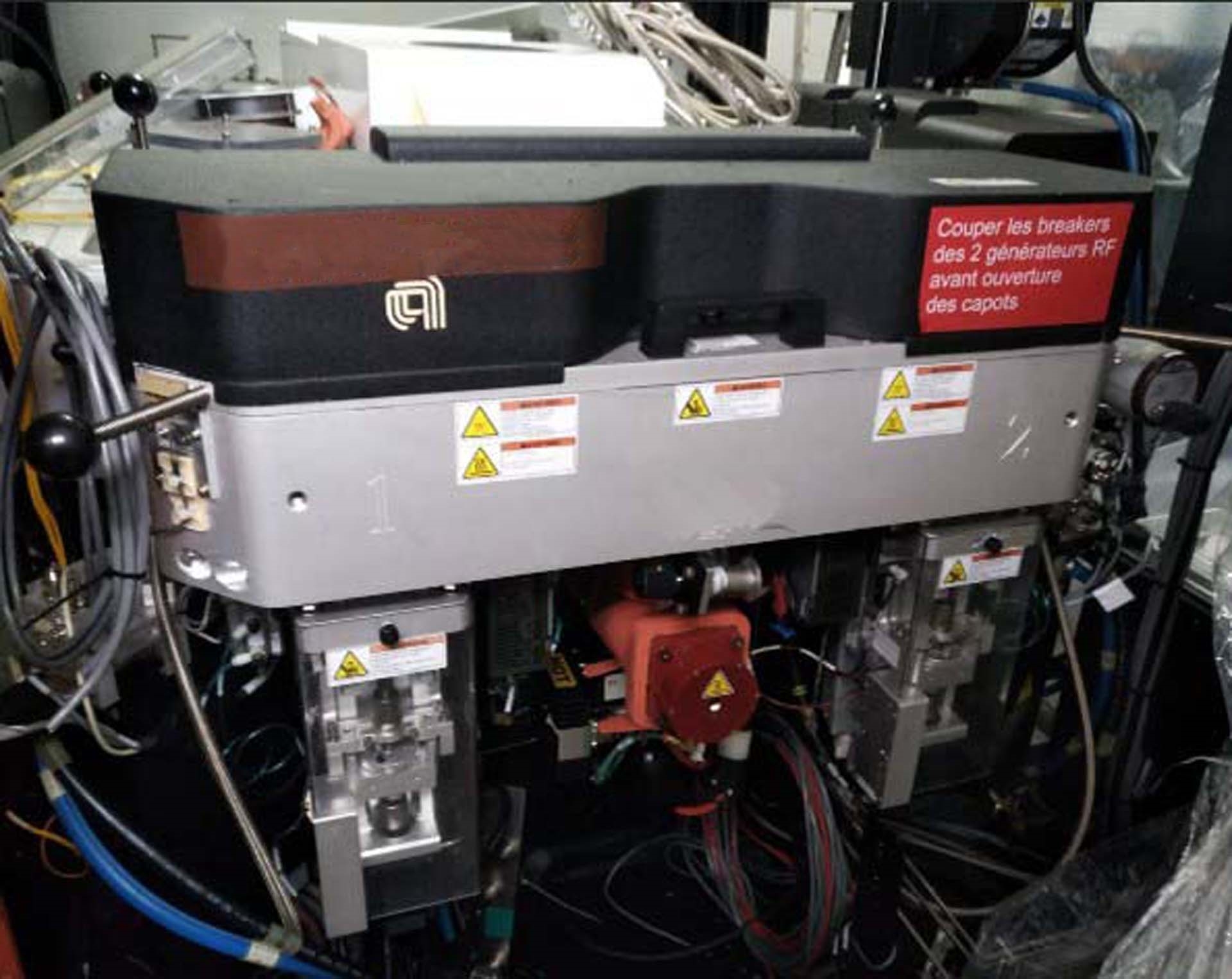

Used AMAT / APPLIED MATERIALS Producer III #9240095 for sale

URL successfully copied!

