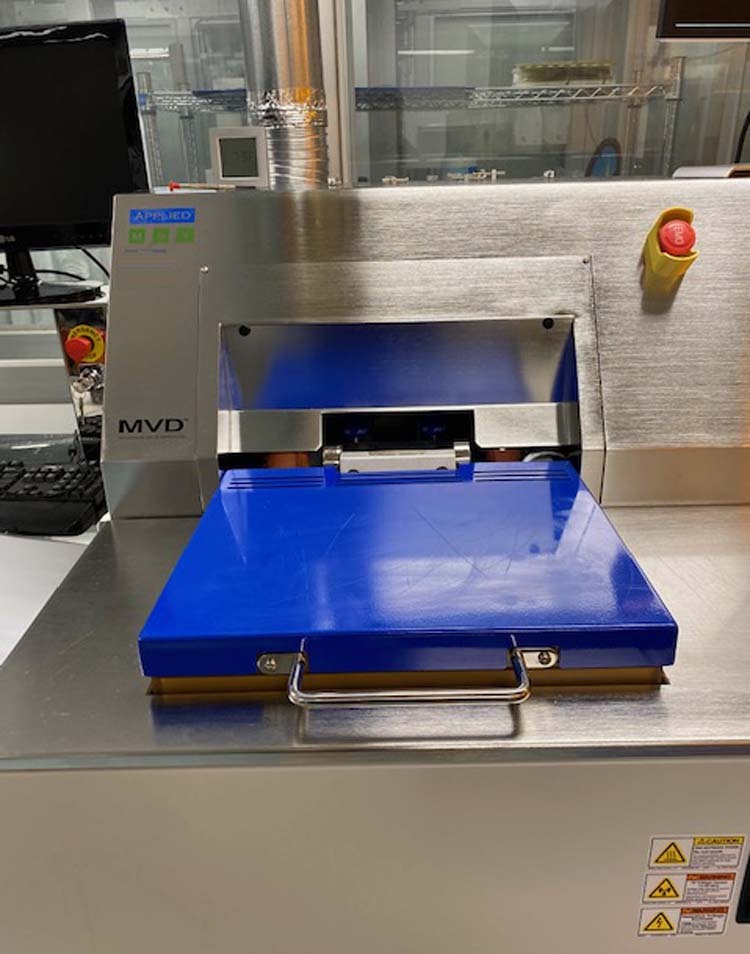

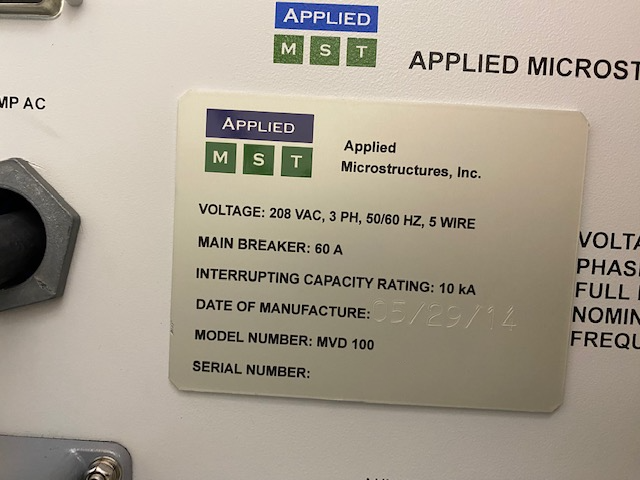

Used APPLIED MICROSTRUCTURES MVD 100 #293647151 for sale

URL successfully copied!

Tap to zoom

ID: 293647151

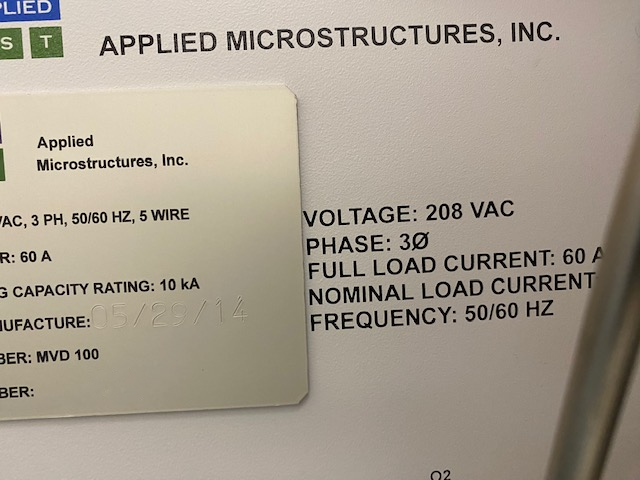

Vintage: 2014

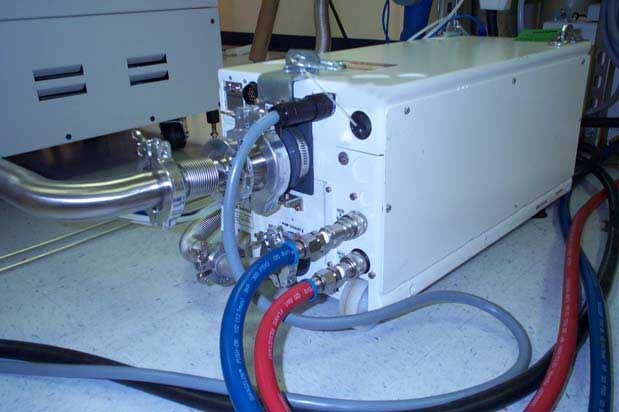

Molecular Vapor Deposition (MVD) system

Vacuum:

Pumping speed: ≥100 m³/h

Base pressure: ≤10 mTorr

Storage:

Humidity: 25 to 85% (Non - condensing)

