Used AMAT / APPLIED MATERIALS Producer SE #9163057 for sale

URL successfully copied!

Tap to zoom

ID: 9163057

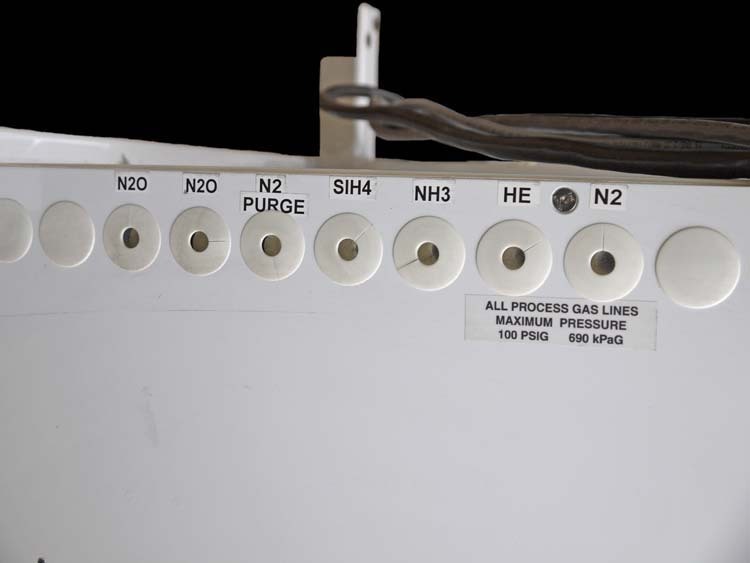

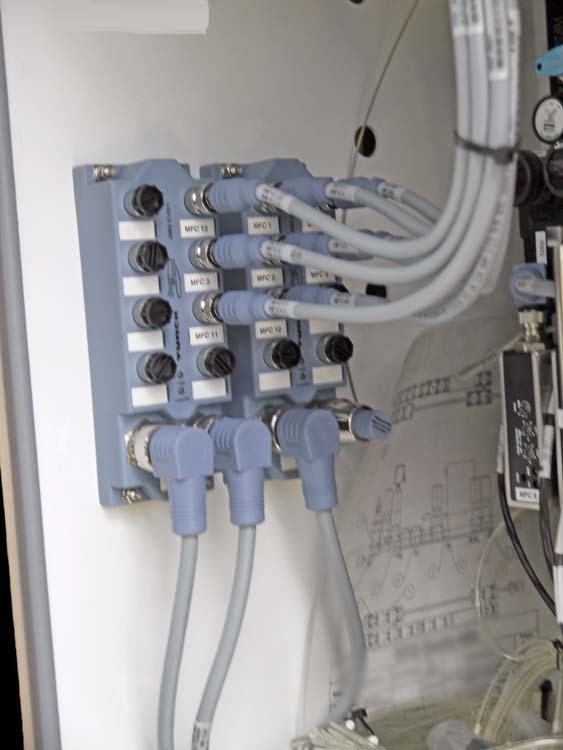

Vapor control system assembly

Industrial enclosed gas

P/N: 417336-DF-GP.

AMAT / APPLIED MATERIALS Producer SE (AMAT) is a equipment for physical vapor deposition (PVD) applications used in the production of semiconductors. The reactor provides the environment for efficient film deposition, offering uniform, high-quality results. It is designed to achieve process control, resulting in superior yields and lower cost of ownership. This allows producers to produce a greater volume of semiconductors at a lower cost. The complex process of producing semiconductors is achieved by creating a film of metal-containing compounds on a substrate. This film is then deposited onto a patterned wafer. The conventional PVD deposition process is slow, with unacceptable levels of process variation. This is where AMAT Producer SE makes a difference. APPLIED MATERIALS Producer SE utilizes an innovative concept called Reactive Enhanced PVD (REPVD). This technique increases process yields by utilizing a reaction between the vacuum chamber, the substrate, and the film-forming precursor gas. The reaction takes place because the chamber is heated to a temperature in the range of 230 to 270°C, allowing the reactants to form an adherent film on the substrate. The deposition process is further optimized with built-in feedback control, allowing producers to fine-tune and monitor all aspects of the process. Additional features of Producer SE include a high-silicon throughput layer system for uniformity across large areas and advanced PowerMax technology for high-speed deposition. In addition, AMAT / APPLIED MATERIALS Producer SE offers several safety features. This includes a patented Active Carrier Cleaning Unit that keeps the chamber clean and an active Reaction Protection Machine that monitors pressure and keeps it within the optimal range. These features ensure a safe process at all times. Overall, AMAT Producer SE is a powerful tool for semiconductor manufacturing. It combines the latest advances in PVD deposition technology with features that ensure process control and reliability. Its versatility makes it suitable for both large-scale and small-scale producer applications.

There are no reviews yet