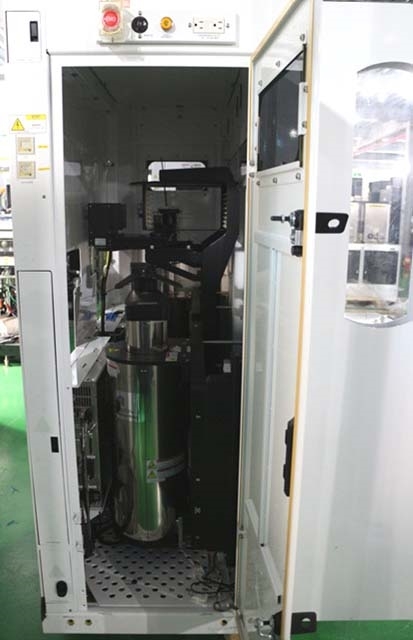

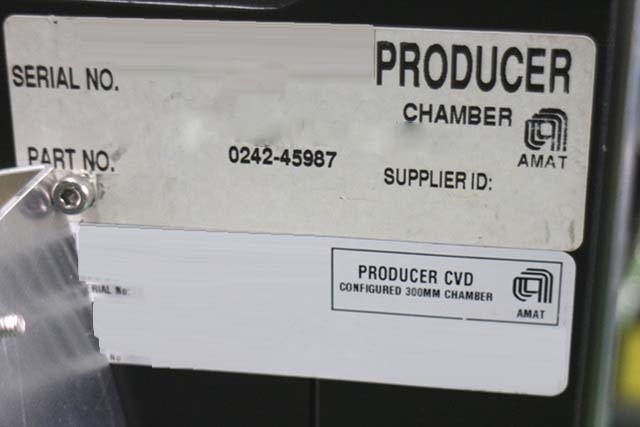

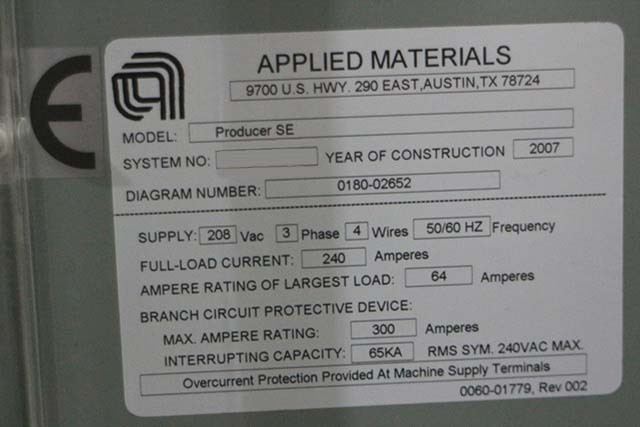

Used AMAT / APPLIED MATERIALS Producer SE #9153559 for sale

URL successfully copied!

Tap to zoom

ID: 9153559

Wafer Size: 12"

Vintage: 2007

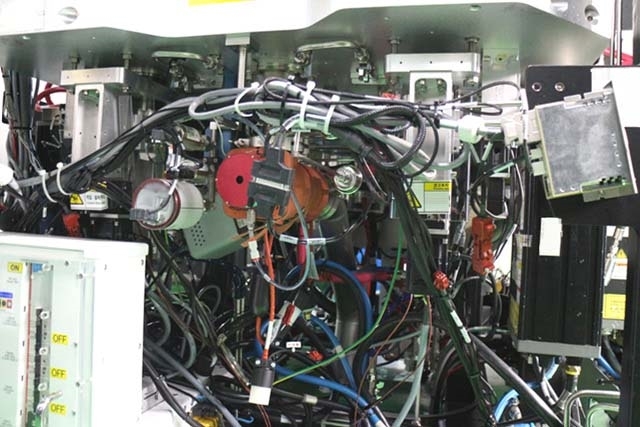

CVD System, 12"

(2) Chambers

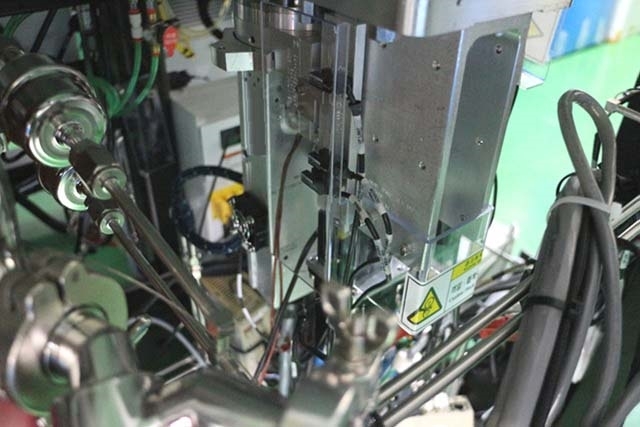

Chamber A and B:

Chamber process: XJ (PE Si-lane twin)

APEX 3000 RF Generator

Gas delivery:

