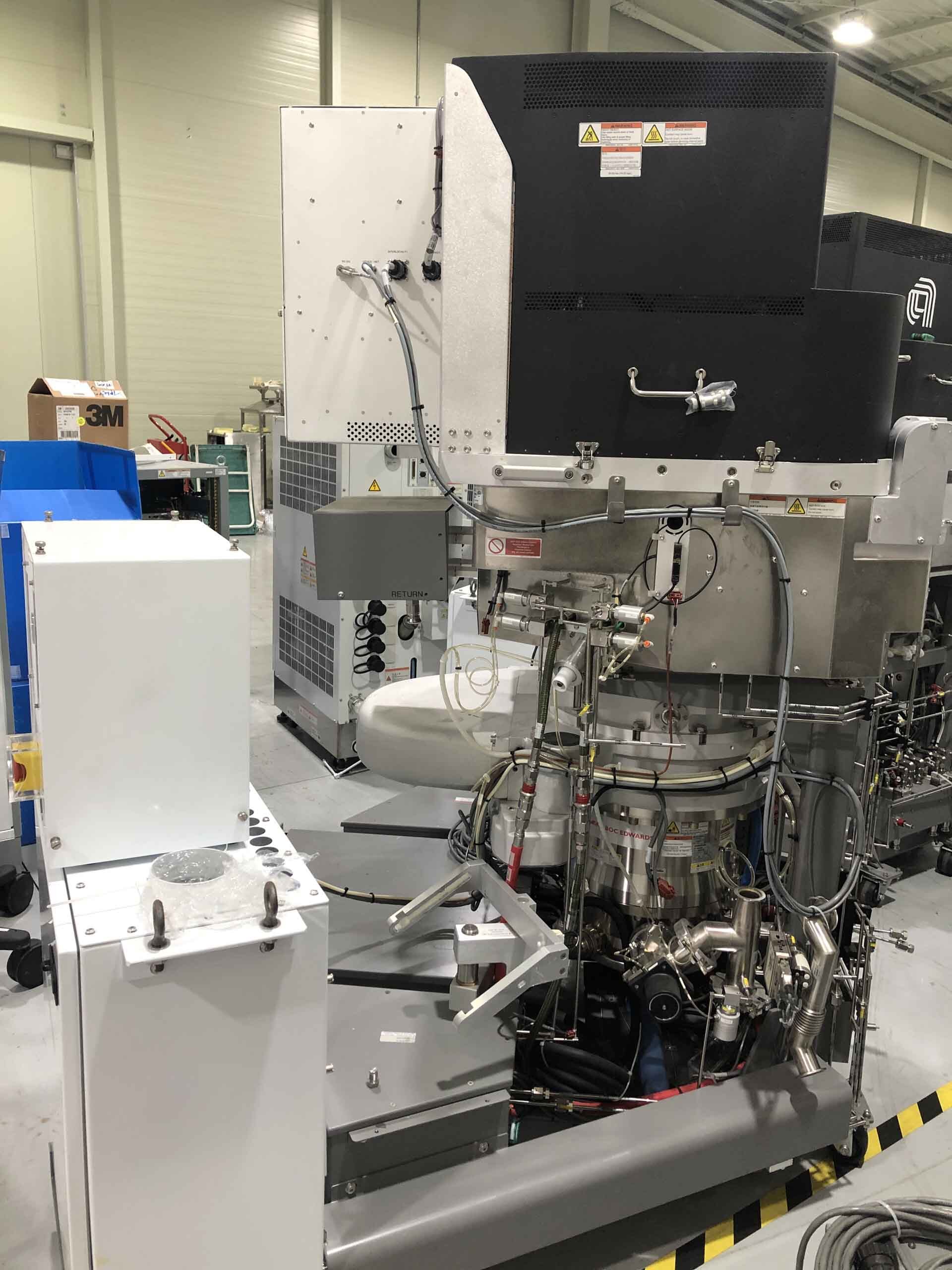

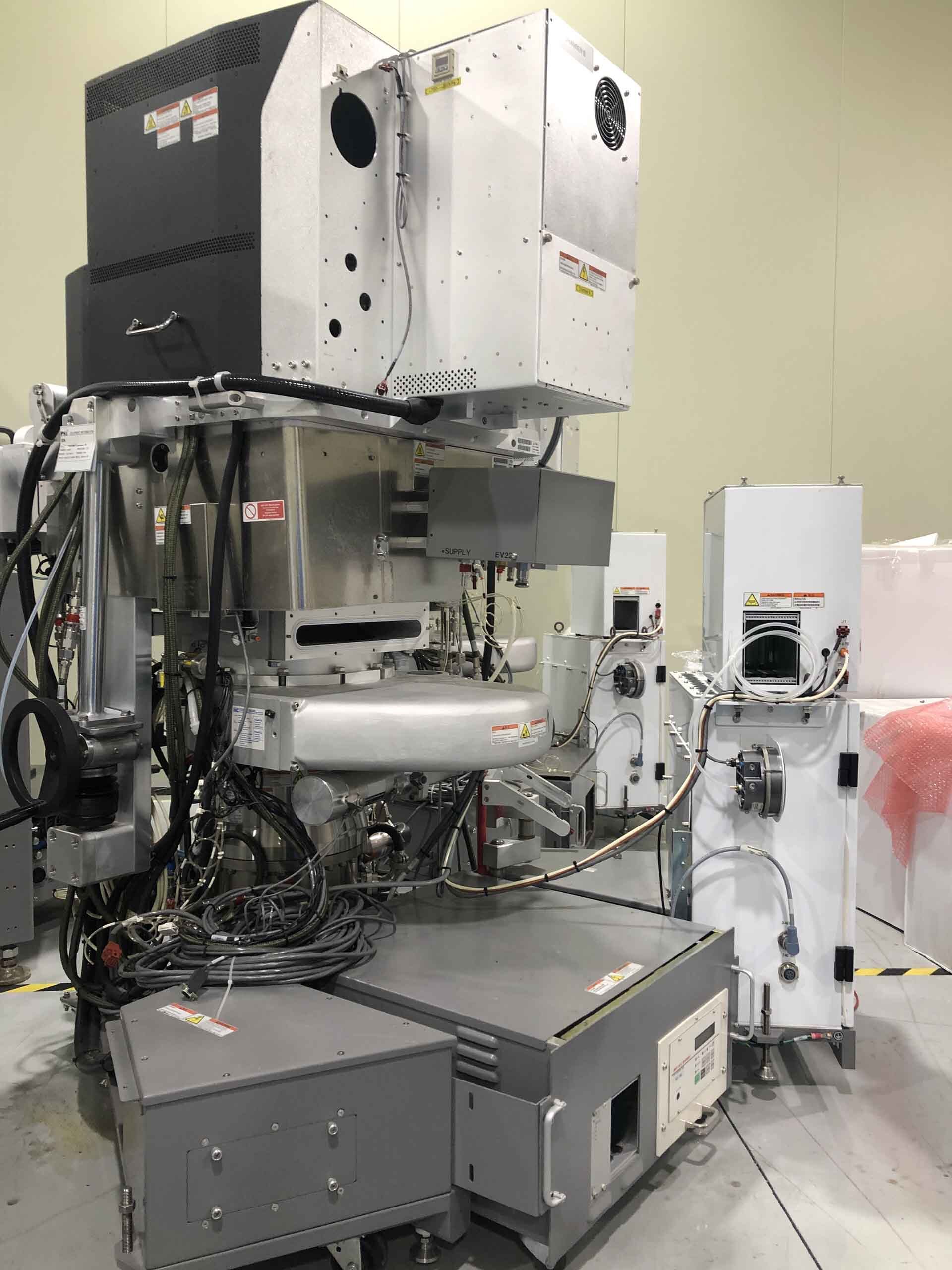

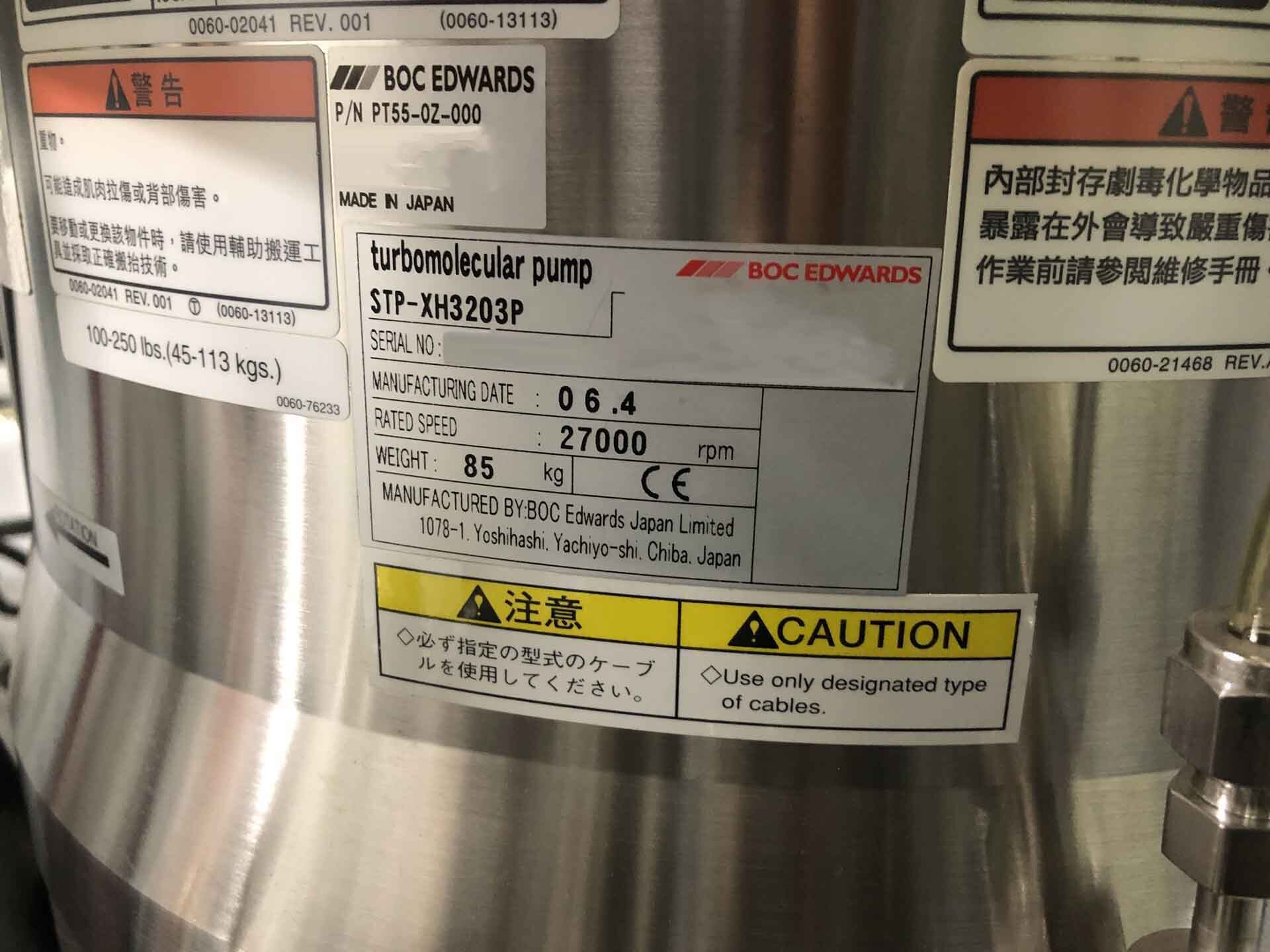

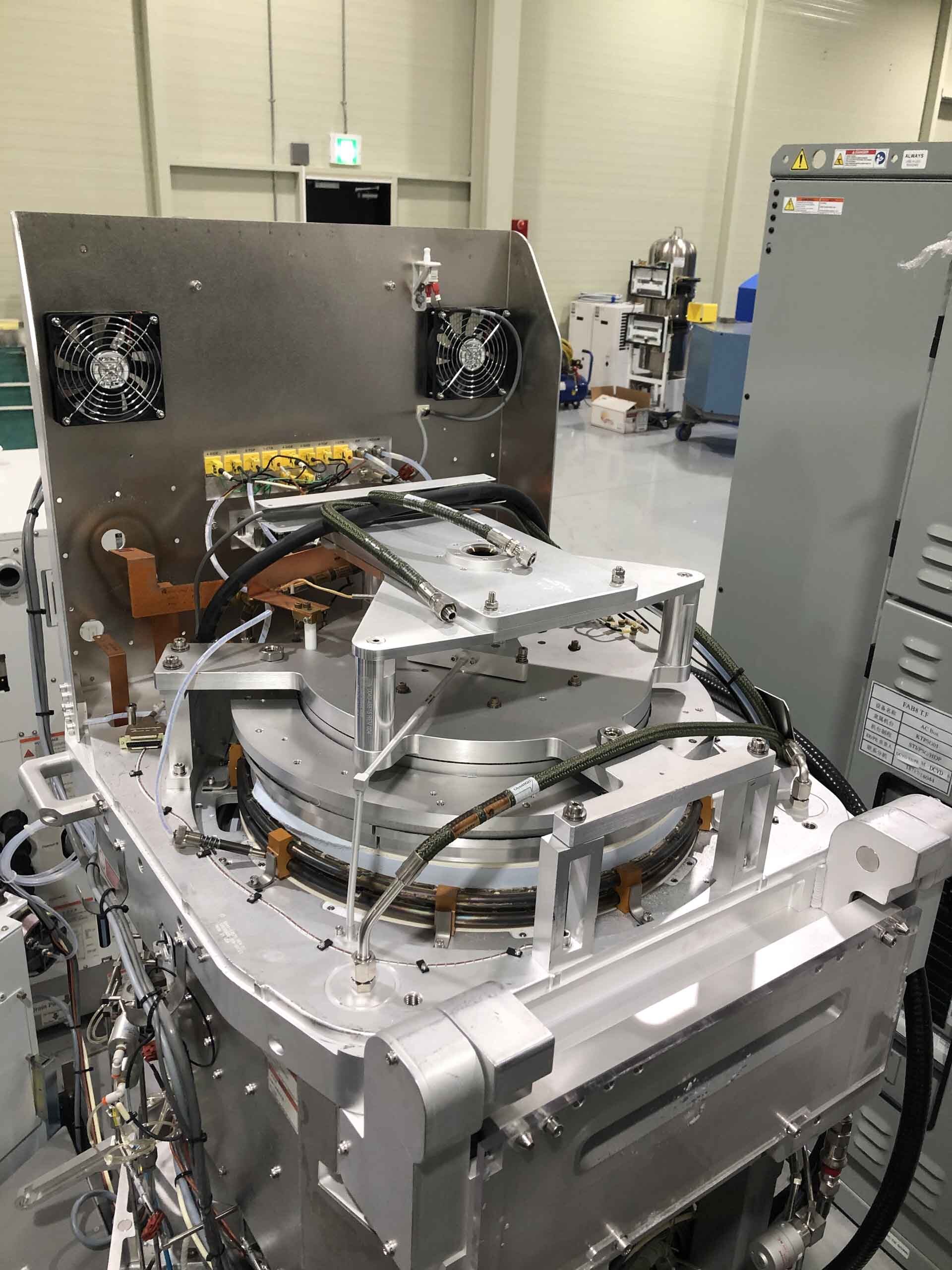

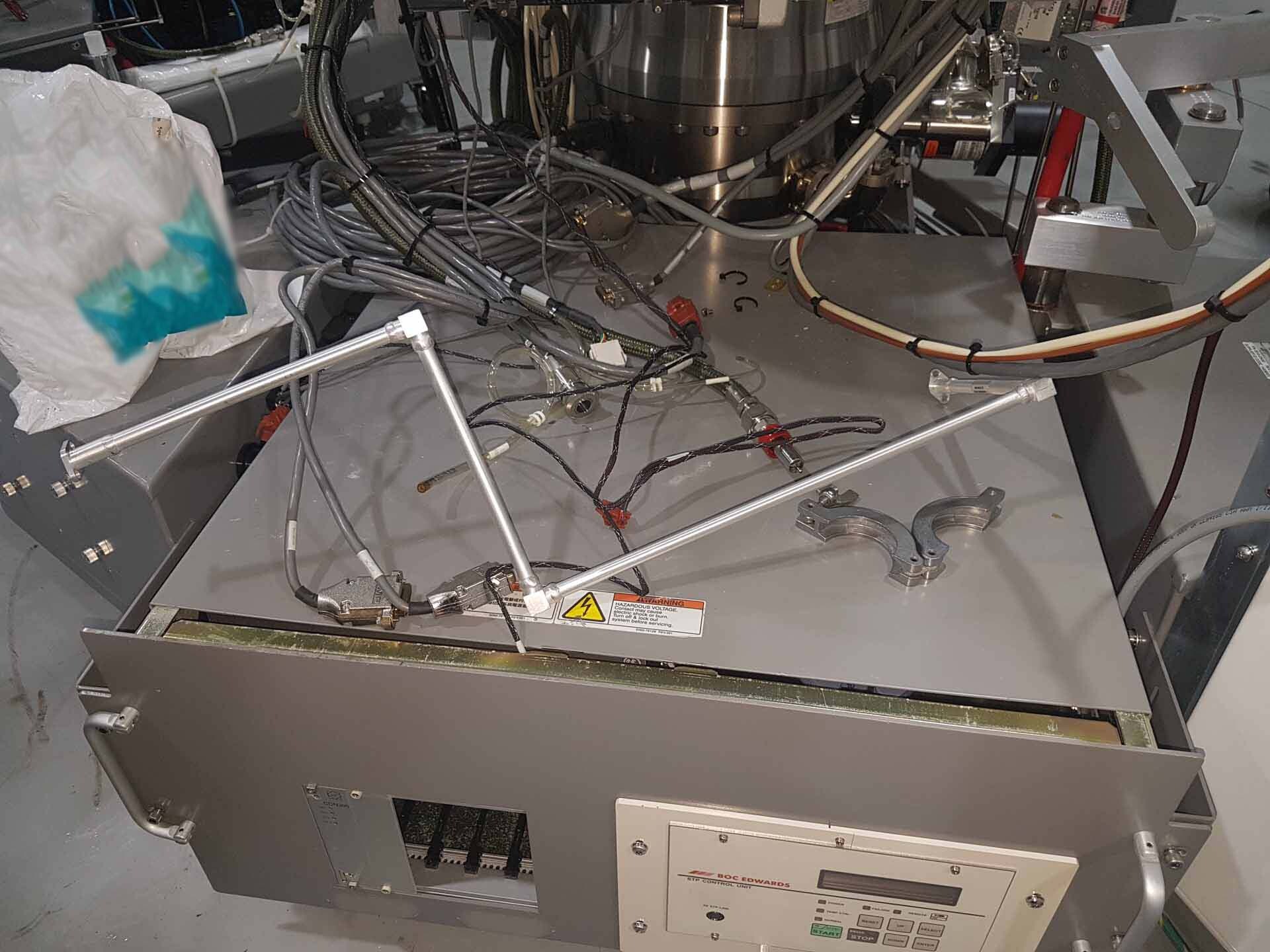

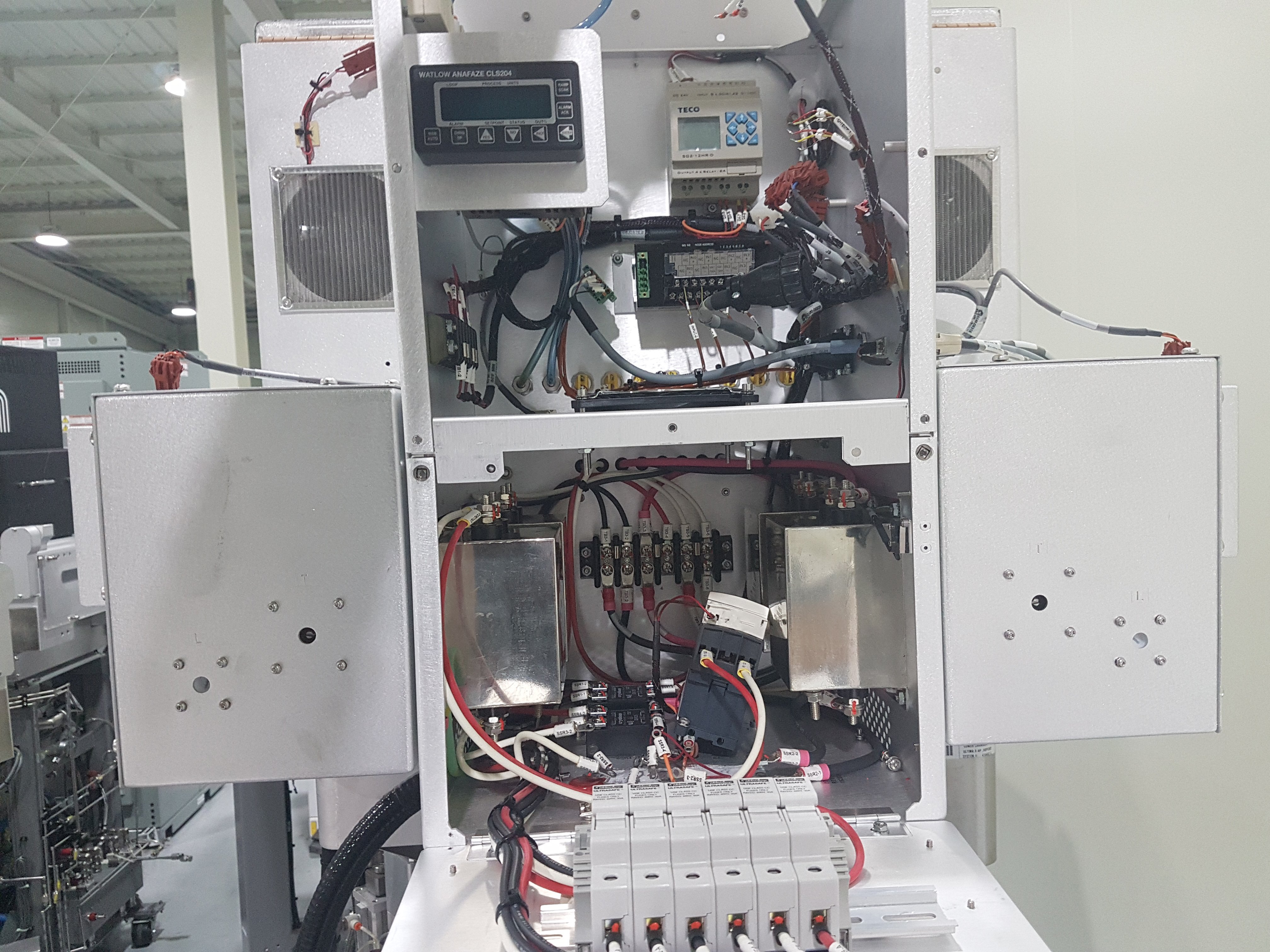

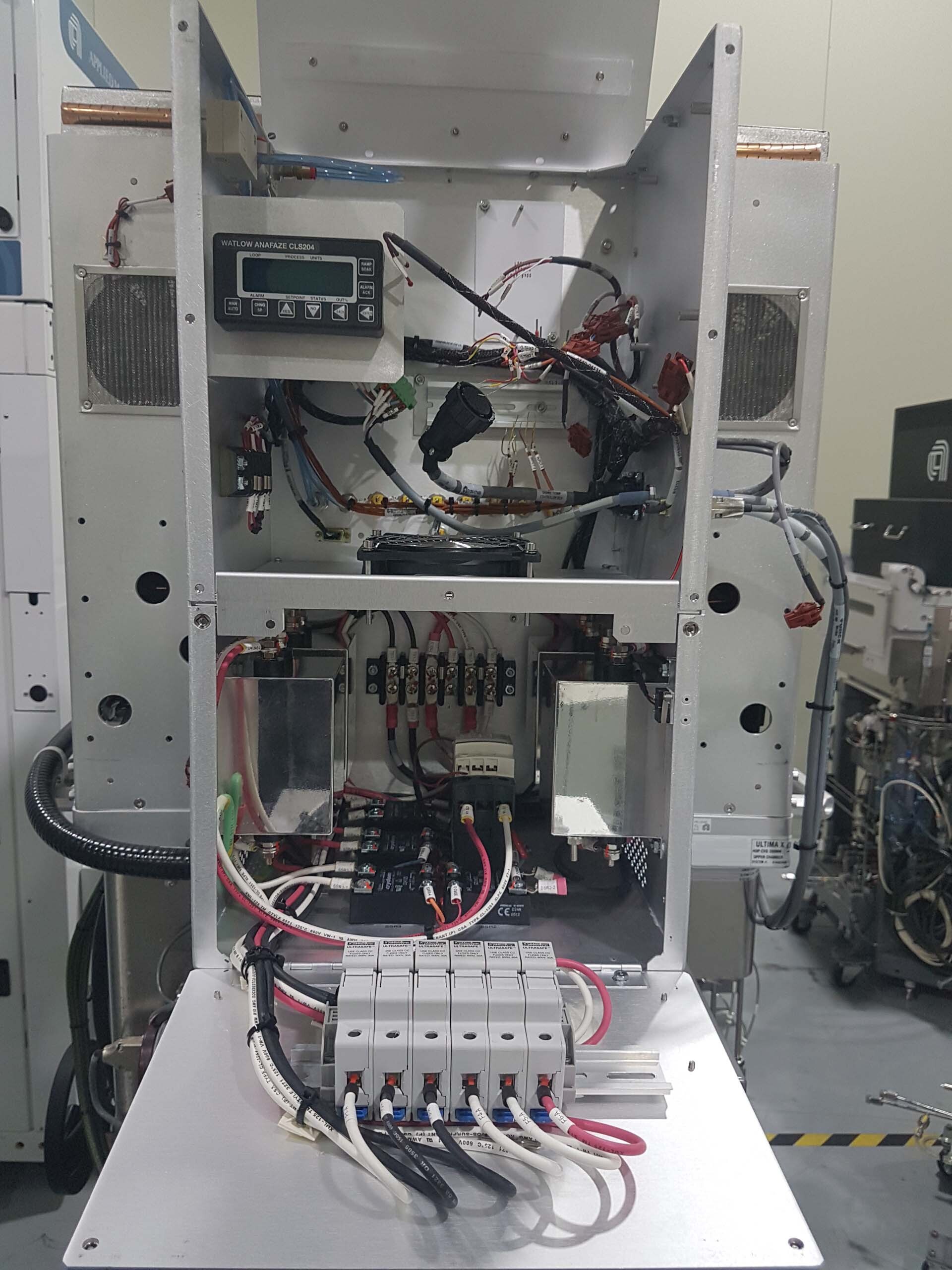

