Used AMAT / APPLIED MATERIALS Producer SE #9215469 for sale

URL successfully copied!

Tap to zoom

ID: 9215469

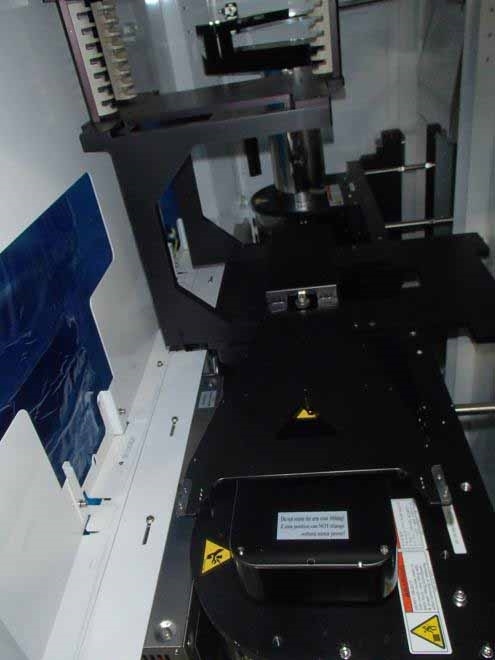

Wafer Size: 12"

Vintage: 2003

CVD System, 12"

Process: SA-USG

(2) Twins

FI Robot: KAWASAKI

Chamber configuration: Chamber-A,B

RPS: MKS ASTRONex FI80131

Heater: ALN

MKS AX8407A Ozone generator

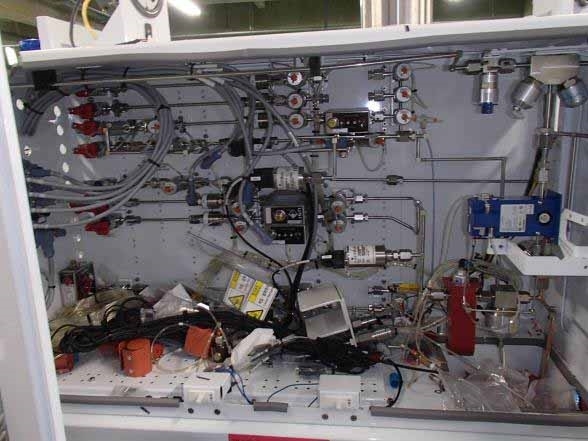

Gas delivery

Chamber A,B:

Gas / Size / Model

O2 / 30slm / Unit 8526C

N2 / 50slm / Unit 8565C

He / 30slm / Unit 8565C

NF3 / 7slm / Unit 8565C

Ar / 15slm / Unit 8565C

TEOS / 7g/min / STEC LF-A40M-A-EVD

Missing parts:

Noise filter

RPSC Line

Lid cover

HDD

Floppy

H/E

Chiller

OTF

iPump

INTLK PCB

Lid hinge

Heater lift assy

Gas: N2

2003 vintage.

AMAT / APPLIED MATERIALS Producer SE is a semiconductor reactor designed to enable customers to achieve thinner full wafers and uniform film deposition. The reactor is ideal for producing super integrated circuits and advanced memory devices. The reactor utilizes high levels of process control to ensure reliable and repeatable wafers. The process chamber is built with a stainless steel liner for durability and easy reconfiguration. The chamber also integrates industrial-grade vacuum systems and insulated windows. This insulation helps to reduce energy losses which leads to better process control. The chamber also offers improved wafer loading/unloading and better substrate pre-alignment. The process chamber is equipped with a deactivator to ensure optimal cleaning between different wafer runs. The tool features an advanced dual zone control equipment with a rotating deactivation system and a static deactivation unit. This machine enables superior process recipes which can be tuned to achieve maximum yield and performance. The reactor is equipped with an isolated zone to reduce the risk of contamination from wafer-to-wafer processes. It features an advanced in-situ plasma generator with a highly configurable control architecture. This in-situ plasma functionality increases process yields by decreasing the amount of variables associated with wafer cleaning. The hot wall design of the reactor achieves high temperatures with low thermal gradients. It delivers precise temperature control on small substrates and generates superior thermal uniformity on large substrates. The hot wall also enables better efficiency of energy use. The vacuum tool used on AMAT Producer SE reactor ensures that wafers are processed under precise vacuum conditions. The vacuum asset uses a combination of turbo pumps, a rotary vane pump, and a mechanical booster pump. The combination ensures high levels of process stability and repeatability. The reactor is equipped with an advanced remote monitoring model that provides real-time diagnostics and data access. It also provides detailed process logs to simplify operations and maintain equipment performance. The remote monitoring equipment also enables improved troubleshooting and process optimizations.

There are no reviews yet