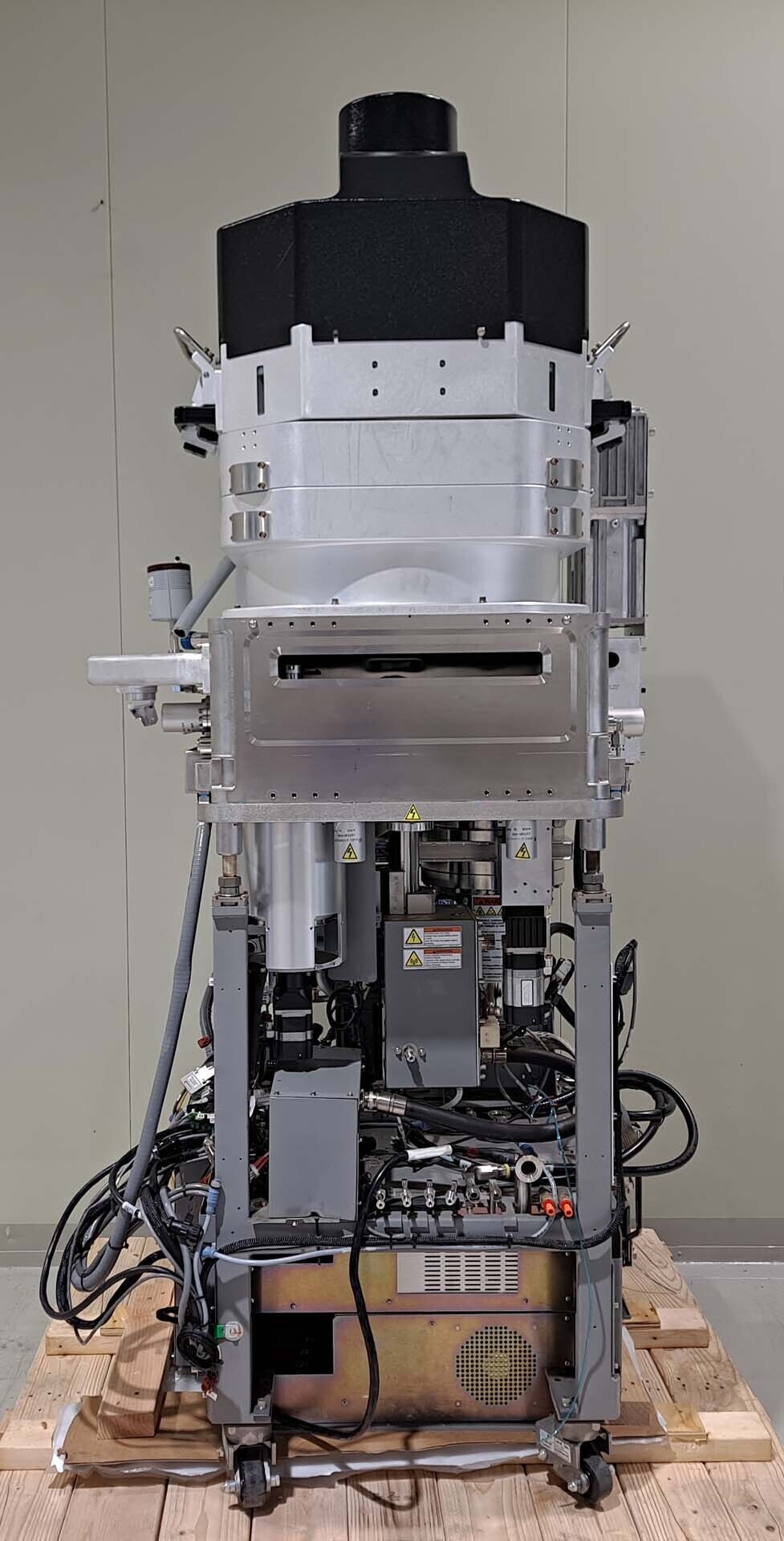

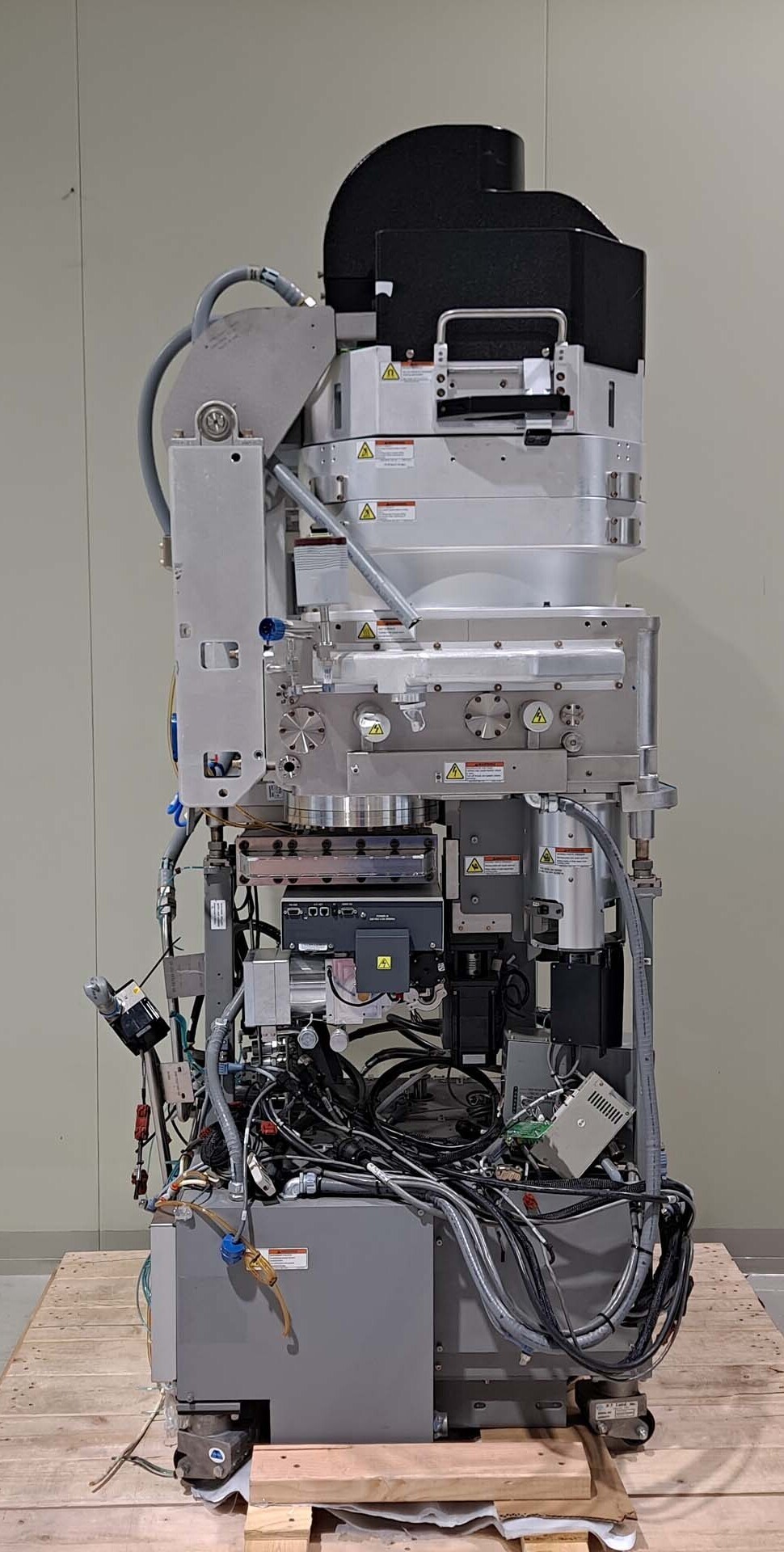

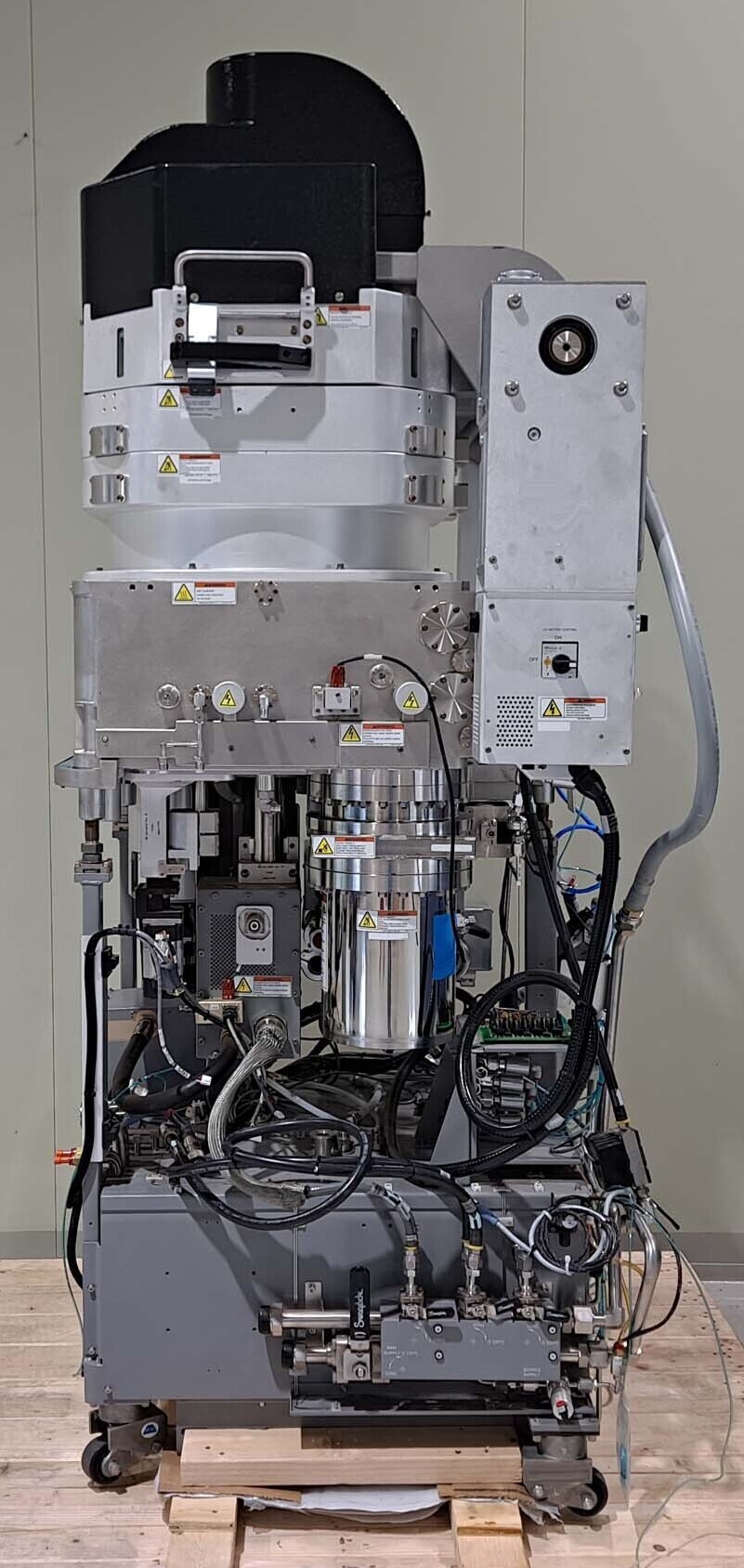

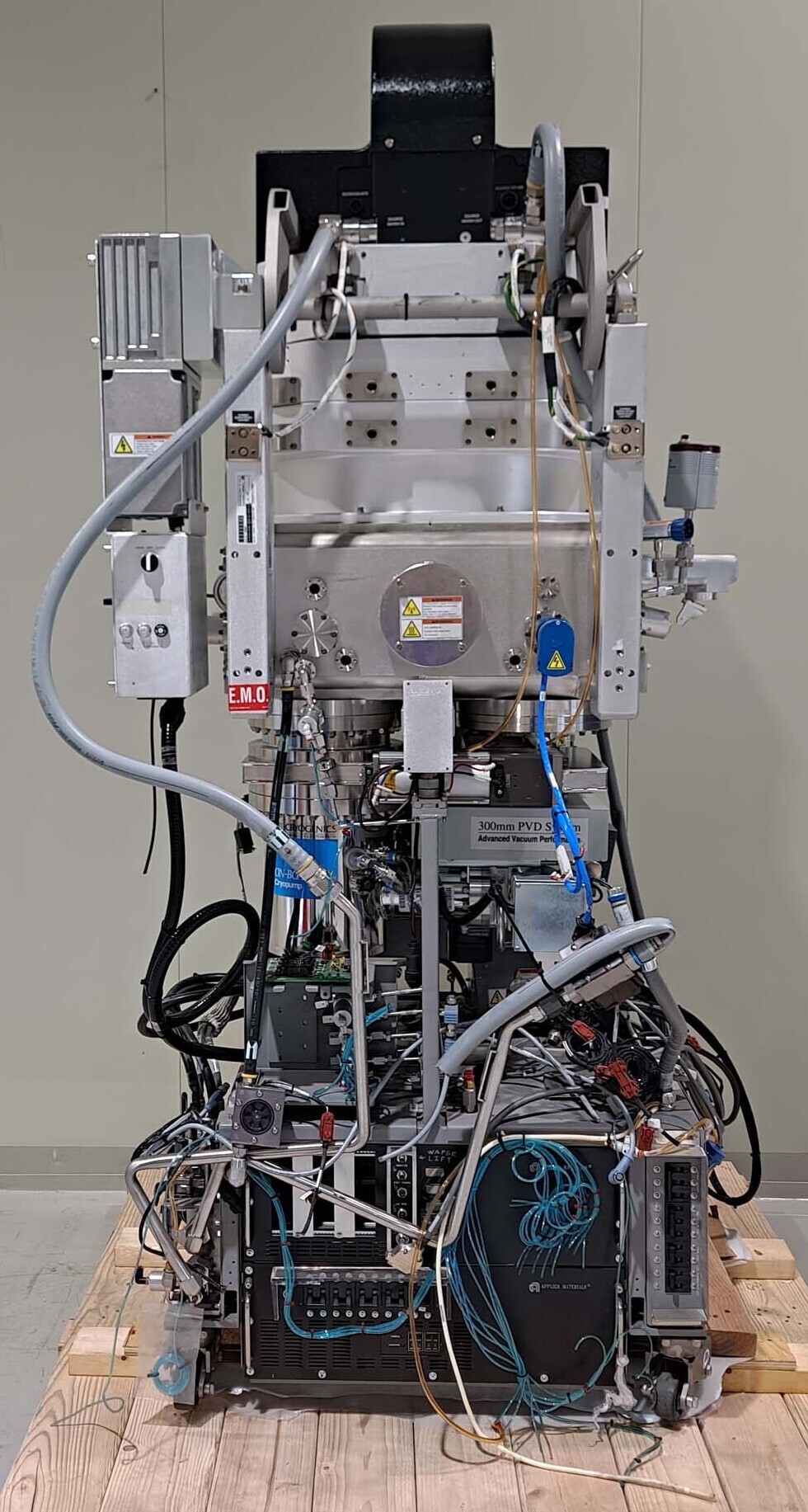

Used AMAT / APPLIED MATERIALS SIP Chambers for Endura CL #293664859 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS SIP Chamber for Endura CL is a reactor designed to carry out chemical vapor deposition (CVD), physical vapor deposition (PVD), and mechanochemical processes inside a vacuum environment. It is used in the manufacture of semiconductor devices, including transistors, memories, integrated circuits, and other