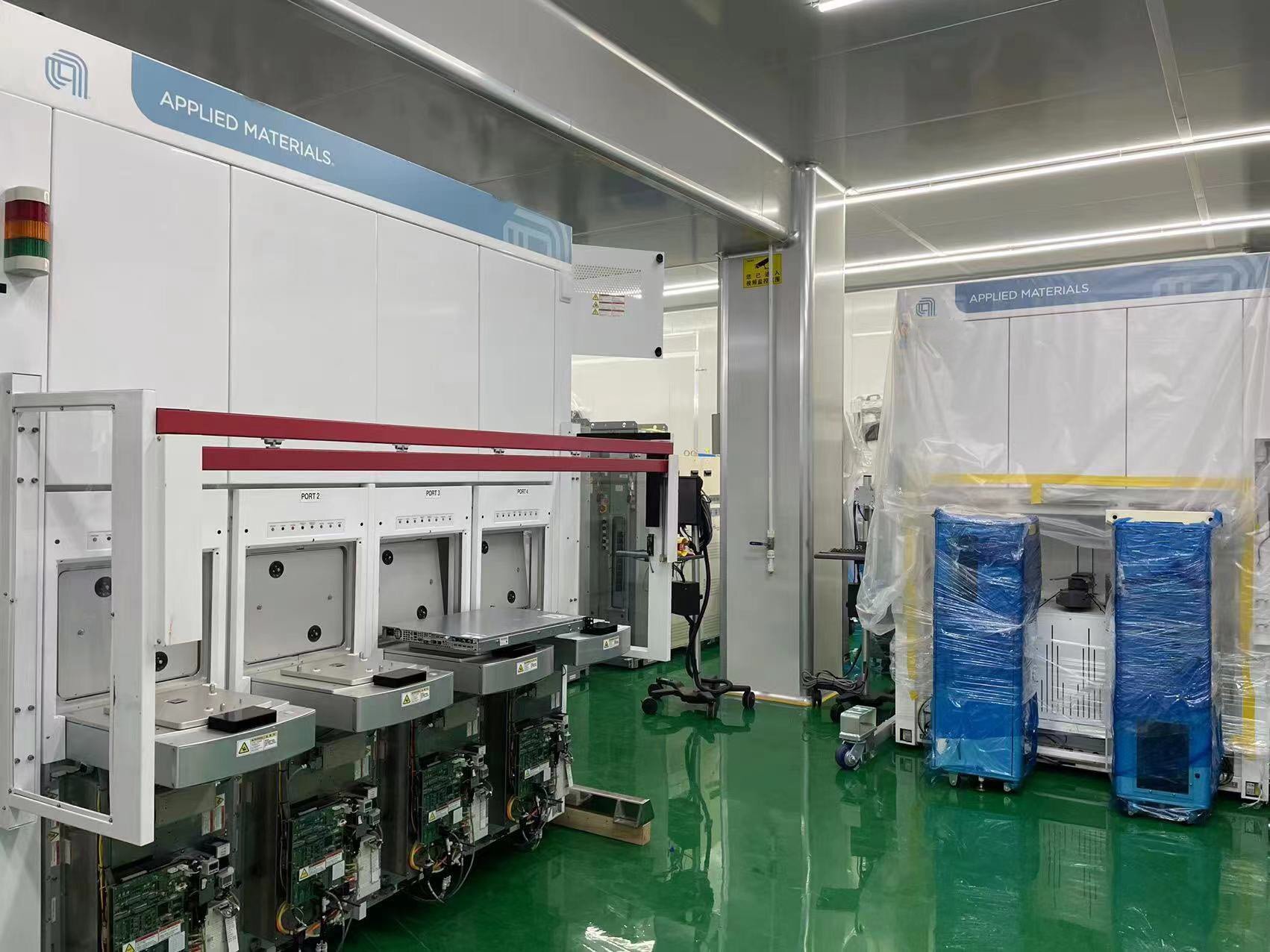

Used AMAT / APPLIED MATERIALS Producer #293603980 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

AMAT / APPLIED MATERIALS Producer (sometimes referred to as an AMP) is an advanced, multi-process chamber designed for the fabrication of thin film coating and deposition of thin film materials. The AMP is capable of performing many different types of deposition processes such as sputter deposition, chemical vapor deposition (CVD) and Atomic Layer Deposition (ALD) in a single equipment. The AMP processes are developed to meet industry's growing needs for advanced thin film materials and coatings. The AMP chamber is constructed from corrosion-resistant materials and features three process zones, each of which is outfitted with a main process cavity. The main process cavities are sealed for optimal control of the process environment and to ensure the repeatability of thin film coatings. Each process zone is also equipped with its own specialized components, such as a substrate heater, transport mechanism and remotely operated lift arm. The AMP chamber has a fully automated loading and unloading system which is capable of handling multiple substrates at the same time, while maintaining a clean and contamination-free environment. The AMP can also be equipped with a variety of process tools to facilitate different deposition techniques including magnetron sputtering, Ion Beam Deposition, CVD and Electrolytic Deposition. Each of these deposition techniques provides a suite of benefits, including increased control over the quality and uniformity of thin film coatings, quicker manufacturing times and improved energy efficiency. In addition to the process tools, the AMP chamber also contains various controls, feed lines and flow controllers to provide optimal process control. The chamber is also equipped with a gas unit to accurately control the gas pressure and composition within the chamber. The gas machine also helps reduce thermal or plasma damage during deposition operations. Finally, the AMP also features a sophisticated monitoring tool that can provide detailed process data, including process time and film thickness readings. This data can be used to adjust the deposition process in order to optimize the quality of thin film materials and coatings. The AMP is an advanced fabrication asset that is capable of meeting industry standards for precision and accuracy.

There are no reviews yet