Used ASM / ACCU-FAB Epitaxy / 1250 #156237 for sale

URL successfully copied!

Tap to zoom

ID: 156237

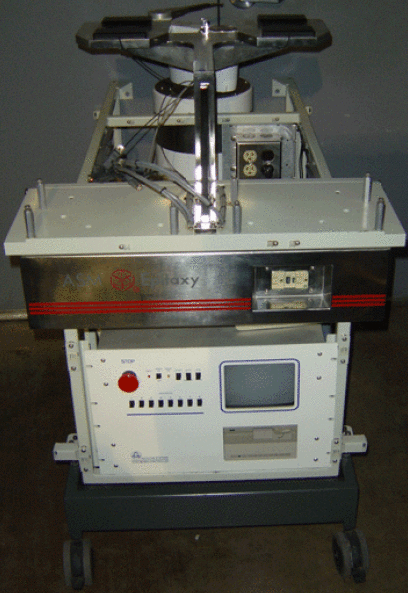

EPI reactor

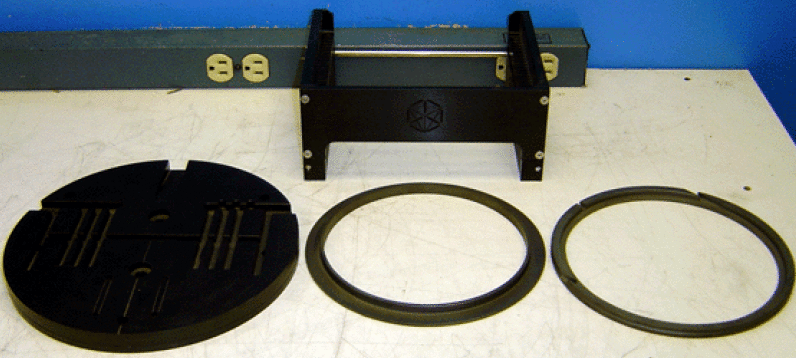

Includes:

ACCU-FAB 1250 max servo motion controller system:

Power: 115 VAC +/- 10%, 50/60 Hz, Single Phase, 1500 VA Max

EPI reactor loader

Built to interface EPI reactor with a Smith interface

(1) 8" cassette (up to 26 wafers)

ACCU-FAB 1250 servo controller:

19" rack mountable chassis

AT bus

Two RS-232 ports

64k non-volatile CMOS memory

(10) Relay outputs

(12) Optically isolated inputs

5.25 or optional 3.5 floppy disk drive, hard disk, and 1 MB RAM

Built-in CRT and keyboard

ACCU-FAB Accubot:

Compact, clean-room compatible

Four-axis SCARA style robot

Four independent joints, cassettes can be located side-by-side vs radially

Range of Motion:

Standard Axis 1 (Z): 9.25 Inches

Custom Axis 1 (Z): 9.3 to 30.0 Inches available

Axis 2: +/- 157

Axis 3: +/- 179

Axis 4: +/- 169

R1 (centerline A1 to centerline A2 = 15.0 inches to tool flange): 7.5 Inches

R2 (centerline A2 to centerline A3): 7.5 Inches

Repeatability: +/- .002 Inch

Weight: 86 Pounds (Does not include the entire item or Shipping I believe)

Maximum Speed:

Axis 1: 10 in. /sec.

Axis 2: 180 / sec.

Axis 3: 180 / sec.

Axis 4: 180 / sec.

Accelerations: 32 inch / sec^2, 540 / sec^2

Payload:

At maximum speed: 3 lbs.

At reduced speed: 6 lbs.

Allowable end effector moment of interia: .02 inch-pounds-sec^2.

ASM / ACCU-FAB Epitaxy / 1250 is a piece of process equipment used for epitaxy, which is a technique for growing layers of different materials over a single substrate surface. Specifically, ASM 1250 is a horizontal furnace designed for production of epitaxy layers on semi-conductor (Si, GaAs, InP) and optical substrates for a wide range of application. The 1250 is a multi-zone furnace composed of an insertable wafer canoe, oxidizer, loadlock, heater and a carrier gas in a quartz tube. The furnace is capable of processing up to 12" wafers and comes equipped with quartz tube diameter of 4" and a tube length of 30.5cm. This allows the 1250 to have greater temperature uniformity over the entire substrate surface and supports a higher process accuracy. It also allows the epitaxy substrate to receive a continuous flow of gases over a fixed temperature gradient. The 1250 includes a multi-zone control system which enables precise temperature control in crucial areas. This helps to enhance epitaxy uniformity and repeatability of the process parameters. In addition, the 1250 is outfitted with ancillary components such as flow controllers, pressure indicators, rotameters, mass flow controllers and bubbler controllers, among others. These components allow for precise and uniform dosing of gases and carrier flow into the epitaxy process. The 1250 also includes a servo-control platform and embedded microprocessor to facilitate remote monitoring of the epitaxy process. This ensures safe, accurate and repeatable operation of the process. Overall, ASM Epitaxy / 1250 reactor is a state-of-the-art process equipment for the production of epitaxy layers on semi-conductor and optical substrates. It is an ideal choice for producers of high-quality and reliable semiconductor devices. With its precise temperature control, low maintenance costs, and convenient remote monitoring capabilities, the 1250 can provide the epitaxy requirements for a broad range of applications.

There are no reviews yet