microelectronic components. The SIP Chamber consists of several interconnected parts, including the reaction chamber, an exhaust equipment, a hot wall furnace, an inlet and outlet manifold, heating and cooling elements, a vacuum pump, and controllers. It has a cylindrical shape and is typically constructed from stainless steel and aluminum. The reaction chamber has an inner diameter of around 8 inches and a vertical height of around 4 feet. The chamber walls are heated to temperatures ranging from 300 to 1200°C, allowing for low-temperature chemistries. The hot wall furnace allows for uniform heating of the reaction chamber. Heating elements are located in the inner wall of the furnace and consist of ceramic, graphite, or metallic materials. The furnace houses a thermocouple for precise temperature control. Further control of the process can be achieved by setting the oxygen flow rate. The vacuum pump maintains the desired background pressure in the reaction chamber. The system utilizes a cryopump and can reach base pressures of 0.1 Torr. AMAT SIP Chamber for Endura CL is designed for versatility in terms of the chemistry, temperature, and throughput. It offers precise deposition control, with excellent uniformity and repeatability. The unit is capable of producing a wide range of films, such as metal chalcogenides, III-V compounds, and dielectric materials. APPLIED MATERIALS SIP Chamber for Endura CL offers a safe and efficient platform for manufacturing semiconductor microelectronic components. It ensures consistent product quality, improved device performance, and optimized process parameters. The machine is well suited for a variety of applications, including microelectronic manufacturing, optics, optoelectronics, and optoelectronic packaging.

There are no reviews yet