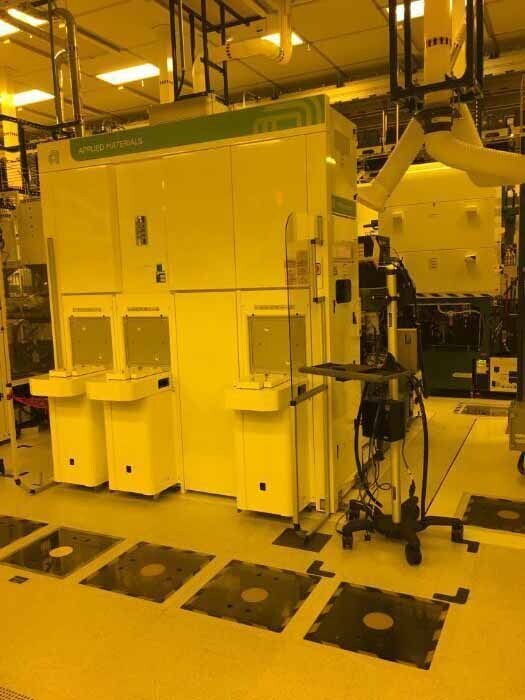

Used AMAT / APPLIED MATERIALS Producer SE #9354294 for sale

URL successfully copied!

Tap to zoom

ID: 9354294

Wafer Size: 12"

Vintage: 2014

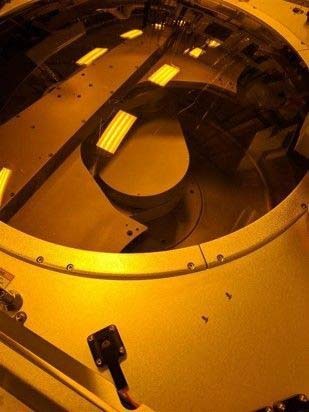

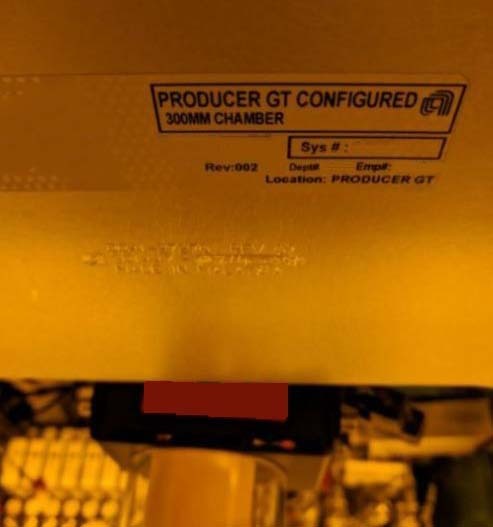

PECVD System, 12"

Process: TFM U Low-K dielectric

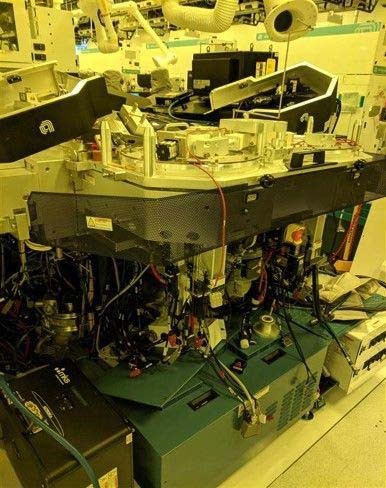

(3) Chambers:

Chamber A-BCHD

Chamber B-BCHD

Chamber C-BCHD

(3) FOUPs

CVD85x

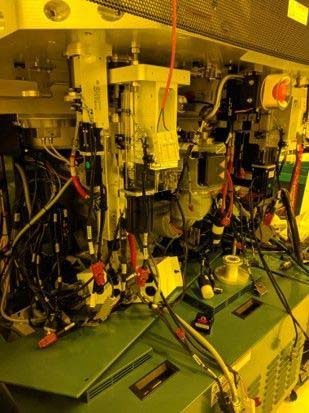

Missing parts:

User interface monitor / Keyboard

Heater

MF AC Panel

Manometers

RF Generator

MF-LL Heater

MF- Foreline

FI- Door interlocks

FI- KVM and Monitor

MF-LCF Sensor

MF- Buffer robot

MF- Gold box

Lid stack

Lid covers

RPS

FI- FFU Pid

Gas Box

RF Generators

MF- MF LL

MF- MF I/O

AC Box

RPS

FI-FI ATM

GPLIS and gas panel

Robots and controller

CIM: SECS / GEM

2014 vintage.

AMAT / APPLIED MATERIALS Producer SE (AMAT) reactor is a type of semiconductor reactor that is used in the fabrication of modern integrated circuits (ICs). The reactor works by depositing thin layers of material, such as silicon, onto a semiconductor substrate. The substrate is typically made of silicon, but may also include other materials such as gallium arsenide or aluminum oxide. The semiconductor film is then etched with lithography, allowing for transistors and other components to be patterned on the substrate. APPLIED MATERIALS reactor has a variety of capabilities, including depositing and etching process. The deposition process involves using a physical or chemical vapor deposition (PVD/CVD) process to layer materials onto the substrate, from the nanometer range to a few hundred nanometers in thickness. The etching process uses lithography; the lasers used can reach anywhere from the ultraviolet up to the infrared range to precisely pattern the substrate in the desired way. The reactor is designed for use in high volume, high-precision processes. For many applications, AMAT / APPLIED MATERIALS reactor is capable of providing accurate results in a timely manner. This is due to its tightly controlled environment, high-powered laser systems, and the computer-aided design tools that programs the entire process. The reactor has high throughput, meaning that it can produce many products in a short amount of time. It also provides an excellent platform for precise etching and precise monitoring of the process, which is essential for many semiconductor applications. Overall, AMAT reactor is an ideal tool for the modern IC fabrication processes. It provides the necessary accuracy and speed that is demanded in the current semiconductor industry. It is a reliable tool that is well-suited to any number of applications and is an irreplaceable tool in the world of semiconductor technology.

There are no reviews yet