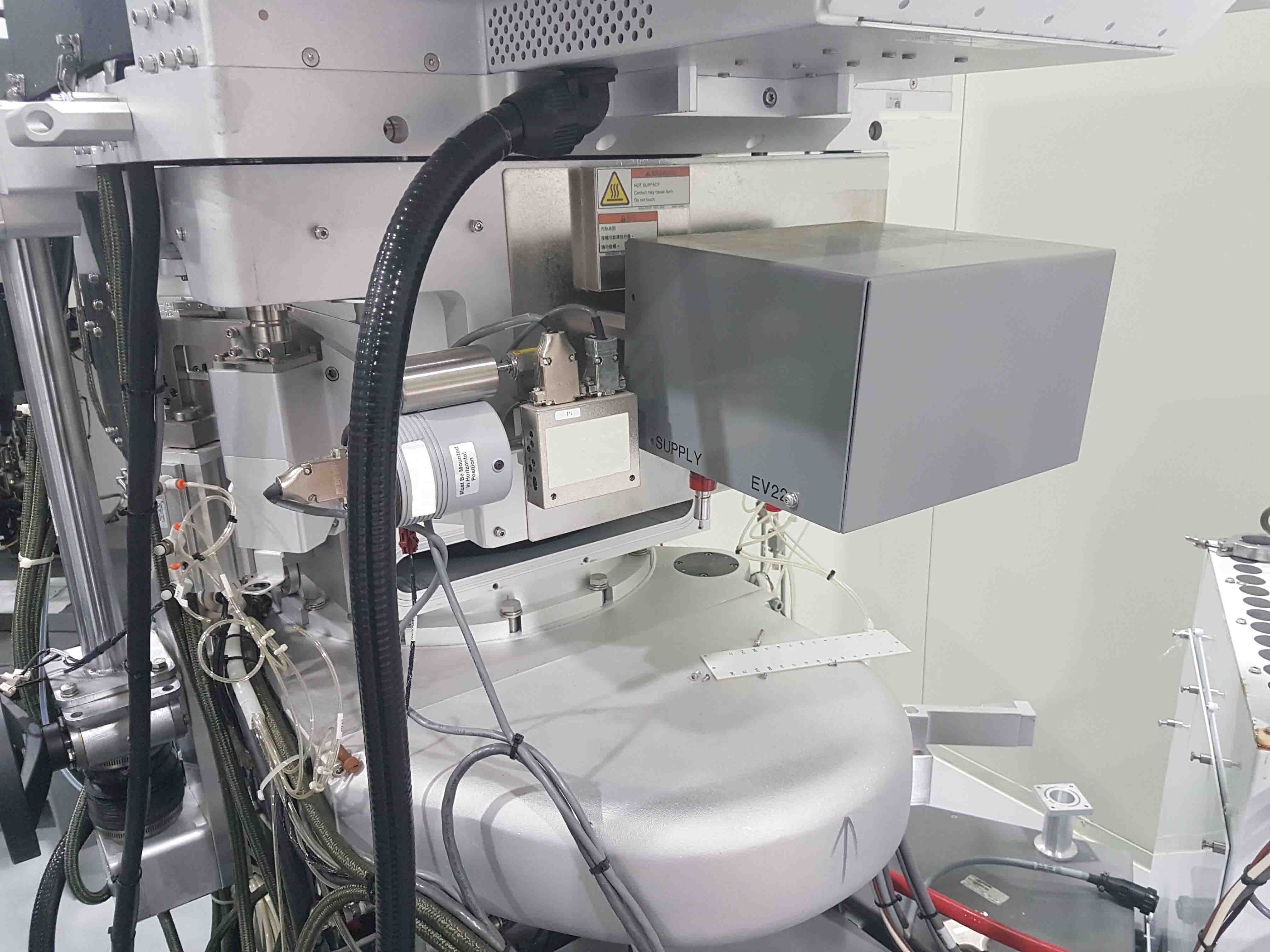

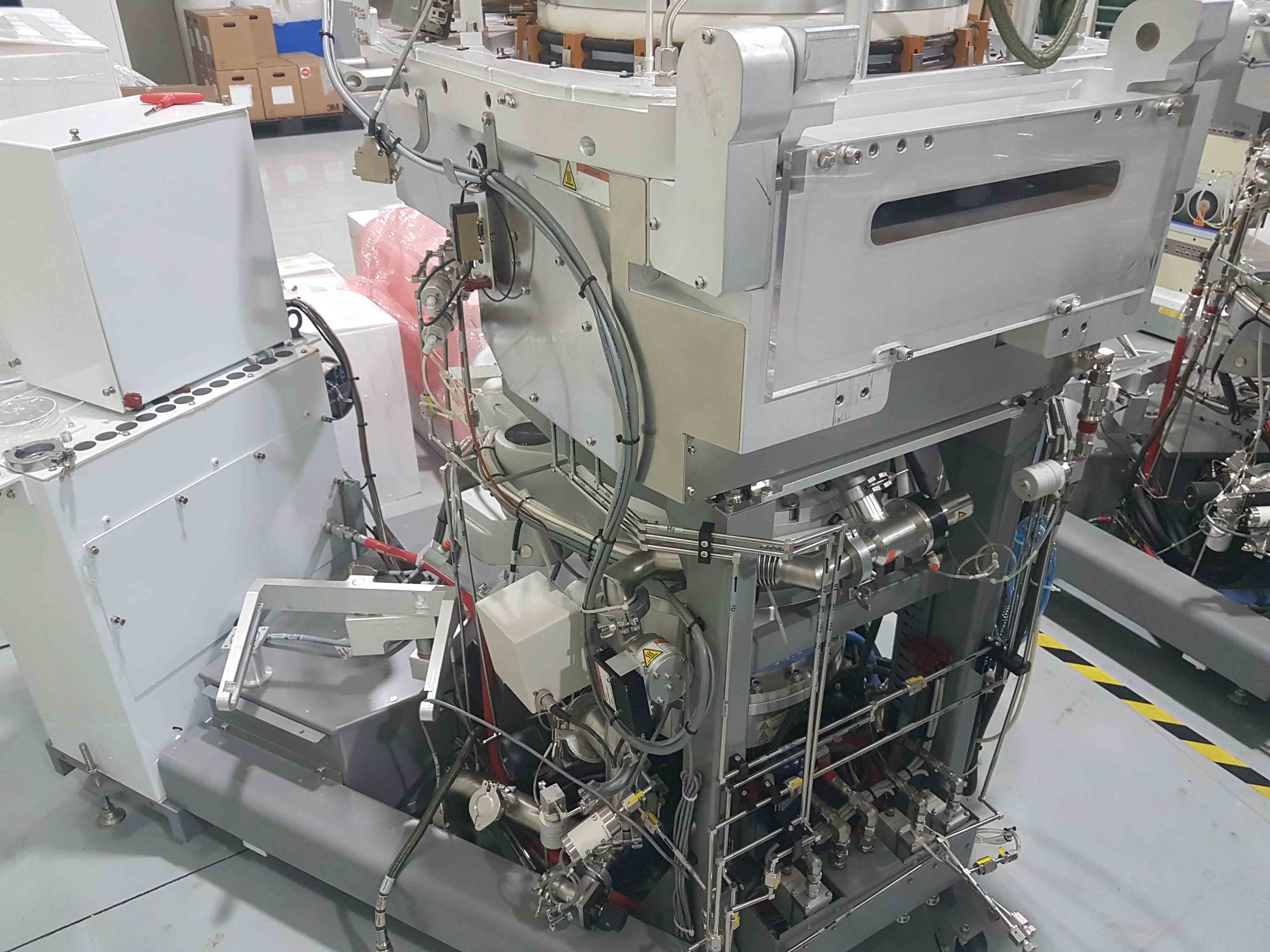

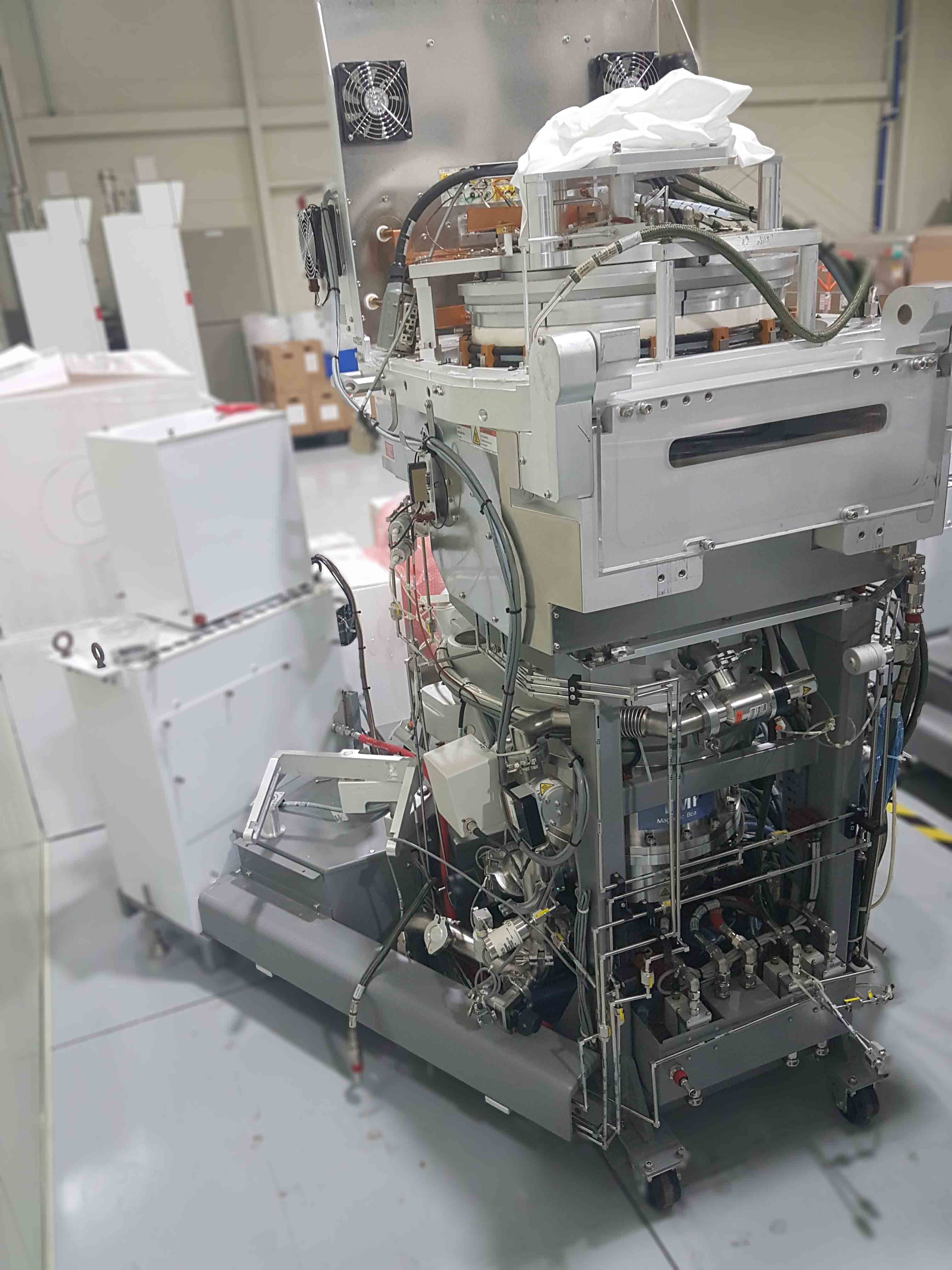

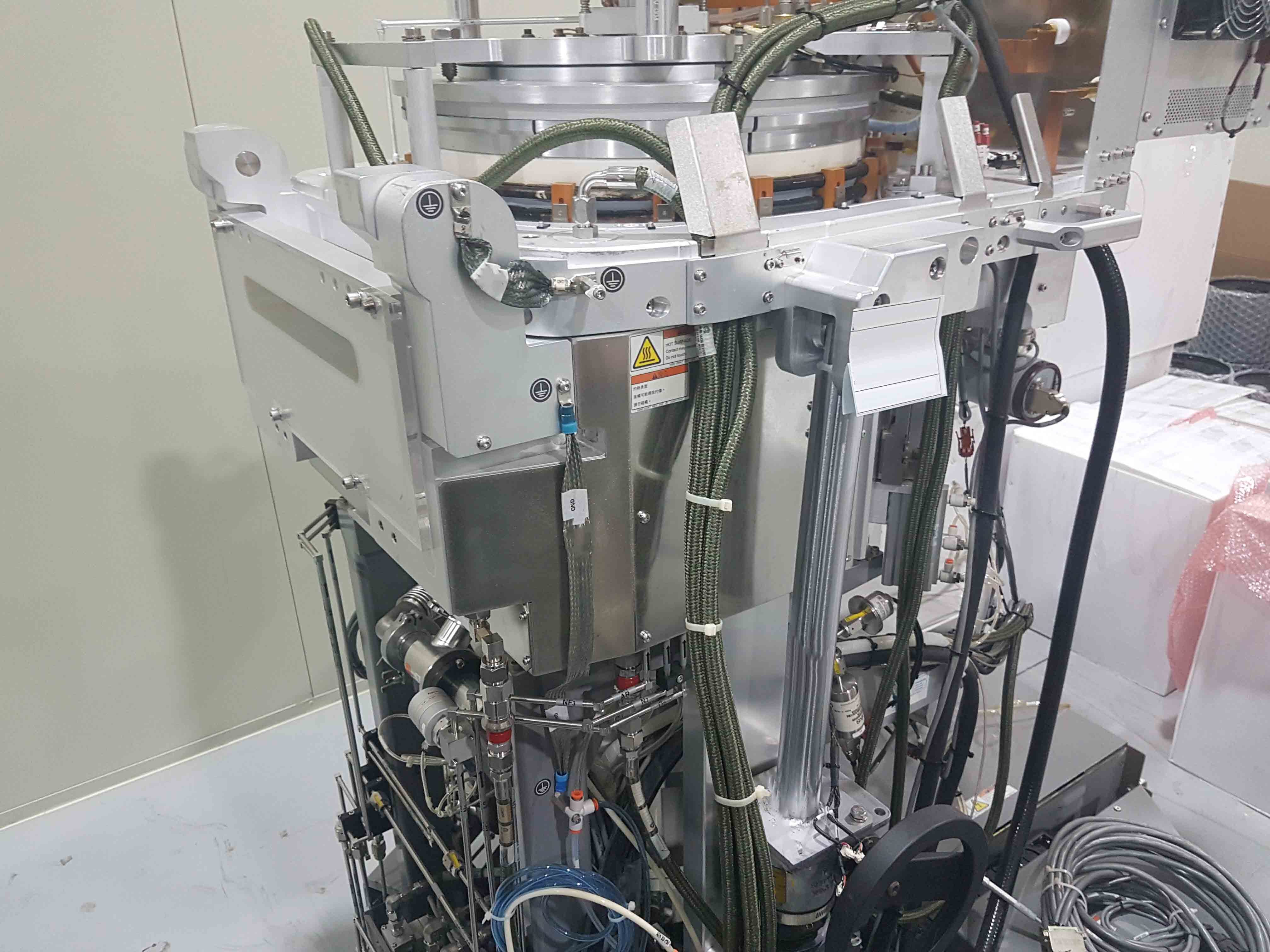

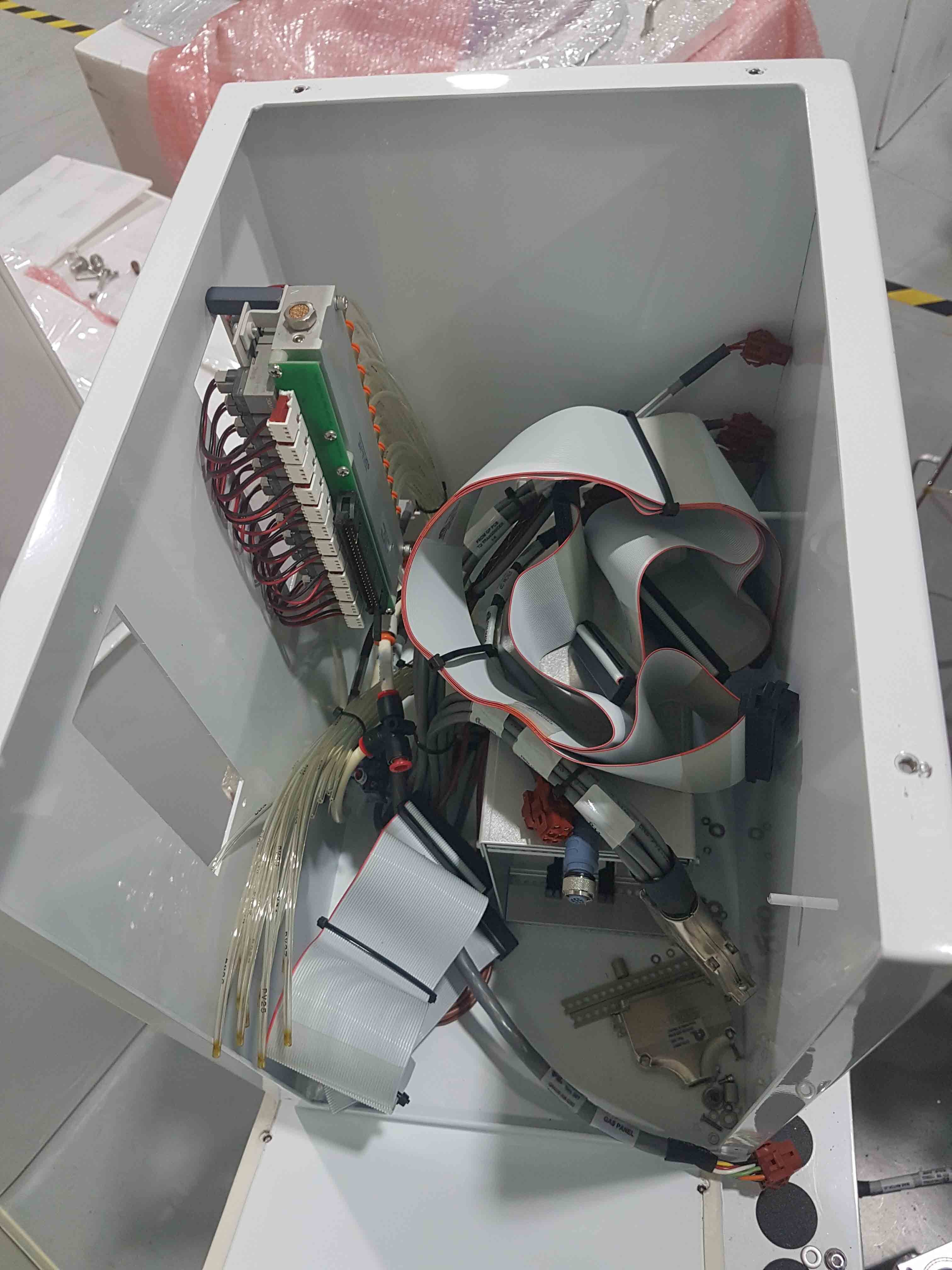

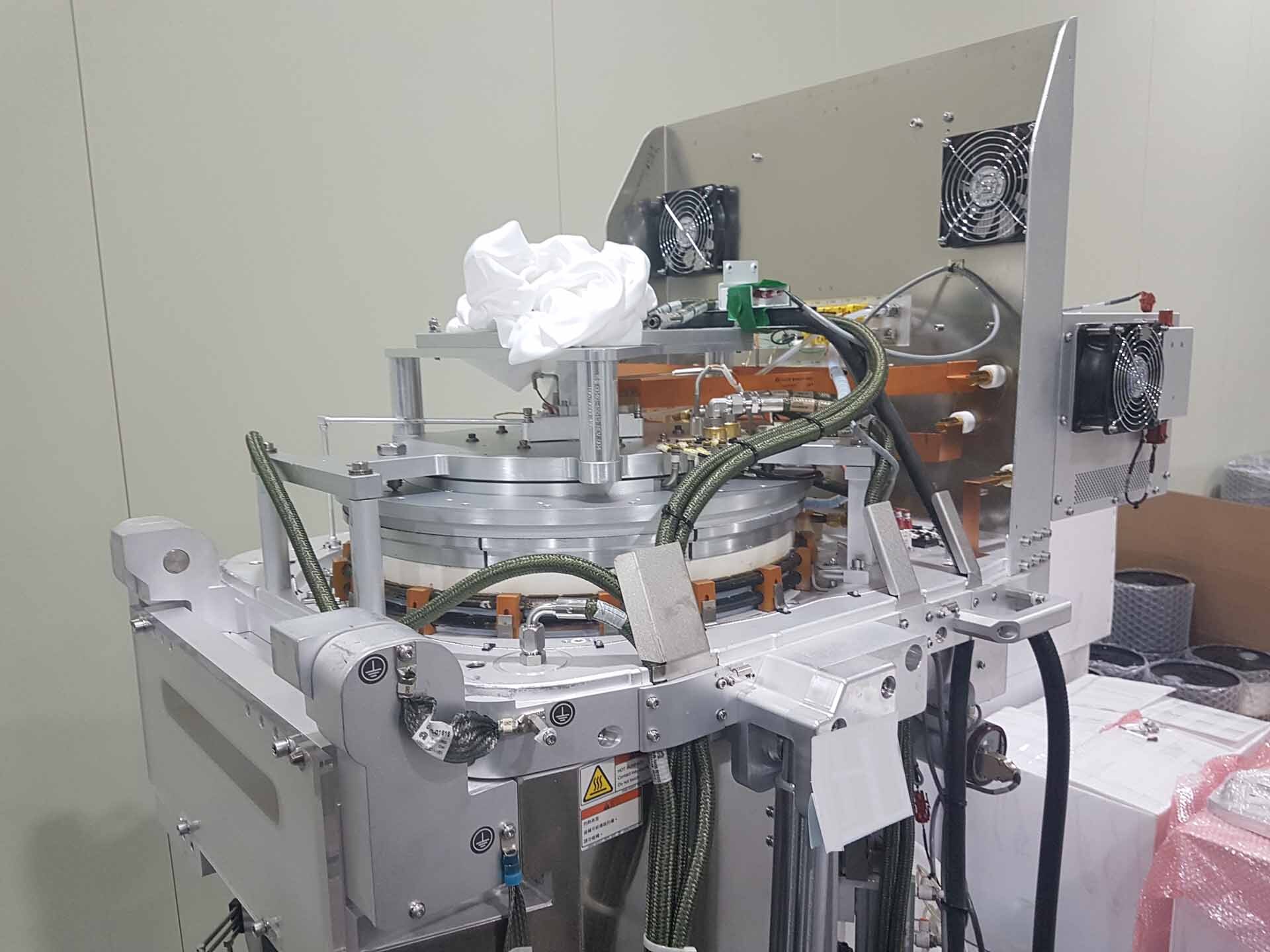

