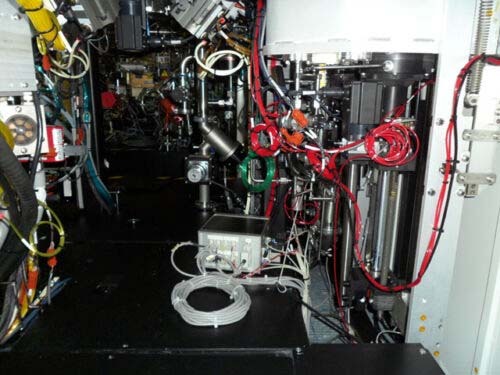

Used AMAT / APPLIED MATERIALS Widebody loadlock for Endura #293651962 for sale

URL successfully copied!

Tap to zoom

ID: 293651962

AMAT / APPLIED MATERIALS Widebody loadlock for Endura is a specifically designed reactor that enables uniform deposition of thin film materials on a variety of substrates. The equipment is designed to maximize deposition uniformity, minimize contamination, and provide an economical solution for thin film deposition processes. The Loadlock is an important component of the Endura thin film deposition system, as it allows for efficient loading, alignment, and transfer of substrates into and out of the deposition chamber. The widebody loadlock has two load ports and two evacuate/purge ports, both of which are tapped with O-ring sealed vents to maintain the process environment. The base of the loadlock chamber is mounted to the bottom of the unit, and features a lift plate for substrate transfer. Heated gate valves prevent contamination of the process chamber during substrate transfer. The loadlock is equipped with a two-piece quartz lid, which is capable of intermittent opening and closing to minimize process interruptions. Once the lid is opened, the vacuum mechanism is engaged, which allows substrates to enter the chamber without any disruption to the process. The loadlock chamber is surrounded by a pre-mixed, non-reactive nitrogen/argon based atmosphere that helps prevent contamination. The use of a dual-gas mixture eliminates the need for purging nitrogen or argon lines, reducing maintenance costs. The interior of the loadlock chamber is coated with durable RF power supplies, ruby-quartz windows, and rough-cut diffusion baffles to ensure uniform thin film deposition. The widebody loadlock is designed specifically for the Endura thin film deposition machine, and it can easily handle a large variety of substrates, from large ones (300 x 300 mm) to small ones (as small as a few microns). In addition to its thin film deposition capabilities, AMAT Widebody loadlock for Endura is also equipped with an exhaust stack that is used to minimize process and deposition by-products from entering the process chamber. This exhaust stack helps maintain a safe and clean process environment, as well as ensure optimal process uniformity for consistent thin film deposition. The tool also includes a teardrop-shaped lid that adds extra protection to the asset, while allowing for efficient and safe substrate transfer. APPLIED MATERIALS Widebody loadlock for Endura is a reliable and robust model, designed with efficiency and uniformity in mind. The equipment is designed to minimize contamination and maximize uniform deposition of thin films, while also providing an economical solution for thin film deposition processes. With its advanced technology and durable components, Widebody loadlock for Endura is the ideal choice for thin film deposition needs.

There are no reviews yet