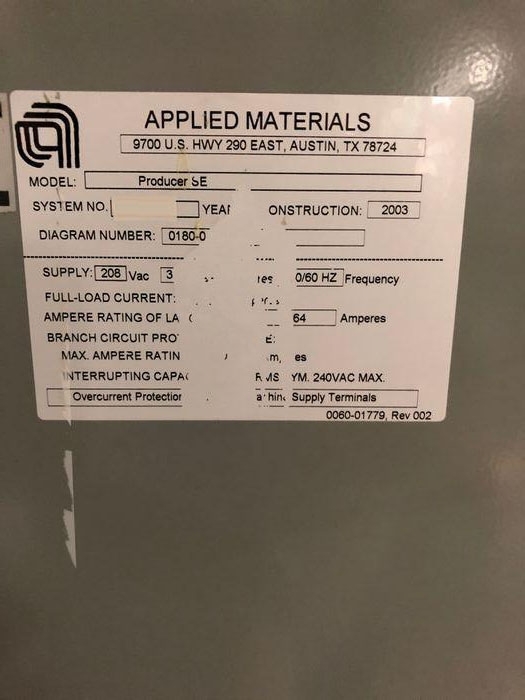

Used AMAT / APPLIED MATERIALS Producer SE #9280551 for sale

URL successfully copied!

Tap to zoom

ID: 9280551

Wafer Size: 12"

Vintage: 2003

CVD System, 12"

Process: NBLOK

(3) Chambers

(6) RF Generators

FOUP Interface

(2) KAWASAKI FI Robots

VHP Buffer robot

A-Box

SMC Heat exchanger

Missing / Faulty parts:

(2) FI Robot blades

Delta Tau CPU Board

(2) LL Heater lift drivers

SECS, GEM

2003 vintage.

AMAT / APPLIED MATERIALS Producer SE (AMAT) is a high-throughput chemical vapor deposition (CVD) reactor used for the precise conformal deposition of thin films onto a variety of substrates. The reactor is well-suited for producing thin films of high optical, electrical, or thermal properties, which are often used in the fabrication of semiconductor devices, thin-film batteries, displays, and other components. AMAT Producer SE utilizes an advanced pulsed-silicon-controlled rectifier (SCR) power supply to generate precise and repeatable pulse shapes, allowing for the precise control of the plasma and vapor chemistry during the CVD process. Its integrated gas mixing system enables a mix of reactant gases to be delivered with high-precision to be used in the deposition process. Additionally, a dual-zone temperature control technique allows for different temperatures to be set for the substrate and its surrounding environment. The customizable process chamber of APPLIED MATERIALS Producer SE has a volume of less than 2,000 cubic centimeters, allowing for it to support substrates of up to 10 inches in size. The chamber has a working pressure range of 25-50 millitorr and is designed to limit the effect of stray gas and ensure high vacuum levels. Furthermore, the transverse flux design of the process chamber provides optimal uniformity of deposition and improves the productivity and yield of the process. The advanced features of Producer SE allow for a wide variety of films to be produced, from low resistivity copper films to semi-transparent conductive aluminum oxides. It can provide up to four layers of materials with unique compositions and crystal structures. The repeatable process parameters of the system guarantee reproducible high-performance thin films with a consistency of quality. The flexibility and precision of the process combined with the scalability of AMAT / APPLIED MATERIALS Producer SE reactor make it an ideal tool for manufacturers in the semiconductor and electronics industries. Its unparalleled processing capabilities make it possible to produce high-performance components with industry-leading yields and cost efficiency.

There are no reviews yet