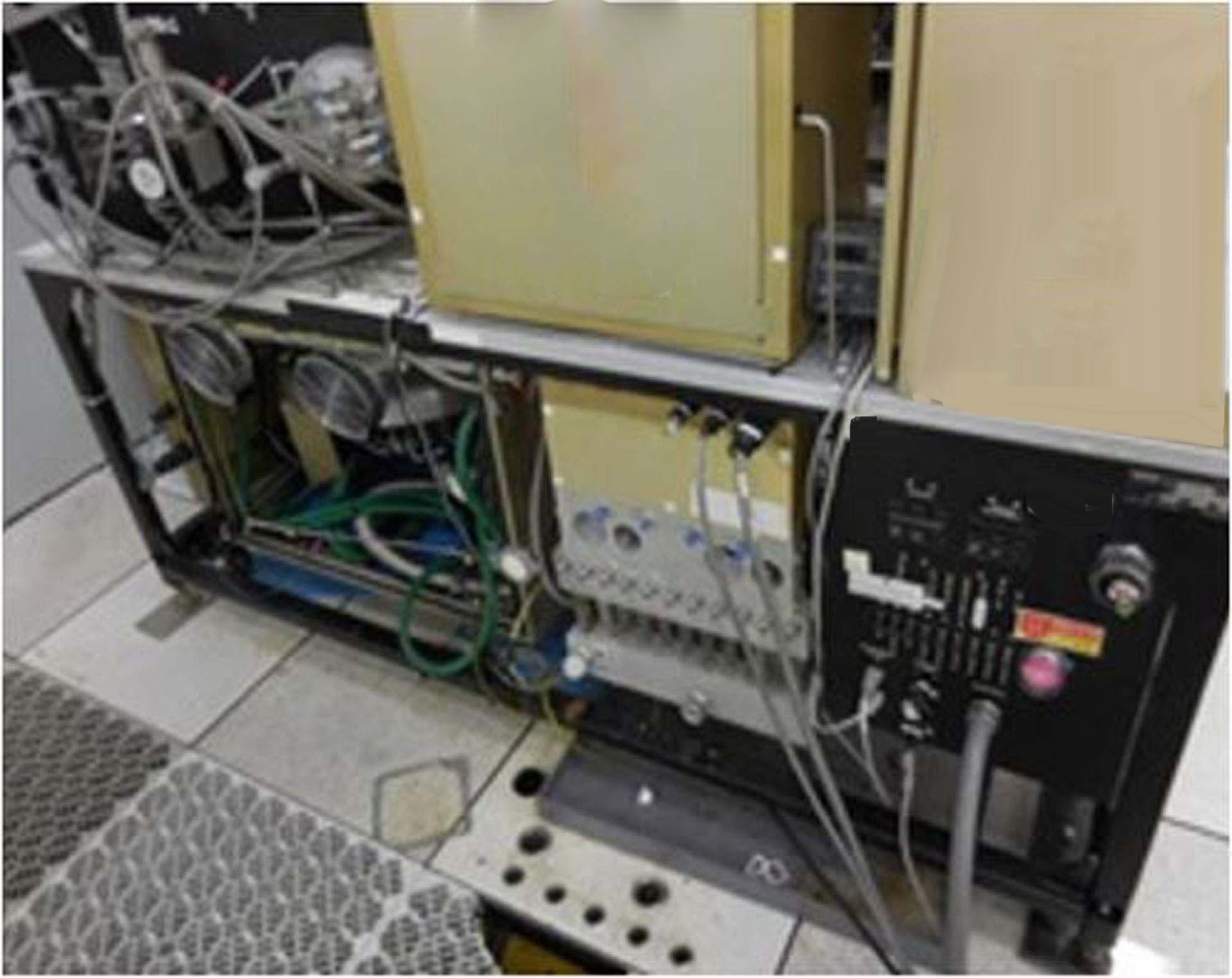

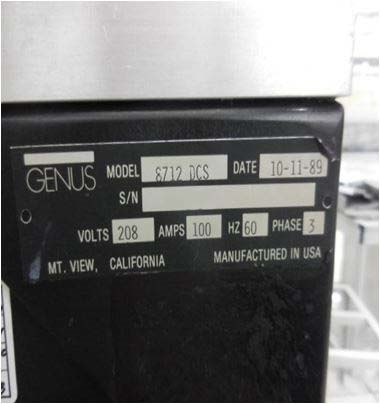

Used GENUS 8712 DCS #9203993 for sale

URL successfully copied!

