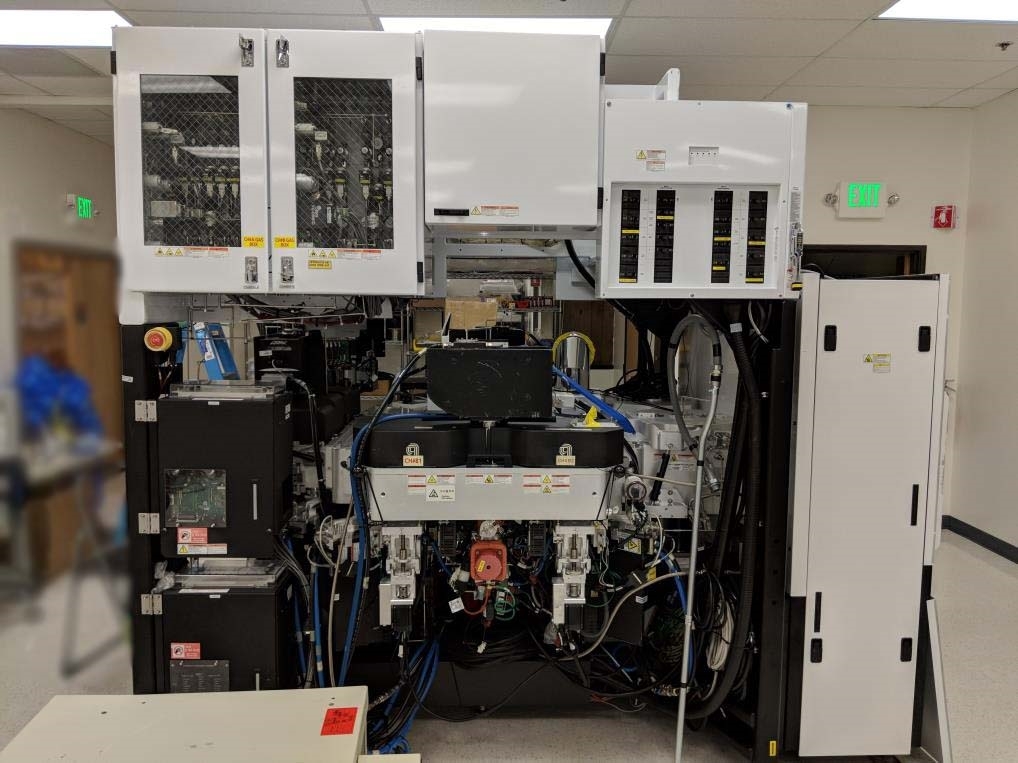

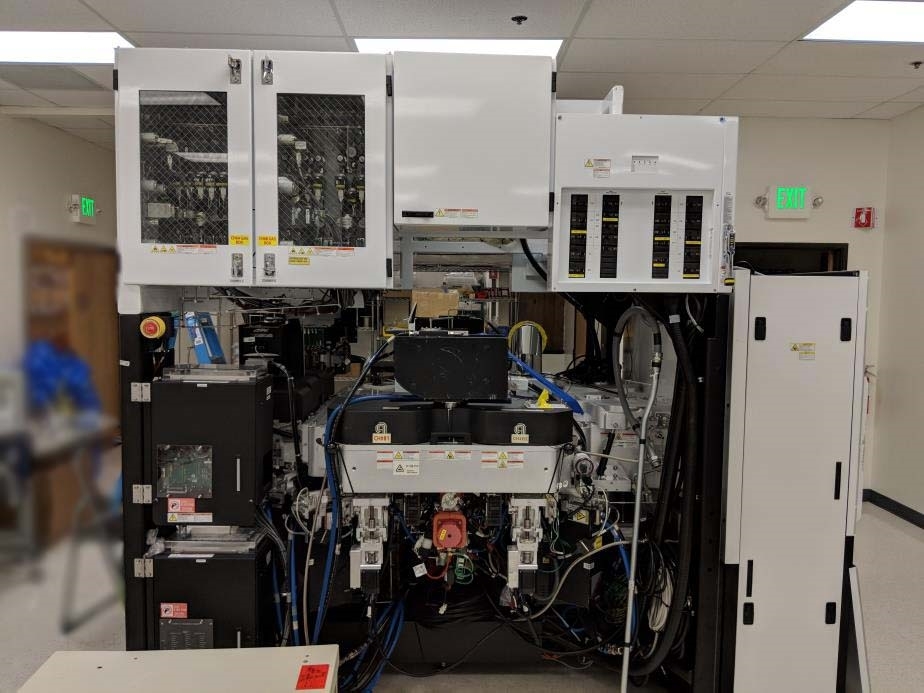

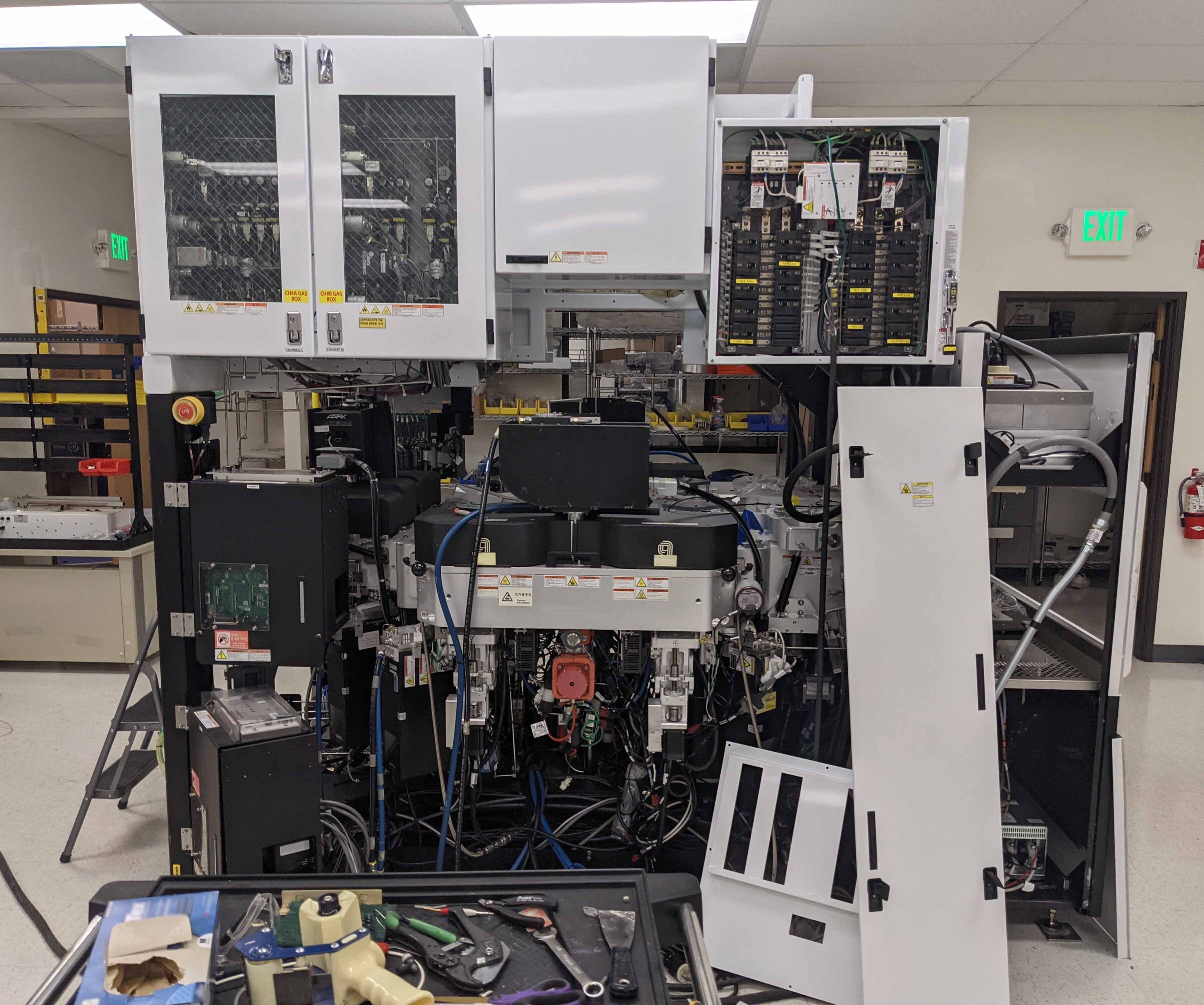

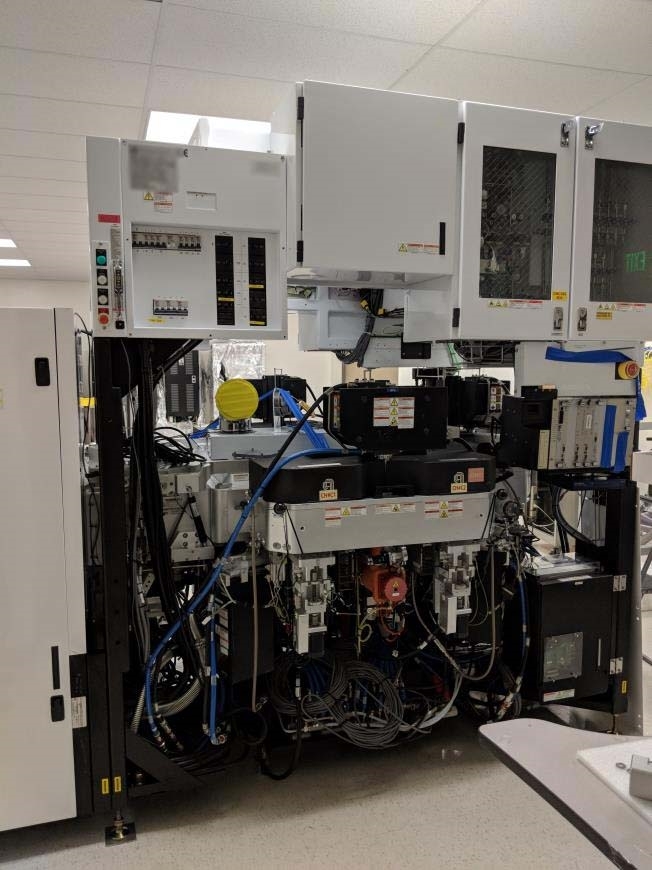

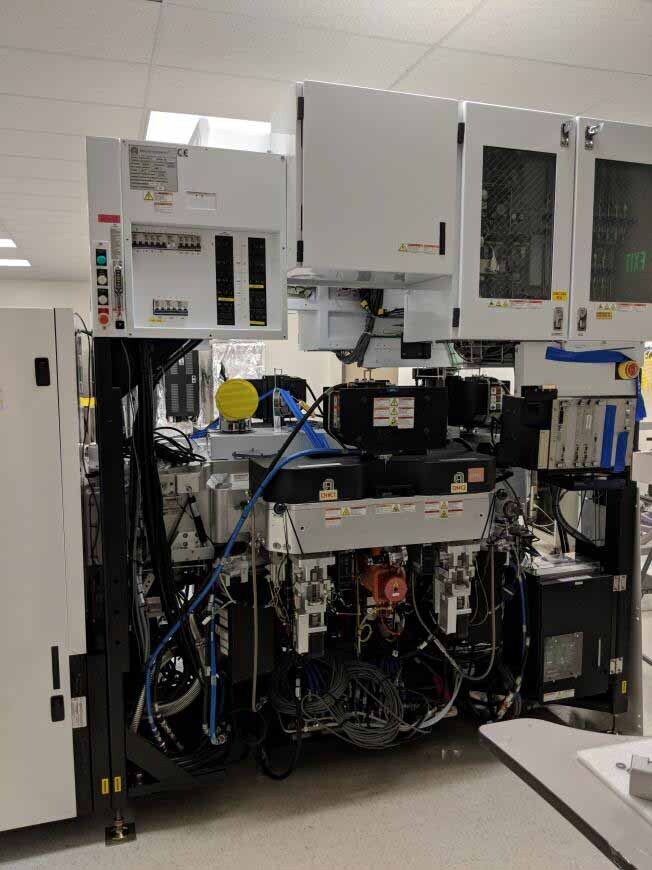

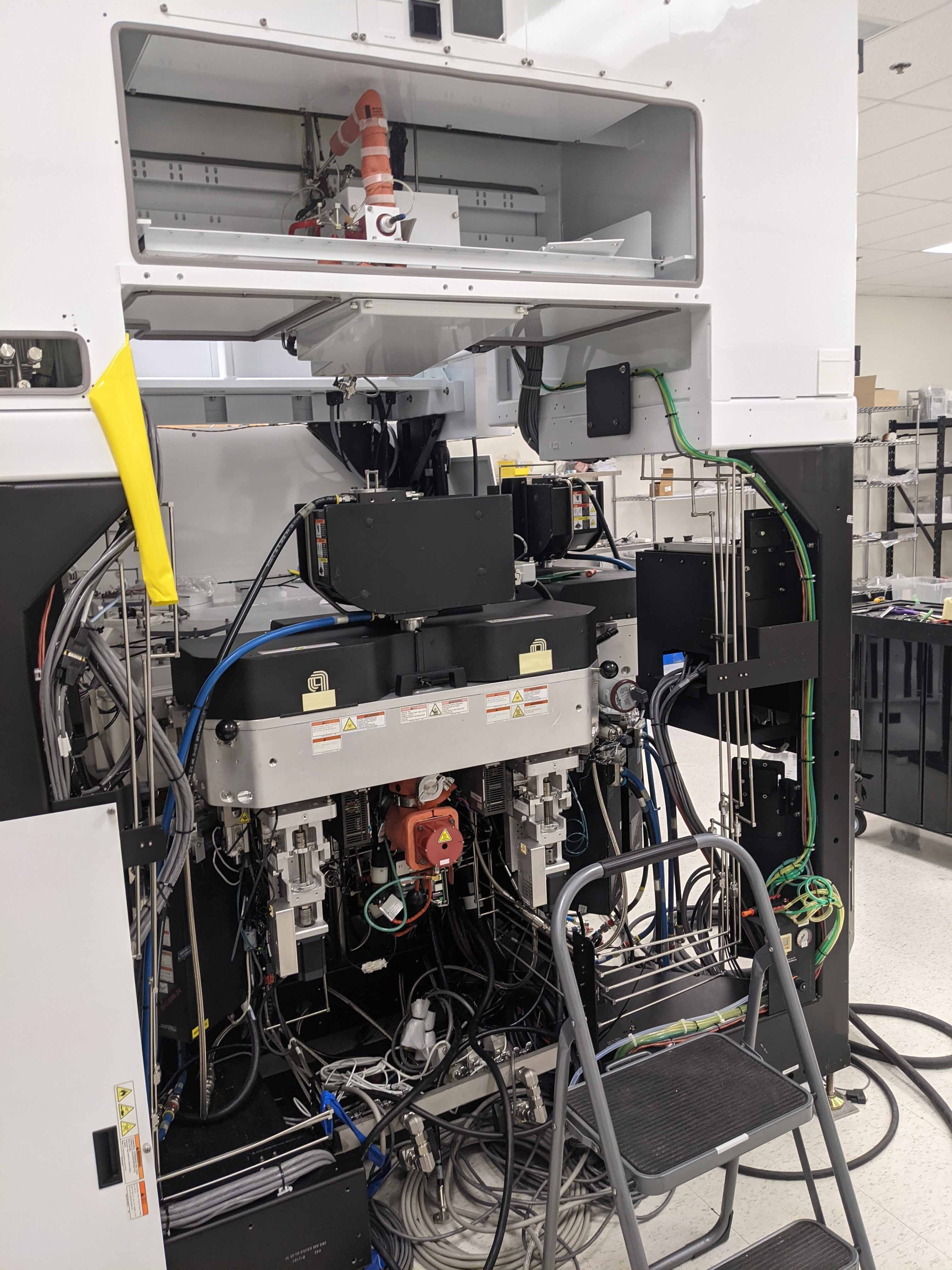

Used AMAT / APPLIED MATERIALS Producer S #9291526 for sale

URL successfully copied!

Tap to zoom

ID: 9291526

Vintage: 2005

CVD System, 8"

(2) PECVD SiN

PECVD TEOS

(3) Twin chambers

Wafer shape: SNNF

No SMIF interface

Chamber:

A twin:

PE OX

SIN

ARC

APF

B twin:

PE OX

TEOS

SIN

ARC

C twin:

PE OX

SIN

ARC

APF

Chamber A:

Single frequency

Manometer: 10/100 Torr

Clean type (RPC): ASTEX

No DPA

Chamber B:

Single frequency

Manometer: 10/100 Torr

Clean type (RPC): ASTEX

No DPA

Chamber C:

Single frequency

Manometer: 10/100 Torr

Clean type (RPC): ASTEX

No DPA

System monitors: Through the wall

Mainframe

Mainframe type: Shrinkage

Robot type: Dual VHP

Load cassette: Manual (2) cassettes

No SMIF

VME Racks:

SBC

VGA

MEI1

MEI2

I/O Expan

Monitor

Floppy Disk Drive (FDD)

