Used AMAT / APPLIED MATERIALS Producer SE #9215447 for sale

URL successfully copied!

Tap to zoom

ID: 9215447

Wafer Size: 12"

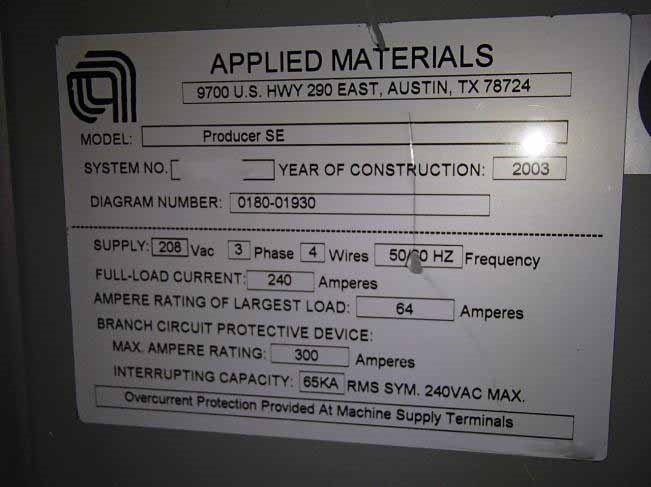

Vintage: 2003

CVD System, 12"

Process: P-TEOS(USG)

(2) Twins

FI Robot: KAWASAKI

Chamber configuration: Chamber-A,B

RPS: MKS FI120620

Heater: ALN

RF:

ADVANCED ENERGY APEX3013

ADVANCED ENERGY PDX-900-2V

Gas delivery

Chamber A&B:

Gas / Size / Model

NF3 / 5slm / Unit 8565C

TEOS / 7mgm / STEC LF-A40M-A-EVD

TEOS / 7mgm / STEC LF-A40M-A-EVD

Missing gases for chamber A & B: O2, Ar, He

Missing parts: H/E, HDD, OTF, iPump

Power requirements: 200/208 V, 60Hz

2003 vintage.

AMAT / APPLIED MATERIALS Producer SE is one of the leading silicon processing reactors available on the market. This reactor is designed to make a wide variety of materials, including silicon for the production of chips. It has a wide range of features to help ensure efficient production of high-quality semiconductors. AMAT Producer SE has four different zones for different functions. The first zone is a chamber which is designed for processing solid substrates such as silicon wafers. This chamber is equipped with a rotating inner wall to help evenly distribute the incoming gases. There is also an adjustable showerhead for the application of liquid precursors onto the substrate. The second zone, referred to as the "Process Zone" is where the metal deposition process takes place. This zone contains a Multi-View Illumination System (MVIM) which facilitates the uniform deposition of metal onto the substrate. The MVIM also allows for greater control over film thickness, uniformity, and coverage. The third zone is the Unloading/Loading Zone which allows for the removal of completed wafers. This zone is designed to make it easy to remove and load wafers quickly and efficiently. The fourth zone is the Gas Distribution System (GDS) which is used to regulate and monitor the pressure and velocity of the process gases as they flow through the reactor. APPLIED MATERIALS Producer SE has a range of adjustment and monitoring features that allow for optimal process control and stability. This includes pressure and temperature sensors, as well as the ability to adjust power, gas flow rates, and chamber size. The reactor also has a computer system which allows for remote monitoring of the process and provides performance data. Producer SE is a highly efficient, reliable reactor that is capable of producing high-quality silicon and other semiconductor materials. Its features make it a good choice for those looking for reliable and efficient semiconductor production.

There are no reviews yet