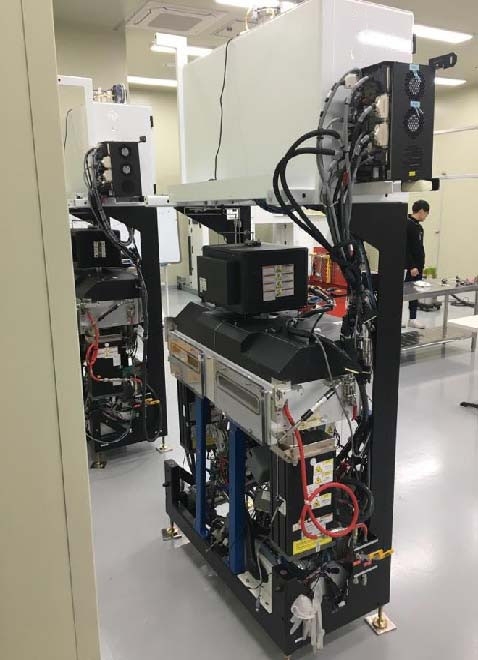

Used AMAT / APPLIED MATERIALS Producer SE #9204009 for sale

URL successfully copied!

Tap to zoom

ID: 9204009

Wafer Size: 12"

Vintage: 2006

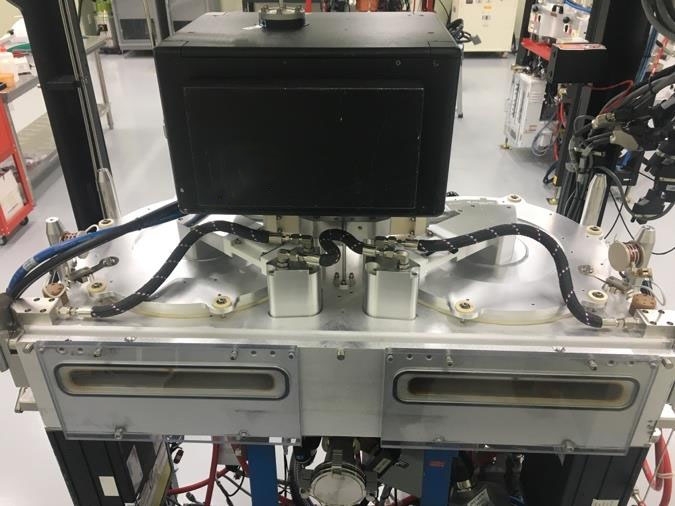

Twin chamber, 12"

Process: APF

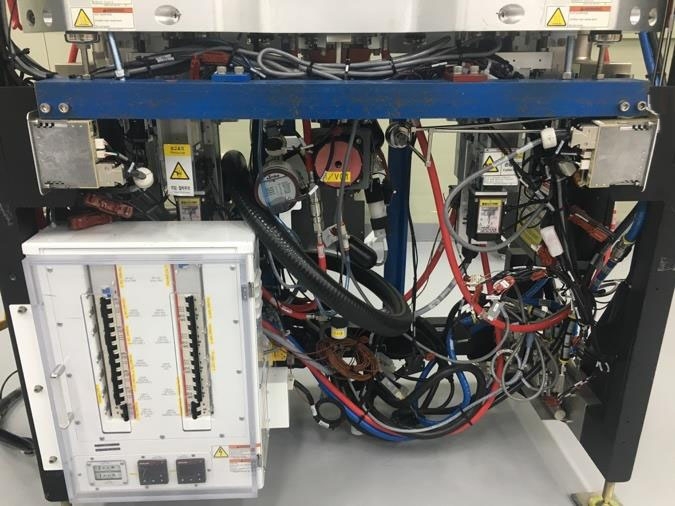

Major part:

RPS: MKS FI80131(Astron ex)

HF RF Generator: 0920-00107(Apex3013)

Ceramic heater: AlN

Gas panel: 1-1/8 C-Seal surface mount

AC box: 0195-01042

Heater lift driver: 1080-00126

Pin lift driver: 0190-13840

Throttle valve: 683B-26033

ISO Valve: 99D0654

Manometer: 20T / 100T

Process kit:

