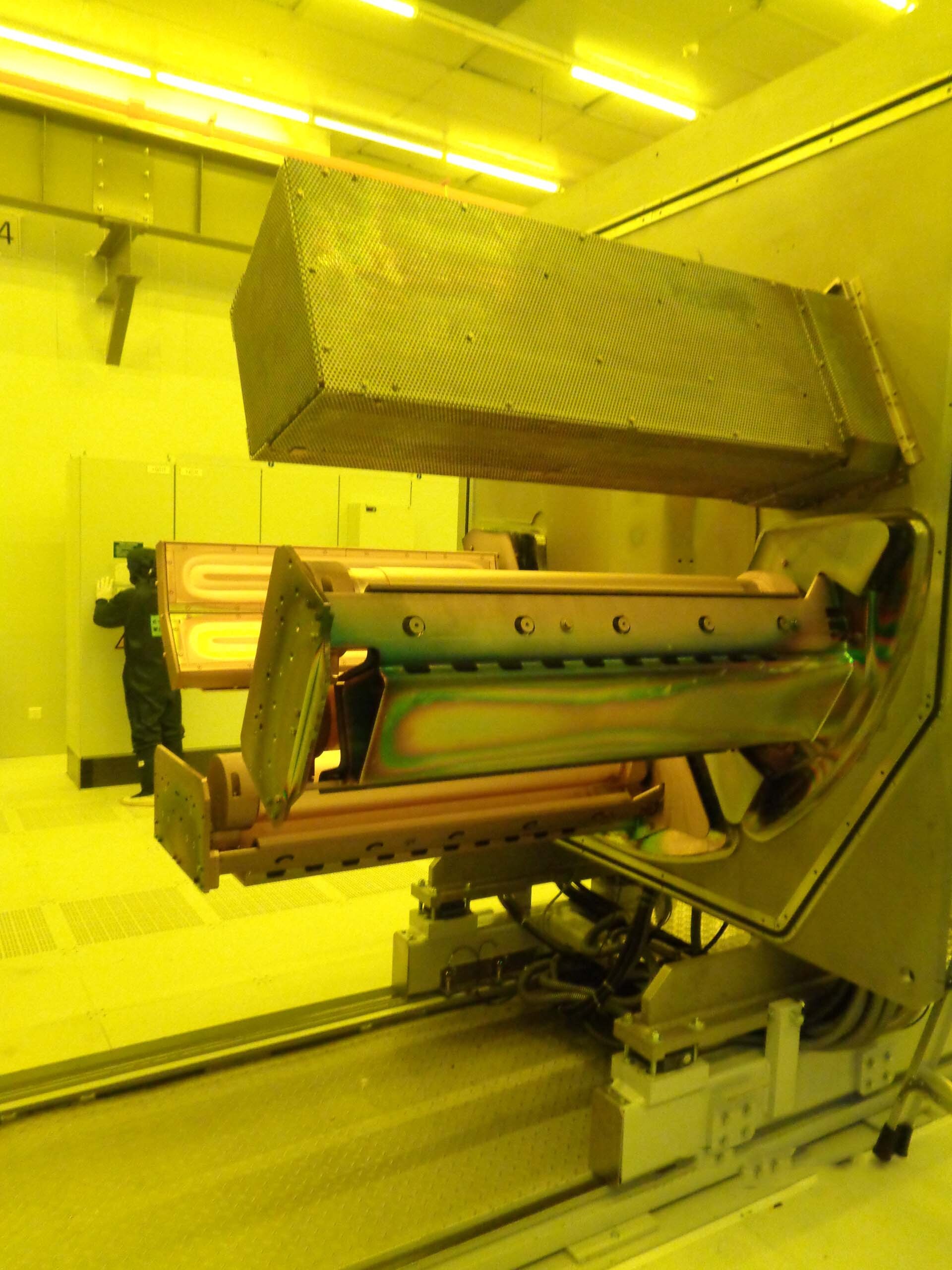

Used AMAT / APPLIED MATERIALS Smartweb SL-3L/800 #293745938 for sale

URL successfully copied!

