Used APPLIED MATERIALS P 5000 Mark II #67130 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 67130

Metal etch system, 6"

Configuration details:

Precision 5000 Mark II MxP Etch system 6”

Mark II mainframe containing load lock chamber

Cassette to cassette wafer handling

VME system controller with hard disk and floppy disk storage

28 line compatible on-board gas panel

Bolt down load lock chamber lid and load lock purge system

Microprocessor controller including CRT display, self diagnostics, host computer interface via RS232 port SECS II protocol

Standard floppy and hard disc (170NMB) storage

Etch chambers include:

Temperature controlled pedestal

Magnet modules and cylinder lift mechanisms

Slit valve, gas distribution components

RF isolator, RF match

Capacitance manometer, throttle valve

Independent helium cooling

Integrated end point detector

Remote package including pumps, RF power supplies, heat exchanger, NESLAB recirculator, main AC box and other facilities

Fifty foot remote package cable length

Features:

(2) metal etch chambers and one strip chamber system

Chamber A: 6” clamped metal etch process kit

Chamber B: 6” clamped metal etch process kit

Chamber C & D: 6” advanced strip and passivation chamber

Including 1200 Watt generator process kit, hardware gas distribution plate and MFC controller gas line per chamber

6” metal etch process kit with:

AL etch ceramic fingered basic kit 0240-31587E

0.95” fingered ceramic focus ring 0240-09757E

Tapered head SiC DC Pick-ups 0240-31359

Unilid gas distribution plate - 119holes 0020-32259

6” advanced strip and passivation chamber process kit basket style wafer support

Gas panel A&B: BCL3, Cl2, CF4, N2, SF6 / C: O2, N2, H2O

Through the wall system

Heat Exchanger AMAT 1 and Heat Exchanger AMAT0

(1) NESLAB HX150 is missing

(1) etch chamber is leaking glycol (can be repaired but it is better to change the body chamber)

Second chamber has been repaired for the same problem

Machine was in production until Q3 2009

Currently installed in fab

Gases are purged and the machine is powered off

Can be inspected and powered on to see software only

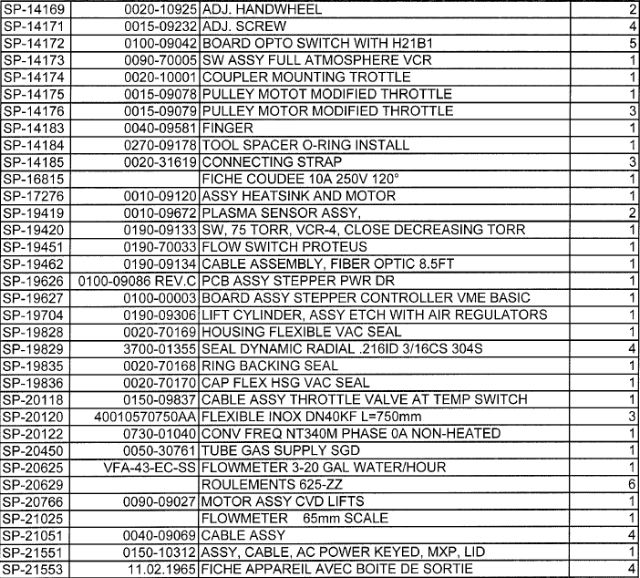

Spare parts available, list is shown in photos

1998 vintage.

APPLIED MATERIALS P 5000 Mark II is a high-performance configurable parallel processing reactor designed for multi-stage deposition process of a wide variety of materials. It is the most advanced deposition equipment on the market, offering unmatched process flexibility and monitoring capabilities. APPLIED MATERIALS P5000 MARK II is a high volume production process reactor that can accommodate chambers up to 5.5 x 4.0 meters in size, giving it up to 20 simultaneous chambers and a total throughput of over 8,400 wafers per hour. It is able to precisely process a range of wafer sizes, from 75mm to 300mm, and is capable of performing a wide variety of in-situ diagnostics, quality assurance testing, and electrical characterization in a single reactor chamber. The system provides an industry-leading level of process control and uniformity, with features such as automated dose control, chamber cycling, results reporting, parametric optimization, and fault detection and prevention. P 5000-MARK II also features an advanced replaceable pedestal designed for quick process maintenance and tool-changing. Its wafer cassettes and high-performance gas delivery unit ensure consistent process repeatability and uniformity. An integrated vacuum machine with multiple vacuum pumps and exhaust ports offer reliable operation and minimize any process leakage. APPLIED MATERIALS P 5000 MARK II is designed specifically for the fabrication of advanced semiconductor materials, including silicon carbide, gallium nitride, copper indium gallium diselenide, and more. It is capable of performing a range of deposition processes, including radial-plasma, sputtering, light exposure, and atomic layer deposition (ALD). Its HMI software provides graphical monitoring and trend analysis of all chamber parameters, as well as full-spray analysis and optimization. P 5000 MARK II is the perfect choice for a reliable, high-throughput process reactor with the highest level of precision and flexibility. With its sophisticated and integrated HMI, it offers a cost-effective solution for meeting the most exacting production requirements. Its reliable, consistent and automated process repeatability ensure highest yields, quality, and throughput.

There are no reviews yet