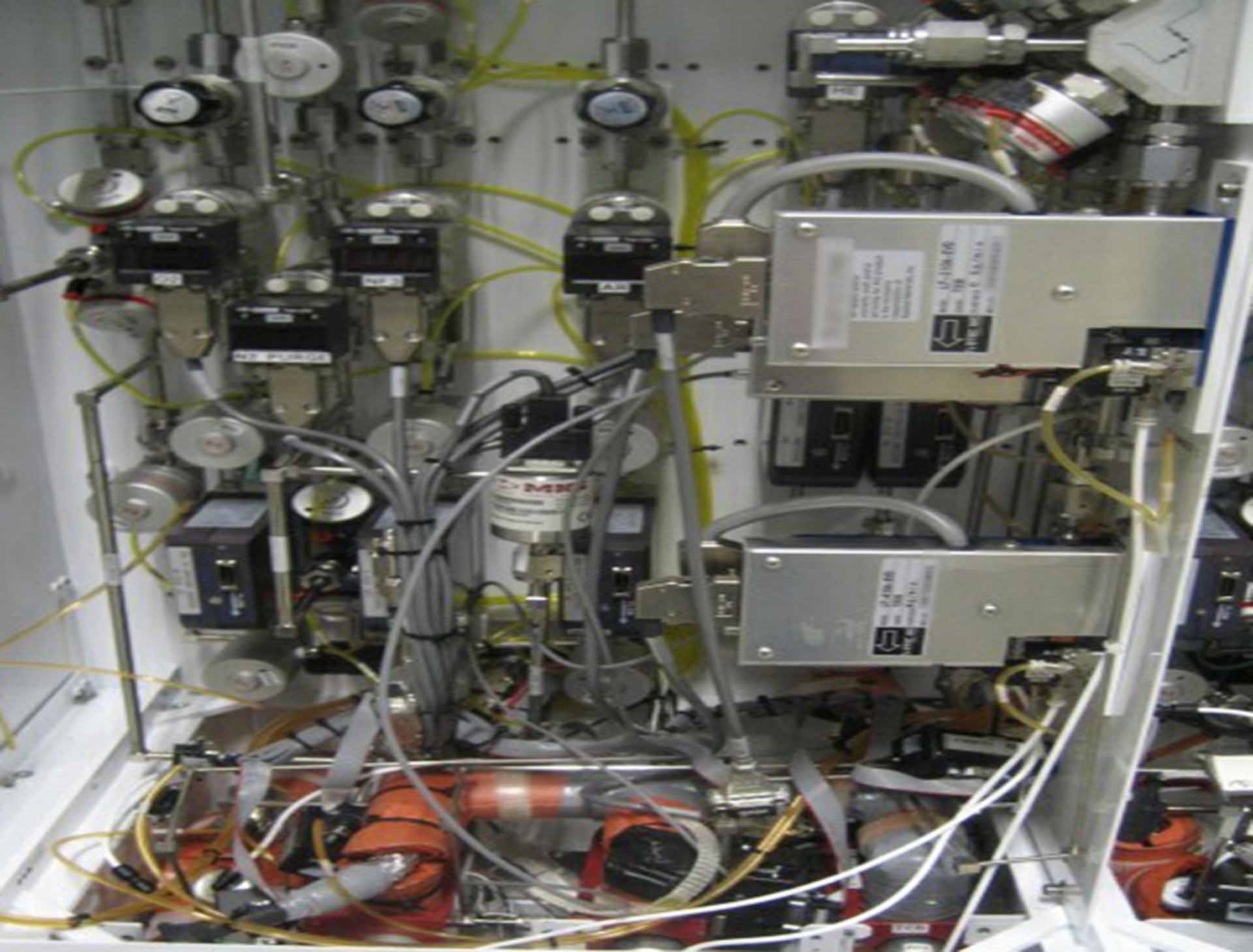

Pressure gauge: MKS 20 Torr / MKS1000 Torr

RF Power

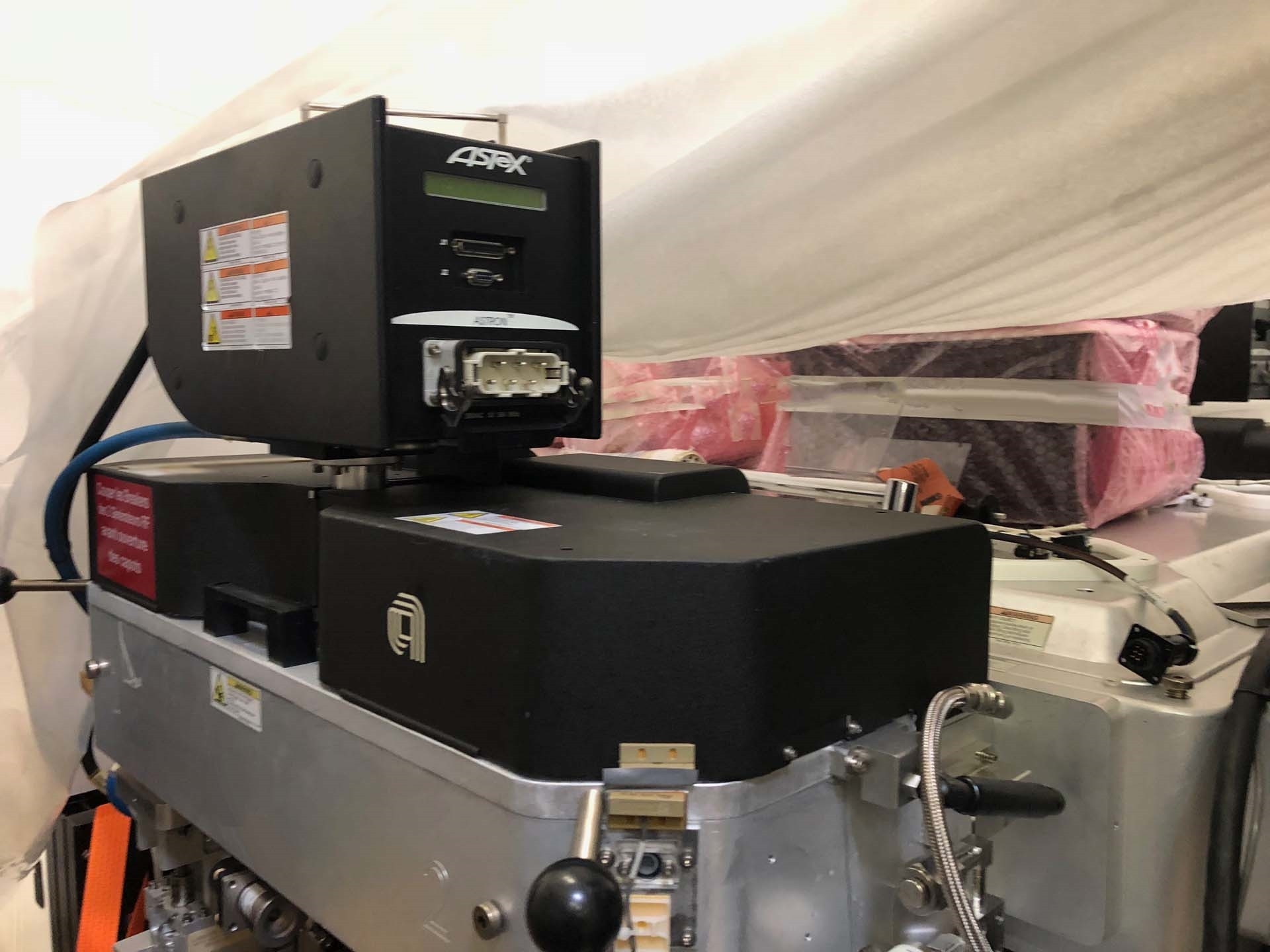

RPS Type: (MKS ASTeX)

Chiller: Steel-head 1

Ozone rack

Gas panel: BPSG

Vacuum system

ISO / Throttle valve: C-PLUG

Includes:

Open cassette type

VHP Robot

IPX Pump

(3) Oxide chambers

Loadlock configuration:

Cassette type: 200 mm

Fast vent option

Power supply:

Line voltage: 208 V

Full load current: 300 Amp

Frequency: 50/60 Hz

CE Marked

2000 vintage.

AMAT / APPLIED MATERIALS Producer III is a reactor designed for purposes of etching and depositing materials via chemical vapor deposition (CVD) for the production of III-V and quartz semiconductor wafers. It is a large-scale machine with the working chamber measuring at 25.6 cm (10 inches) in length. The reactor contains two main chambers: the source and the plasma, which deposit layers of material in the desired thicknesses. The source chamber is equipped with up to four chemical precursors and contains a bubbler, a heating element, a distributor, a showerhead, and an RF generator. The plasma chamber contains high-frequency plasmas which are generated through a coaxial antenna placed in the top of the chamber. The output gas is then filtered and pumped through the showerhead as a uniform, steady vapor. The particles then collide with the surface of the wafer, depositing the desired materials. AMAT Producer III uses multidimensional process mapping to achieve precise control of the etch rate of the wafer or layer thickness. It has a control system to enable repeatable etch processes and can be accurately modified to meet specific customer requirements. The reactor has been designed for both batch and single wafer process capability. The chamber airlocks allow for easy loading and unloading of the wafers, resulting in improved productivity. In addition, APPLIED MATERIALS Producer III has been equipped with a comprehensive range of protection systems to ensure safe operation. These include flammable gas detection, low-temperature monitoring and emergency shutdown systems. In conclusion, Producer III is an efficient and reliable reactor used for etching and materials deposition. It utilizes multidimensional process mapping to ensure precise control of etch rate and layer thickness. It has been designed for both batch and single wafer process capabilities with a comprehensive range of safety features. This reactor system delivers consistent, high-quality results for the production of III-V and quartz semiconductor layers.

There are no reviews yet