Tap to zoom

ID: 293745938

Vintage: 2018

Roll to roll coating system

(2) Chillers

Roughing pump system

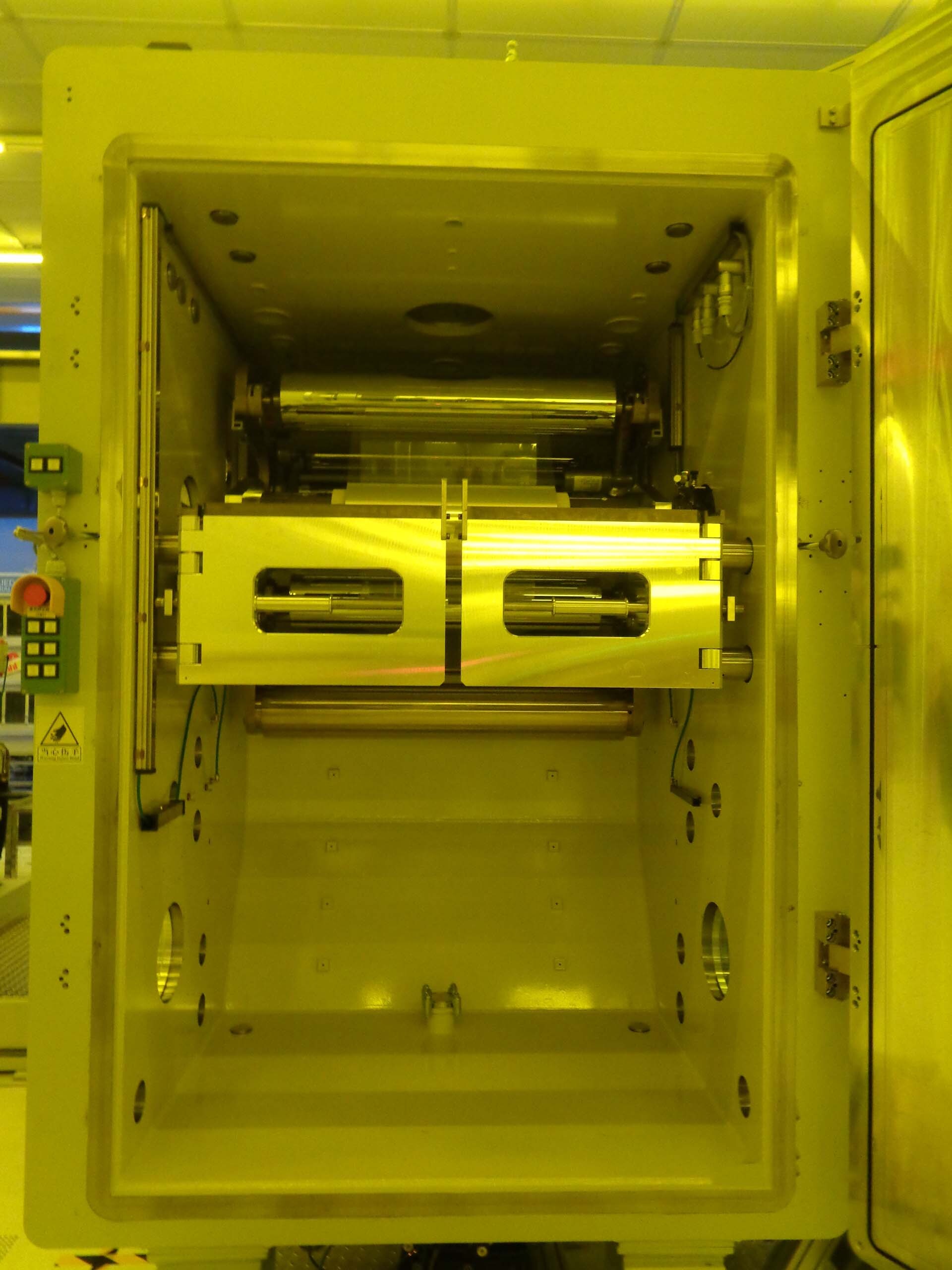

Process and rewinding module

Media supply

Electrical cabinet

Cooling

Heating

Trolley

Cathode colling

Control PC

Console table

Scrubber

Coatings:

Materials / Mode

Metals: Copper, Gold, Silver, Aluminium, Molybdenum, Titanium / DC

Alloys: Ni/Cr 80/20 / DC

Dielectrics: ITO, AI:ZnO / DC

SiOx, AI2O3, TiO2 /MF

ZnO / DC, MF

System cooling water:

Inlet pressure: 4 to 6 bar

Outlet pressure: Pressure-less, Open drain

Consumption: Maximum 50 m³/h

Average consumption: Approximate 26 m³/h

Temperature (Inlet): Minimum 18°C, Maximum 22°C

Temperature rise: Maximum 6°C

Carbonate hardness: <6 to 8°

pH value: 8.5 to 10

particle size: Maximum 100 μm

Particle concentration: Maximum 10 parts/cm³

CO2-content: Maximum 15 mg/l

CI-content: Maximum 20 mg/l

Cathode cooling circuit:

Filling quantity: Approximate 1100 Liters

Carbonate hardness: <7°

pH value: 8.0 to 9

Particle size: <5 µm

Solved oxygen: Maximum 5 mg/l

Resistivity at + 25°C: >2 x 103 Ohm cm

Compressed air:

Pressure: 6 to 7 bar

Average consumption: Approximate 1 m³/h

Particle size: Maximum 5 µm

Particle concentration: Maximum 5 mg/m³

Oil-content: Maximum 5 mg/m³

Dew point: 2°C

Gases: Argon, Nitrogen, Oxygen, Argon/Oxygen 80/20

Pressure: 1, 2 bar

Purity: 99.995

Gas tubing: Stainless steel, Coupling

Winding:

Web speed: 0.5 to 20.0 m/min + 0.1% of nominal speed at the motor shaft

Unwind / Rewind: 60 to 600 N

Tension measuring rollers with analog load cell

Vacuum:

