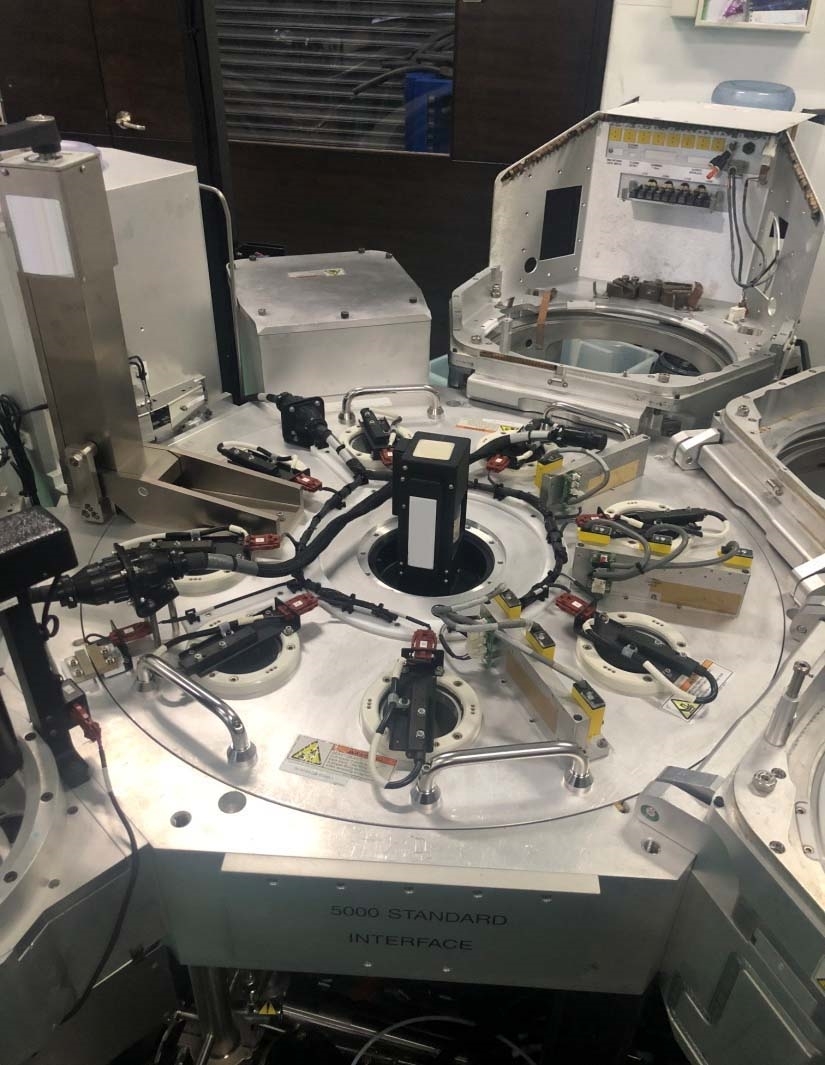

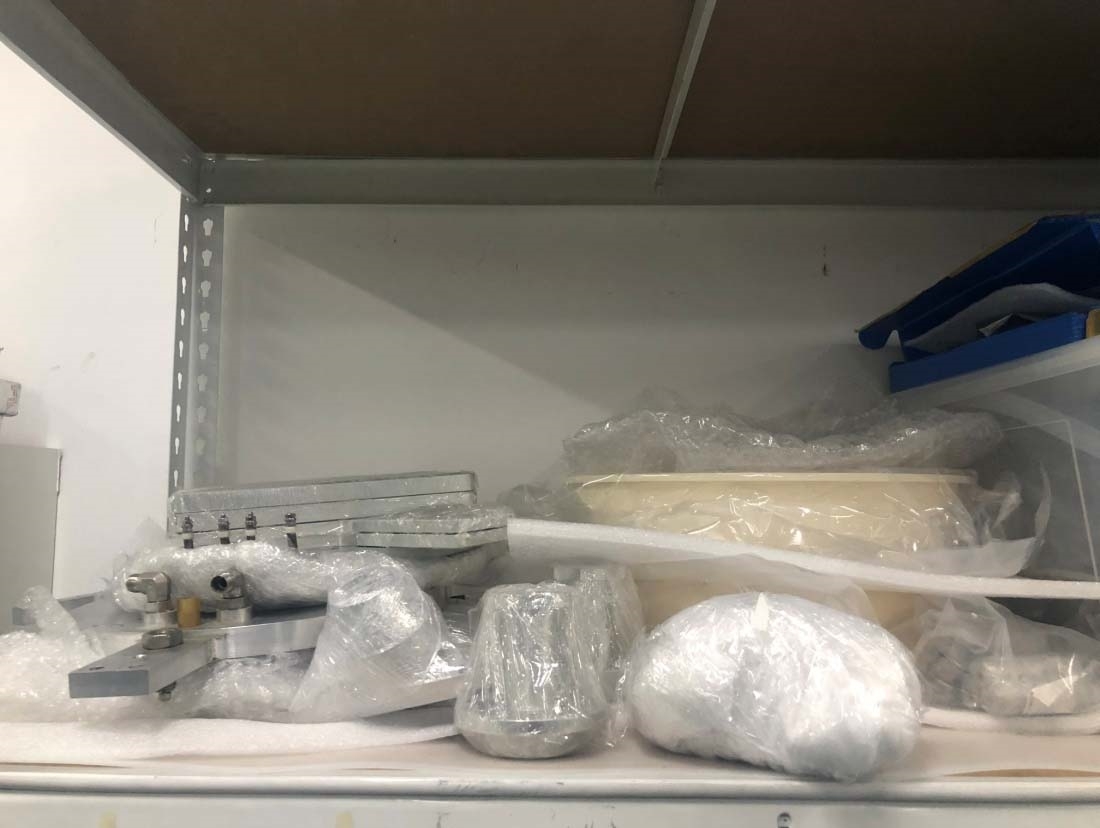

Used AMAT / APPLIED MATERIALS Ultima Plus #9256871 for sale

URL successfully copied!

Tap to zoom

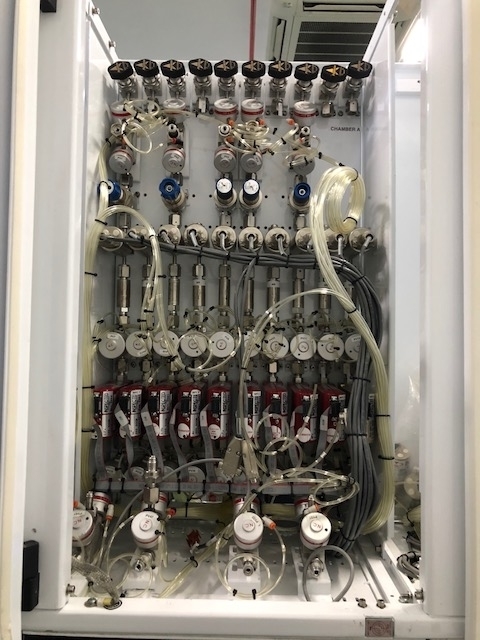

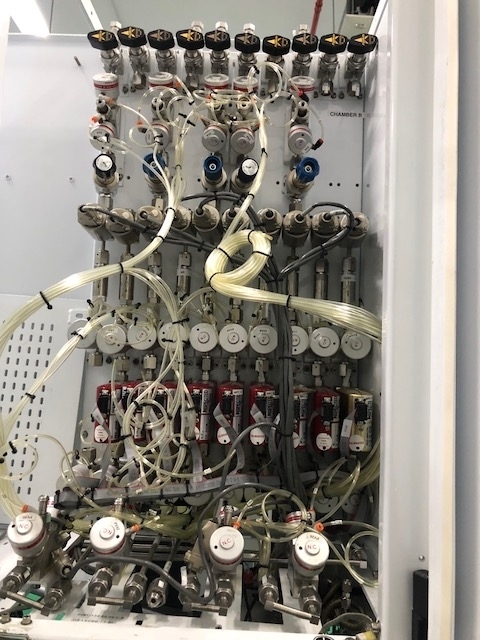

AMAT / APPLIED MATERIALS Ultima Plus is a next-generation chemical vapor deposition (CVD) reactor equipment designed for advanced materials processing applications. This versatile rector system enables batch processing of a variety of materials such as metals, semiconductors, oxides, nitrides, and magnetic/ferroelectric films. It is is an enhanced version of the company's Ultima® tool. The design of this rector features an integrated combination of highly efficient material heating, uniform plasma performance, and process control innovation. The quartz reactor includes two edge-shielded plasma sources, a dual-susceptor powered by a RF generator and a heated lift-pin. The lift-pin is designed for a homogenous transfer of the heated wafer from the susceptor to the gas box in the reactor. The motor controller of AMAT Ultima Plus allows users to finely adjust the distance between the susceptor and the gas box to adjust the processing space. It also enables users to accurately control the temperature across the wafer as well as the position of the wafer in the center of the plasma reactor. This reactor has a low-pressure and multi-zone capability with a range of process temperatures from room temperature to 600°C. It also offers low-pressure processing for materials such as GaN, diamond, and carbon nanotubes, and can process a wide range of materials where high-pressure processing would not be suitable. APPLIED MATERIALS Ultima Plus is comes standard with diagnostic processes such as in-situ ellipsometry, Raman spectroscopy, and reflectometry. Additionally, it features multi-tube load-lock, a stainless-steel bellows, a four magnetron bias plasma source, a powerful pulse modulated plasma source, an automated operation controller, and a vacuum unit. The machine is designed to optimize throughput while minimizing the possibility of contamination. Ultima Plus enables the users to quickly and accurately control their processes by customer-defined parameters such as time, pressure, RF power, and temperature to precisely dial-in the optimal recipe. The advanced safety systems included in the reactor guarantee a safe operation and protecting the process environment from any type of contamination.

There are no reviews yet