Tap to zoom

ID: 9240095

Wafer Size: 8"

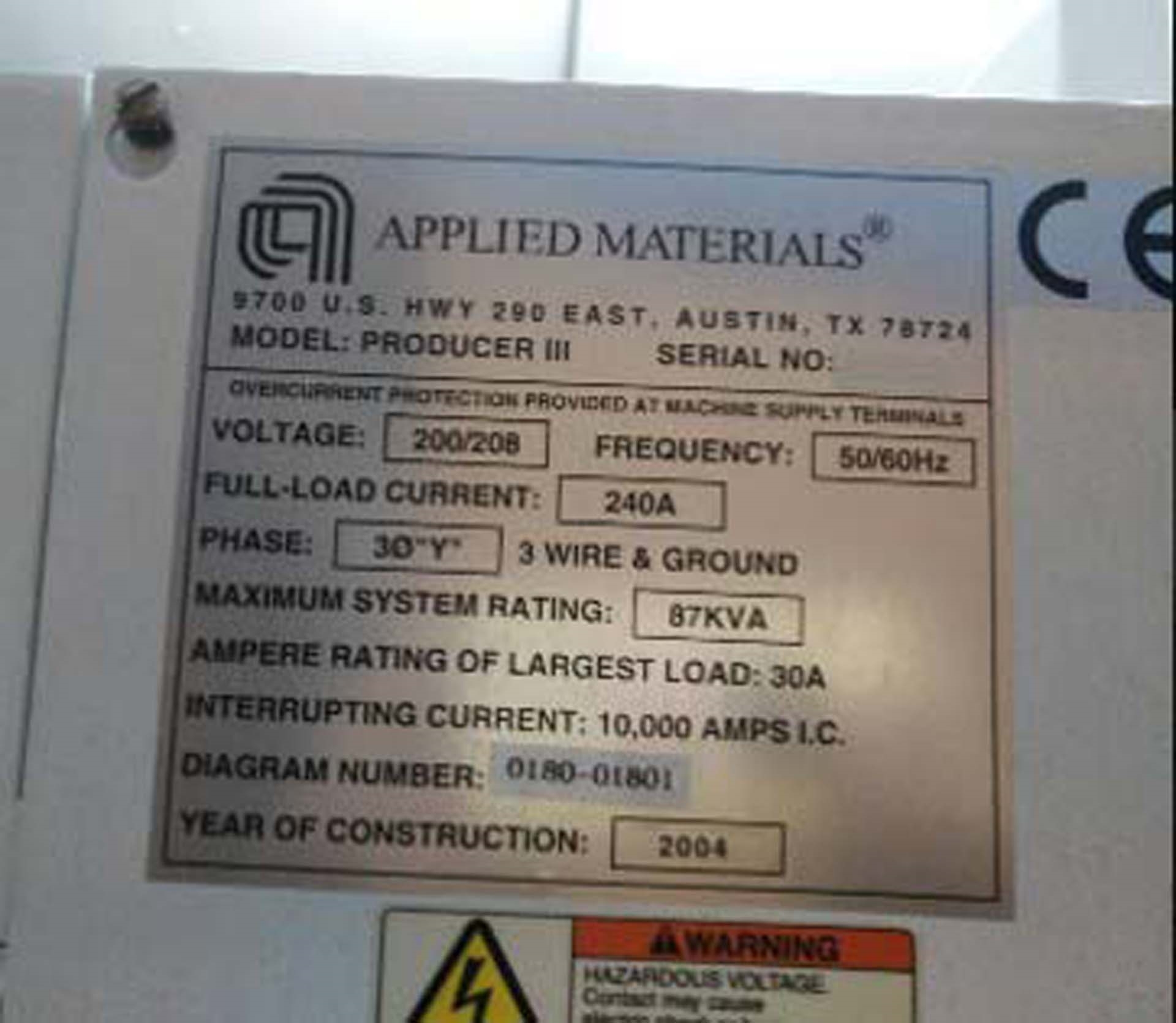

Vintage: 2004

CVD System, 8"

