Used AMAT / APPLIED MATERIALS PVD Chamber for Endura II #293649500 for sale

URL successfully copied!

Tap to zoom

ID: 293649500

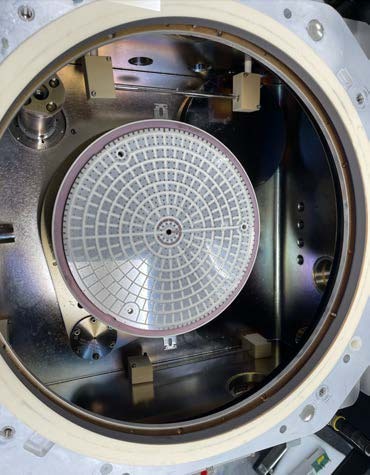

Wafer Size: 12"

12"

Application: Aluminum

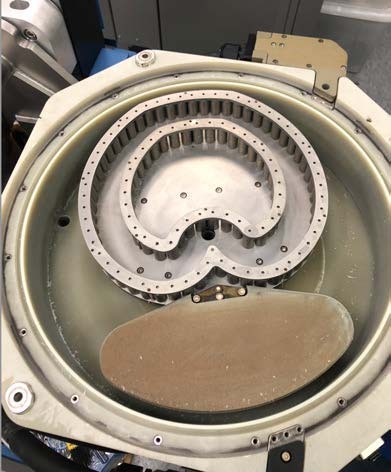

Magnet, P/N: 0010-03485

Adapter, P/N: 0040-89818

Heater, P/N: 0010-27430.

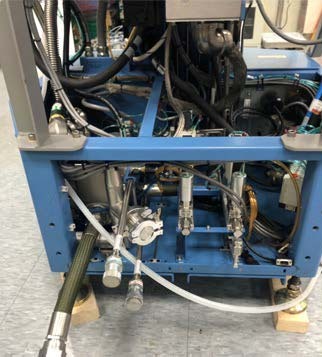

AMAT / APPLIED MATERIALS PVD Chamber for Endura II is an advanced Physical Vapor Deposition (PVD) reactor designed for use in microelectronics and semiconductor manufacturing applications. This chamber enhances current Endura II platforms and further enables the creation of thinner and smaller components through its enhanced control, precision, and efficiency. AMAT PVD Chamber for Endura II is designed to achieve a wide range of deposition characteristics in a dynamic, challenging environment. The robust chamber is equipped with advanced components and controls, allowing for greater accuracy and repeatability during the deposition process. Its advanced feedforward and feedback controls, matched with closed-loop dynamic pressure control, enable quick response and stable operation in a wide range of application conditions. The chamber features base pressures as low as 1x10-7 Torr, with reliable source seals and a helium-filled column chamber envelope, resulting in exceptional performance and robust metals evaporation processes. The chamber is outfitted with various sources and gas handling systems, as well as an automated source height adjuster and highly configurable wall and ceiling heaters. This enables precision control of layer thickness, temperature and uniformity, with maximum conformality in difficult deposition challenges. APPLIED MATERIALS PVD Chamber for Endura II also allows for greater customization of the sputtering process. Its ion-beam assisted deposition and ion etch modules promote greater sputtering uniformity compared to other systems, in addition to higher deposition rates, better surface coverage, and more control over the physical composition and electrical properties of the deposited material. The chamber is also designed for easy integration into existing Endura II production lines, as well as for scaling up from laboratory settings. The PVD chamber is reliable and highly productive, with time tested evaporation algorithms and advanced sputter deposition delivery systems for batch process enhancement. Overall, PVD Chamber for Endura II provides greater control and precision in deposition processing, resulting in higher quality microelectronic components and a more efficient production process. Its combined features, precision elements, and advanced technologies enable companies to increase the accuracy and speed of their manufacturing production lines.

There are no reviews yet