Gas pallet type: Surface mount vertical

No regulated gas panel

No regulated TMS

Top gas feed

Gas panel cabinet exhaust: Top

No facilities interlock indicator

SETRA Transducers

Nippon filter

Manual and pneumatic valves: Hamlet

No liquid source

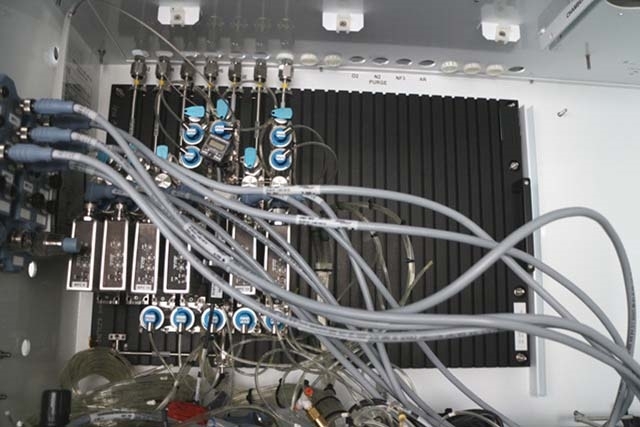

Gases:

Chamber A:

Gas position / Gas / MFC Size

Gas 1 / C3H6 / 3000 SCCM

Gas 2 / H2 / 15000 SCCM

Gas 8 / O2 / 30000 SCCM

Gas 9 / AR / 15000 SCCM

Gas 10 / HE / 5000 SCCM

Gas 13 / N2 / 15000 SCCM

No regulator

No transducer

Chamber B:

Gas position / Gas / MFC Size

Gas 1 / C3H6 / 3000 SCCM

Gas 2 / H2 / 1000 SCCM

Gas 8 / O2 / 30000 SCCM

Gas 9 / AR / 15000 SCCM

Gas 10 / HE / 5000 SCCM

Gas 13 / N2 / 15000 SCCM

No regulator

No transducer

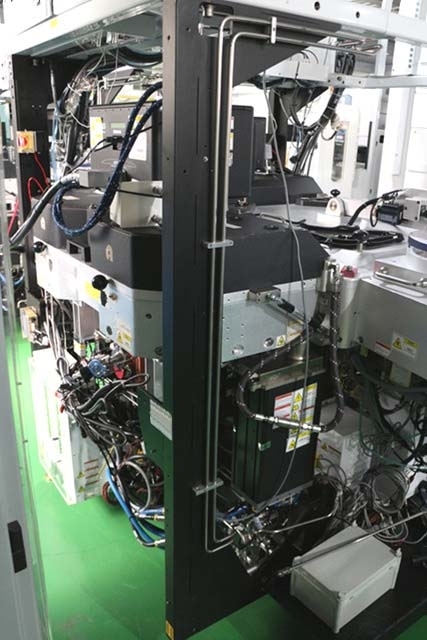

Mainframe:

No local center finder

No Cu wafer sensor

Third MF IO motion card

Robot blade: Standard VHP

Factory interface, 12":

Options: 5.3

WIP Delivery type: OHT

Wafer pass thru and storage: DSM Specific cooling tray

KAWASAKI Track robot with edge grip

No docked E99 reading capability

Load port types: Enhanced 25 wafer FOUP

Load port operator interface: Standard 9 light

No configurable color lights

No docking flange shield

Front facing intake plenum air system

E84 Pl/O Sensors and cables: Upper E84 sensors and cables

OHT Light curtain

Carrier ID host interface

(3) Colors configurable light towers

Heat exchanger:

No AMAT / APPLIED MATERIALS HX Hose and manifolds

Remote AC:

Facilities UPS interface

Chamber configuration:

Channel A / Channel B:

BFC

Foreline, 2"

T/V Type: 683B

0090-05813 RF Filter

RPS

FFU Controller

Power supply: 200-208 VAC, 60 Hz

2007 vintage.

AMAT / APPLIED MATERIALS Producer SE is a single wafer planetary reactor designed and manufactured by AMAT, a leading global supplier of advanced semiconductor equipment. This reactor combines advanced features with easy-to-use software to produce uniform, precise, and reliable results in the production of advanced semiconductor materials for high performance, low power, and reliability applications. The single-wafer Advanced Materials AMAT Producer SE is ideal for process engineers and scientists, and is capable of providing high-yield, high-quality results for a wide range of thin film processes and substrates. The reactor provides accurate and repeatable wafer production with process uniformity, reliability, and wafer shape consistency. The reactor is equipped with a process chamber that is sealed for ultra-high vacuum (UHV) and near-vacuum (NV) processes. The equipment is designed to achieve processes on both single- and multiple-wafer substrates and to process multiple gases simultaneously. The reactor is also equipped with a low-emissivity deposition view window that gives users a direct view when depositing materials, as well as a refrigerator system that maintains cool process gases at a constant temperature. For control and service, APPLIED MATERIALS Producer SE is supported by a suite of Easy-to-Use software developed by APPLIED MATERIALS. This suite provides intuitive interface for training, maintenance, monitoring, and service. Additionally, the producer's software platform allows for customization to address individual unit and deposition needs. Producer SE offers a number of features designed to maximize production and increase productivity levels. It is equipped with automatic wafer centering vehicle and robotics systems that keep substrates in place and minimize yield loss. Additionally, the advanced digital processing control machine maintains optimum process speed and positional accuracy, as well as provides continuous feedback on the status of the wafer. The single-wafer Advanced Materials AMAT / APPLIED MATERIALS Producer SE allows for fast and easy process execution and control, and is designed to help ensure the highest yield and quality possible. It is a reliable and cost-effective choice for semiconductor manufacturers looking to optimize their production and achieve the best results.

There are no reviews yet