(3) Twin chambers

Platform: Producer S

Wafer shape: SNNF

Load lock:

Cassette type, 8"

Fast vent option

Mainframe:

Buffer robot type: VHP

FI Robot type: Manual

Buffer robot blade

Chamber A: Producer APF

Chamber B: Producer DARC

Chamber C: Producer SAUSG

(2) Heater exchangers: Steelhead 0

Chiller MX-500

O3 Rack

Front end type: Manual

Front end robot: PRI BROOKS ABM407

Buffer robot: VHP

Transfer pump: IPX Pump

Chamber slit valve / LL Door: VAT

L/L Gauge

Hard disk

Floppy disk: 1.44 M

Chamber A: (APF)

Chamber parts:

Gas feedthrough assy

Gas box

Face plate

Heater / TC: OEM

Pressure gauge: MKS 20 Torr / MKS 100 Torr

RF Power:

RF Generator: ADVANCED ENERGY 2000-2 V

Match type: ADVANCED ENERGY Fixed match

Gas panel: C3H6, Ar, He, O2

Vacuum system:

Throttle valve: MKS 253B-24627

ISO Valve: MKS

Chamber B: (DARC)

Chamber parts:

Gas feedthrough assy

Gas box

Face plate

Heater / TC: OEM

Pressure gauge: MKS 100 Torr / MKS 10 Torr

RF Power:

RF Generator: ADVANCED ENERGY 2000 - 2 V

Match type: ADVANCED ENERGY Fixed match

RPS Type: MKS ASTEX

Gas panel: CO2, N2O, He, NF3, SIH4

Vacuum system:

Throttle valve: MKS 253B-24627

ISO Valve: MKS

Chamber C: (SAUSG)

Chamber parts:

Gas feedthrough assy

Gas box

Face plate

Heater / TC: OEM

Pressure gauge: MKS 20 Torr / MKS 1000 Torr

RF Power:

No RF generator

No match

RPS Type: (MKS ASTEX)

Gas panel: O2, NF3, Ar, He, O3, TEOS

Vacuum system:

Throttle valve

ISO Valve

Light tower: RYGB

Power: 208 V, 50/60 Hz

Full load current: 240 A

CE Marked

2004 vintage.

AMAT / APPLIED MATERIALS Producer III Reactor is a manufacturing machine that is designed to produce substrates at high temperatures. It is an advanced reactor that is intended for processing semiconductors, hard materials, and tribological materials. The reactor is primarily used for semiconductor research, production, and automation testing. The reactor is composed of three chambers that operate at separate temperatures: the first chamber is designed to reach up to 2000°C, the second chamber is programmed to reach up to 1000°C, and the third chamber is capable of reaching up to 500°C. The reactor is also equipped with a gate valve which adjusts pressure in the chamber. The Producers III Reactor is equipped with an advanced cooling equipment that cools all three chambers simultaneously. This cooling system is designed to reduce the time it takes to start up the reactor and prevent thermal runaway from occurring. The Producers III Reactor has advanced safety features including a failsafe unit, multiple safety interlocks, and an emergency shut down. The reactor also has an electrostatic containment machine which isolates the reactor from the outside environment. The reactor is also designed to process materials efficiently by using the ID AMAT proprietary deposition tool which sprays a steady, uniform film of material onto the substrate. This deposition asset is capable of reaching the desired temperatures quickly and efficiently. This highly advanced reactor is capable of performing a wide range of processes such as nitridation, oxidation, rapid thermal processing, and deposition. AMAT Producer III Reactor is a versatile and efficient tool that is used in the semiconductor industry to produce substrates.

There are no reviews yet