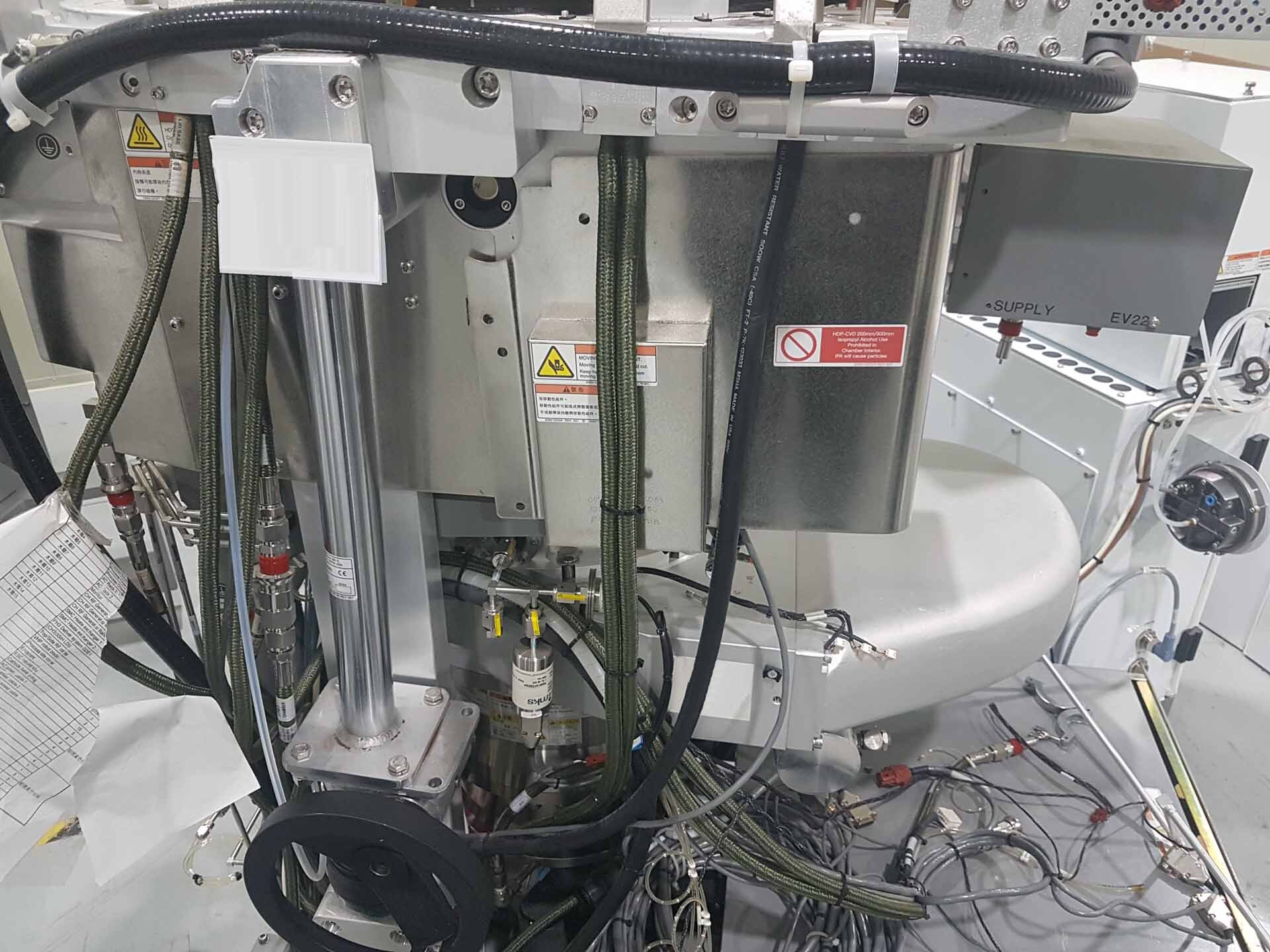

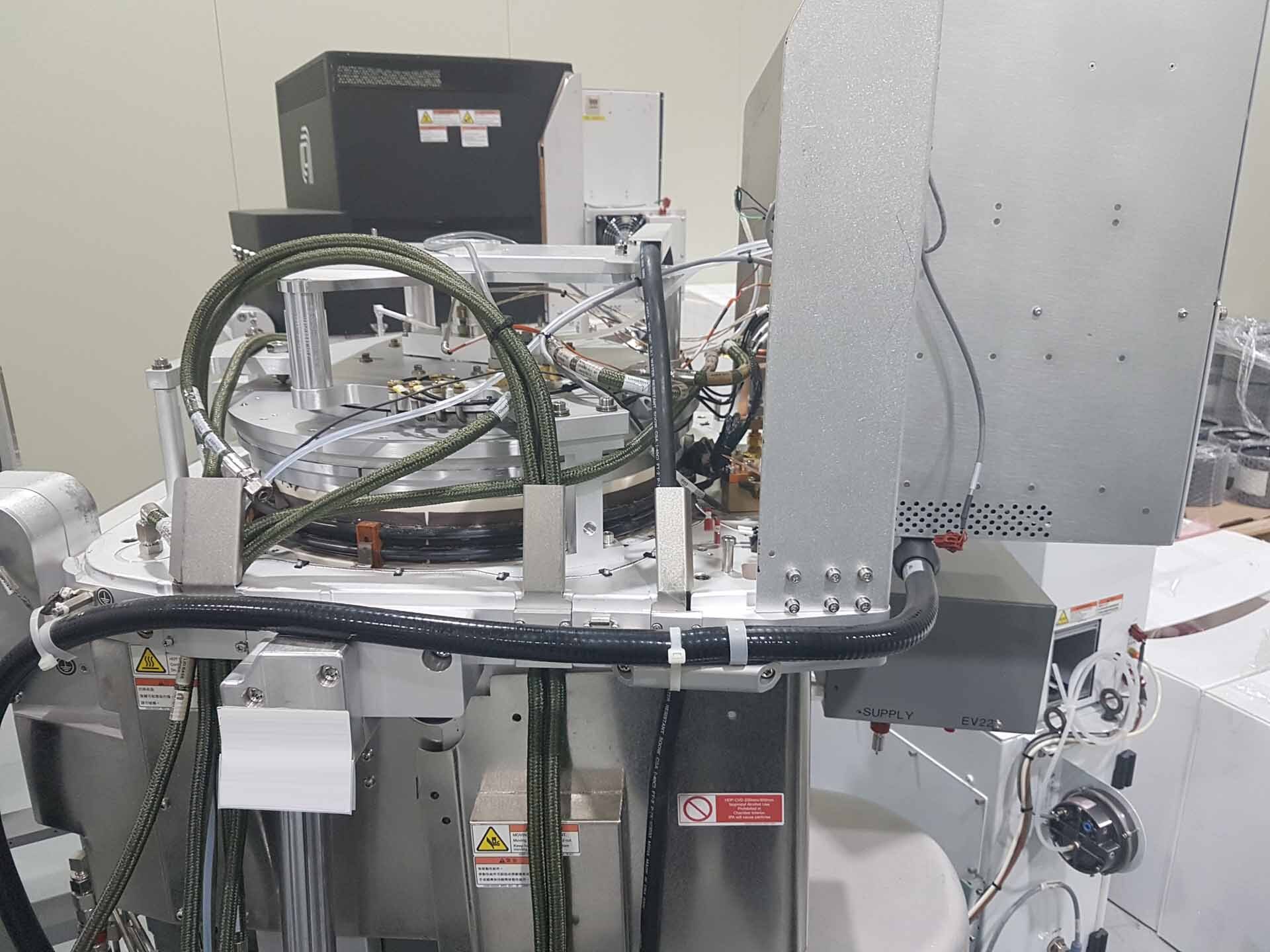

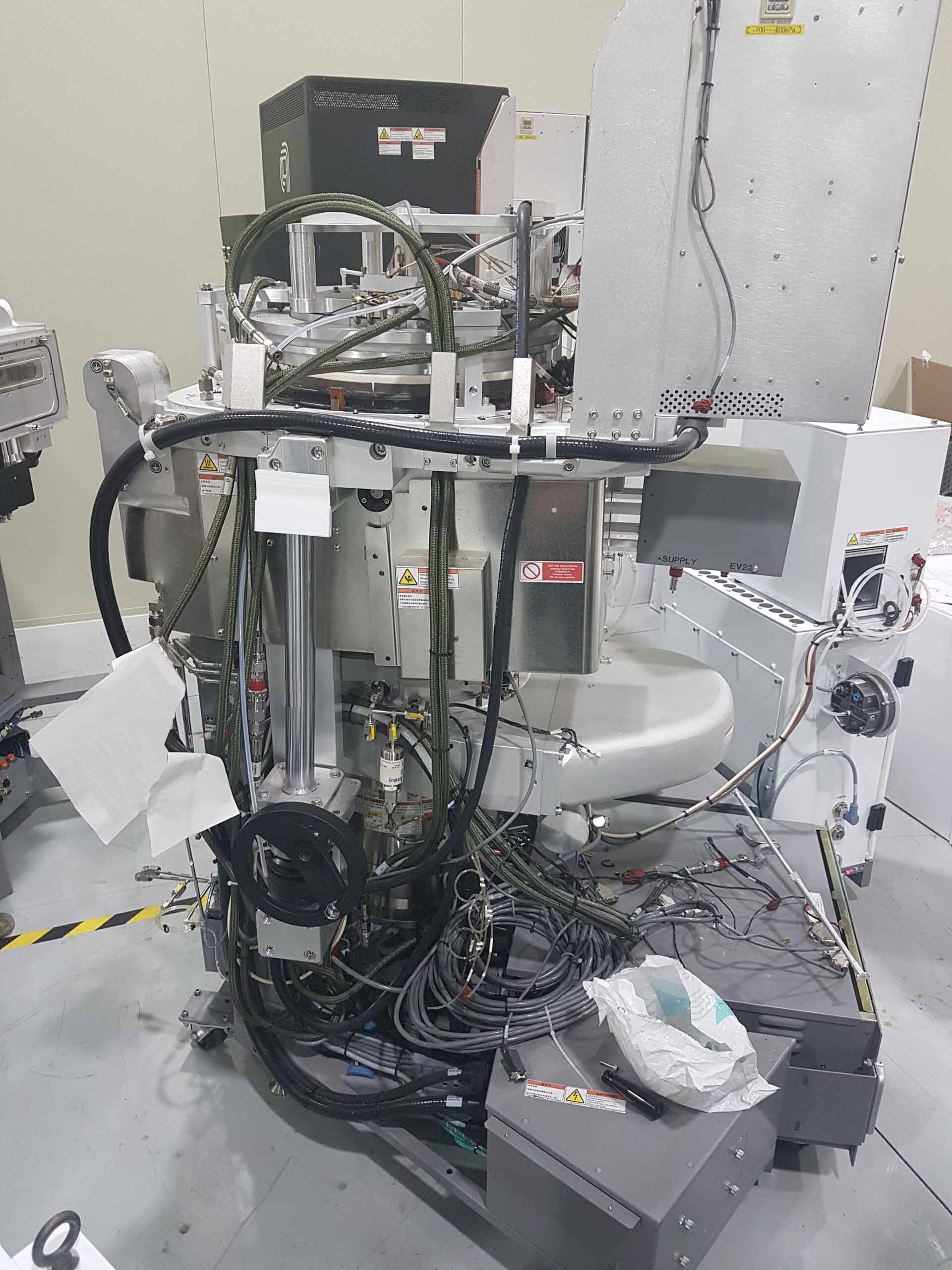

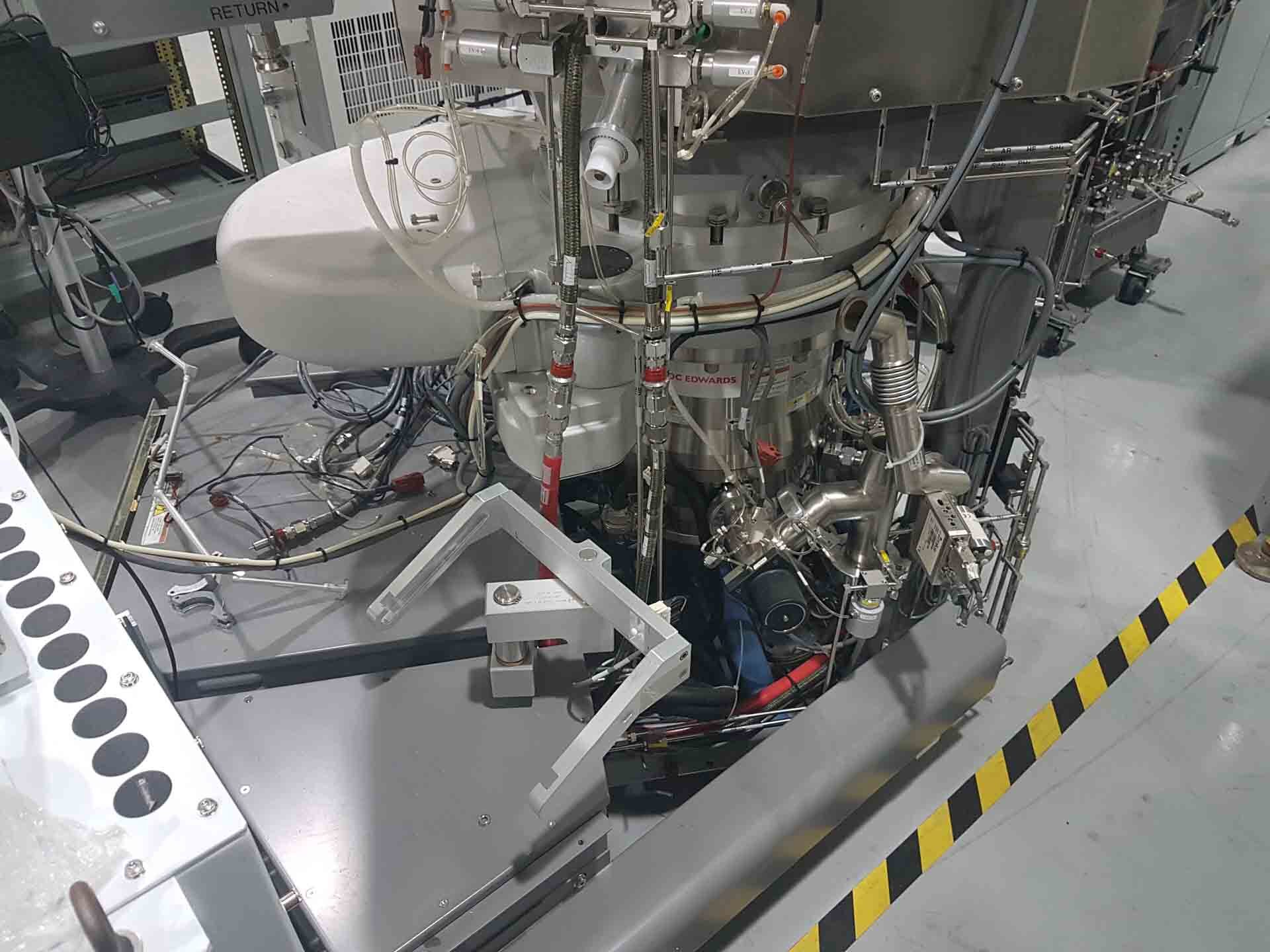

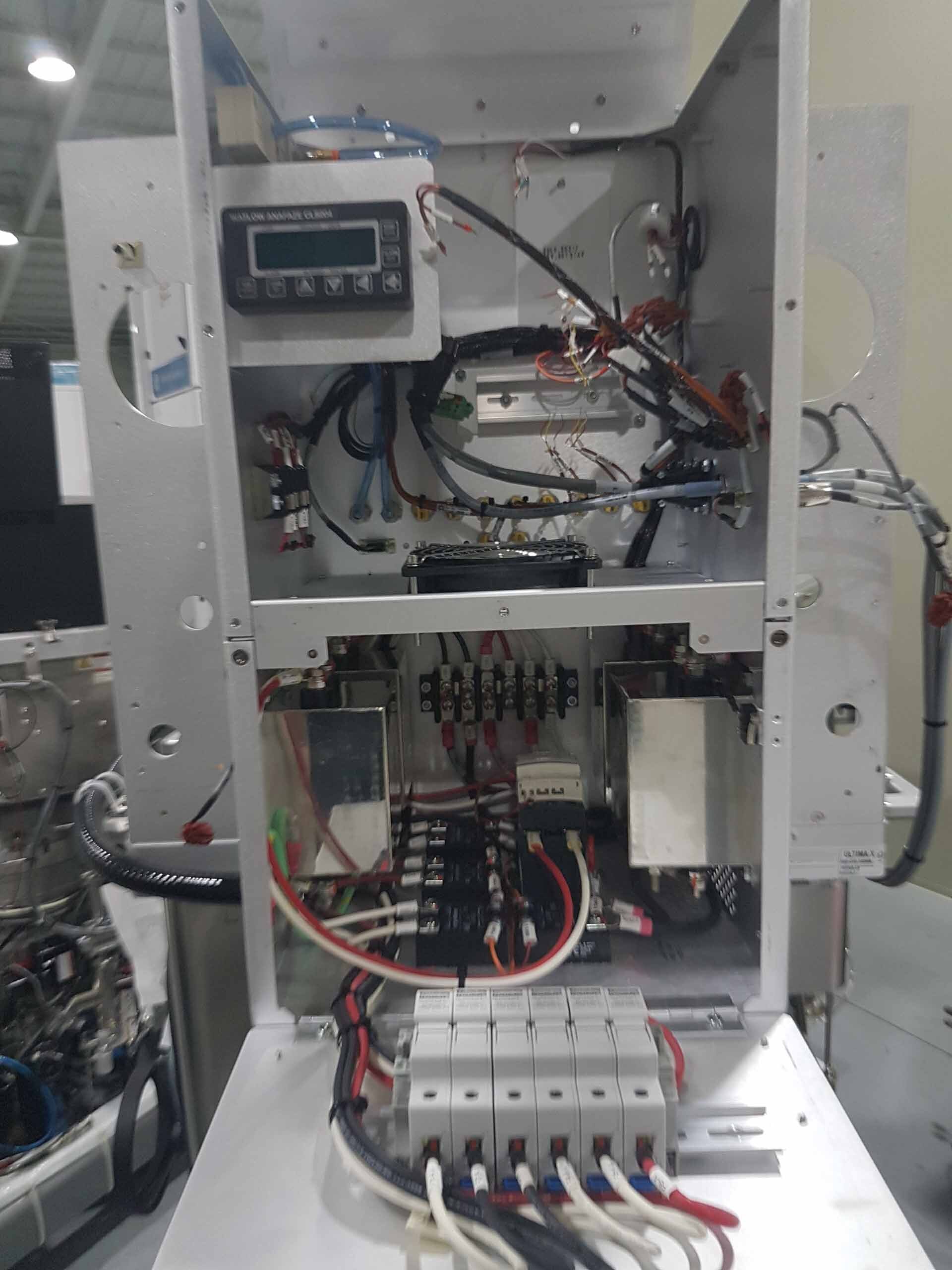

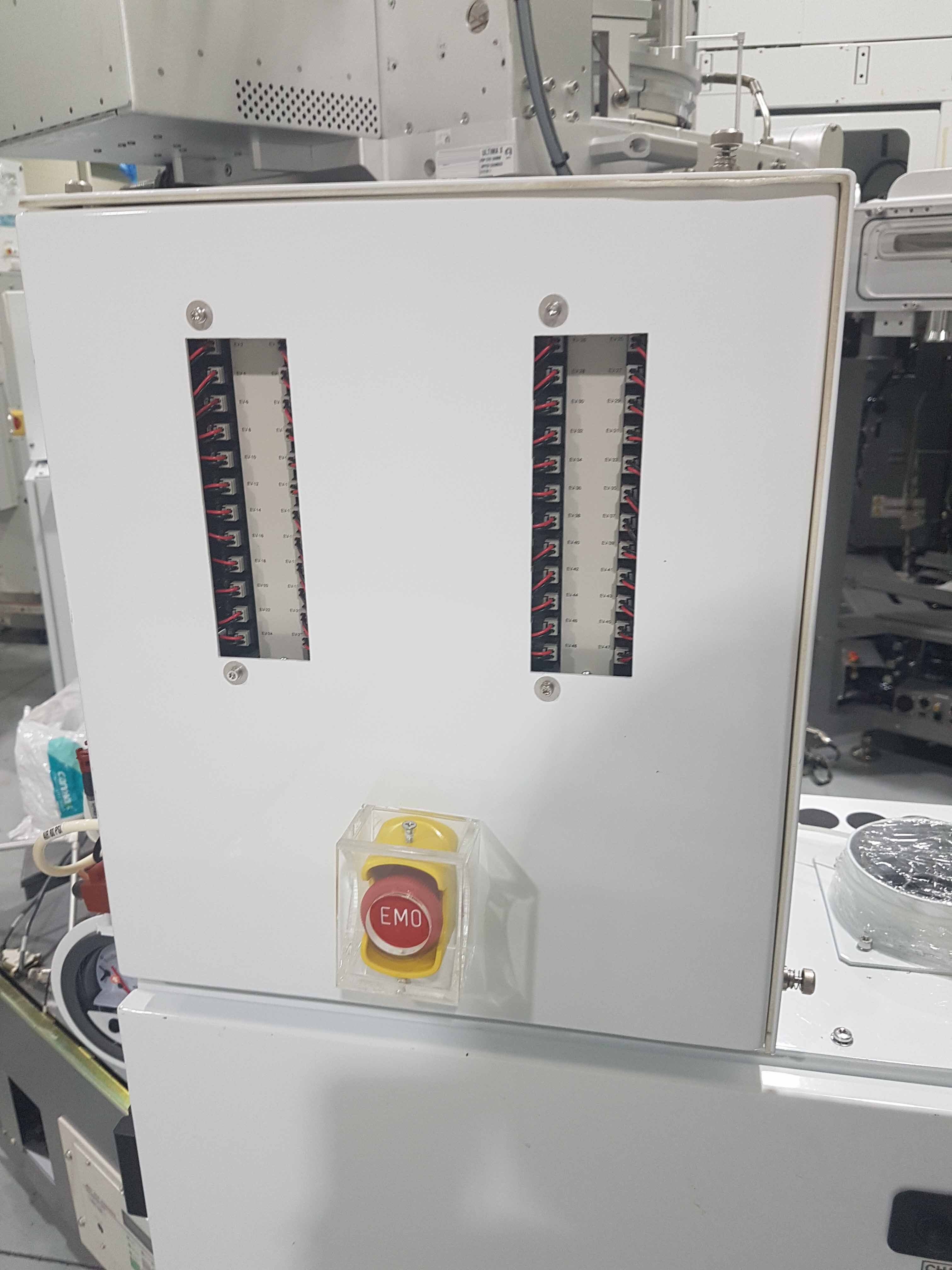

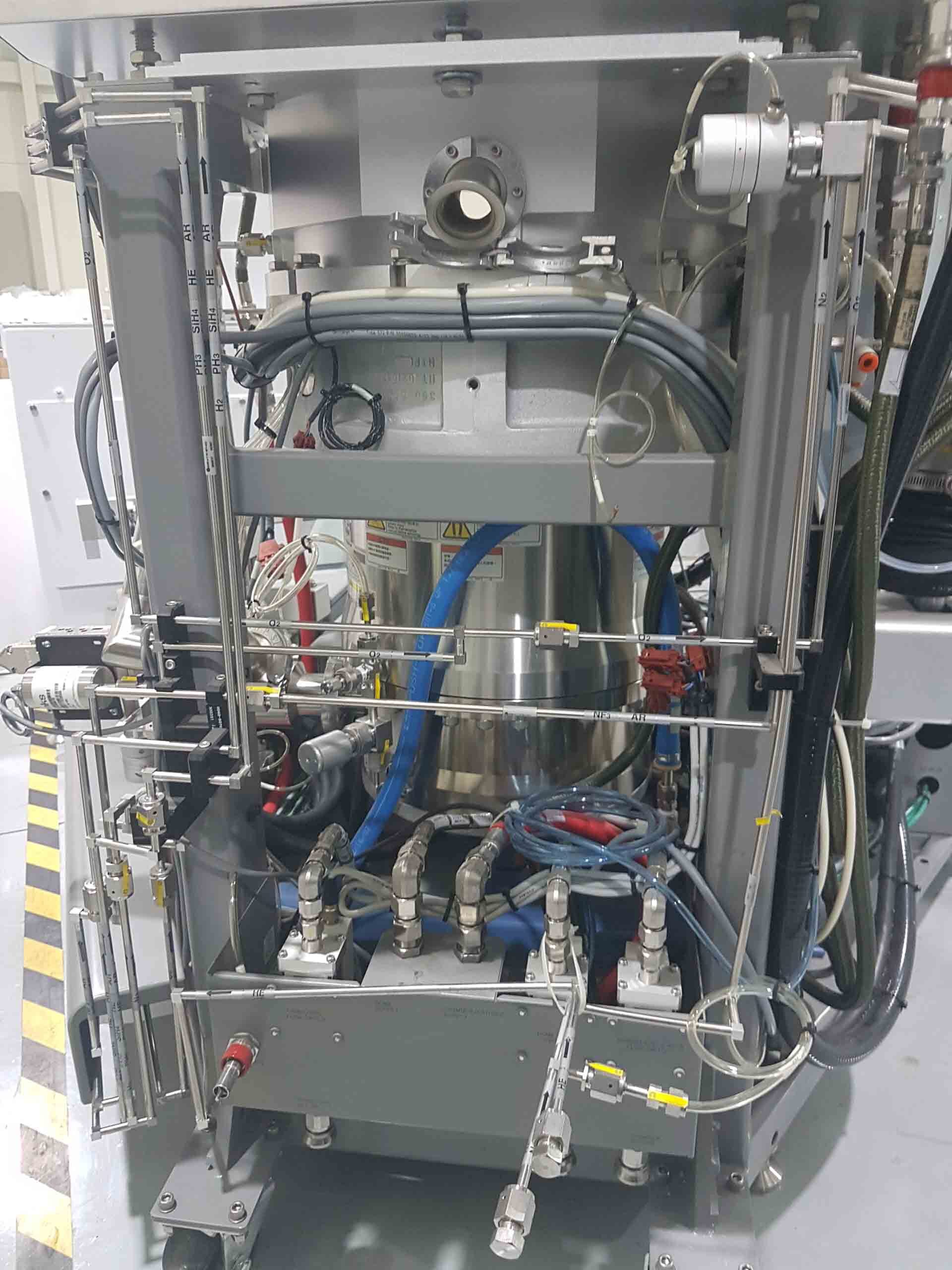

