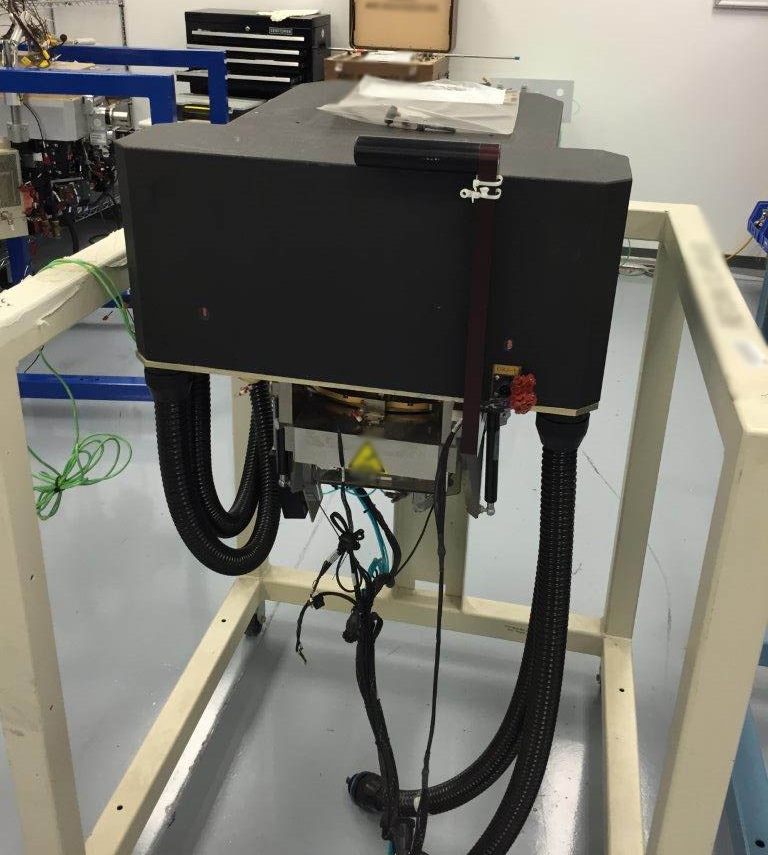

Used AMAT / APPLIED MATERIALS RTP #9103291 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

AMAT / APPLIED MATERIALS RTP is a state-of-the-art reactor technology used in the semiconductor manufacturing industry. It stands for Rapid Thermal Processing (AMAT RTP) which is used to speed the growth of semiconductor structures. APPLIED MATERIALS RTP is a highly customized technique that maximizes growth rates for silicon wafers and other substrates. RTP works by rapidly heating and cooling a substrate to specific temperatures, also known as temperature profiles. These profiles are programmed for specific needs based on the desired semiconductor material growth. The temperature profiles combined with advanced gas chemistry precisely control the composition of the growth layers. AMAT / APPLIED MATERIALS RTP combines two systems, the thermal control equipment and the loadlock system. The thermal control unit is the machine that controls the temperature profiles of the substrate As the substrate is heated and cooled, various gases, such as volatile gases and inert gases, are introduced at predetermined levels to assist the thermal energy transfer. These gases also provide additional reaction site chemistry and rate control to enhance thermal processing. The Endura 5500 tool, for example, is capable of reaching temperatures of 1000°C for particular applications. The loadlock asset is a vacuum chamber that maintains a clean environment. Inside, a sample boat holds up to 4-6 substrates. To ensure the desired temperature profiles, the boat is vacuum-sealed and loaded with nitrogen to create a controlled atmosphere. As the boat is evacuated, a precise temperature is reached within seconds. Once the boat is loaded and the temperature profiles set, the reactor carries out the processing. The boat is placed into a quartz tube, sealed, and heated to the desired temperature profile. Then, the reactive gases are introduced and the heated gas is circulated around the substrates. The result is the precise growth of the desired semiconductor layer. Once the process is complete, the substrates are transported to the cooling chamber, where they cool down to room temperature. The entire process is highly precise and yields extremely high quality growths. This makes AMAT RTP a reliable and precise model for growth of modern semiconductor circuits.

There are no reviews yet