Used APPLIED MATERIALS Centura DPS #134510 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 134510

R1 metal / ASP+ etcher, 8"

Specifications:

Wafer size: 8"

Install Type: Stand-Alone

Cassette Interface:

(2) Brooks SLR200LPTSM/R Bolt-On SMIF

Wafer Shape: SNNF (Notch)

Centura (Common) M/F:

Robot: HP

Robot Blade Type: Metal

Wafer on Blade Detect

Umbilicals :

Cntrl M/F: 40ft

Pump M/F Intfc: 75ft

RF PS Chamber: 75ft

Water Leak/Smoke Detection

Facility Connections: M/F Rear

M/F Exhaust Line: 304SST

Status Lamp (RYGB configurable)

System AC / Controller:

Phase 1

System SW: Legacy B3.62B

End-Point SW: ENDP30.4 (B1)

GEMS II / SECS Interface

GEMS SW ver.: OS2 B3.63B

Load Locks:

Wide Body w/Auto-Rotation

Corrosive Resistance

25-Wafer Cassettes

Wafer Mapping

Fast Wafer Mapping

Chambers:

Position

Chamber Type

E Cool-Down

F Orienter (OA)

A DPS R1 Metal

B DPS R1 Metal

C ASP+

D ASP+

Chamber F: Orienter (OA)

Lid Type: Hinged

Chamber A&B: DPS Metal R1

Lower Chamber Type: Rev 1

Upper Chamber Type: SAA

Pedestal Type: Polyimide ESC

Lid Type: Screw-down Lid

DTCU Type: Rev 1

DTCU PN: 0010-39750 Rev A

DTCU Lifters: installed

Source RF PS: ENI GWM-25

Bias RF PS: ENI OEM-12B3

Process Kit: Ceramic Single Ring

Endpoint Type: Monochromator

Endpoint SW present: ENDP30.4 (B1)

Throttling Valve + Gate Valve : Vat 64

Turbo Pump (Ch-A/B): Seiko Seiki STP-H1303CV

Chamber C&D: ASP+

Lid Type: Clamp

Source PS: Astex AX2115

MWave Tuning: Auto-Tune

Applicator Type: 1-Piece

Wafer Holding: Chuck

Process Kit: Quartz GDP

Heat Exchanger / Chiller:

(1) Steelhead 0

(3) Neslab 150

Fluid Type: 50/50

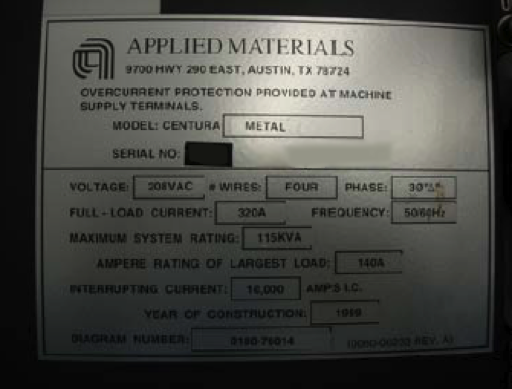

Power Requirements: V 208, 320A, 3-Phase, 4-Wire, Freq 50/60Hz

1999 vintage.

APPLIED MATERIALS Centura DPS is an advanced equipment designed to provide high-quality deposition of thin films. It is a plasma-based reactor that utilizes a high frequency power source to produce a controlled and highly energetic plasma environment. This environment enables precise and repeatable thin-film deposition with a high degree of control. Centura DPS reactor contains four primary components: a high frequency power source, a plasma chamber, a temperature-controlled substrate holder, and a gas feed system. The power source is the heart of the unit, providing the energy necessary to initiate a plasma state. It consists of an RF (radio frequency) generator and associated matching network. The plasma chamber contains the high frequency electromagnetic fields that drive the plasma. It also houses the target material for deposition, either within the chamber or externally, depending on the application. The temperature-controlled substrate holder is used to maintain the proper temperature for substrate deposition. The gas feed machine is used to control the gas flow in the reactor to allow control of the reaction environment. APPLIED MATERIALS Centura DPS is able to generate a wide range of reactive species under various gases feed conditions. This tool provides excellent control over the reactant species, reaction parameters, and the plasma species at various pressures. These features make it one of the best reactors for the deposition of thin films. The physical vapor deposition (PVD) process is used with Centura DPS, in which atoms are ejected from the target material by the energetic plasma environment and deposition onto the substrate. This method is highly advantageous for thin-film deposition, as it allows for precise layer-by-layer control over thickness, composition, and morphology. The process also enables deposition of material onto curved or irregular substrates, allowing for a wider range of product design possibilities. Overall, APPLIED MATERIALS Centura DPS is an excellent tool for component manufacturing, particularly for thin-film deposition. It provides excellent uniformity of coverage, excellent repeatability for process control, and high quality of deposition. With its wide range of capabilities and ability to deliver high precision deposits, Centura DPS is definitely a valuable tool for component production.

There are no reviews yet