Used APPLIED MATERIALS Endura 5500 #180431 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 180431

Wafer Size: 8"

Vintage: 1999

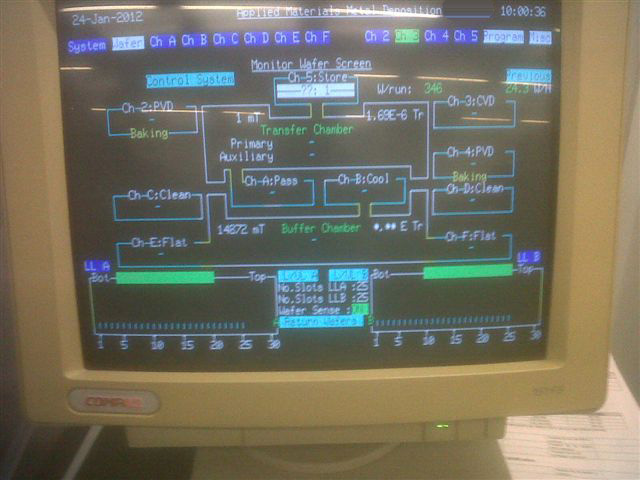

PVD system, 8"

Specifications:

Main frame: through the wall configuration

Wafer handing: SNNF

Front panel type: Painted

Software version: 8.91

Single board computer in controller: Yes

Ion gauges: 451 nude

Robots:

Buffer robot: HP+

Blade material: Original metal

Load lock: No wide body

Index handler type: Enhanced tilt out

Loadlock vents: Variable soft vent + fast vent

Transfer robot: VHP

Blade material: CVD compatible

Narrow body: Yes (Tilt-out)

Chamber specifications:

Chamber 2:

Metal / Applic.: IMP Tin

Body Style: Vectra Imp

Source type: Vectra Imp

Power Supply: 12kW

Power Supply: 12kW

Heater: B101

Basic chamber setup:

A. Pass through

B. Cool down

C. PC 2

D. PC 2

E. Orientor with Std Degas

F. Orientor with Std Degas

Gasline fittings: AMAT specifications

For preclean / CVD:

Chamber C:

Vacuum pump type: Ebara

RF match: 180431

Cable length: 75"

RF match type: 8"

Power supply: RFPP 10A

Chamber D:

Vacuum pump type: Ebara

RF match: 180431

Cable length: 75"

RF match type: 8"

Power supply: RFPP 10A

MFC type:

Process MCF-1:

2: AR (size 100)

3: Hecar; BTpur;EDpur ;Phat (size 500;2000;3000;1)

4: AR (size 100)

C: AR (size 20)

D: AR (size 20)

Process MFC-2:

2: N2 (size 100)

3. 500;2000;3000;1 (size 1000;1000;1000)

C. AR (size 300)

D. AR (size 300)

Paste chamber: Yes (chamber 5)

System roughing pump type: Ebara

Chamber cryo pump type: OB8F

Umbilicals:

- mainframe to controller: Yes

- mainframe to generator racks: Yes

- mainframe to cryo compressor: Yes

- main AC to system controller/sys. AC: Yes

- syst cont/sys AC to primary Gen rack: Yes

- main AC to primary generator rack: Yes

- main AC to pump frame: Yes

- main AC to Neslab heat exchanger: Yes

- monitor cable: Yes

- monitor2 cable: Yes

- monitor3 cable: Yes

CE Mark: Yes

EMO Option: Yes

EMO button guard rings: Yes

Water leak detector: Yes

Buffer and transfer lid hoist: NO

Support Equipment:

Heat exchangers:

Number: 1

Type: AMAT

Cryo compressors: Yes

Number: 2

Type: 9600

Cryo He lines Yes

Neslab present: Yes

Resistivity meter: NO

Manuals not included

Installed

1999 vintage.

APPLIED MATERIALS Endura 5500 is a high-end, multi chamber reactor dedicated to improving the performance and reliability of silicon based devices. Endura 5500 is designed to provide high yields at the lowest possible cost while still maintaining the highest quality and precision. The advanced design of APPLIED MATERIALS Endura 5500 allows for various silicon-based processes to be carried out in a single tool, such as deposition, etch, anneal, deposition, etch and inspection. As a result, Endura 5500 is able to provide the highest throughput with the highest yields in the industry. APPLIED MATERIALS Endura 5500 uses an innovative dual pump equipment, which allows for flexibly and fast tuning of process parameters at all stages of production. The system uses highly efficient pump speeds in order to reduce contamination, while also providing the necessary power to complete many different processes. Additionally, the unit utilizes infrared heating on the wafers, giving the user complete control over the process temperatures. Endura 5500 is a reliable and robust reactor well suited for fabricating semiconductor wafers using the most advanced semiconductor processes. The machine is equipped with a high degree of automation, which allows for the realization of complex procedures without manual intervention. Furthermore, APPLIED MATERIALS Endura 5500 is designed to be compatible with modern control systems and allows for the integration of different software platforms into the tool. Endura 5500 is capable of carrying out a wide variety of processes, including Chemical Vapor Deposition (CVD), to deposit materials in a controlled environment, process temperatures up to 1100°C and a pressure range up to 10 Torr. This allows for single and double sided processes, such as metalization and photolithography, to be completed quickly and with a high degree of control. APPLIED MATERIALS Endura 5500 is equipped with a unique Crystal Grower Module (CGM) which is capable of crystal growth and doping services, both of which are necessary for the creation of certain types of semiconductor devices. The CGM provides exact control over the temperature and pressure, allowing for the controlled and precisely doped materials to be obtained. Endura 5500 reactor is designed to be an automated, cost effective and technologically advanced asset. It's comprehensive range of features makes it an ideal choice for the fabrication of semiconductor devices that require the highest levels of precision and quality. This reactor is a reliable and trustworthy tool, suitable for many different processes and will provide reliable performance for many years to come.

There are no reviews yet