Used AMAT / APPLIED MATERIALS Producer SE #9182254 for sale

URL successfully copied!

Tap to zoom

ID: 9182254

Wafer Size: 12"

Vintage: 2006

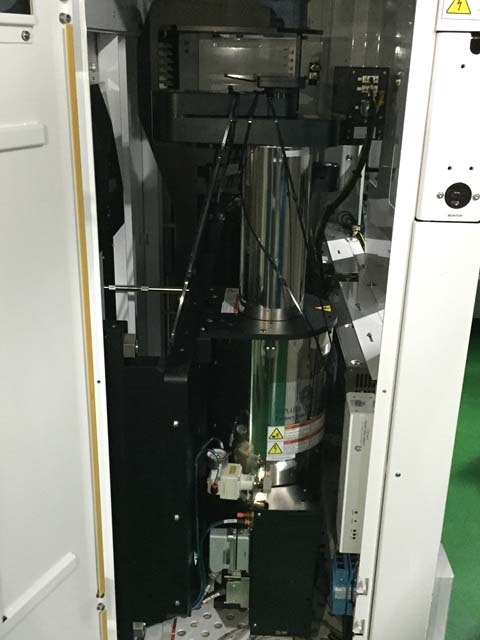

CVD System, 12"

(2) Chambers

Customer fab options:

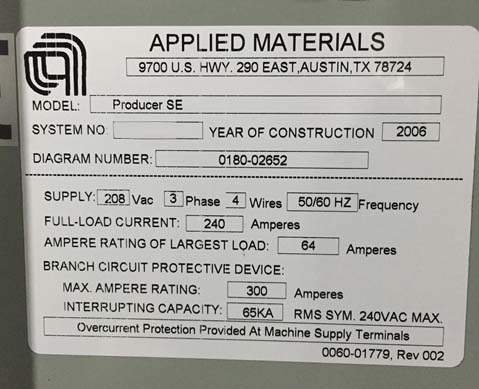

Electrical requirements:

Line frequency: 60Hz

Line voltage: 200/208 VAC Platform

Chambers:

Chamber A and B:

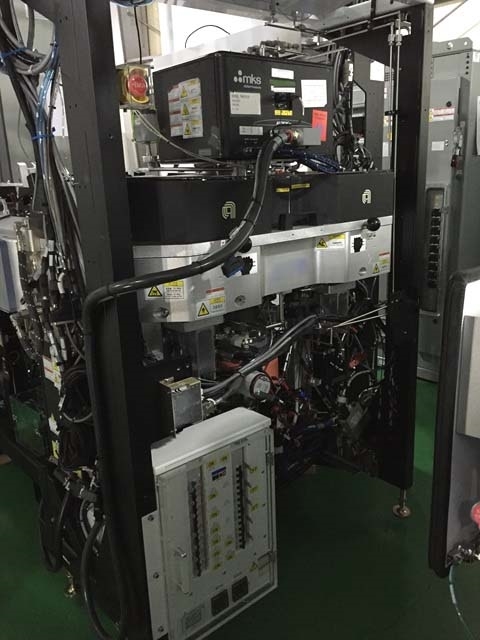

Chamber process: XJ (PE Silane twin)

RF1 Generator: APEX 3000

Gas delivery:

Gas pallet type: Surface mount vertical

Regulated gas panel: No

Regulated TMS: No

Gas feed: Top

Gas panel cabinet exhaust: Top

Facilities interlock indicator: No

Facilities / Scrubber interface output: Fault

Transducers: Setra

Filters: Nippon

Manual valves: Hamlet

Pneumatic valves: Hamlet

Liquid source: No

Gas pallet configuration supplement:

Chamber A:

Gas line stick position / Process gas / MFC Size / Regulator (Yes, No) / Transducer (Yes, No)

#1 / C3H6 / 3000sccm / No / No

#3 / NF3 / 1000sccm / No / No

#8 / 02 / 30000sccm / No / No

#9 / AR / 15000sccm / No / No

#10 / HE / 5000sccm / No / No

#11 / O2 / 15000sccm / - / -

#12 / AR CLN / 10000sccm / No / No

#13 / N2 CLN / 15000sccm / No / No

Liquid 1 / P-N2 / - / No / Yes

Liquid 2 / P-N2 / - / No / Yes

Chamber B:

Gas line stick position / Process gas / MFC Size / Regulator (Yes, No) / Transducer (Yes, No)

#1 / C3H6 / 3000sccm / No / No

#3 / NF3 / 1000sccm / No / No

#8 / O2 / 30000sccm / No / No

#9 / AR / 15000sccm / No / No

#10 / HE / 5000sccm / No / No

#11 / O2 / 15000sccm / - / -

#12 / AR CLN / 10000sccm / No / No

#13 / N2 CLN / 15000sccm / No / No

#17 / P-N2 / - / No / Yes

#18 / P-N2 / - / No / Yes

Mainframe:

Local center finder: Yes

Cu Wafer sensor: No

MF Ch Harness installed: A & B

Third MF IO motion card

Robot blade: Standard VHP

Factory interface options:

