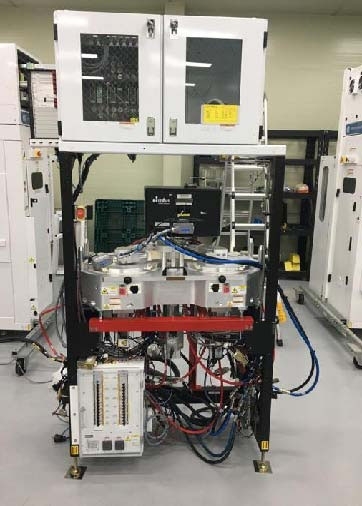

Used AMAT / APPLIED MATERIALS Producer SE #9204012 for sale

URL successfully copied!

Tap to zoom

ID: 9204012

Wafer Size: 12"

Vintage: 2002

Twin chamber, 12"

Process: HT SiN

Major part:

RPS: MKS FI80131(Astron ex)

Ceramic heater: AIN

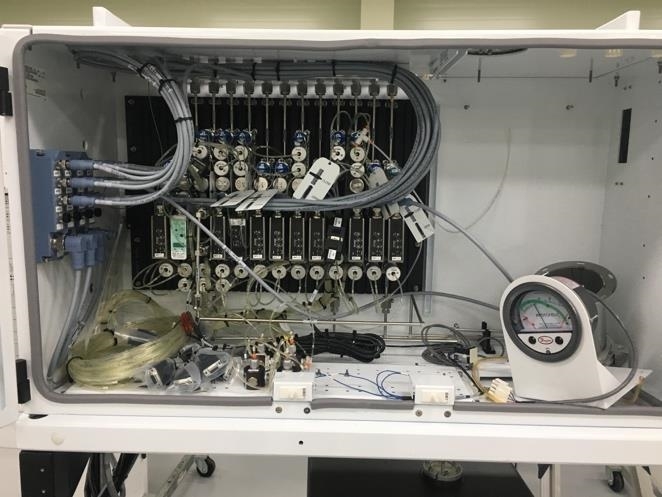

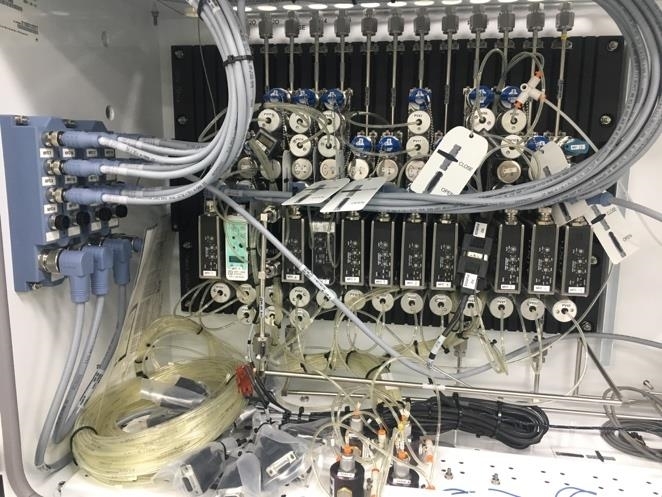

Gas panel: 1-1/8 C-Seal surface mount

AC Box: 0195-02428

Heater lift driver: 1080-00126

Pin lift driver: 0190-13840

Throttle valve: 683B-24562

ISO Valve: SMC XZ-218

Manometer: 10T / 100T

HF RF Generator:

0920-00085

0920-00107

Process kits:

Top liner

Middle liner

Bottom liner

Pumping Ring

Spacer

Lift hoop

EQ Liner

Liner

Nitch

Gas panel configuration:

Gas Size MFC Filter Valve

Stick 3 N20 15,000 UFC-8565 PALL Hamlet

Stick 4 N20 1,000 IFC-125 PALL Hamlet

Stick 5 N2 Purge NA NA Hamlet

Stick 6 SiH4 1,000 UFC-8565 PALL Hamlet

Stick 7 NH3 700 IFC-125 PALL Hamlet

Stick 8 HE 15,000 UFC-8565 PALL Hamlet

Stick 9 N2 25,000 UFC-8565C PALL Hamlet

Stick 10 NH3 5,000 UFC-8565 PALL Hamlet

Stick 11 N2 5,000 UFC-8565 PALL Hamlet

Stick 12 N2 Purge NA NA Hamlet

Stick 13 NF3 5,000 UFC-8565C PALL Hamlet

Stick 14 AR 10,000 UFC-8565 PALL Hamlet

Stick 15 N2 5,000 UFC-8565C PALL Hamlet

Junction box missing

2002 vintage.

AMAT / APPLIED MATERIALS Producer SE is an advanced reactor platform for silicon wafer production. It is the industry's first 300mm-diameter single-wafer processing system that creates the highest quality integrated circuits for the electronics industry. AMAT Producer SE processes semiconductor wafers with the highest yield rate available in the industry. APPLIED MATERIALS Producer SE's state-of-the-art technology is designed to improve overall wafer processing and yield. The reactor includes two components to ensure maximum performance and flexibility: the cluster tool and the process module. The cluster tool is one of the main components of the reactor and is responsible for the production of advanced processes in a single-wafer environment. This tool works to maximize production flexibility, efficiency and cost savings. The cluster tool includes advanced features such as a low-temperature process module, multiple process chambers, a high-speed isolation mechanism and a selective delivery system. It also utilizes AMAT proprietary process recipes to ensure optimal fabrication performance. The second component of Producer SE, the process module, is designed to optimize processing in a single-wafer environment. Utilizing APPLIED MATERIALS proprietary technology, it supports a variety of advanced processes, such as atomic layer deposition, ion implantation, ion milling and etching. It also works to increase throughput, yield and integration density. AMAT / APPLIED MATERIALS Producer SE is equipped to handle a wide range of semiconductor wafers, from 50nm to 10 micron. It has been designed to handle the most advanced process technologies, making it an ideal solution for those looking to fabricate complex semiconductor devices for leading-edge markets. AMAT Producer SE is a powerful and reliable reactor platform for silicon wafer production, offering the highest yield rates in the business.

There are no reviews yet