Ultimate pressure: <8 x 10^-7 mbar in sputtering compartments of process modules

Pump down time to ultimate pressure: 24 Hours

Pressure during sputtering: 1 to 9 x 10^-3 mbar

Pump down time to 6 x 10^-6 mbar: <60 minutes

Measured at a pressure: < 2x10^-3 mbar

Gas separation factor between sputter compartments and sputtering compartments:

>100: 1, only for maximum substrate thickness loaded

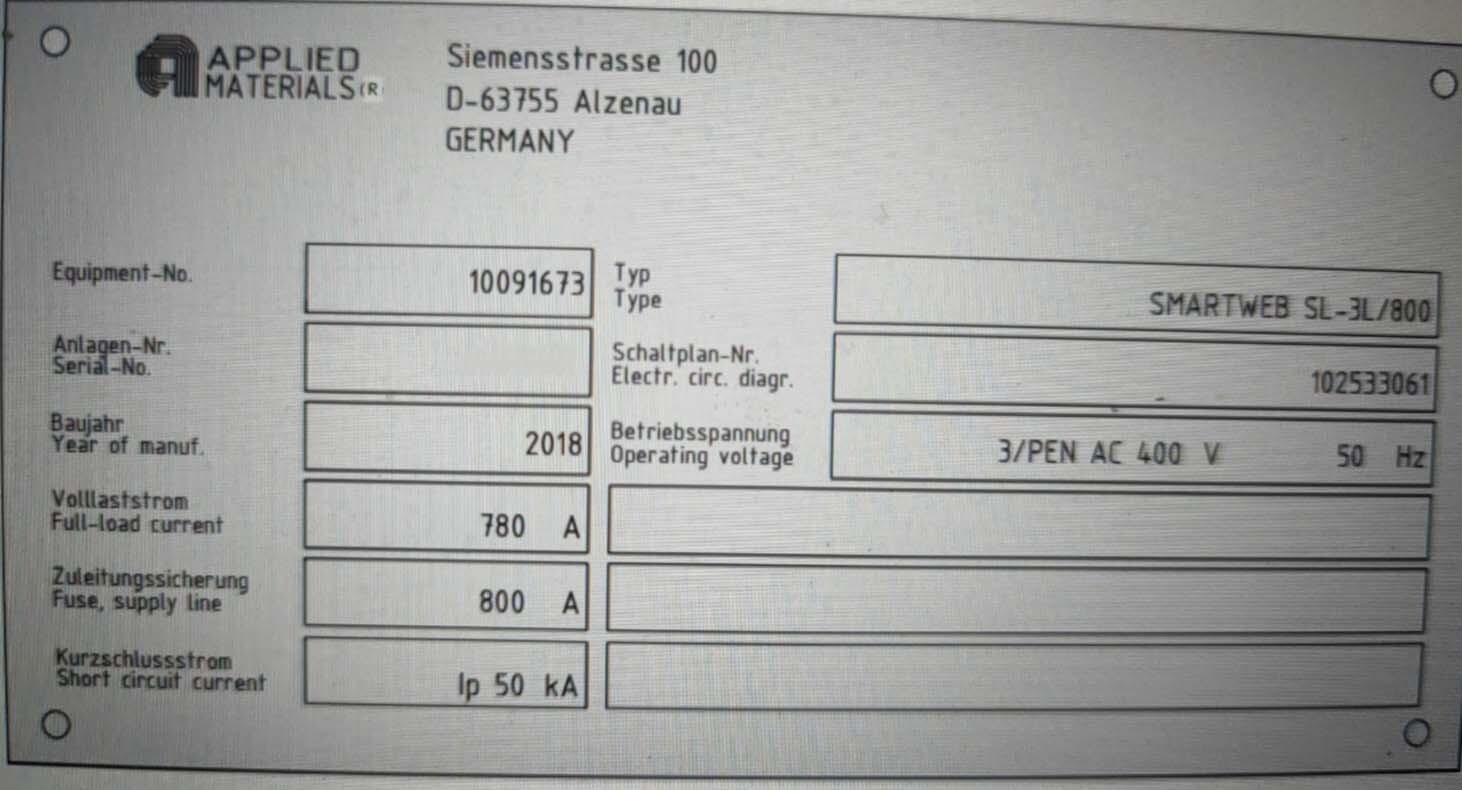

Electrical Services:

Voltage: 400 V +10/-10% 50 Hz, 3 Phase, TN-network with loadable PEN for 60 Hz

Connected load: 320 kVA

Average consumption: Approximate 240 kW

Short circuit current: Maximum 50 kA

Process coating:

Magnetron sputtering coating technology

One coated side

Substrate width: Maximum 820 mm

Coating area web width reduced: 10 mm

Coating width: Minimum: 300 mm, Maximum: 600 mm

Environment:

Temperature: Minimum 15°C, Maximum 35°C

Humidity: Maximum 90% at 20°C, Maximum 50% at 35°C

Maximum altitude of installation site: 1000 m above sea level

2018 vintage.

There are no reviews yet