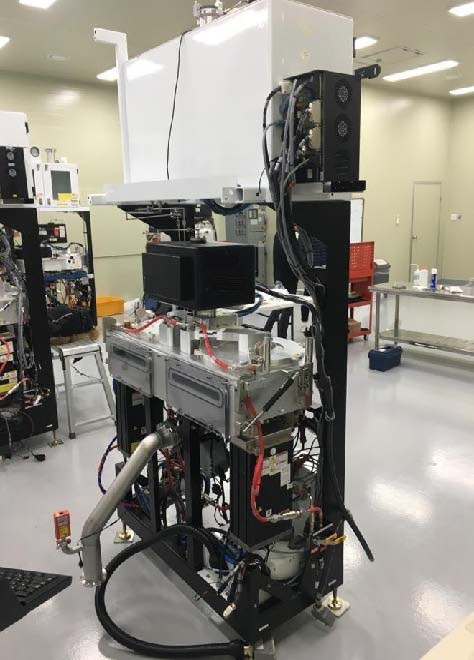

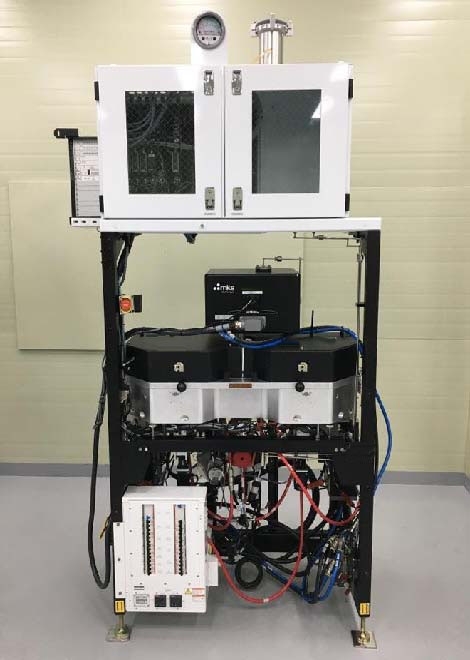

Used AMAT / APPLIED MATERIALS Producer SE #9204008 for sale

URL successfully copied!

Tap to zoom

ID: 9204008

Wafer Size: 12"

Vintage: 2006

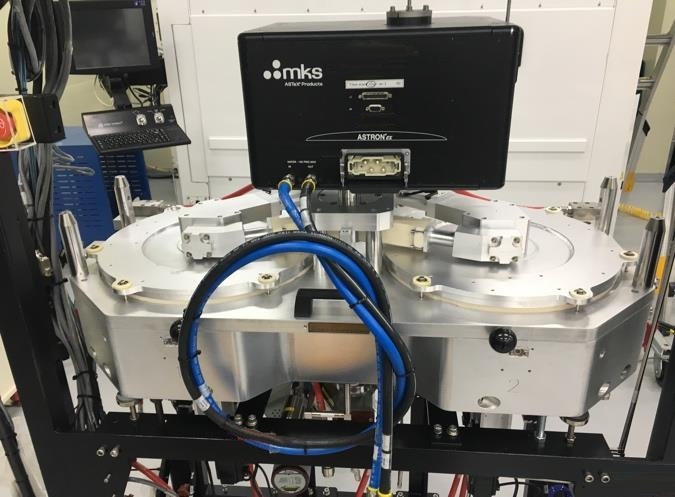

Twin chamber, 12"

Process: APF

Major part:

RPS: MKS FI80131(Astron ex)

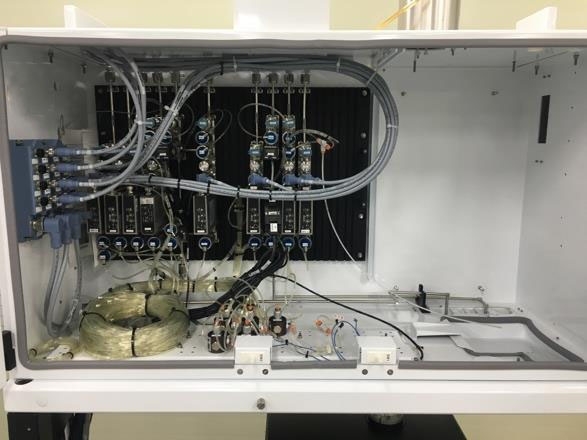

HF RF Generator: 0920-00107(Apex3013)

Ceramic heater: AIN

Gas panel: 1-1/8 C-Seal surface mount

AC box: 0195-01042

Heater lift driver: 1080-00126

Pin lift driver: 0190-13840

Manometer: 20T / 100T

Throttle valve: 683B-26033

ISO Valve: 99D0654

Process kit:

Top liner

Middle liner

Bottom liner

Pumping ring

Lift hoop

AL Spacer

Gas configuration:

Gas Size(sccm) MFC Filter Valve

Stick 1 02 15,000 UFC-8565C NAS Hamlet

Stick 2 AR 5,000 UFC-8565 NAS Hamlet

Stick 3 HE 5,000 UFC-8565C NAS Hamlet

Stick 4 C3H6 3,000 IFC-125 NAS Hamlet

Stick 5 N2 Purge NA NA Hamlet

Stick 7 N2 15,000 UFC-8565C NAS Hamlet

Stick 10 02 15,000 UFC-8565C NAS Hamlet

Stick 11 N2 Purge NA NA Hamlet

Stick 12 NF3 5,000 UFC-8565C NAS Hamlet

Stick 13 AR 10,000 UFC-8565C NAS Hamlett

Aluminum slit insert missing

Lift ring(Fixed type): Localized

2006 vintage.

AMAT / APPLIED MATERIALS Producer SE is an advanced PECVD (plasma-enhanced chemical vapour deposition) reactor designed for the production of high-quality films that are resistant to chemical and physical damage. This reactor has the capability to deposit thin films of nitride, oxide, and dielectric material as well as diamond and amorphous materials. It features a powerful, yet stable and accurate, digital drive power source, which enables precise control over deposition rates and uniformity. These features make AMAT Producer SE an ideal choice for production of various thin films that are used for a variety of applications. The main components of APPLIED MATERIALS Producer SE are its chamber, deposition source, support, and automation. The chamber is designed for high-density PECVD operation, which enables higher rates of deposition than more conventional CVD systems. It is made of stainless steel and has several vacuum seals to maintain a vacuum when the system is in operation. The source is located at the top of the reactor, and includes a microwave and RF plasma generator, gas output valve, and a substrate support. The microwave generator is equipped with a frequency control unit which allows for precise control over the power and frequency of the microwave energy. The RF source provides an additional power source and increases the deposition rate. The substrate support is composed of a stainless-steel frame with alumina ceramic windows which ensures uniform heating of the substrate. The automation system includes a computer-controlled robot arm for loading and unloading substrates, as well as process automation software for controlling the deposition process. Producer SE is a highly advanced platform for producing superior thin films. Its ability to create films that are extremely resistant to chemical and physical degradation make it a great choice for many industrial applications. It is also capable of depositing uniform films with superior performance and reproducibility. The robust digital drive power source also makes it an ideal choice for production of devices and emerging materials for next generation semiconductor devices.

There are no reviews yet