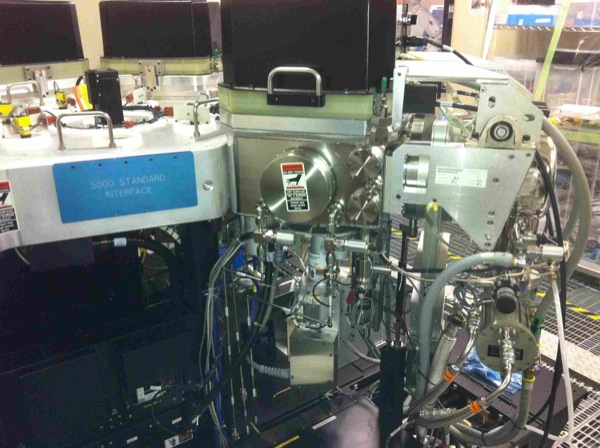

Used APPLIED MATERIALS Endura 5500 #194410 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 194410

Wafer Size: 6"

Vintage: 1993

PDC System, 6", missing parts

Chambers: (2) standard, (1) wide body

Chamber 1: STD-Ta(CLAMP), DURA magnet

Chamber 2: Wide-TaSi(CLAMP), DURA magnet

Chamber 3: STD-AlCu(CLAMP), DURA magnet

Chamber A: PCⅡ(Pedestal)

1993 vintage.

APPLIED MATERIALS Endura 5500 is a reaction chamber used in processes such as deposition, etching, and cleaning. It is used to process semiconductors, thin films, ceramics and other materials. Endura 5500 has an exceptional process window, meaning its impressive range of plasmatic temperatures and pressures can be used for a variety of applications. This makes it uniquely suitable for many tasks, such as etching, ion beam milling, sputtering and other process. APPLIED MATERIALS Endura 5500 is a three-chamber equipment, meaning its several parts are interconnected but can also be operated independently. The chambers are the reaction chamber (which is the main part of the system), the loadlock chamber (which is used to load and unload samples), and the hot process chamber (which is used to control process gases). The unit is Vacuum Compatible (VC) and is capable of a base pressure of 1 x 10-6 mbar. The reaction chamber also deploys sophisticated polygon scanning, which enables efficient utilization of the available space while optimizing the beam line for increased uniformity. Endura 5500's high power supplies are effective for applications that require high pulse power or a higher peak current. It has an ultra-low power consumption of less than 1000W per inch of belt length, making it one of the most energy efficient systems on the market. APPLIED MATERIALS Endura 5500 is equipped with a 10.4'' touch-screen display that provides users with full-fledged remote control. Through its intuitive graphical user interface, users can control all the process variables of the machine. The tool incorporates the latest safety features and is equipped with a fault monitoring asset that can detect any errors and alert operators of a problem. Endura 5500 has a host of capabilities that make it perfect for various tasks. It is FM (functional material) ready and has the capability to clean chamber surfaces using a variety of gas sources, such as hydrogen and argon. It also has the capability to incorporate quartz crystal deposition monitoring and offers plasma process cells of various shapes and sizes in order to achieve perfect etching or deposition. In conclusion, APPLIED MATERIALS Endura 5500 is an excellent model for semiconductor processing. Its advanced features, including polygon scanning and energy efficiency, make it a powerful and reliable tool for tasks such as etching and deposition. The various safety features and intuitive user interface make it ideal for industrial applications.

There are no reviews yet