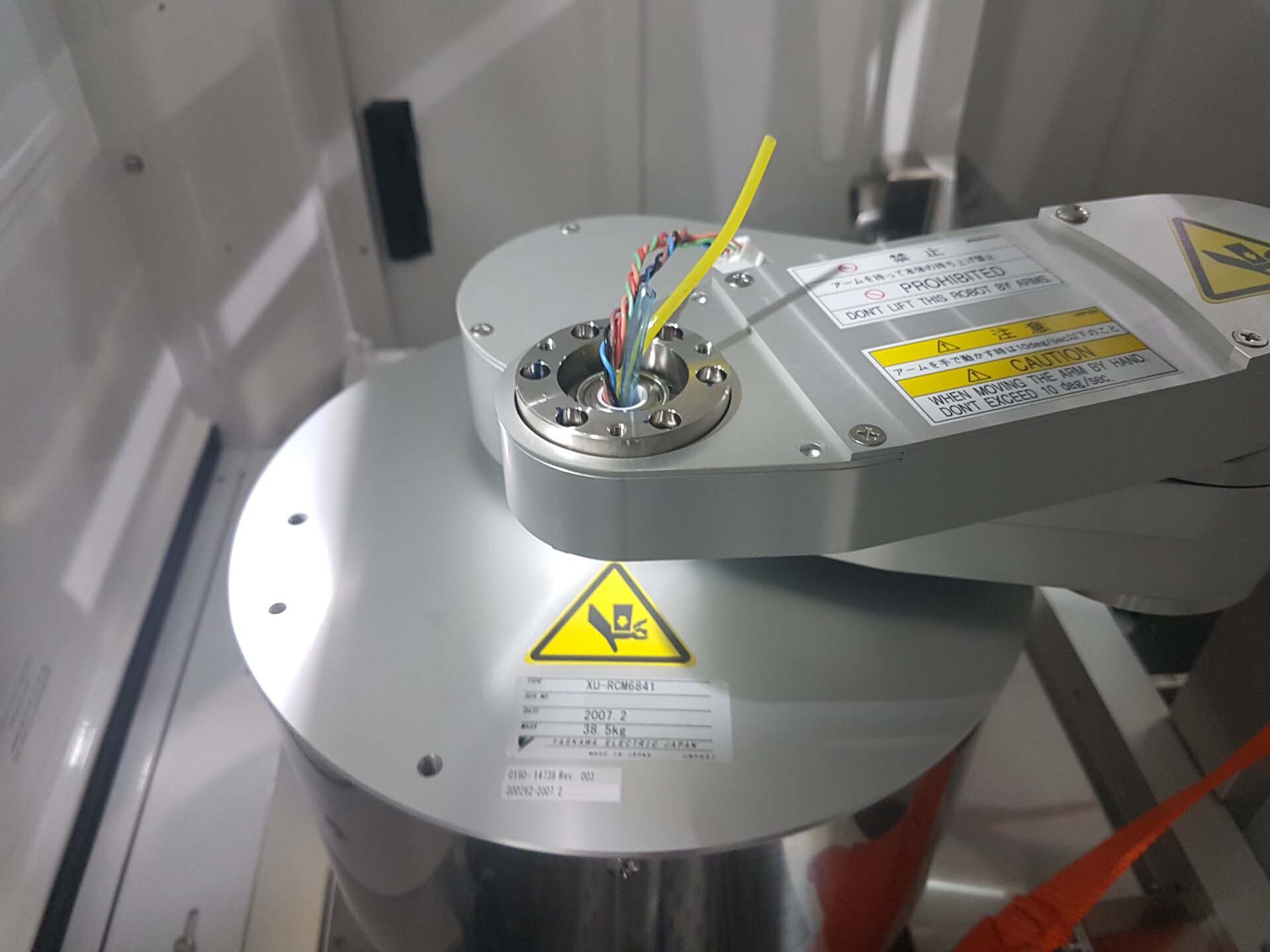

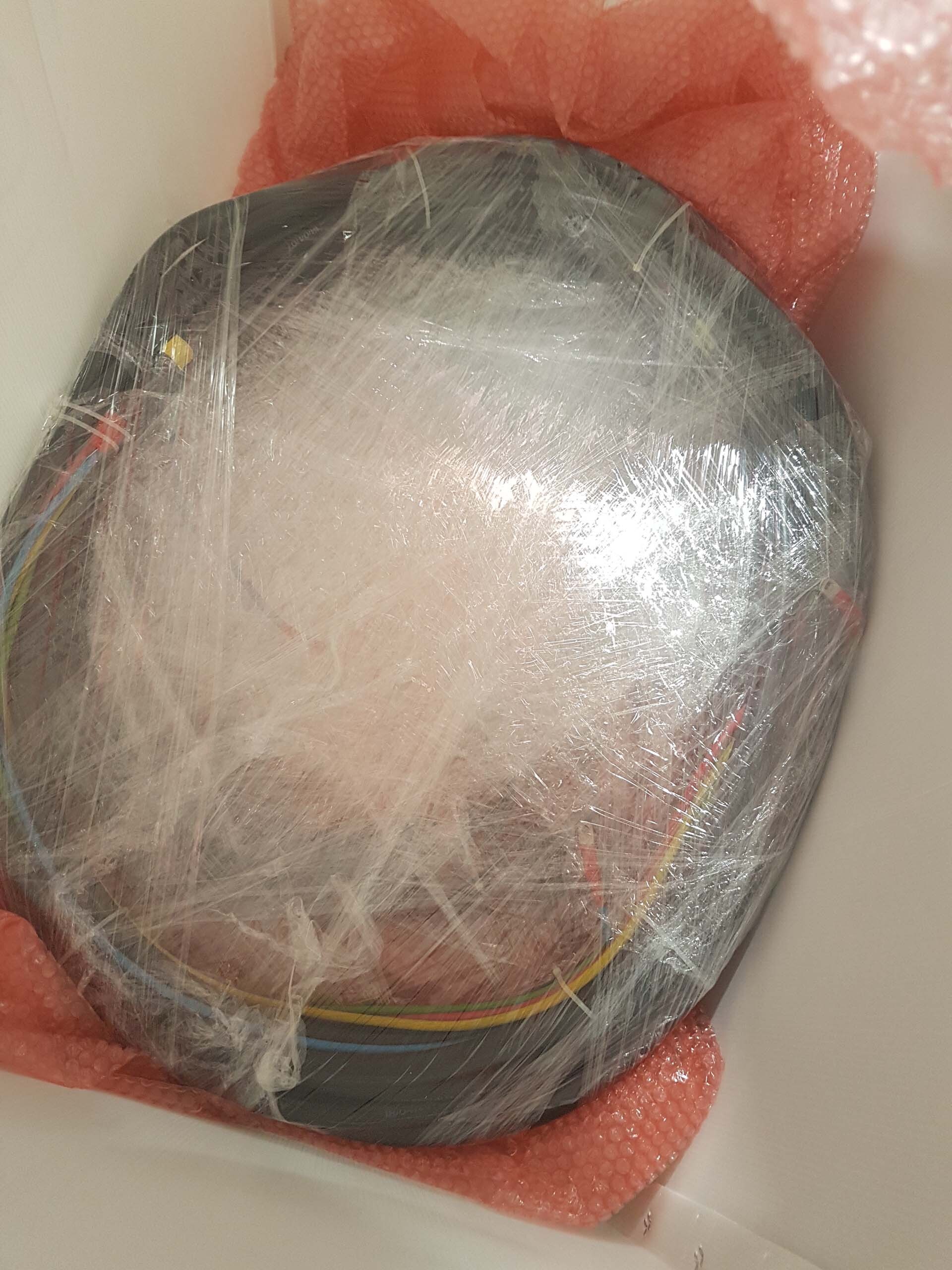

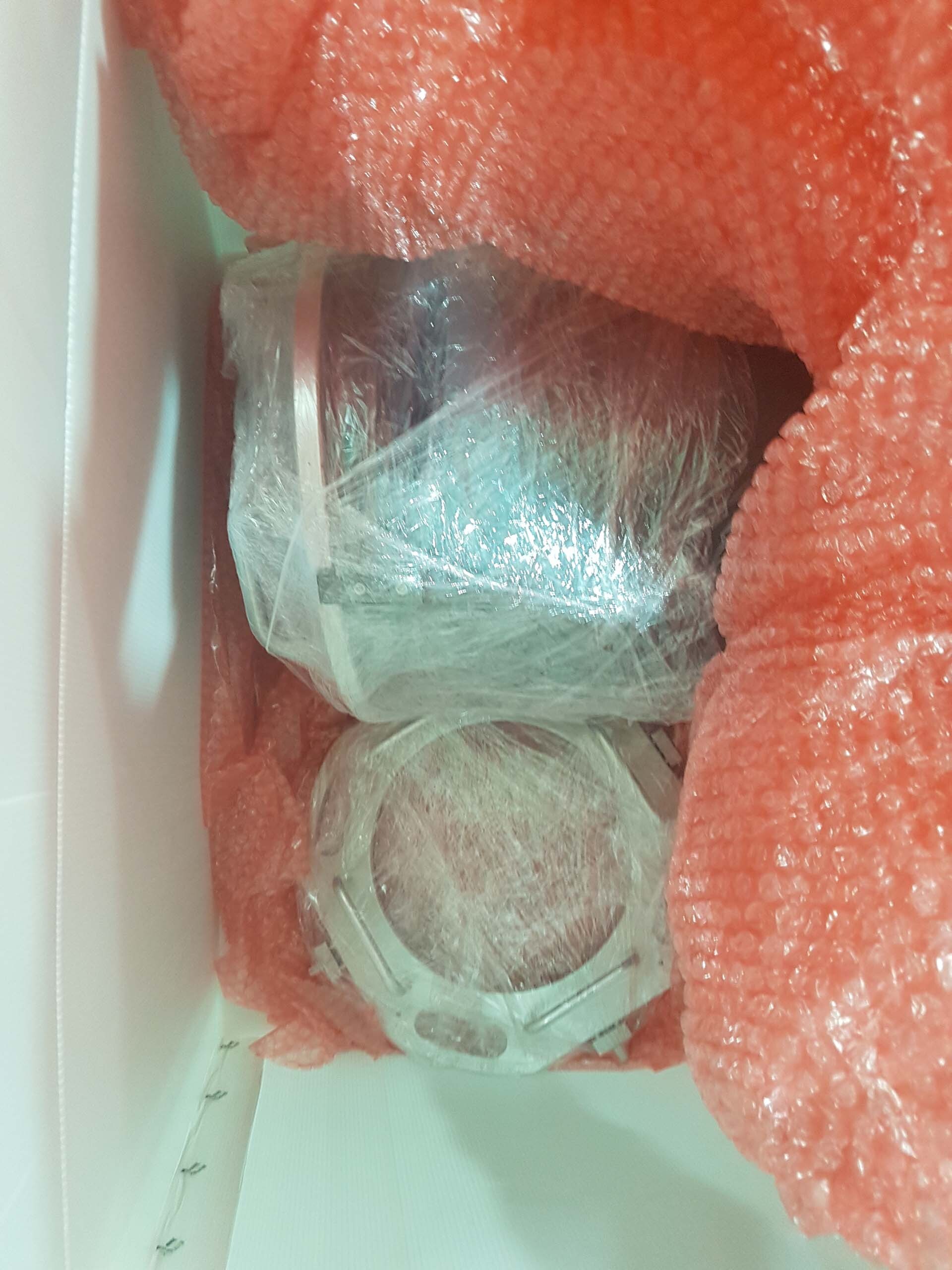

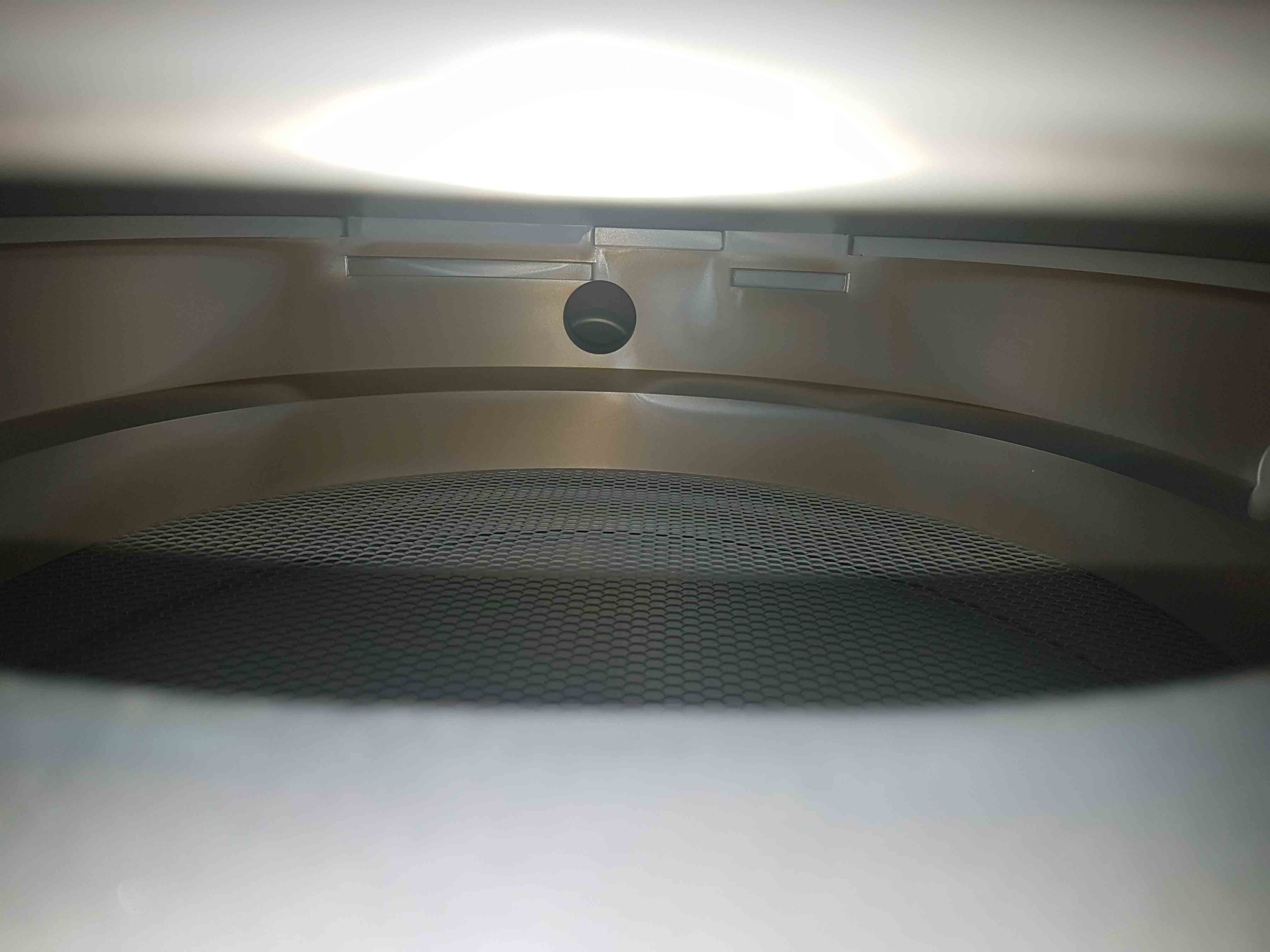

Used AMAT / APPLIED MATERIALS Ultima X #293600876 for sale

URL successfully copied!

