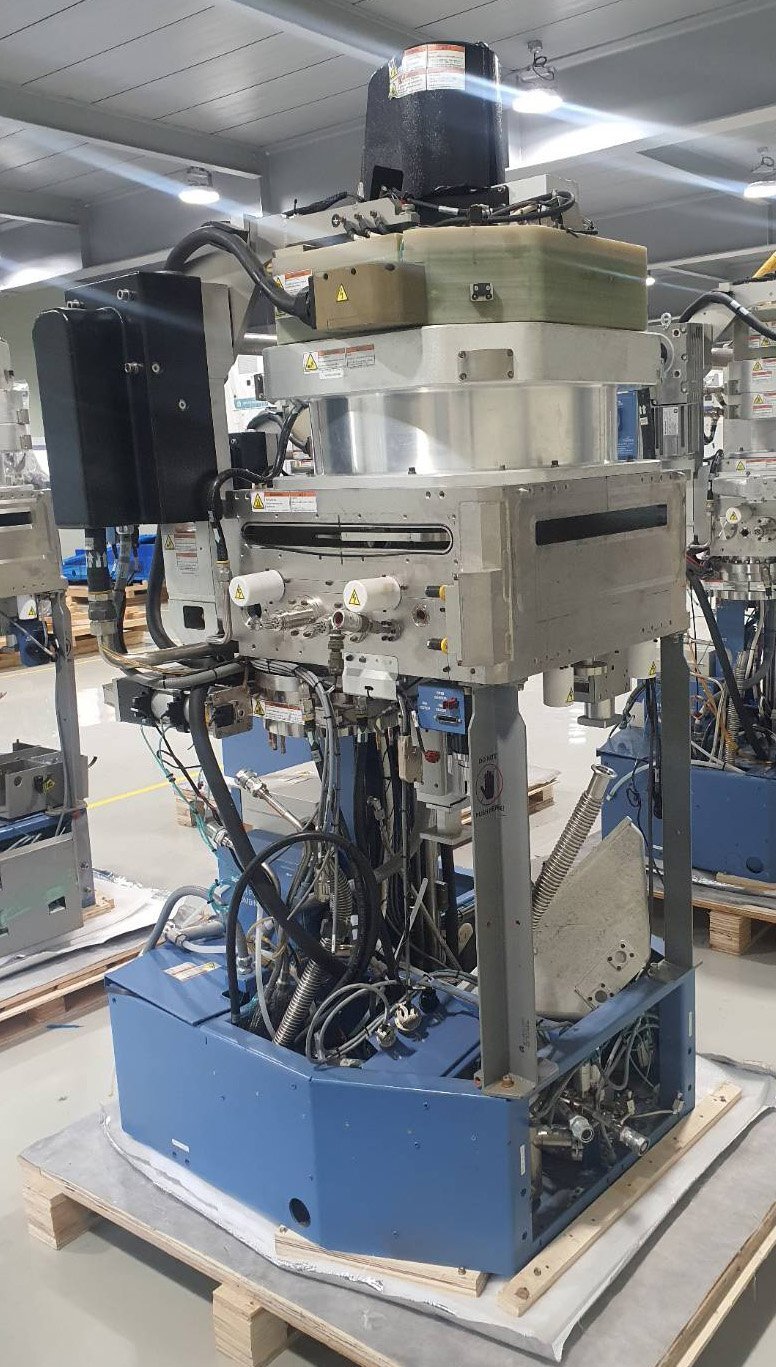

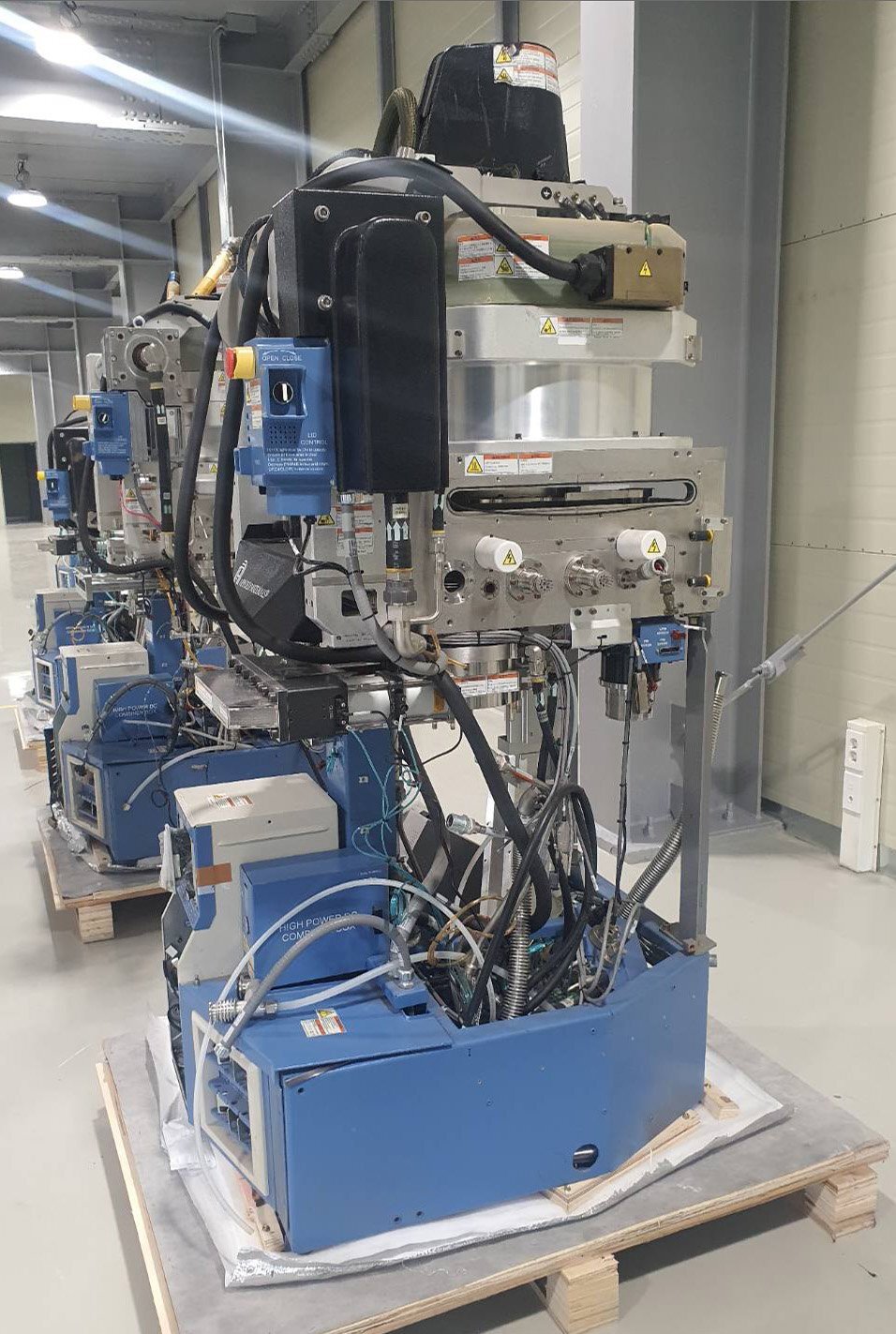

Used AMAT / APPLIED MATERIALS PVD Chamber for Endura II #293664711 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS PVD Chamber for Endura II is an advanced physical vapor deposition reactor designed for thin film deposition. The equipment uses a unique patented technology to deposit conformal thin films on large areas of several substrates. This system's multi-shape chamber offers unmatched uniformity and conformality, allowing for uniform thin film deposits over the full area of the substrate. The unit is optimized for both precursor delivery and reliable chamber cleanliness through design of an innovative chamber geometry and optimized gas flow management. The chamber design combines an expanded substrate-source distance, reduced chamber height, and enhanced gas flow management machine to ensure reliable thin film deposition processes. The chamber features integration with a source materials distribution tool and can be configured with a wide range of source materials and a range of sublimation and evaporation process. It also has advanced safety and control features, with an automated process control asset for protection of personnel and equipment. The model also has a unique advanced hardware-assisted process monitoring and control equipment, with built-in diagnostics and process parameter reporting. The chamber is designed for use in a variety of application areas, such as doped semiconductor materials, metal oxide thin films, polymers, and ceramic materials. The system enables reliable deposition of these materials with controlled process parameters, allowing for repeatable, high-quality thin films with high uniformity over large areas. AMAT PVD Chamber for Endura II is an advanced unit offering a high level of performance and control for thin film deposition. With a range of features and safety systems, the machine is designed to deliver reliable, repeatable results in a wide variety of application areas. The chamber design offers optimised process parameters, exceptional uniformity, and reliable deposition, making it an ideal tool for the most challenging thin film deposition processes.

There are no reviews yet