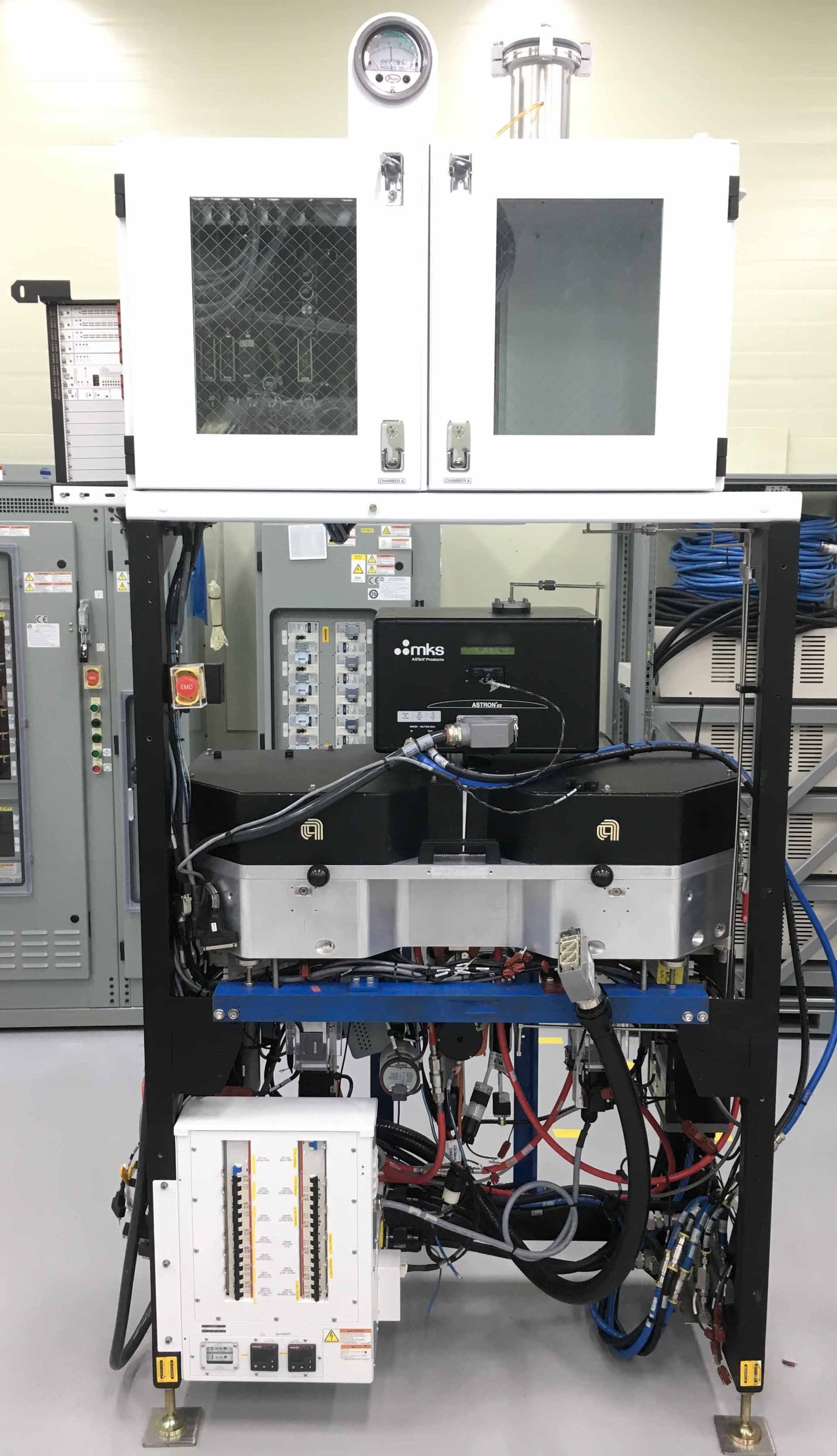

Used AMAT / APPLIED MATERIALS Producer SE #9258633 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9258633

Wafer Size: 12"

Vintage: 2004

PECVD System, 12"

Process: APF

Chamber configuration: CVD ACL (APF)

(2) Twins chambers

EFEM and mainframe configuration:

EFEM: F1 5.3

FIS: IBM 306m

FES: IBM 306m

RT: VMIC 7326

(2) KAWASAKI FI Robots

FI Robot blade: AL Triangle shape

TDK Loadport

VHP Vacuum robot

Ceramic vacuum robot blade

Vacuum robot driver: NSK Driver

WOB Centerfinder

AC Rack: 208 VAC

Slit valve position: Loadlock / Chamber A / Chamber B

Does not include heat exchanger

Chamber configuration:

Process: APF

Chamber position: Chamber A / Chamber B

MKS Fl80131 (6L) Remote Plasma Source (RPS)

APEX 3013 HF RF Generator

0021-85838 Shower head

Process kit: PECVD Kits

ALN Heater

Gas panel:

Stick 1: O2 (15,000)

Stick 2: AR (5,000)

Stick 3: HE (5,000)

Stick 4: C3H6 (3,000)

Stick 5: N2-Purge

Stick 7: N2 (15,000)

Stick 10: O2 (15,000)

Stick 11: N2-Purge

Stick 12: NF3 (5,000)

Stick 13: AR (10,000)

2004 vintage.

AMAT / APPLIED MATERIALS Producer SE is a highly advanced reactive ion etching (RIE) equipment that is designed for etching a wide range of materials in the semiconductor industry. It combines two technologies, namely, advanced plasma sources and advanced etching sources, in one integrated package. The advanced plasma sources enable the production of high throughput with excellent process uniformity while the advanced etching sources make it possible to etch various insulator and conductor materials at high aspect ratios. The RIE system works by introducing a variety of gases into the etching chamber, including a process gas, an oxidizing gas, and a reactive gas. This mixture of gases is then ionized by applying a high frequency electrical field and Plasmalab source, which creates a uniform electric field in the etching chamber and increases the etching rate. Once the mixture of gases has been ionized, an RF generator is used to generate the high voltage ion sputter, which is then used to bombard the workpiece with energetic ions. This bombardment removes the unwanted material from the surface of the workpiece, allowing structured etching. AMAT Producer SE has advanced computer control for optimizing etching processes and making improvements in productivity. Its software enables full automation of the etching process, allowing for enhanced process control and greater repeatability. The etching process can be finely tuned for different materials and geometries through programmable parameters, thus improving process reproducibility and significantly increasing yield. The integrated process recipe memory allows for quick process setting changes for different etching sequences, eliminating operator errors. In addition to its etching capabilities, APPLIED MATERIALS Producer SE also offers plasma-assisted deposition processes, such as atomic layer deposition (ALD), providing high accuracy deposition of thin films and allowing for complex gate structures and devices to be created. This advanced, multi-functional unit can significantly reduce cycle times and increase productivity, while ensuring process accuracy and consistency. Producer SE is an extensive RIE machine, capable of etching a wide range of materials with excellent process uniformity. It is an ideal tool for creating high quality and repeatable structures, with selectivities and aspect ratios that are not possible using traditional wet etch processes. In addition, the ability to fine-tune the etching parameters for different materials, geometries, and depositions allows for greater process control, repeatability, and increased yields. These features make AMAT / APPLIED MATERIALS Producer SE an ideal solution for semiconductor etch applications.

There are no reviews yet