Tap to zoom

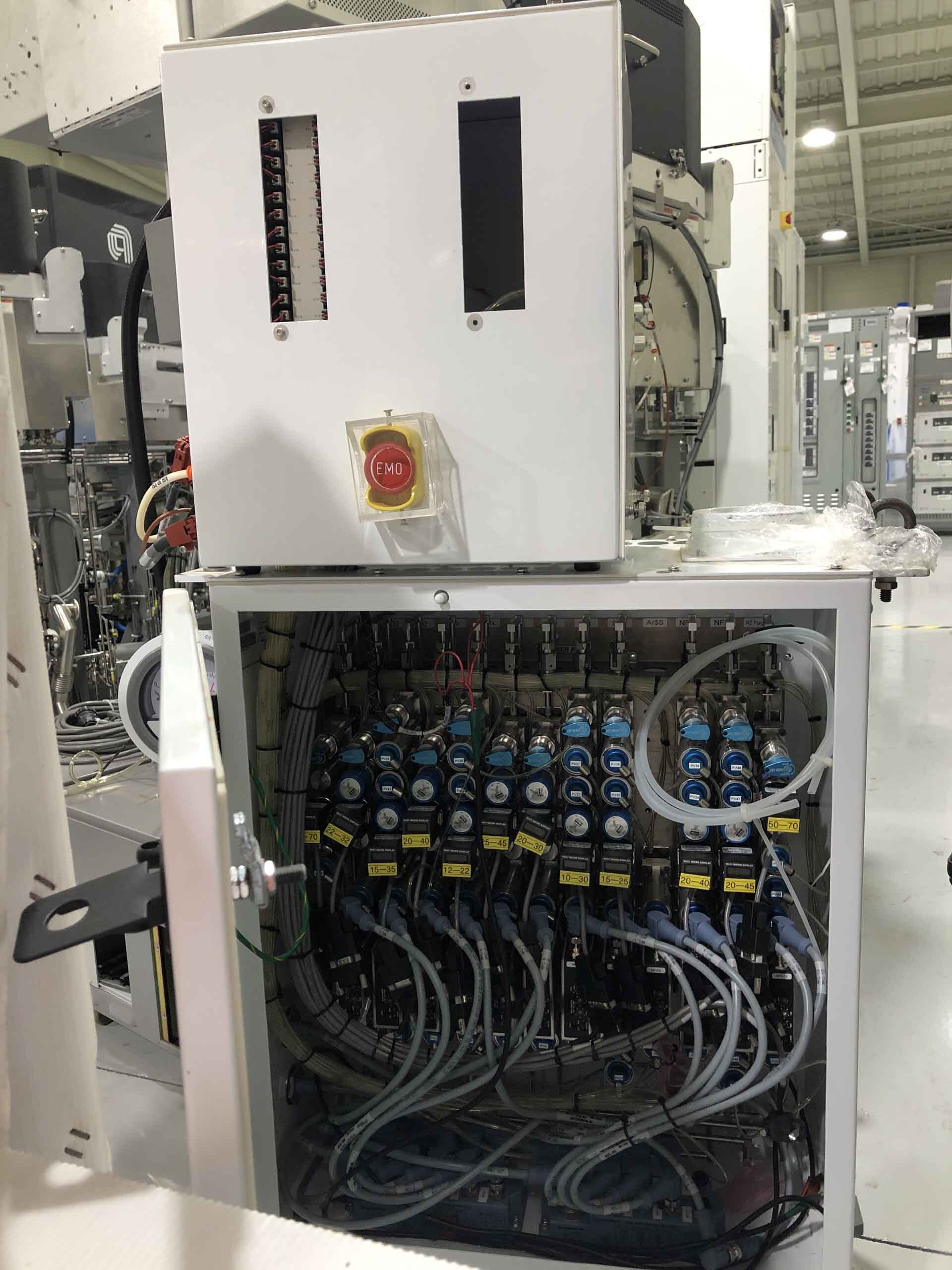

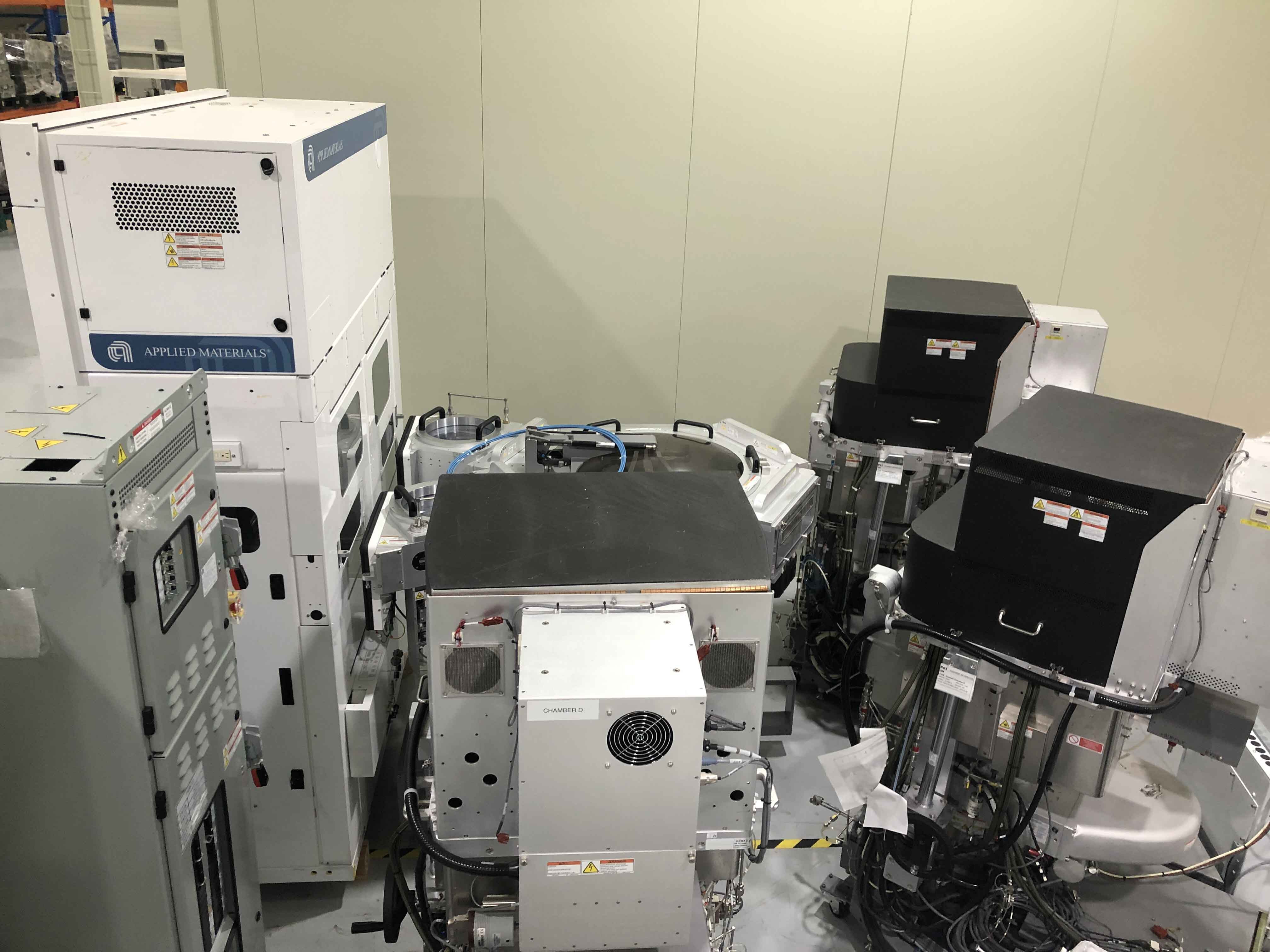

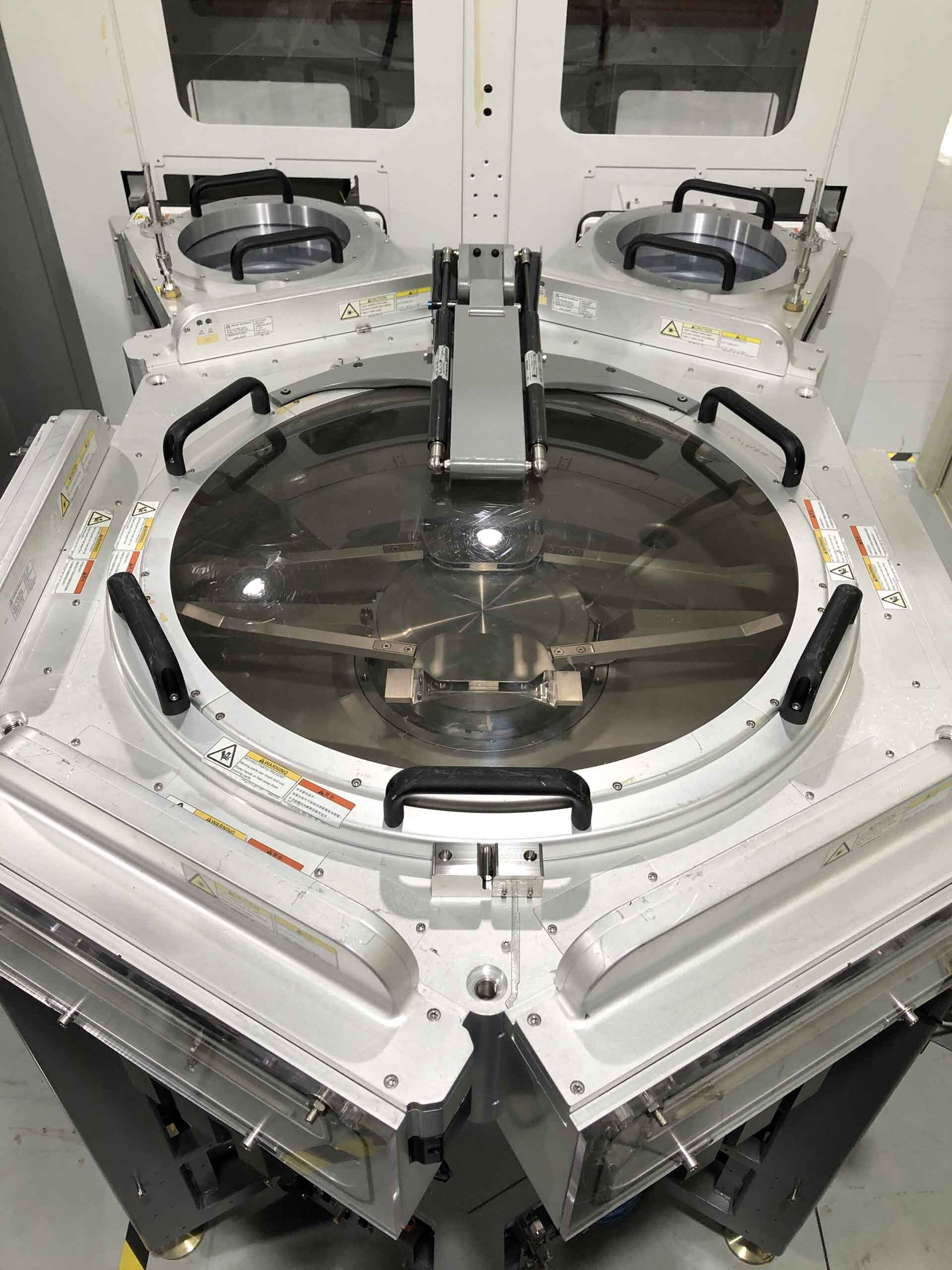

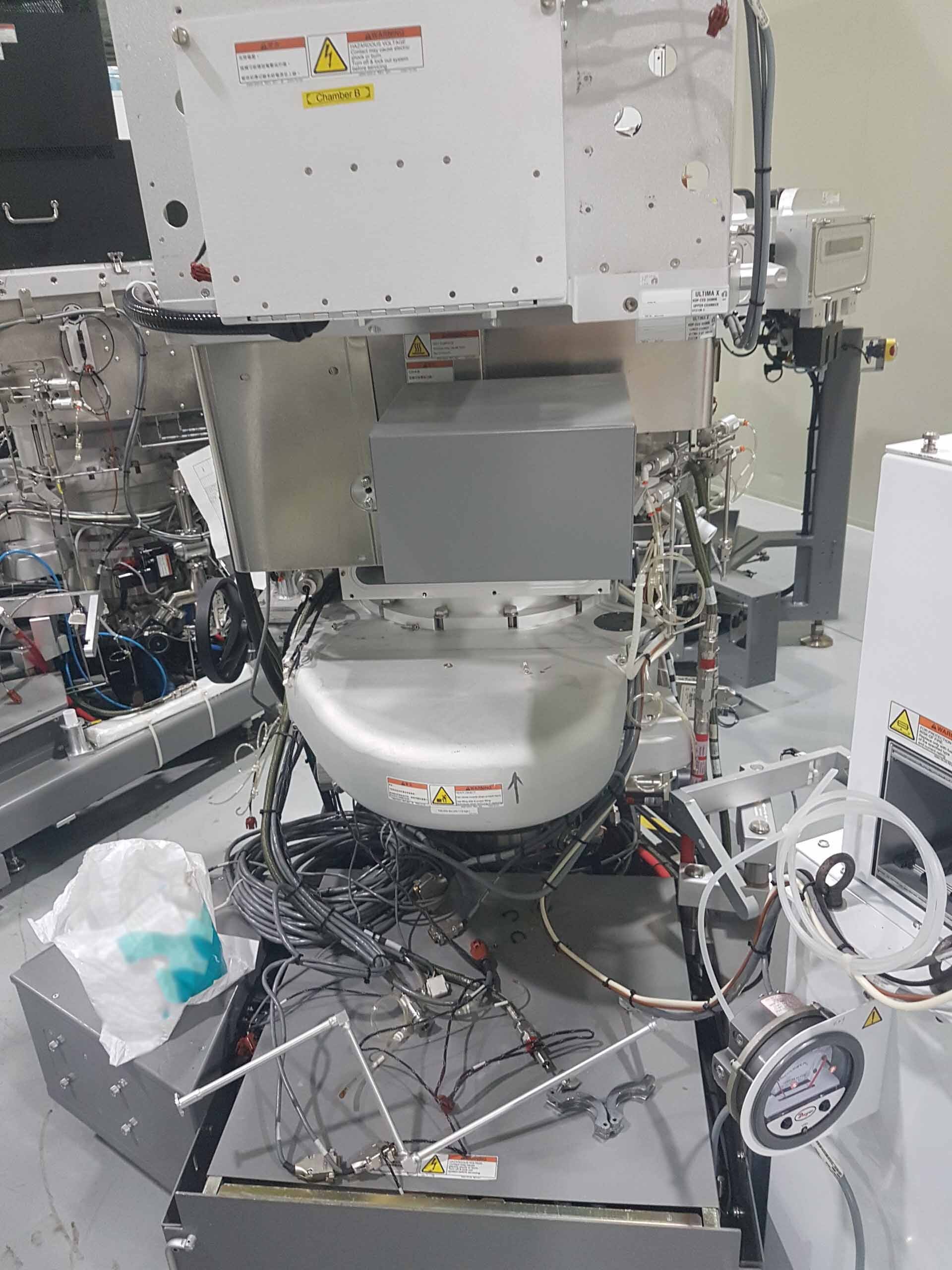

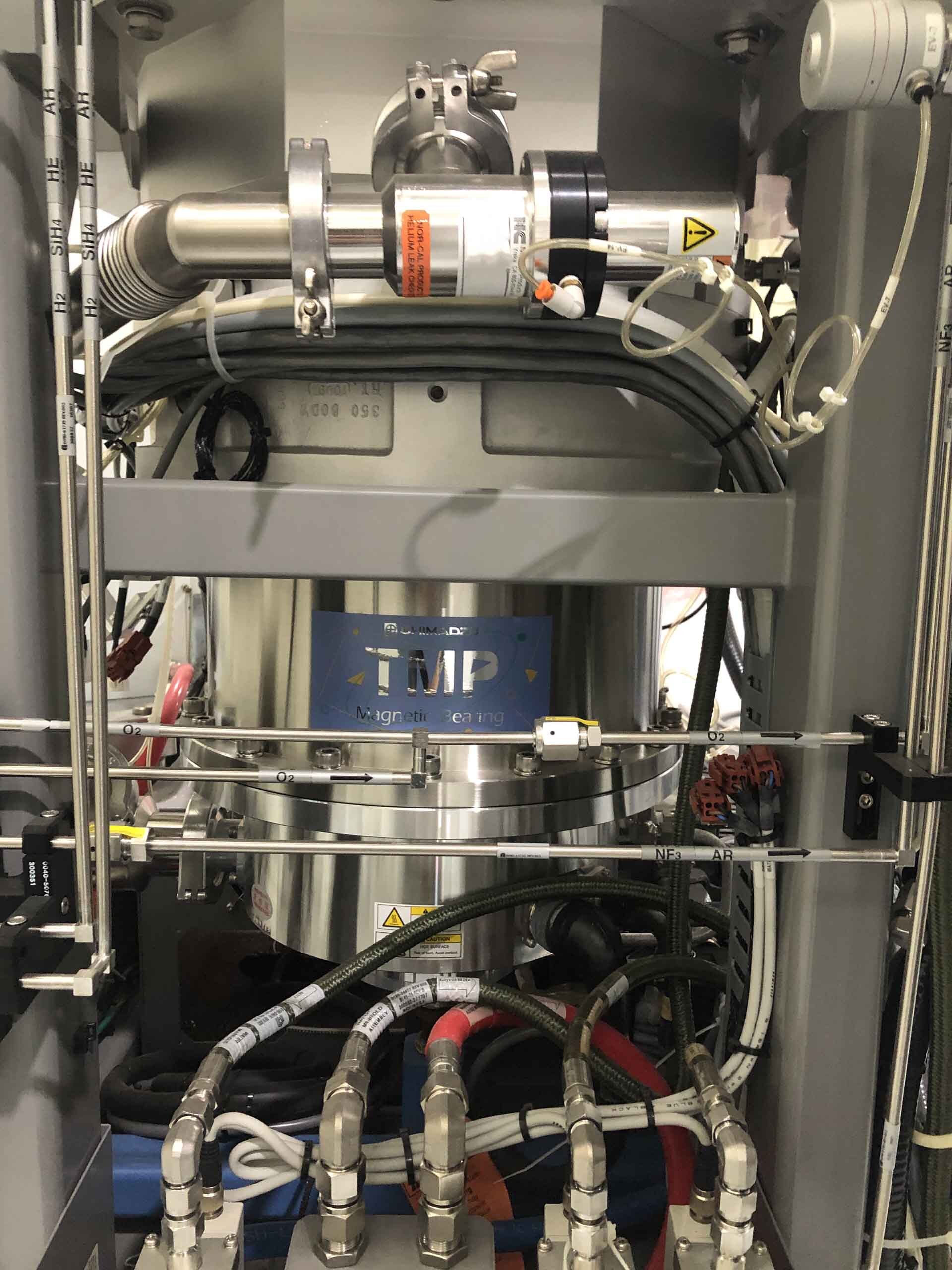

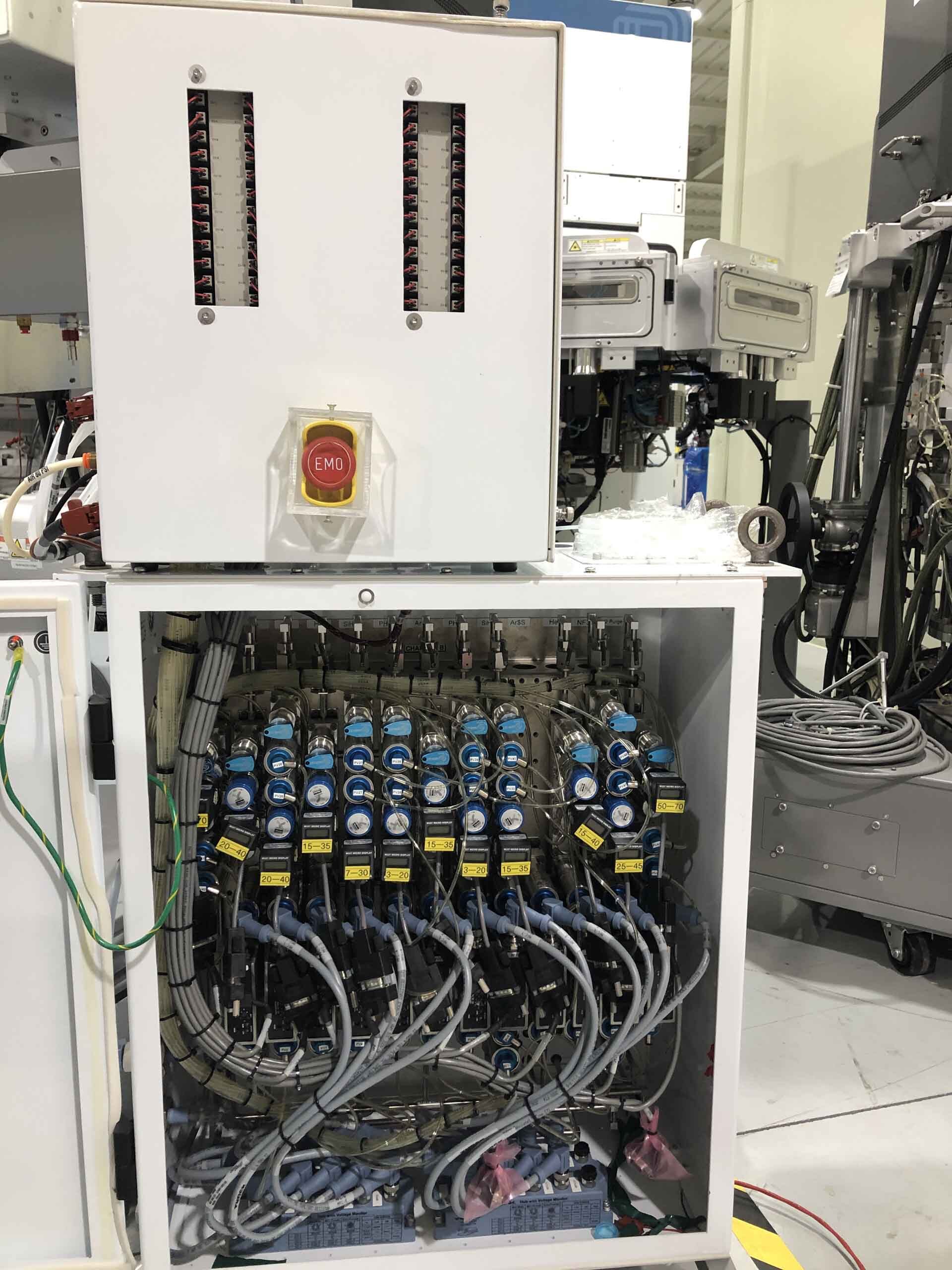

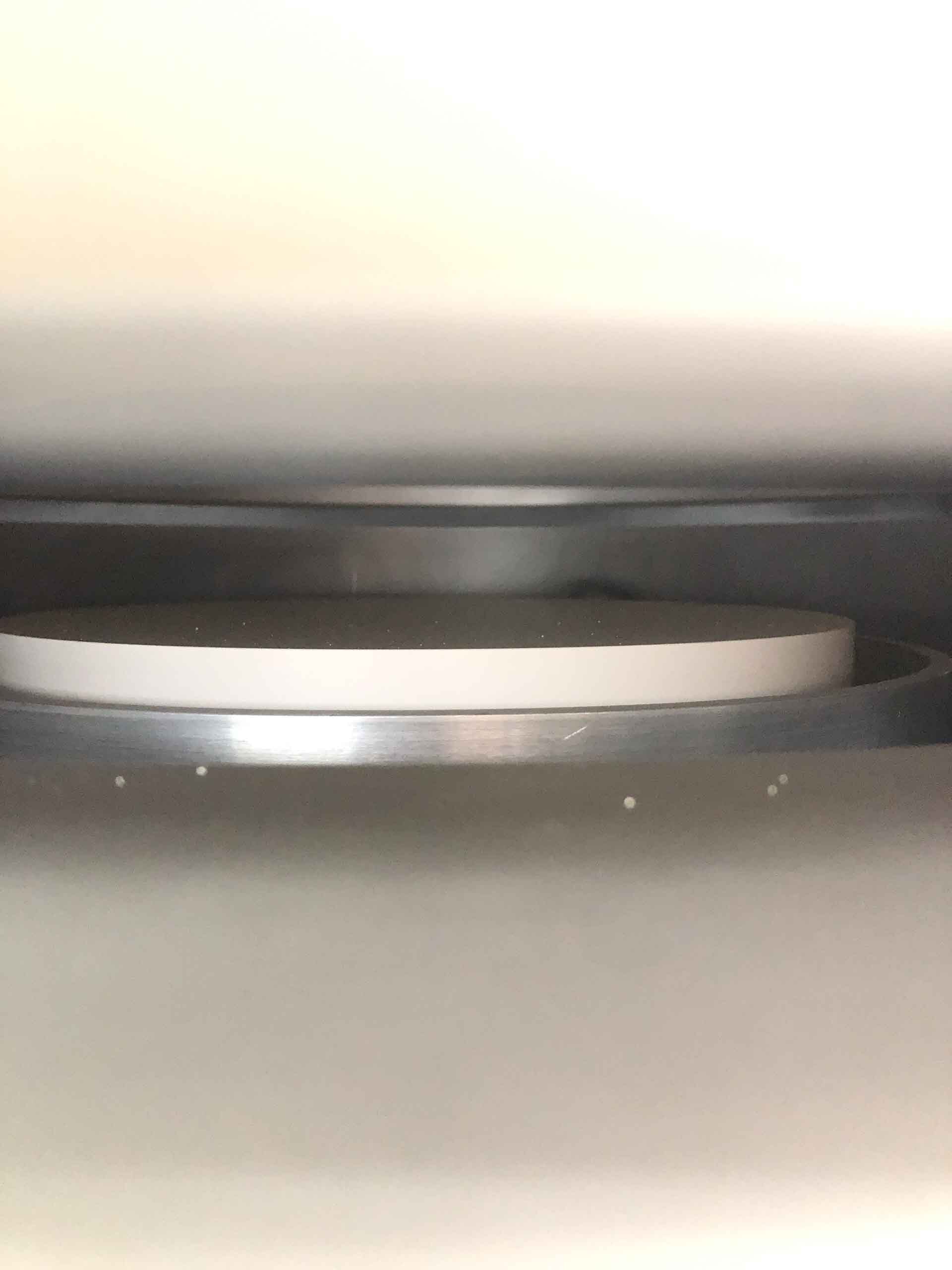

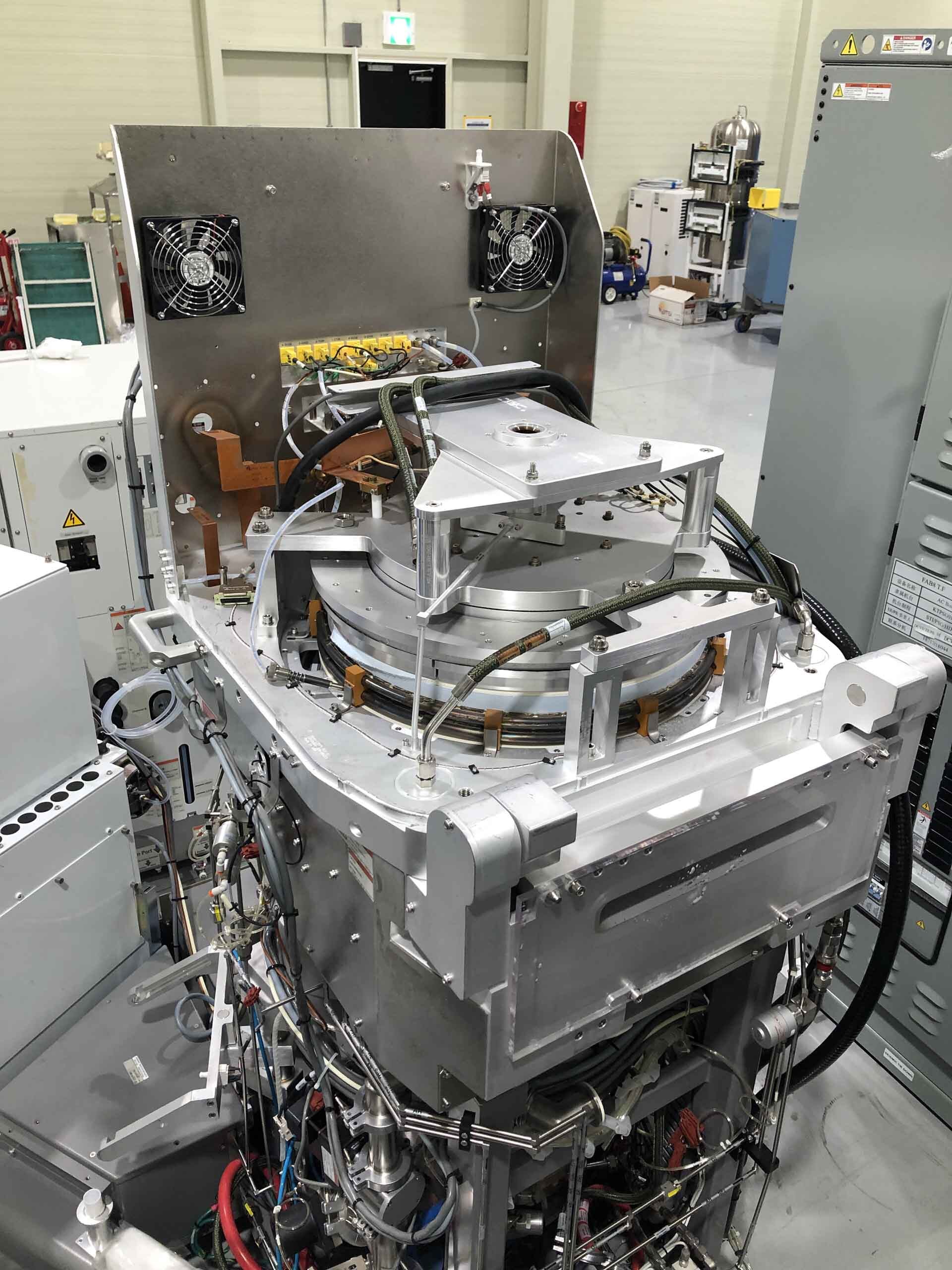

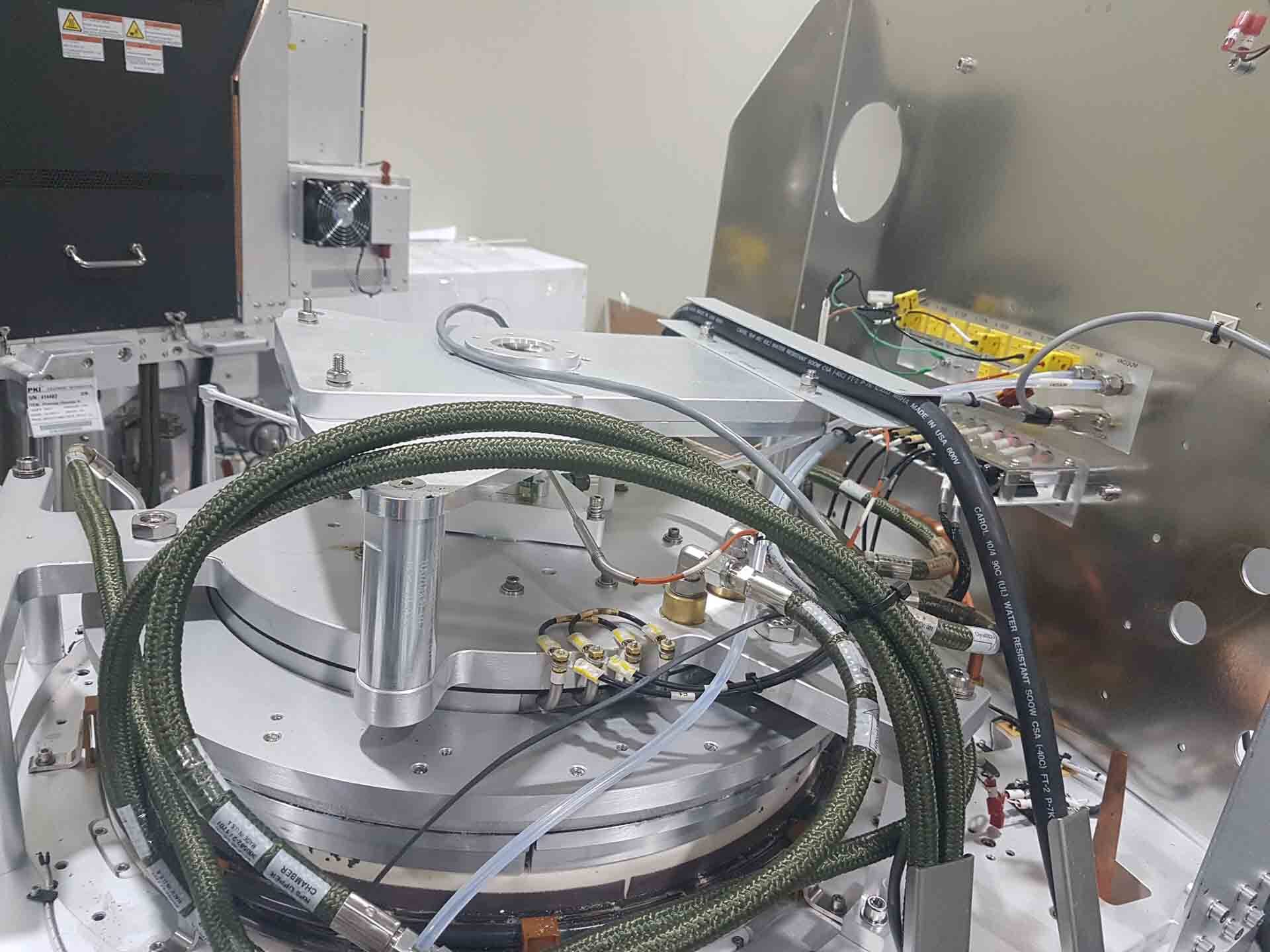

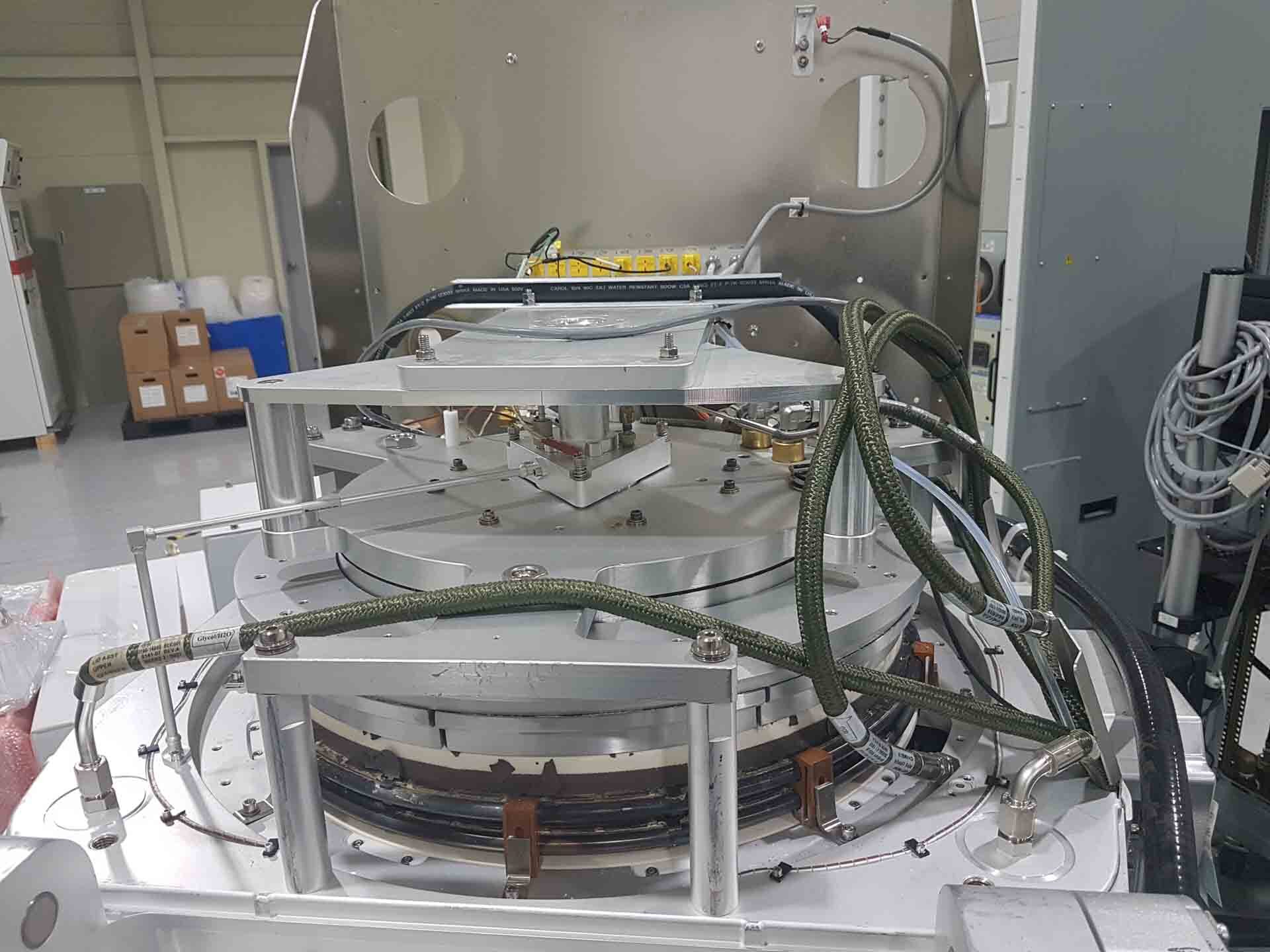

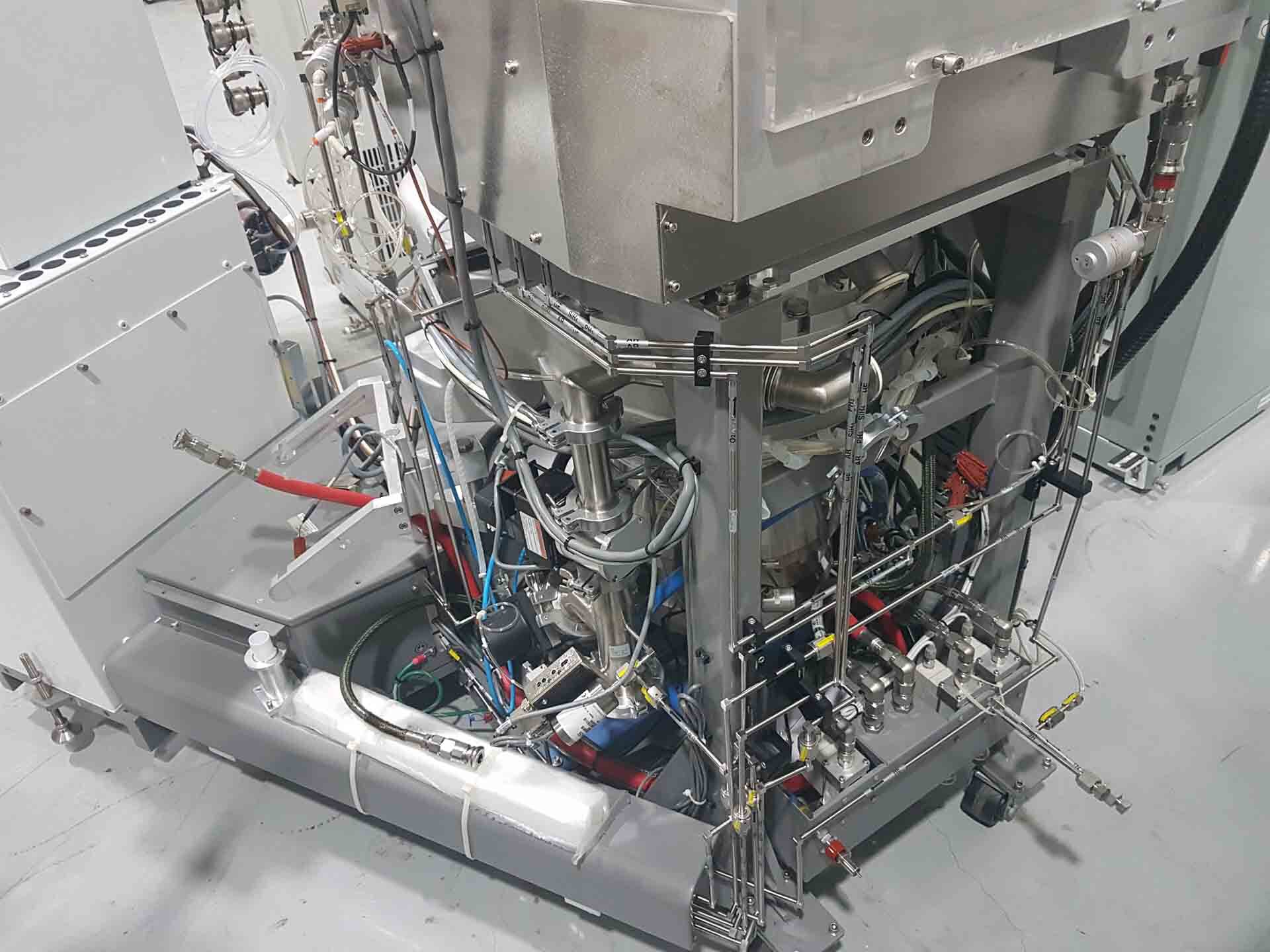

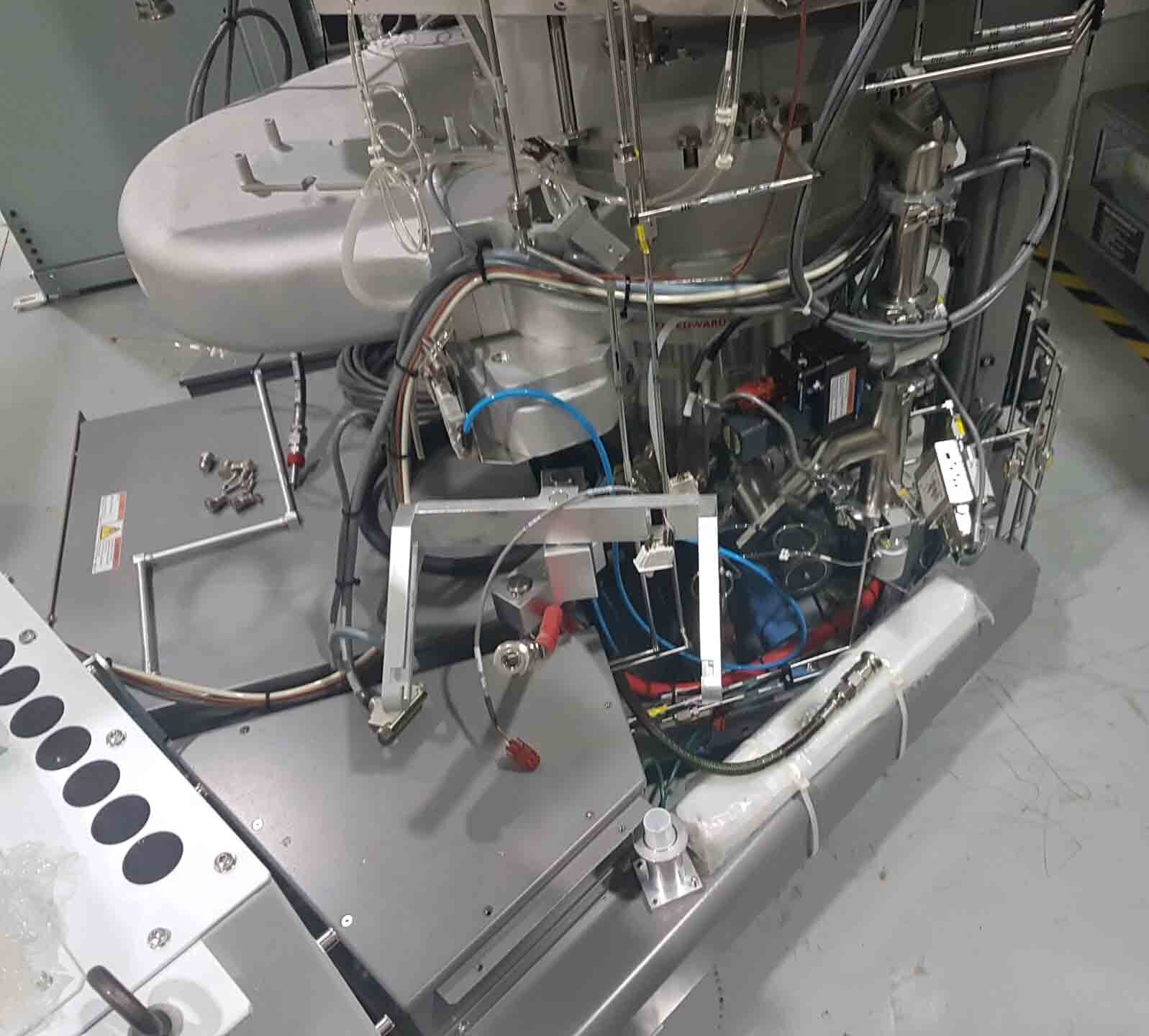

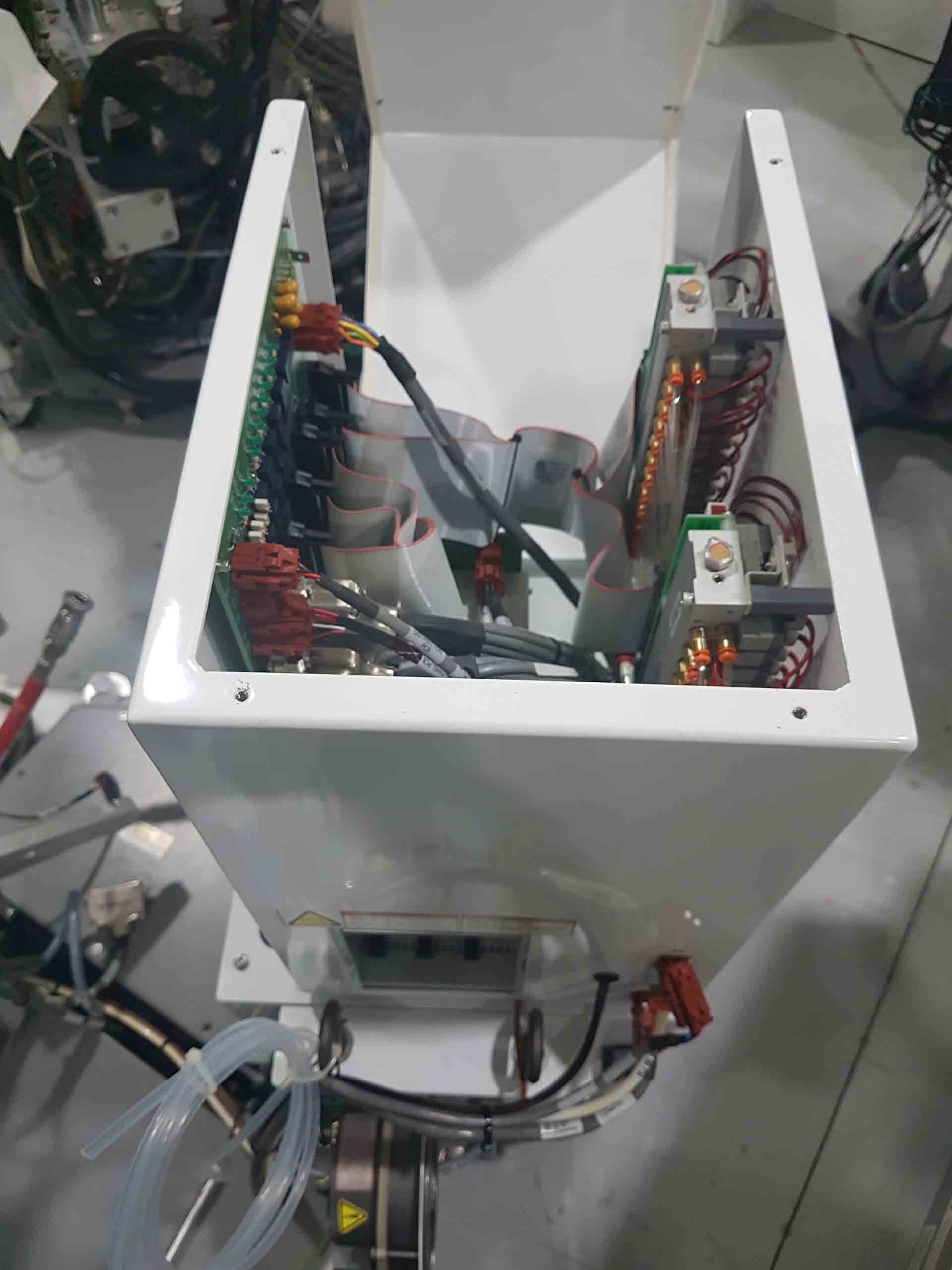

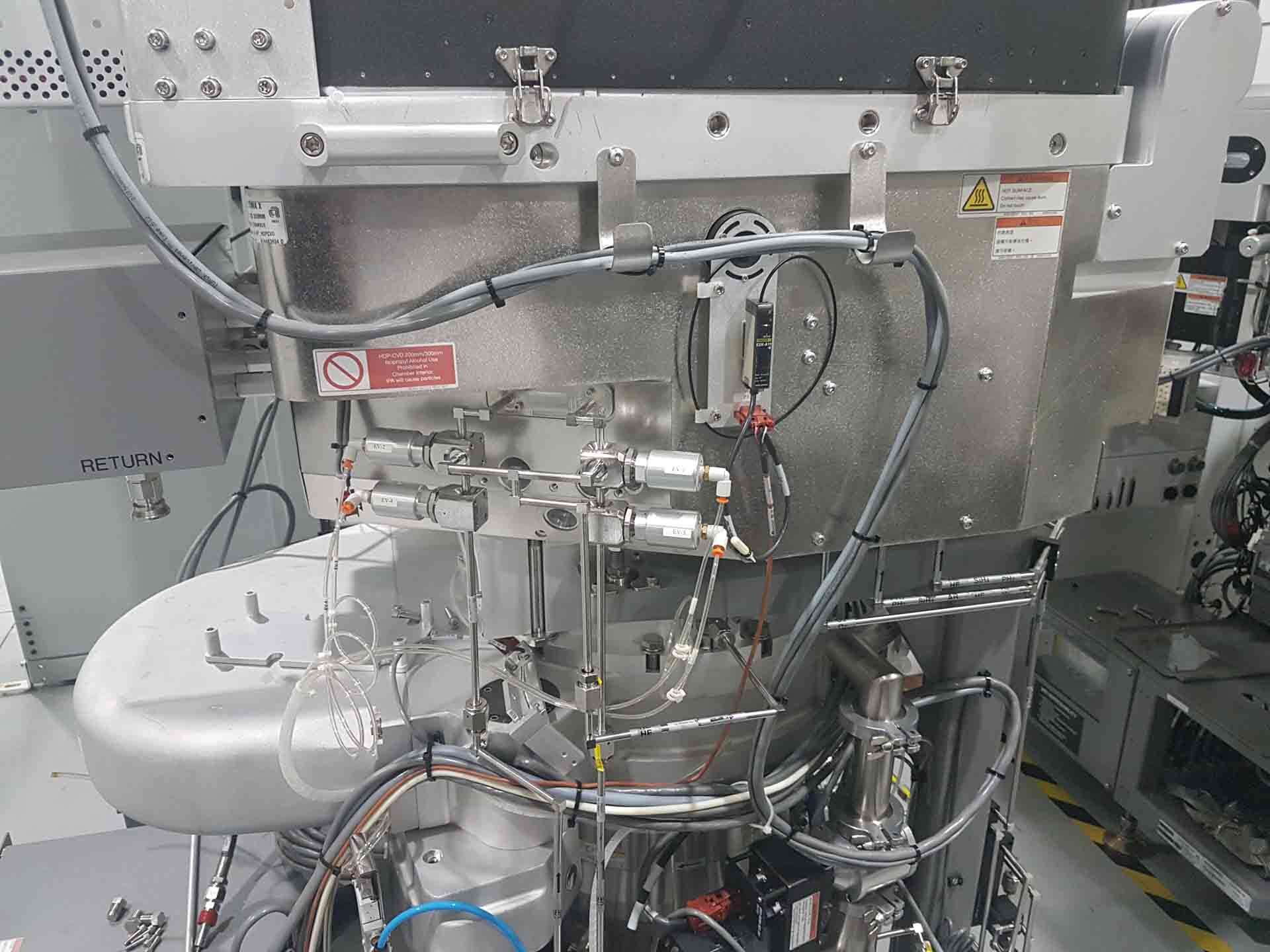

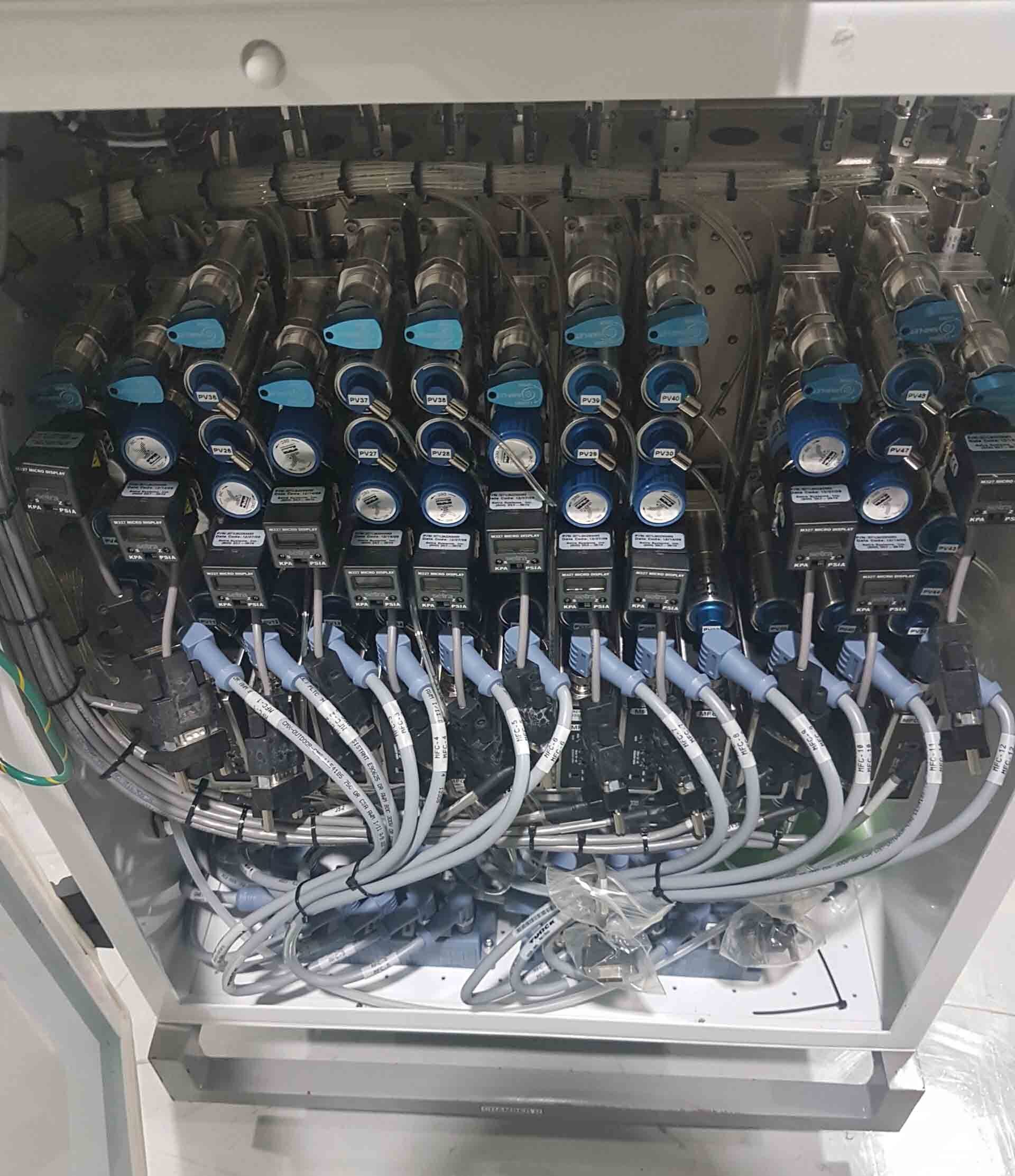

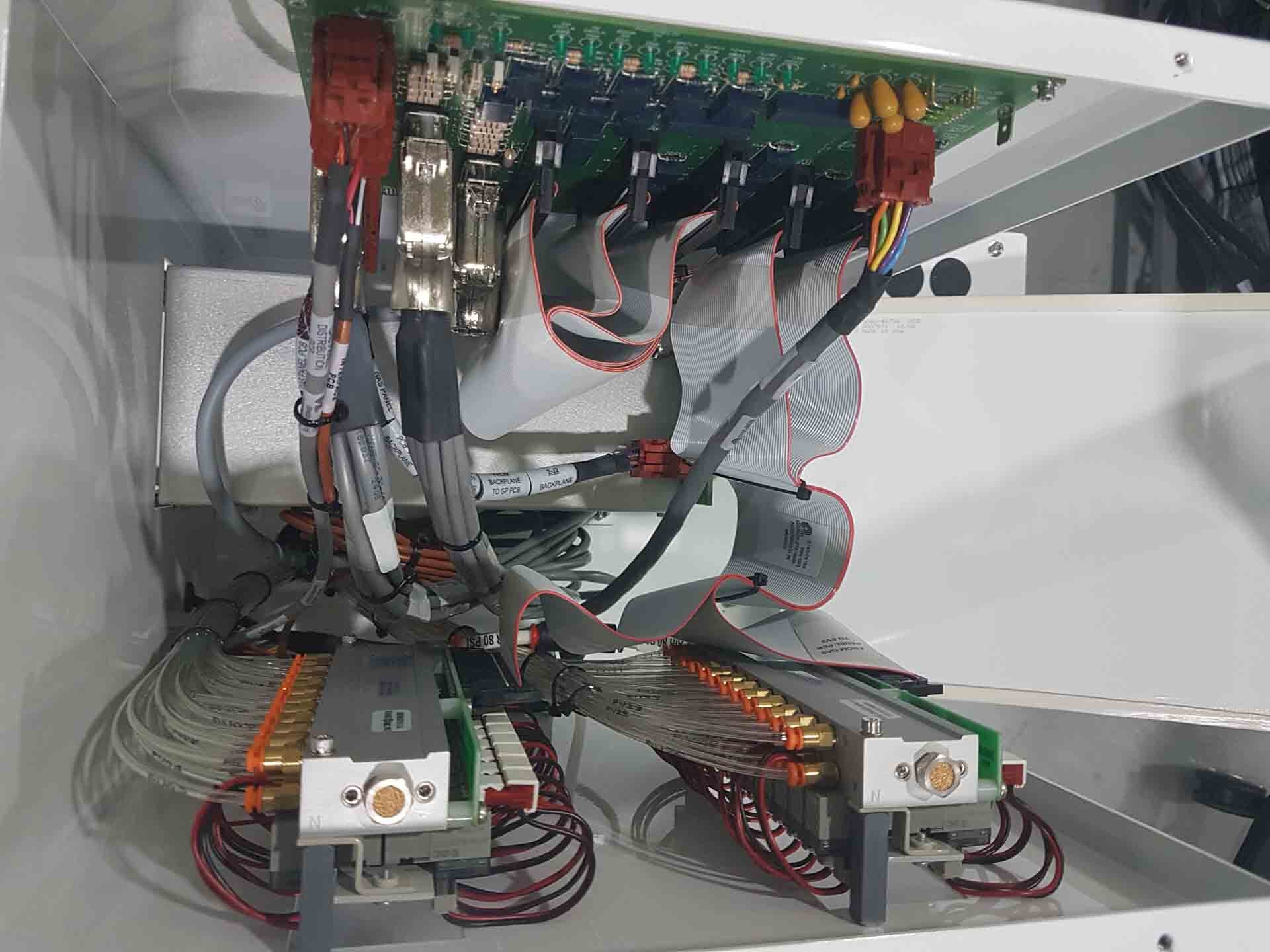

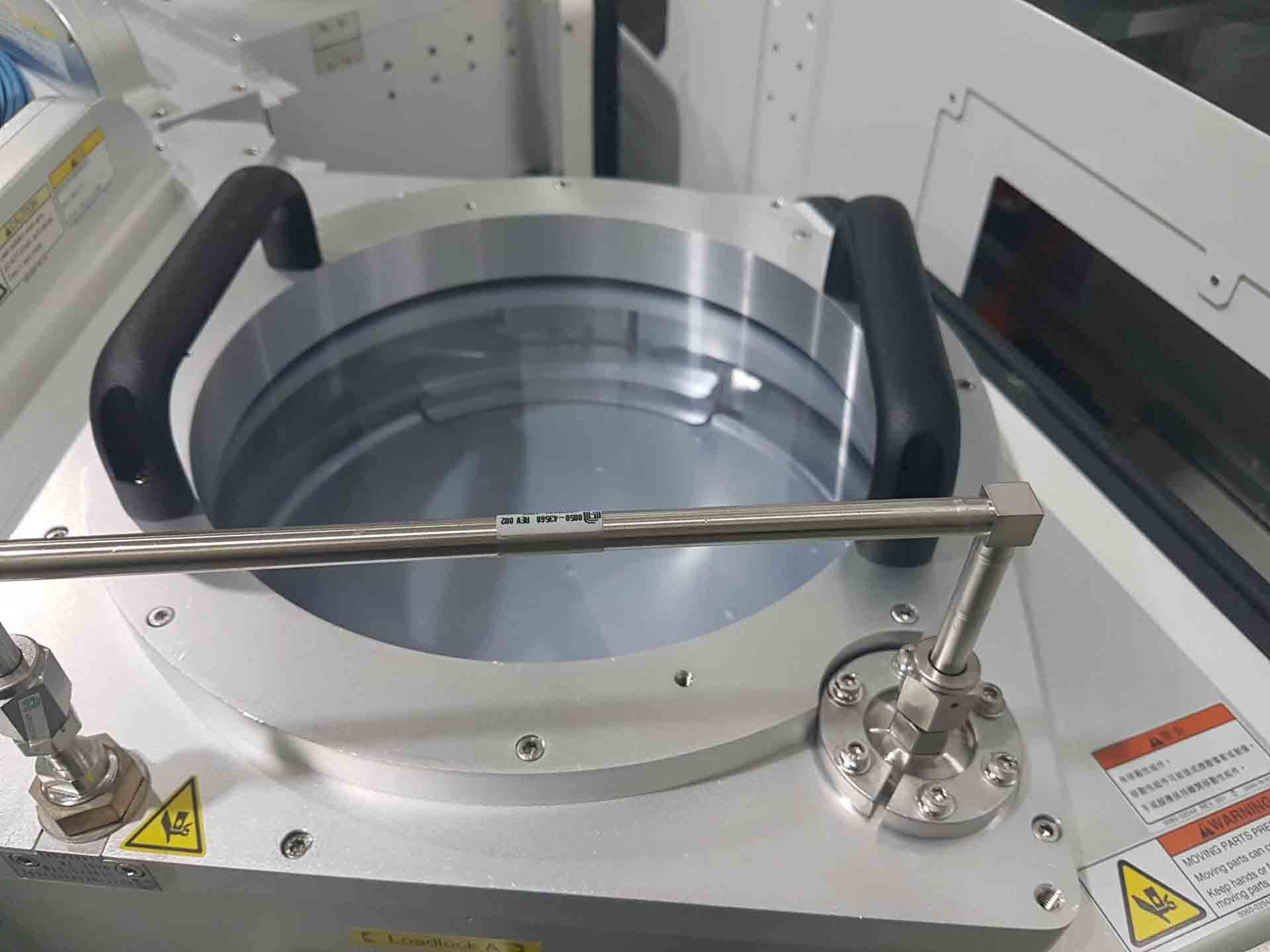

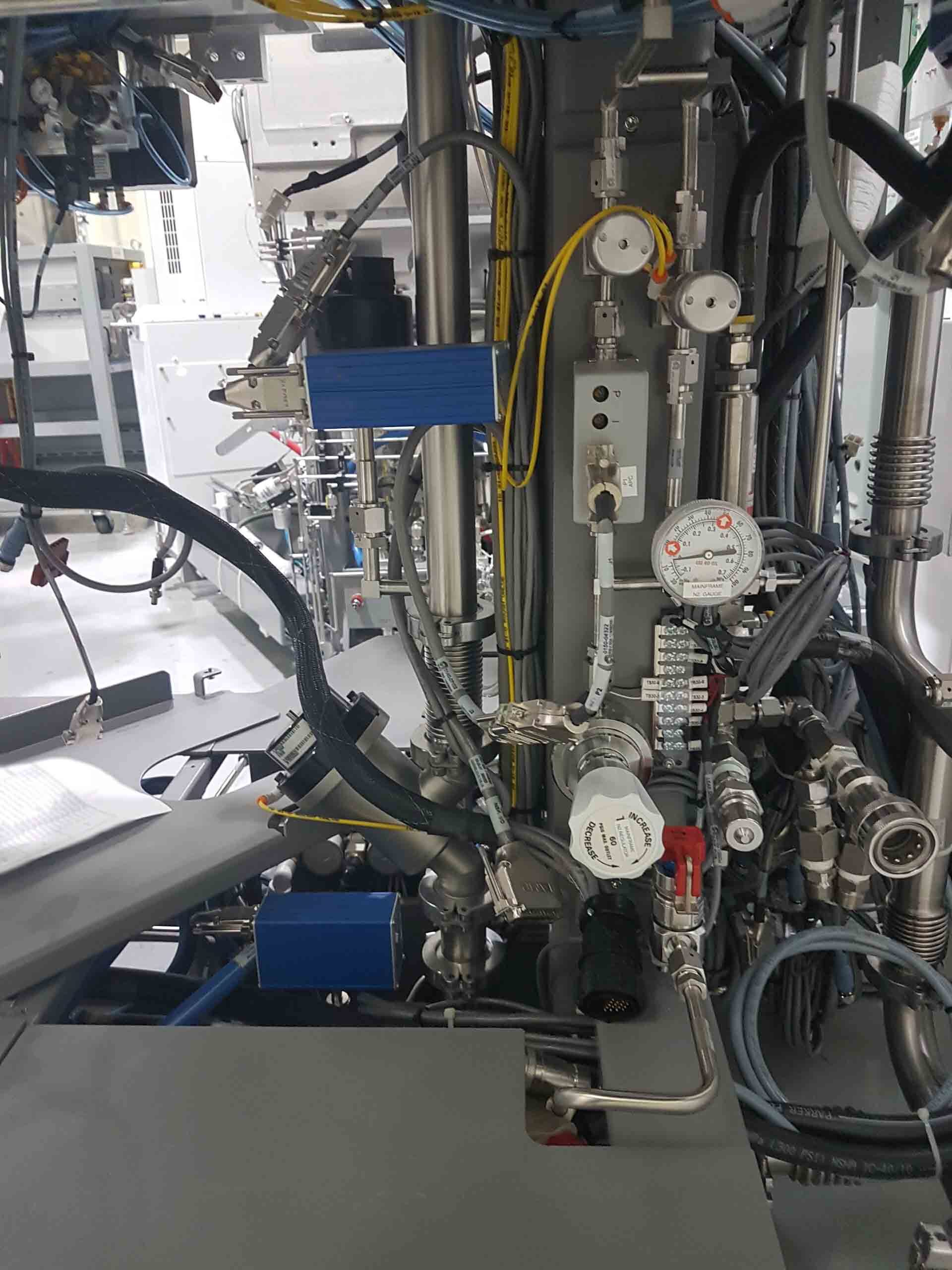

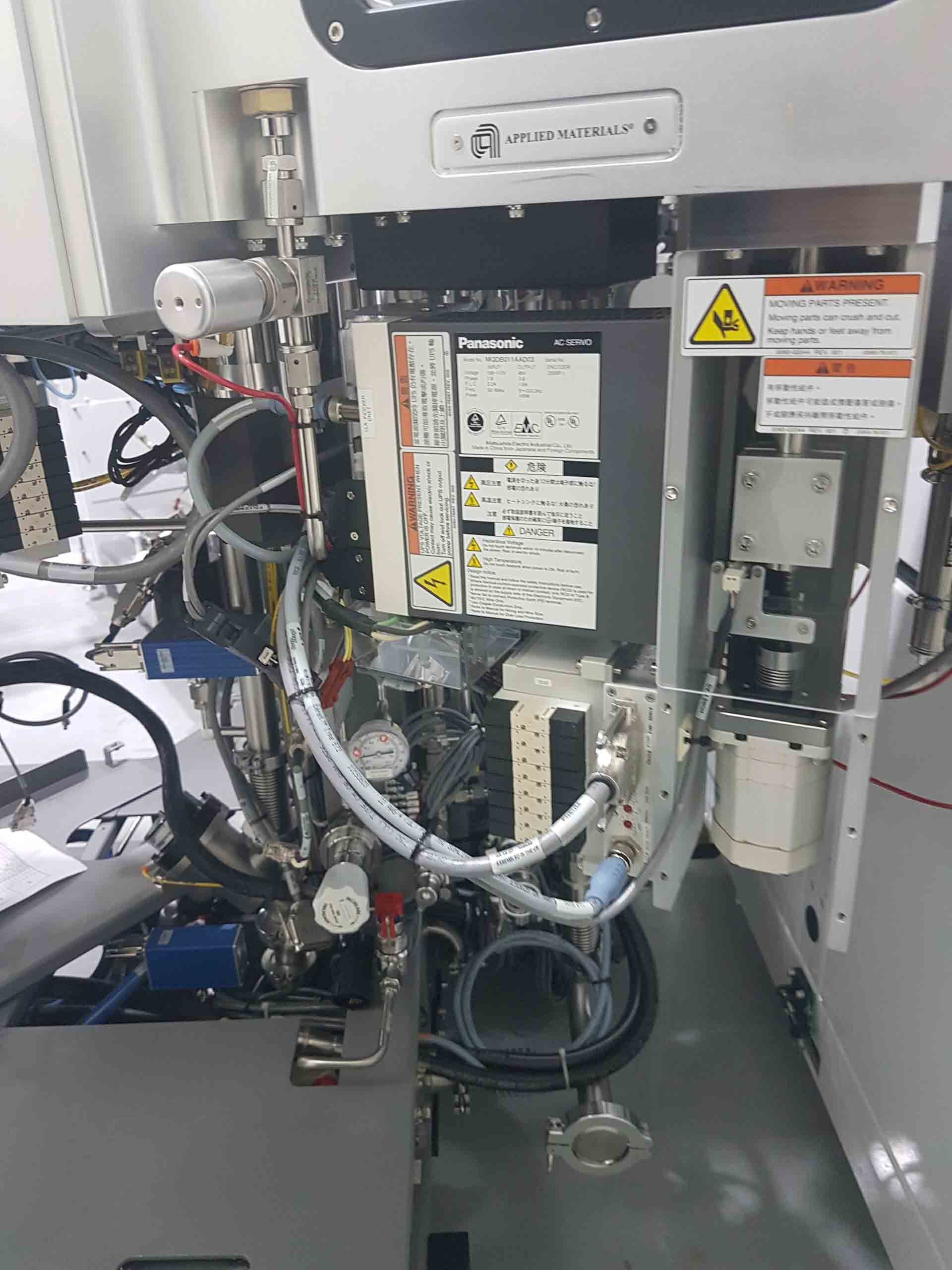

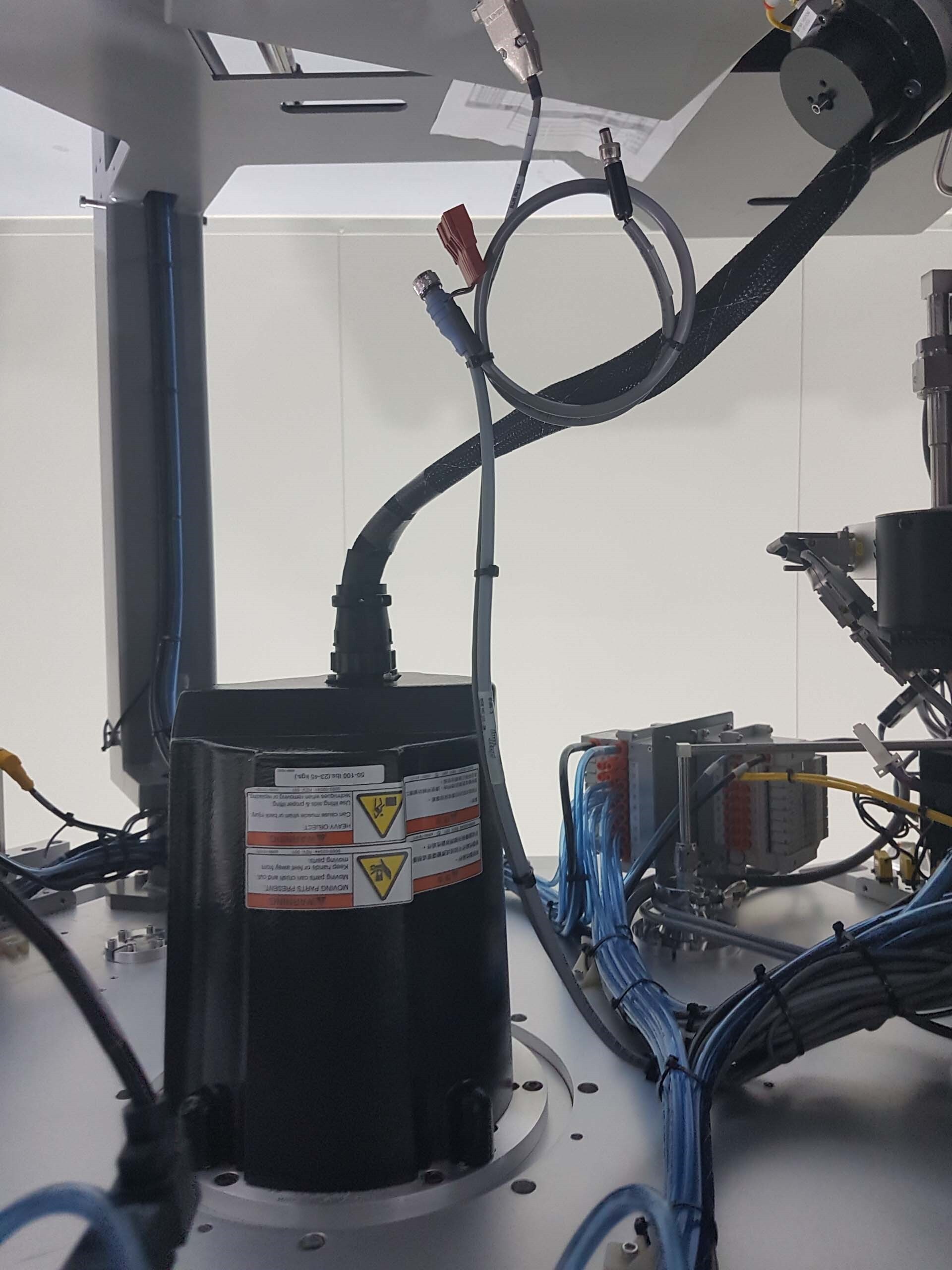

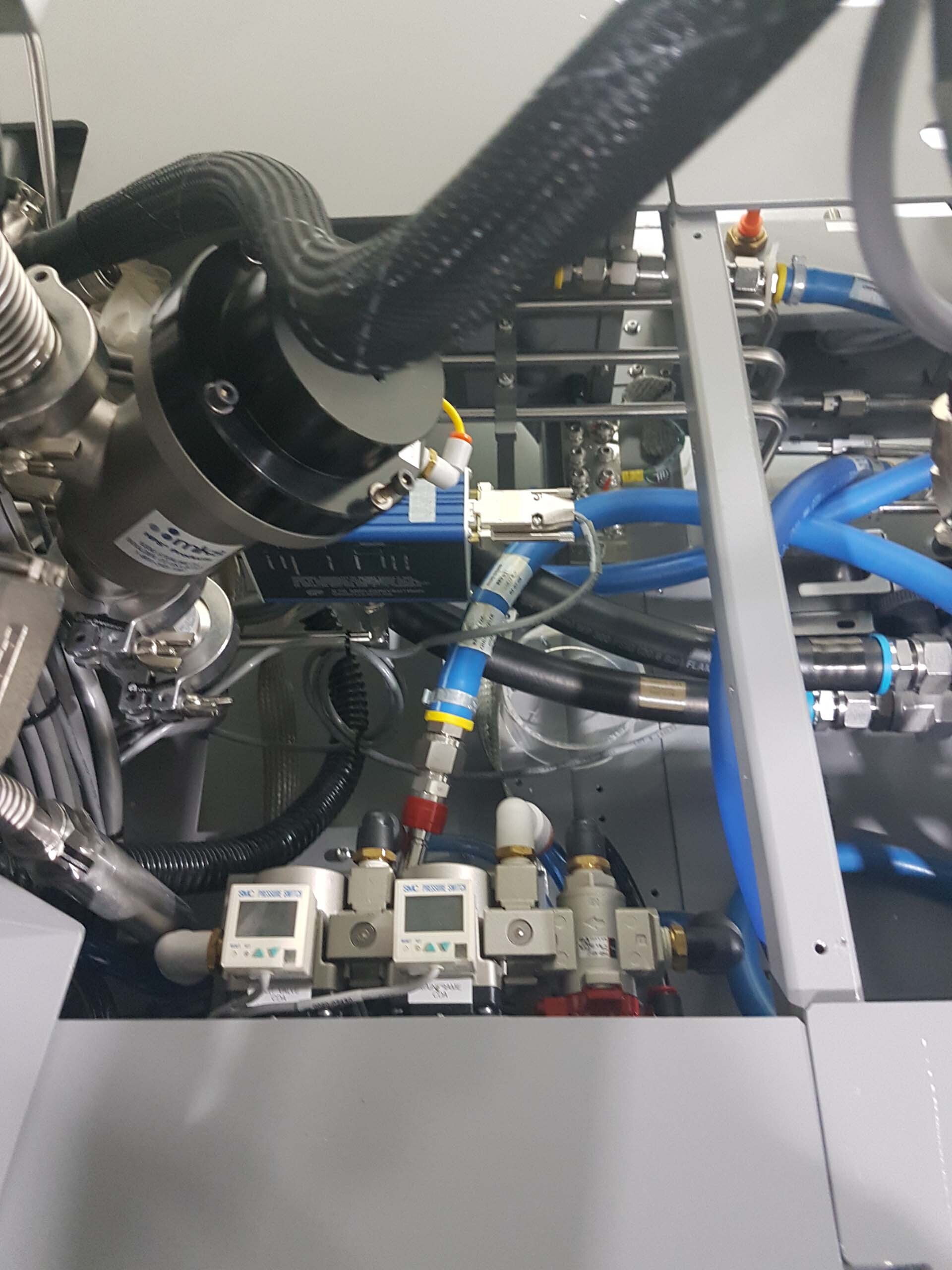

