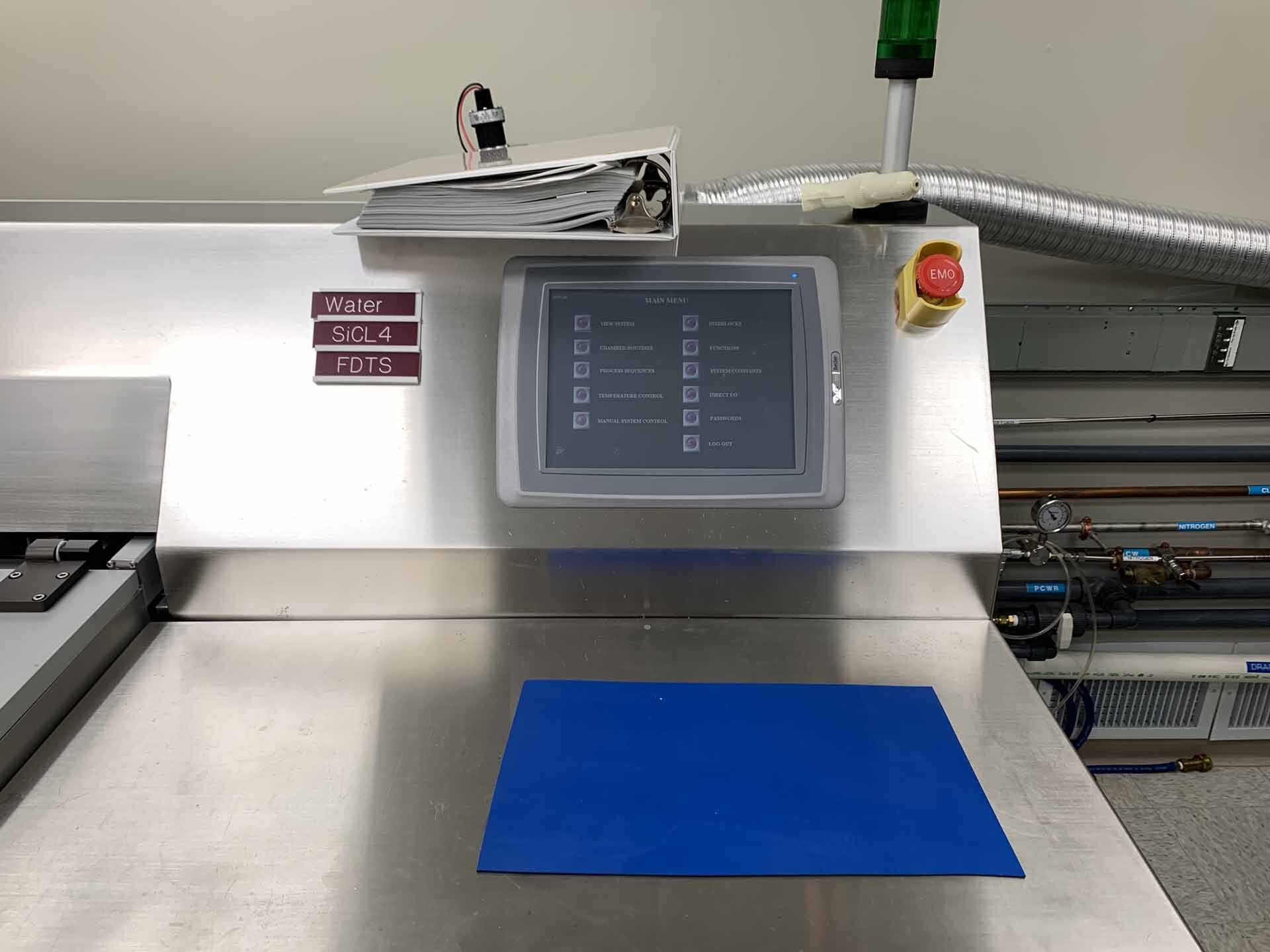

Used APPLIED MICROSTRUCTURES MVD 100 #9412587 for sale

URL successfully copied!

Tap to zoom

ID: 9412587

Molecular Vapor Deposition (MVD) system

Capacitance manometer

(2) Precursor cylinders

(3) Vapor delivery lines

Vented gas cabinet

Gases: N2, O2, CDA

Exhaust (200 cfm): Ventilation duct, 6"

Chamber

Vacuum pump with interface

External interface

Manual loading

Power supply: 208V, 50A.

APPLIED MICROSTRUCTURES MVD 100 is a reactor that is used in a variety of research applications to study the behaviours of materials at the micro level. It is equipped with an up-scalable vacuum-based design, and an automated high-temperature and high-pressure operation, allowing advanced microstructure formation and analysis. MVD 100 offers researchers with a combination of both a high-pressure and high-temperature environment, enabling them to monitor the reaction of materials under variable conditions. APPLIED MICROSTRUCTURES MVD 100 reactor utilizes a water-cooled non-magnetic vessel that is capable of withstanding up to 1,000 bar of pressure and temperatures up to 1,200°C. It is equipped with a vertically mounted viewport that enables a camera to monitor the reaction of materials during the experiment. MVD 100 includes multiple cooling channels in its pressure vessel that allow cooling to any selected temperature needed during experimentation. It also features an automated system for wet and dry sample processing, allowing for quick sample extraction and insertion. APPLIED MICROSTRUCTURES MVD 100 is suitable for studies requiring investigated samples to be in contact with other elements over extended periods of time. It is also used for the preparation of thin films in the construction of micro-devices, enabling the study of structure- property relationships and providing a range of geometries for different materials combinations. The reactor has a variable flow rate of up to 600 mL/min and is programmable for repeatable operation. MVD 100 is a versatile and reliable reactor that offers a wide range of capabilities for different research purposes. It is designed for maximum flexibility in the processing of samples of all sizes, shapes, and materials combinations. Its advanced features, such as its high pressure, temperature capacity, and automated processing make it an essential tool for researchers who need to create and study microstructures.

There are no reviews yet