300mm Factory interface 5.3 options:

WIP Delivery type: OHT

Pre alignment and centering: Single axis aligner

Wafer pass thru & storage: 8 Slot wafer pass thru

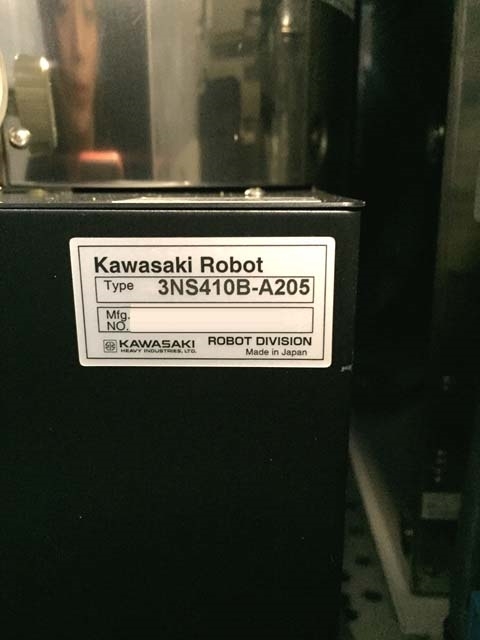

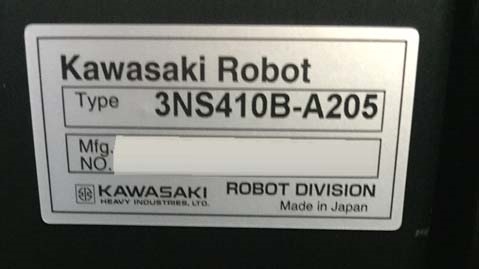

Atmospheric robots: KAWASAKI 2 fixed robots with edge grip

Remote control system cabable: Yes

Docked E99 reading capability: No

Load port types: Enhanced 25 wafer FOUP

Load port operator interface: Standard 9 light

Configurable color lights: No

Docking flange shield: No

Air intake system: Front facing intake plenum

E84 Pl/O Sensors and cables: Upper E84 sensors and cables

OHT Light curtain: Light curtain

Carrier ID host interface: Yes

Light towers: (3) Colors configurable

Fast data gateway software: No

Heat exchanger / Chiller:

Heat exchanger

AMAT HX hose and manifolds: No

Remote AC:

Facilities UPS interface

Chamber configuration:

Ch A / Ch B:

BFC

2" Foreline

T/V Type: 683B

RF Filter: (0090-05813)

RPS

FFU Controller

2006 vintage.

AMAT / APPLIED MATERIALS Producer SE (Plasma Enhanced Epitaxy Reactor) is a commercial-grade, plasma-based epitaxy process used for high-quality semiconductor growth on both silicon and non-silicon substrates. AMAT Producer SE provides full process control using a highly reliable, sophisticated, and cost-effective production platform. The reactor is capable of delivering high-quality films with excellent uniformity and excellent flexibility for process tuning. It is the most advanced, cost-efficient plasma epitaxy tool available and ideal for high-volume production. APPLIED MATERIALS Producer SE offers a range of features such as a unique parallel-plasma source configuration, adjustable slit shutter technology, low defect densities, and a wide choice of deposition process capabilities. The parallel-plasma source configuration enables wafer-to-wafer process uniformity and superior dopant uniformity across large wafer diameters. The adjustable slit shutter technology provides precise control of the depth of the plasma diffusion and eliminates variations due to varying gate bias. Furthermore, the low defect density and wide range of film deposition capabilities ensure high yields of defect-free, high-performance films and the ability to tailor film properties to meet specific device requirements. The reactor is well-suited for device manufacturing, scaling from 200 mm to 300 mm wafers, with a minimum feature size capability of 8 nm. It is suitable for many different deposition processes, including for silicon and non-silicon substrates, such as silicon nitride, Low Pressure CVD, PECVD, SiGe, and HFO. Producer SE processor has the capability for three separate step-flow processes automatically integrated into standard processing and the ability to combine different deposition processes. AMAT / APPLIED MATERIALS Producer SE also offers batch processing over a wide range of temperatures as well as high-rate deposition and faster baking times. The reactor's high-accuracy power supplies provide precise control of film thicknesses down to oxide thicknesses of 0.5-1.0nm. A variety of non-invasive diagnostics can be performed on the reactor, like pressure swing analysis, RF testing, wafer monitoring, and deposition uniformity verification. Lastly, AMAT Producer SE surpasses industry requirements for performance and reliability, demonstrated by its extremely low radial drift over the life of the product. Overall, APPLIED MATERIALS Producer SE is the most reliable and cost-effective tool for deposition of high-quality epitaxy films for various semiconductor applications. It offers a wide range of features and capabilities, ensuring superior process uniformity and excellent flexibility for process tuning, enabling high-volume fabrication of advanced semiconductor devices.

There are no reviews yet