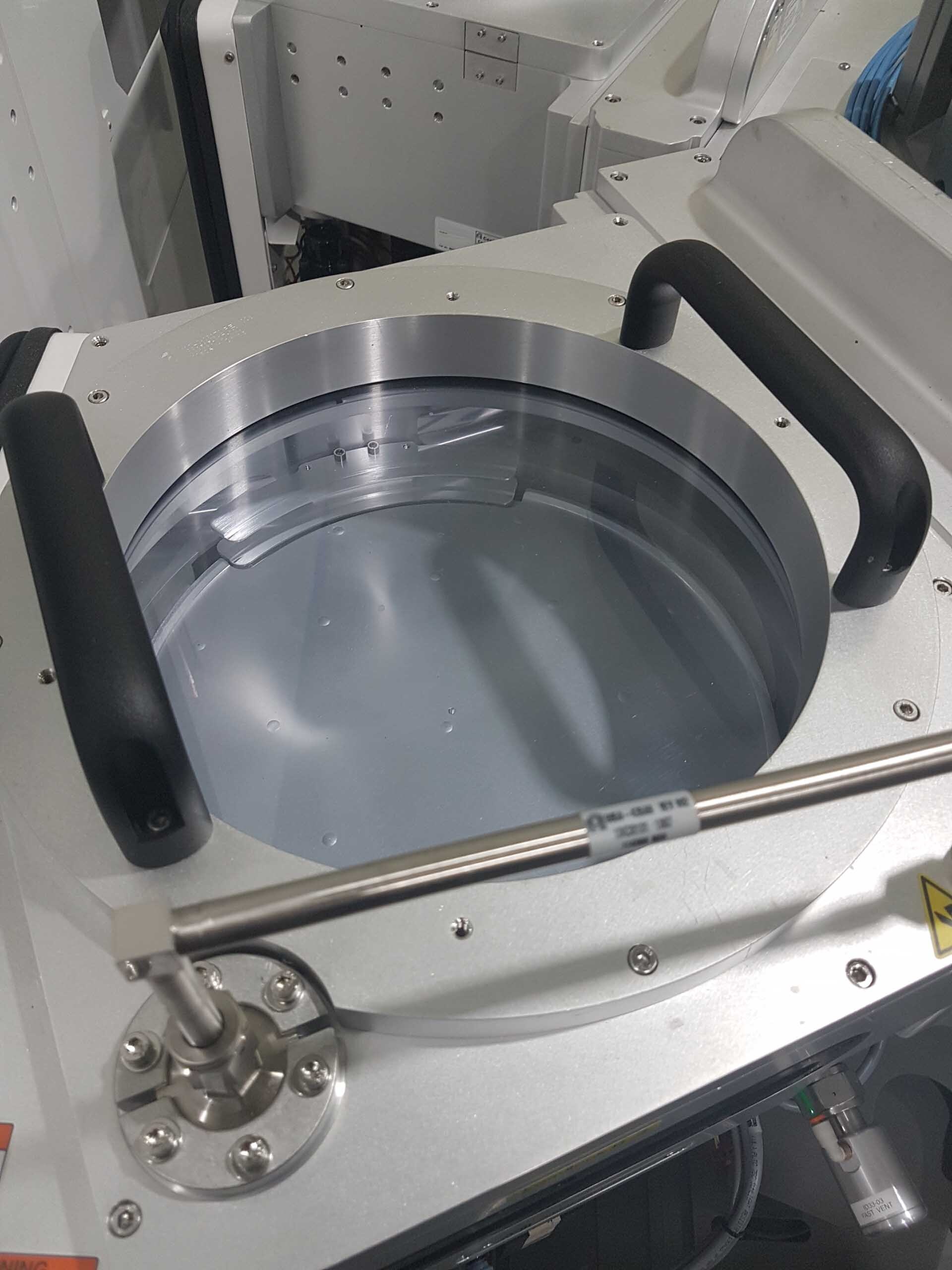

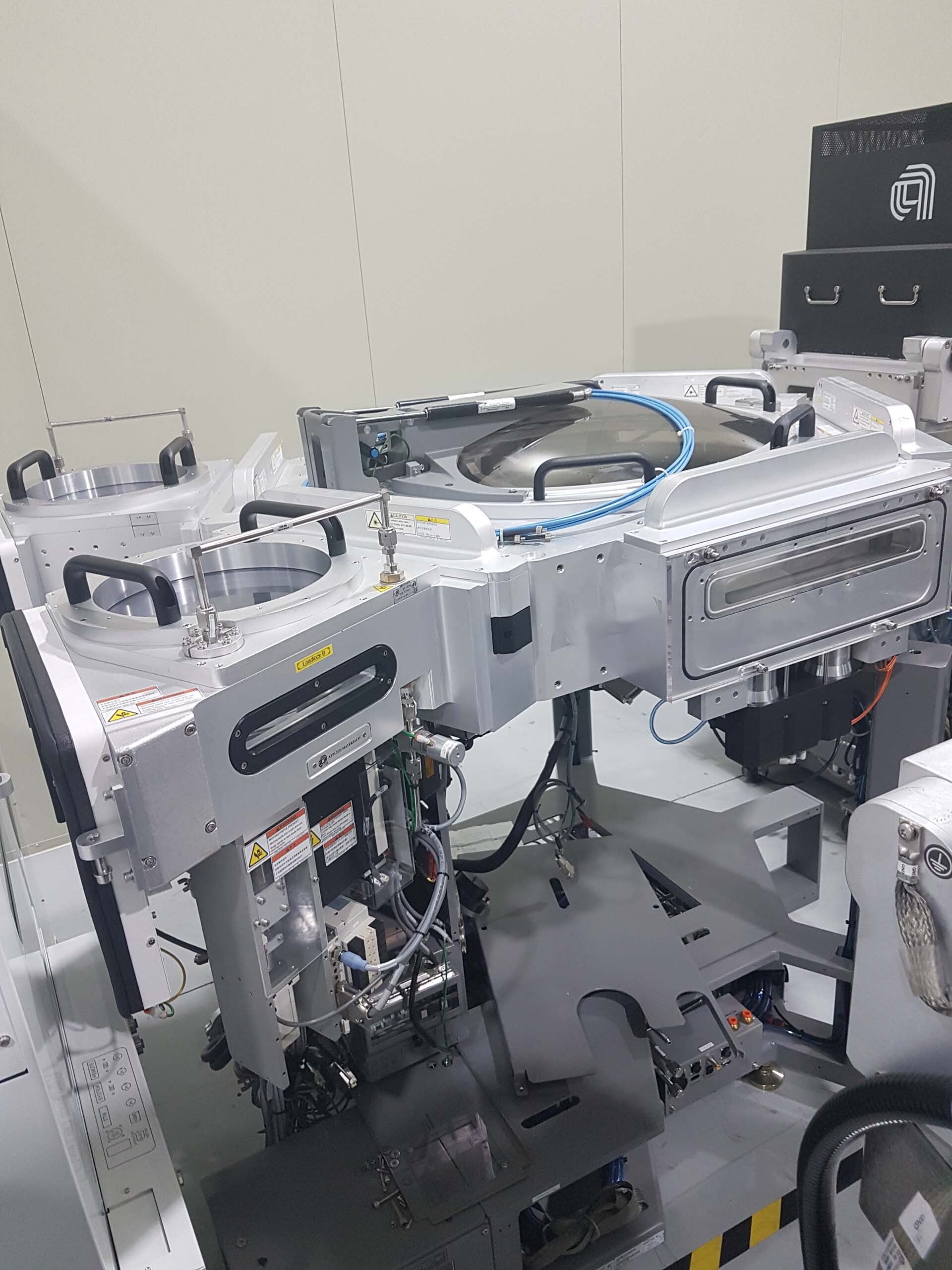

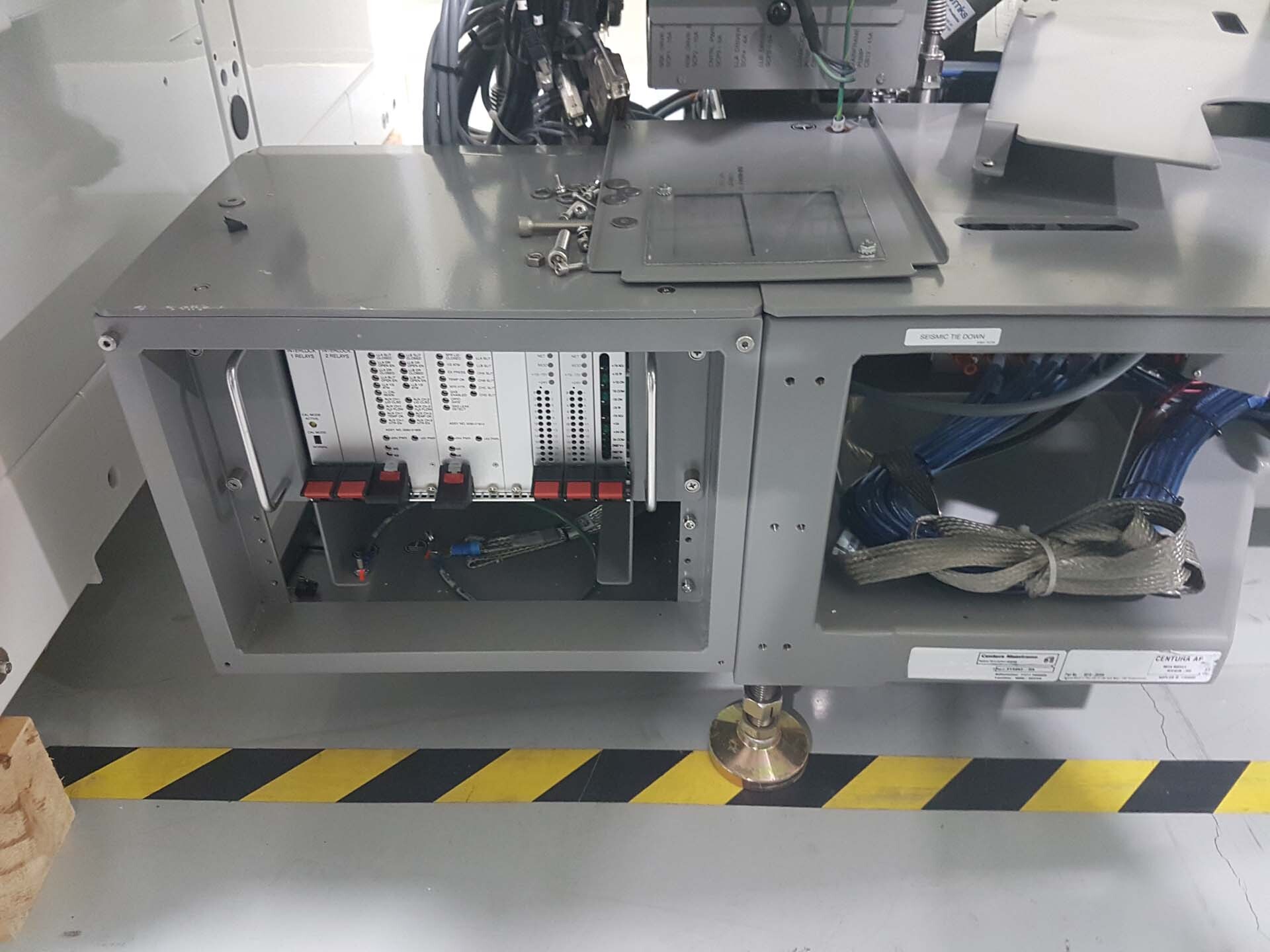

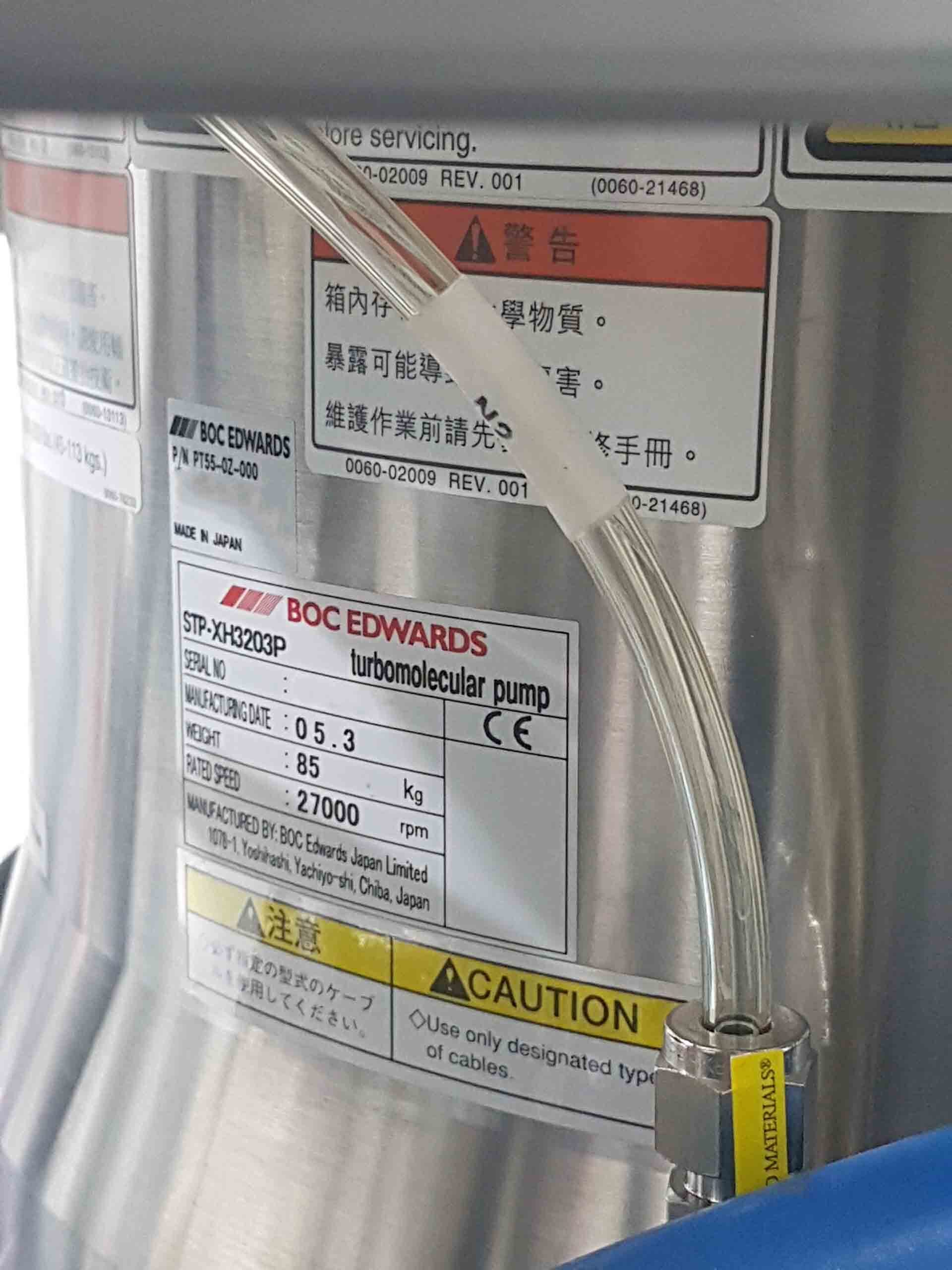

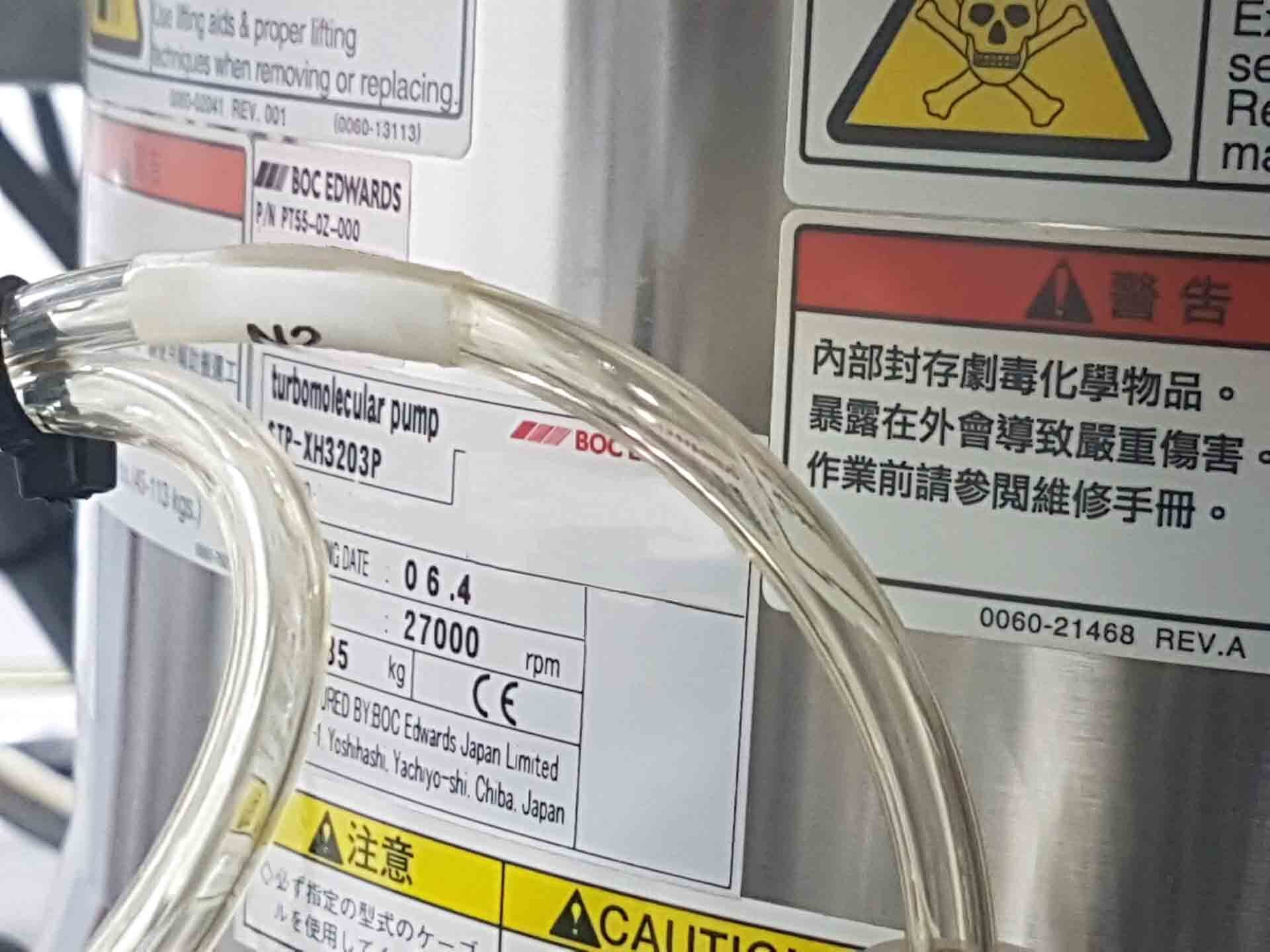

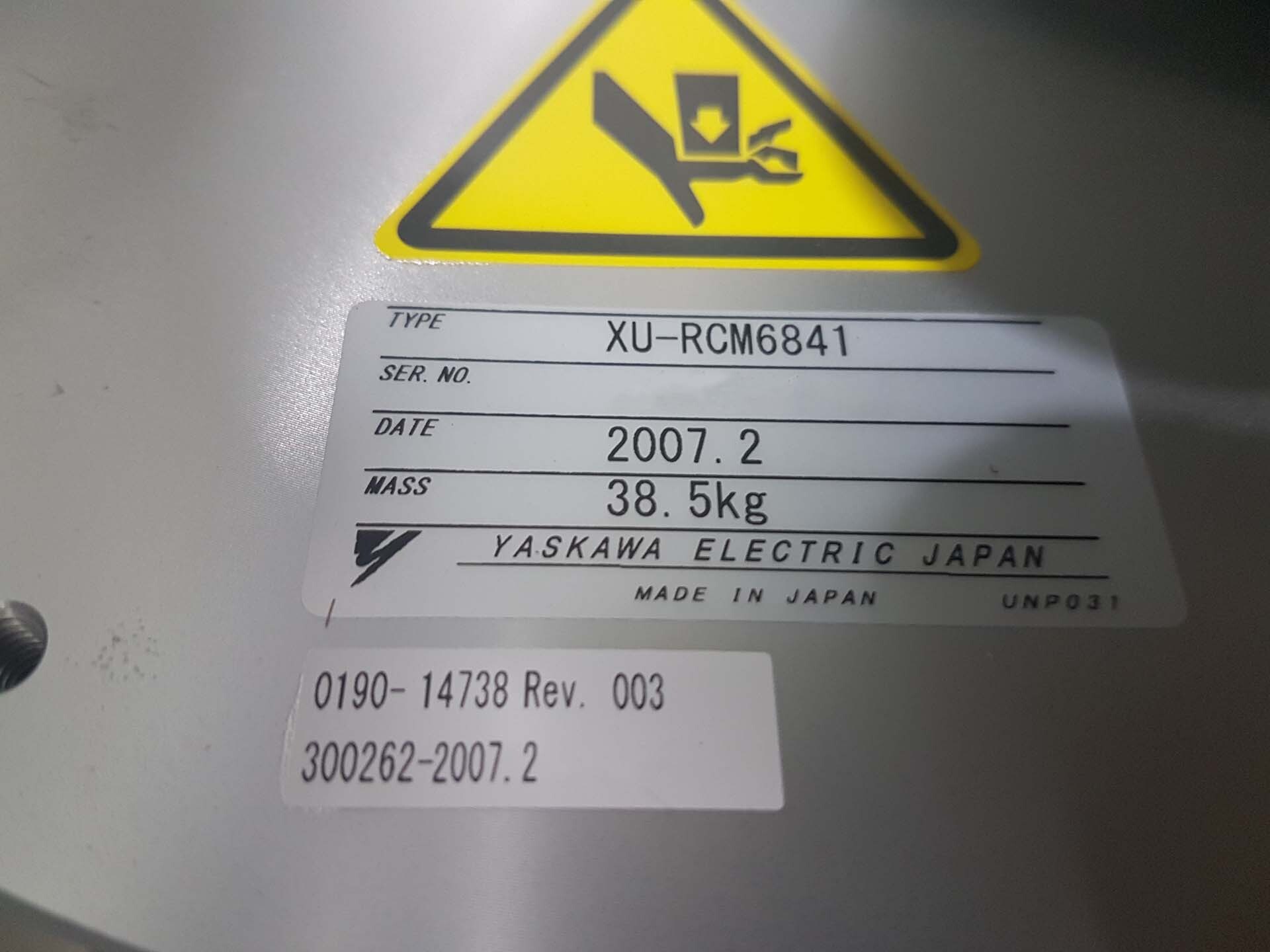

AMAT / APPLIED MATERIALS Ultima X reactor is a high-performance, high-volume semiconductor processing equipment designed to enable a wide range of applications in OLED, TFT, and FinFET device fabrication. Utilizing AMAT proprietary technologies, AMAT Ultima X operates under extreme temperatures and high pressures to enable an efficient manufacturing process for the production of leading-edge semiconductor devices. Utilizing APPLIED MATERIALS Ultima X reactor's unique thermal insulation characteristics and high-volume processing capability, users are able to optimize their device fabrication process without adversely affecting their yield or productivity. Ultima X reactor