Temperature: 5 to 70°C (41 to 158°F)

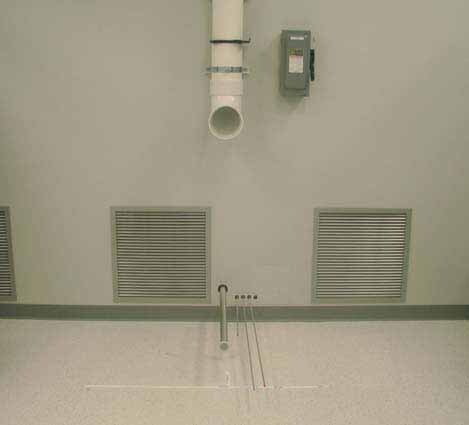

Exhust flow:

System exhaust: 200 CFM

Gas panel louvers: 200 CFM

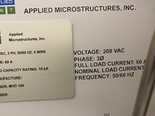

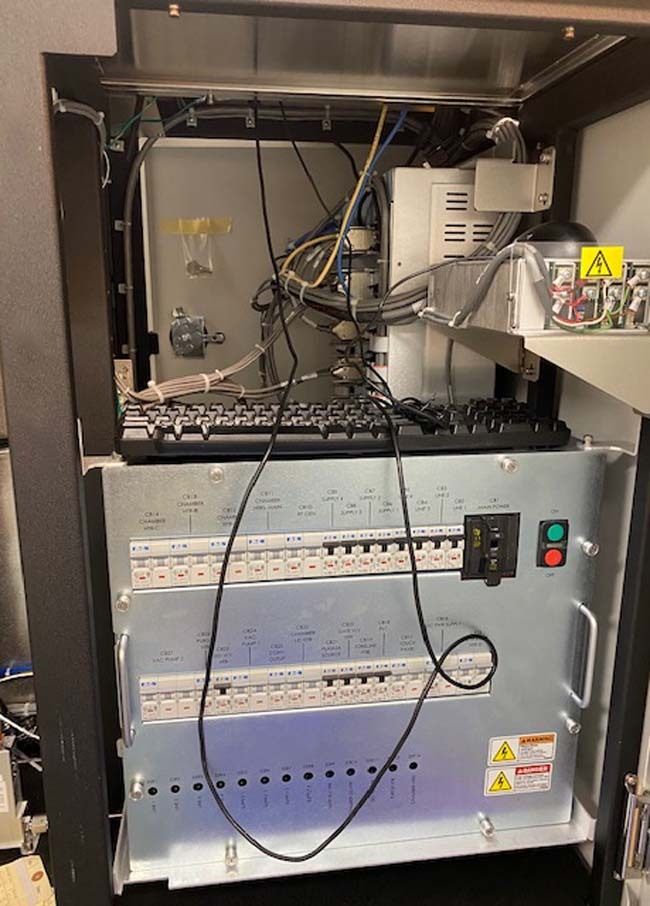

Power supply:

Voltage: 208 VAC, ±10%, 3Φ, 5 Wire-Y (Ground + netural)

Current: 60 Amps

Full load:

58 Amps (Maximum)

46 Amps (Nominal)

CB1 Interrupter current: 10 K at 240 V

K1 Impuls withstand voltage: 8 kV

2014 vintage.

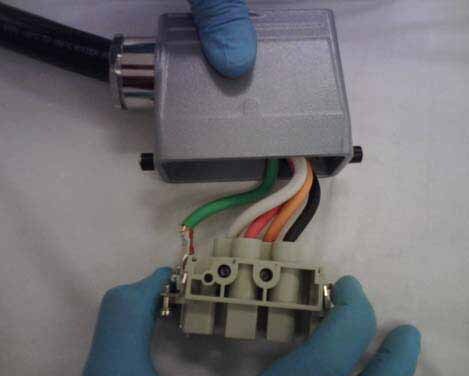

APPLIED MICROSTRUCTURES MVD 100 is a compact, ultra-high-vacuum (UHV) microwave-plasma-based thin film reactor designed to support a variety of industrial thin-film manufacturing processes. Its mission is to provide a cost-effective and reliable platform for the deposition of thin films in a variety of compositions and thicknesses. This reactor is fitted with a dual frequency equipment that operates in either 2.45 or 5.8 GHz frequency bands, providing the operator with the ability to switch between depositions depending on the desired film material. Its stainless steel construction coupled with an rugged aluminum chamber make it a robust system capable of withstanding long-term production-level maintenance cycles. MVD 100 utilizes an innovative, high energy dry vacuum unit to capture extremely small residual particles and to ensure a film-free vacuum environment before deposition begins. This machine uses a combination of direct-drive turbo pumps, chemical pumps, and oil-free compressed air pumps to achieve a base pressure of 10-8 Torr, with the option of reaching 6 x 10-9 Torr. The innovative plasma delivery tool employed by APPLIED MICROSTRUCTURES MVD 100 is designed to ensure maximum plasma uniformity and minimal contamination of the substrate materials. It is capable of creating a plasma environment with a range of densities and plasma species. The asset can be adjusted for specific requirements of either reactive or non-reactive processes. The design of MVD 100 further ensures a cost effective solution for preventive maintenance. Its modular design allows quick and easy access to all its components, including the power supply, plasma control, packaging and transport, as well as other external connections. Additionally, its built in safety features include a safety interlock model, which immediately power-down the plasma when unexpected pressure fluctuations are detected. APPLIED MICROSTRUCTURES MVD 100 is an essential tool for the manufacturing of thin films, such as those used in microelectronics, optical coating, and flat panel display technologies. Its performance and cost benefits make it a viable candidate for many industrial thin-film manufacturing processes.

There are no reviews yet