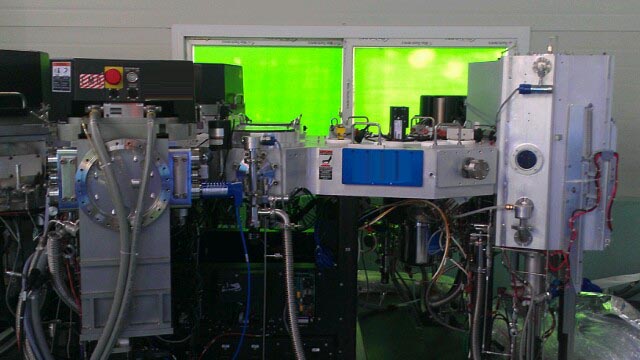

Used APPLIED MATERIALS Endura 5500 #155131 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 155131

Wafer Size: 8"

Vintage: 1994

Non-SMIF, 8"

Automation online Component: No

Load lock: Narrow Body

Transformer: Short Body

Robot Type: HP

Serial No: 3033

Chamber Configuration (Chamber Type)

Chamber A: By pass, Narrow Body

Chamber B: Cool down, Wide Body

Chamber C: N/A

Chamber D: N/A

Chamber E: N/A

Chamber F: Orienter/Degas

Chamber 1: Ti, Narrow Body

Chamber 2: Al, Wide Body (TiN)

Chamber 3: Al, Narrow Body

Chamber 4: Ti, Narrow Body (Al)

Chamber Configuration (Heater/Power Type)

Chamber C: N/A

Chamber D: N/A

Chamber 1: 101, 20KW

Chamber 2: 101, 10KW

Chamber 3: 101, 10KW

Chamber 4: 101, 20KW+10KW

MFC Type: STEC

1 Compressor:

Cryo He Line: 50ft

Neslab with resistivity

Hoist: No

RF Rack

Cable Length: 50ft

Pump Type: None

System Rack: STD

1994 vintage.

APPLIED MATERIALS Endura 5500 is a state-of-the-art high throughput equipment used in the production of a variety of specialty materials. This reactor system is an automated platform that provides advanced material syntheses and deposition solutions at higher levels of efficiency and productivity. Endura 5500 reactor is optimized for multiple batches of material synthesis and deposition, with a range of operators able to work on different parameters to make the process highly productive and efficient. It features a high-performance linear motor that offers fast and precise positioning, enabling the operator to perform advanced functions with ease. Additionally, APPLIED MATERIALS Endura 5500's drives are designed for repeatable and accurate movements, enabling reliable process synchronization. Endura 5500 is designed with a large vacuum chamber and cutting-edge exhaust unit for fast evacuation of the chamber and improved process repeatability and accuracy. It offers enhanced process control through its three-dimensional control (3D-CoC) machine that provides unparalleled precision and control during material deposition process. This tool uses advanced algorithms to adjust feed rates on-the-fly, providing a unique and robust solution to material deposition challenges. APPLIED MATERIALS Endura 5500 also includes an intuitive user interface that provides users with visualization, analytics, and real-time data acquisition tools to optimize process controllability and manipulation throughout the entire process. By displaying the process information in both graphical and tabular views, the intuitive user interface gives users greater flexibility and control over how they configure and monitor their processes. It also allows for up-to-date tracking of the reactions and progress of the process, enabling operators to modify conditions and adjust parameters based on the performance of individual batches. Endura 5500 is built to work with a wide range of materials, from metals to thin-film deposition material. With its enhanced process control, high-power linear motor, and the intuitive user interface, APPLIED MATERIALS Endura 5500 provides unprecedented speed, accuracy and deadweight repeatability for material deposition processes.

There are no reviews yet