Top liner

Middle liner

Bottom liner

Pumping ring

Lift hoop

AL Spacer

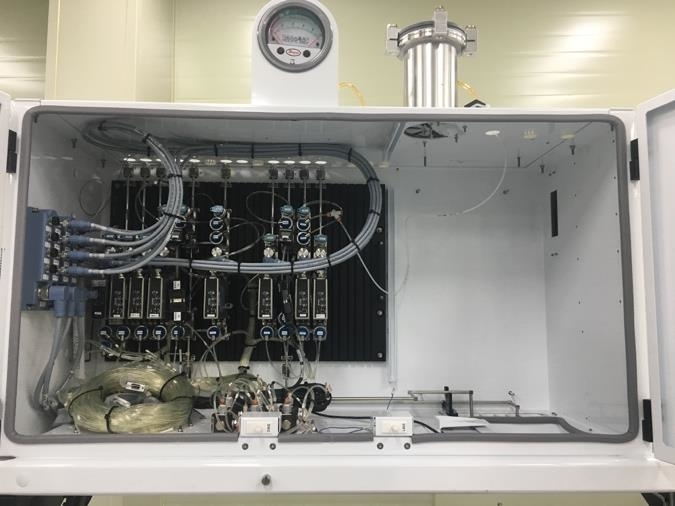

Gas configuration:

Gas Size(sccm) MFC Filter Valve

Stick 1 02 15,000 UFC-8565C NAS Hamlet

Stick 2 AR 5,000 UFC-8565 NAS Hamlet

Stick 3 HE 5,000 UFC-8565C NAS Hamlet

Stick 4 C3H6 3,000 IFC-125 NAS Hamlet

Stick 5 N2 Purge NA NA Hamlet

Stick 7 N2 15,000 UFC-8565C NAS Hamlet

Stick 10 02 15,000 UFC-8565C NAS Hamlet

Stick 11 N2 Purge NA NA Hamlet

Stick 12 NF3 5,000 UFC-8565C NAS Hamlet

Stick 13 AR 10,000 UFC-8565C NAS Hamlet

Lift ring(Fixed type): Localized

Missing parts:

Foreline

Heater lift driver

Aluminum slit insert

2006 vintage.

AMAT / APPLIED MATERIALS Producer SE is a type of shared reactor designed primarily for use in semiconductor fabrication and other industrial applications. It is manufactured by AMAT, Inc. and is designed to enable quick, efficient, and precise operation through a comprehensive suite of tool control, data transfer, and monitoring capabilities. AMAT Producer SE comprises several components, including a reaction chamber, a vacuum equipment, a process gas delivery system, an injector, a conveyor belt, a cooling unit, and an exhaust clean up machine. The reaction chamber is used to contain and isolate the environment within the reactor. It is equipped with an upstream vacuum tool, which is an integral part of the total asset. The process gas delivery model facilitates the delivery of required process gases to the reaction chamber. The injector directs and receives the chemicals required for the process, while the conveyor belt is used to move material within the chamber. The cooling equipment is used to regulate the temperature within the chamber, while the exhaust clean up system helps to ensure that all contaminants are removed from the environment before the product is released. APPLIED MATERIALS Producer SE is a multi-stage reactor which can be used for a variety of processes. It is capable of providing high levels of process control, including precise control of reaction parameters, the injection of precise amounts of chemicals, and process monitoring. It is also designed to provide a high degree of automation, with the ability to dynamically change the operating conditions and to monitor the process in real time. The unit can also securely transfer data, both locally and remotely, providing a unified platform for the management and control of the process. In terms of safety features, Producer SE includes a number of safety-related settings and alarms to help ensure the safety of personnel and the process environment. For example, it is equipped with a built-in safety interlock machine, which prevents the process from operating if certain conditions are not met. The tool also provides comprehensive monitoring and logging of all process parameters, which allows for quick and easy diagnosis of any process-related problems. AMAT / APPLIED MATERIALS Producer SE is an ideal tool for the production of advanced semiconductor devices. With its ability to provide high levels of automation, process precision, and safety, it can bring added value to the manufacturing process.

There are no reviews yet