No Hard Disk Drive (HDD)

Gas delivery:

MFC Type: AERA D980 / BROOKS 6256S

FUJIKIN 5 Ra Max valves

Transducer: MKS With display

Regulators: PARKER

Single Line Drop (SLD)

SLD Gas line feeds: Top feed

Gas pallet:

Chamber A:

Make / Model / Size / Gas

BROOKS / 6256s / 2 SLPM / O2

AERA / FC-D980C / 1 SLM / SiF4

BROOKS / 6256s / 10 SLPM / N2O

BROOKS / 6256s / 400 SCCM / NH3

BROOKS / 6256s / 10 SLPM / N2

BROOKS / 6256s / 500 SCCM / SH4

BROOKS / 6256s / 2 SLPM / (CH3)3SiH

BROOKS / 6256s / 3 SLPM / He

BROOKS / 6256s / 3 SLPM / NF3

BROOKS / 6256s / 5 SLPM / Ar

Chamber B:

AERA / FC-D981C / 20 SLM / N2O

BROOKS / 6256s / 500 SCCM / N2O

BROOKS / 6256s / 5 SLPM / O2

BROOKS / 6256s / 200 SCCM / SIF4

MYKROLIS / FC-2902MEP-T / 500 SCCM / SH4

BROOKS / 6256s / 10 SLPM / N2

BROOKS / 6256s / 5 SLPM / He

AERA / FC-D981C / 400 SCCM / NH3

BROOKS / 6256s / 3 SLPM / NF3

BROOKS / 6256s / 5 SLPM / Ar

HORIBA / 4 g/min / TEOS

Chamber C:

BROOKS / 6256s / 2 SLPM / O2

BROOKS / 6256s / 200 SCCM / SiF4

AERA / FC-D980C / 20SLM / N2O

BROOKS / 6256s / 400 SCCM / NH3

BROOKS / 6256s / 10 SLPM / N2

BROOKS / 6256s / 500 SCCM / SH4

BROOKS / 6256s / 2 SLPM / (CH3)3SiH

BROOKS / 6256s / 3 SLPM / He

BROOKS / 6256s / 2 SLPM / NF3

BROOKS / 6256s / 5 SLPM / Ar

Electrical requirements:

Line frequency: 50/60 Hz

Line voltage: 200/208 V

Line amperage: 240 A

2005 vintage.

AMAT / APPLIED MATERIALS Producer S is an advanced process chamber equipment used in the manufacture of integrated circuits and other semiconductor components. It is a high-temperature chemical vapor deposition (CVD) reactor which allows the production of high volumes of built-in electronics. AMAT PRODUCERS is a multi-functional system suitable for a range of post-processing applications, including CVD, atomic layer deposition (ALD), and physical vapor deposition (PVD). APPLIED MATERIALS PRODUCER-S has a symmetrical ceramic chamber design which creates an ideal environment for the deposition of polymers, oxides, and metals. It can be operated in temperatures up to 1000°C in a nitrogen or oxygen environment and the chamber is designed for uniform film thickness and heat control. The chamber also has an integrated microwave plasma source designed to preserve the quality and consistency of the films being deposited. AMAT Producer S is equipped with a robotized end-effector unit and a collection of gas controls which can be precisely dialed in for desired processes. The multiple in-situ diagnostic capabilities, including an optical emission spectrometer (OES), analyze material deposition and optimize film performance in various processes. An additional option of an angled substrate heater is available to facilitate films with greater uniformity. All of the components are housed in a single enclosure and can be accessed through its modular design, allowing for fast and efficient maintenance. The machine is also equipped with intuitive software and user-friendly features. It facilitates access to real-time process data, predictive modeling, and process optimization capabilities. Operating parameters can be quickly modified and adjusted in order to achieve desired results. The integrated software also allows for remote access, providing increased flexibility and monitoring capabilities. AMAT / APPLIED MATERIALS PRODUCER-S is a robust and highly-capable CVD tool, offering superior quality and high throughput for a range of post-processing applications. Its symmetrical ceramic chamber design enables uniform deposition of polymers, oxides, and metals, providing a controlled environment for the high-temperature chemical vapor deposition process. The improved gas mixing capabilities and multiple in-situ diagnostics ensure material deposition is consistent and of good quality, helping to minimize scrap losses. Its modular design and intuitive software also offer real-time monitoring, making it an ideal choice for integrated circuit manufacturing.

There are no reviews yet