Used APPLIED MATERIALS P 5000 #163402 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 163402

Wafer Size: 8"

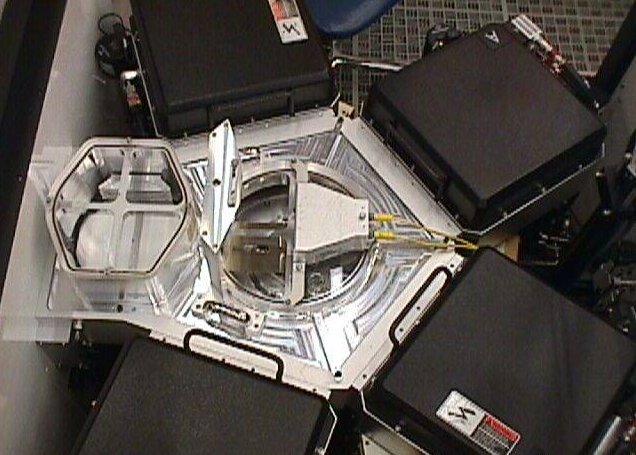

PECVD system, 8"

Configuration: (4) CVD chambers

Process gases: Silane, Ammonia, Nitrous Oxide, Nitrogen Trifluoride

Precision 5000 Mark II Mainframe

Precision 5000 Software Version 5.03 (Year 2000 Compliant)

SECS Communication Port

Laminar flow mini-environment behind input/output window

Mark II ZA (zero adjust) actuators and gates for process chambers

Process chamber configured for ceramic chuck operation

15 slot storage elevator for faster run rates

eDOC remote system for combustion of un-reacted silane

Nitride thin film configured (no hotbox)

Heat exchanger

Remote frame with remote AC power box

(1) High frequency RF generator per chamber on remote frame

(4) BOC-Edwards iQDP40/iQMB250 pumps/blowers for dep chambers

BOC-Edwards iQDP80 pump for loadlock

Ergonomic Cassette Load/Unload

Excursion Prevention (EP) software ready

Currently crated.

APPLIED MATERIALS P 5000 is a specialized chemical vapor deposition (CVD) reactor that is used for the commercial production of electronic and semiconductor materials. Specifically, APPLIED MATERIALS P5000 is used for fabrication of polycrystalline silicon, polysilicon TFT (Thin Film Transistor), polysilicon gate and poly-SiON (polysilicon Oxide Nitride) materials. This multipurpose system works by decomposing chemical precursors in a vacuum chamber to form a film or layer of material on a substrate. This deposition process is known as chemical vapor deposition and it requires high temperatures and precise pressure control. P-5000 reactor provides the high levels of control and precision that are necessary for reliable and efficient production operations. Its advanced design includes a separate dispense chamber, where the precursor feedstocks, reactants, and inert gases are loaded, and a reaction chamber where the deposition takes place. P 5000 reactor also features a wide range of process parameters such as temperature, pressure, and oxygen flow rates, which can all be adjusted to ensure a consistent and uniform film deposition. At the heart of APPLIED MATERIALS P-5000 reactor is its high-powered heating system, which allows for a range of process temperatures between 400°C and 960°C. This helps to reduce the complexity of the deposition process and maintain a consistent layer of film on the substrate. P5000 reactor also features an ultra-precise wafer reaction chamber and optional fan-assisted cooling to further improve the efficiency and product quality of the deposition process. APPLIED MATERIALS P 5000 reactor systems are typically equipped with advanced automation and control systems, with safety features to protect personnel and equipment, and with off-line monitoring systems to ensure compliance with product specifications. In addition, the reactors feature corrosion-resistant components and protective coatings used to reduce maintenance requirements. Overall, APPLIED MATERIALS P5000 reactor offers a reliable, efficient and cost-effective solution for CVD processes used to create electronic and semiconductor materials. It's advanced design, precision capabilities and intelligent control systems make it an excellent choice for commercial production.

There are no reviews yet