utilizes an enclosed reactor chamber for rapid thermal processing with reduced cooling interference and process contamination. The chamber maximizes temperature uniformity, delivering full compressive or high-temperature processes throughout the entire process chamber. It also provides isolation from the external environment, which helps minimize pressure losses and reduce process variation. The product is engineered with a monolithic process chamber, which reduces the build-up of contaminants while maintaining accurate temperature uniformity, and a spray gun assembly to apply uniform coating layers. AMAT / APPLIED MATERIALS Ultima X system also features a fully automated material management and transfer module. This feature allows a more efficient material handling, improving the quality of materials produced. Additionally, the unit's material handling machine is compliant with the most stringent safety standards, enabling improved safety for the operator. AMAT Ultima X also includes an optional integrated unified source of supply, which actually simplifies the supply chain and reduces the scope of material management required during wafer fabrication. Finally, APPLIED MATERIALS Ultima X reactor offers excellent wafer handling capability with a robust wafer handling tool that operates at up to 600mm wafer size per cycle and features a low-profile design that minimizes obstruction. Its integrated vacuum-lift subsystem helps automate the handling process, allowing for a more efficient transfer of each component into and out of the reactor chamber. This allows for a high throughput of semiconductor processing cycles with higher yields. Additionally, the asset utilizes several advanced monitoring techniques and tools to ensure optimal wafer temperature and throughput control.

There are no reviews yet