Tap to zoom

ID: 9203993

Wafer Size: 6"

Vintage: 1989

LPCVD Systems, 6"

Process: Wsix

Robot

Main system

RF Generator

Freme box

Part box 1

Pump rack

NESLAB Chiller

Gas cabinet 1

Gas cabinet 2

Throttle valve: MKS

Computer

Heter controller

Temperature controller

Signal tower

Convectron gauge

Keyboard

Vacuum gauge

Gas line pipe

Cable

Gage:

Loader 1/2:

GRANVILLE PHILIPS / MKS

Transfer chamber: MKS / GRANVILLE PHILIPS

Utility specifications:

CDA (Air)

PN2

Vaccum

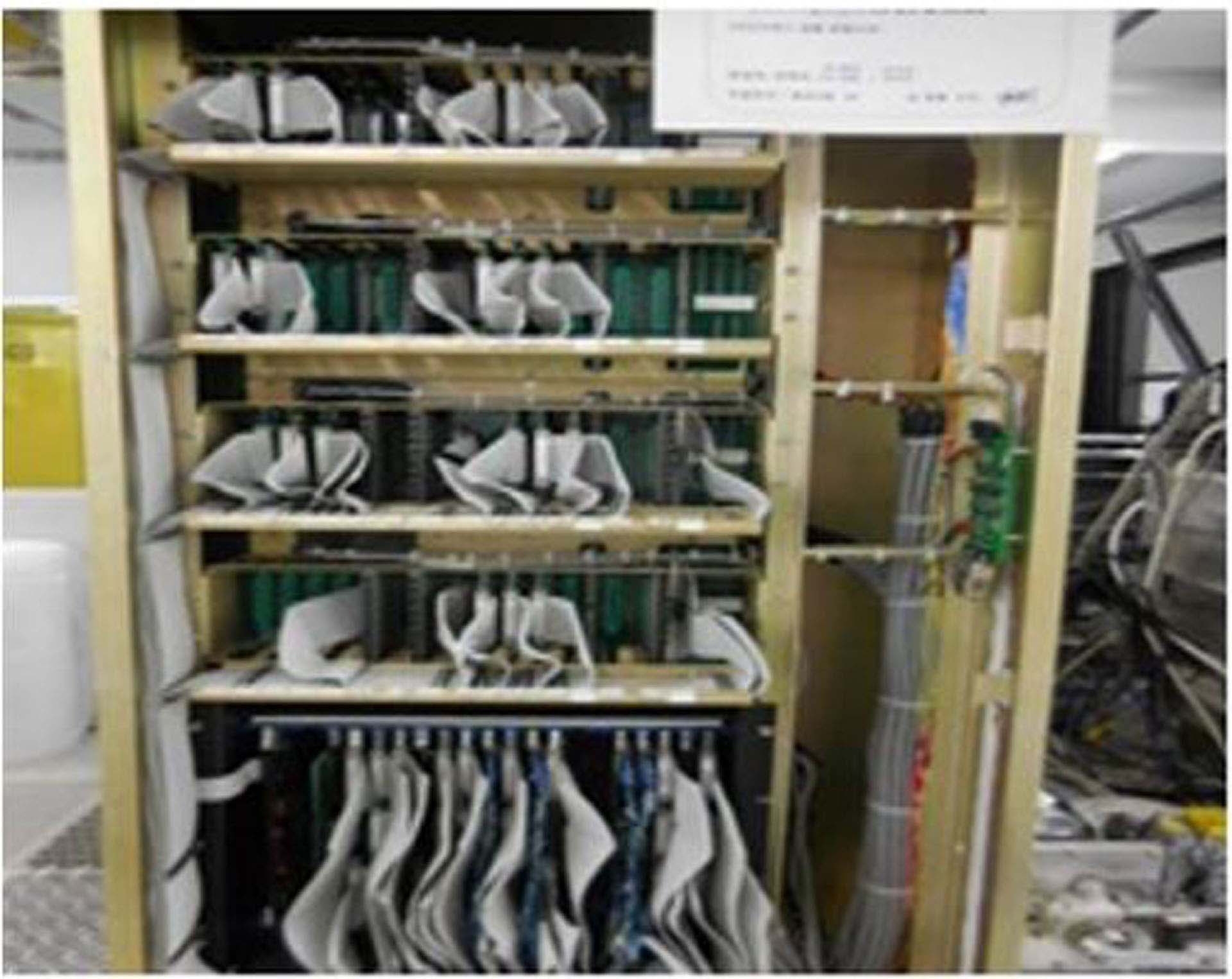

Sub module:

Gas cabinet: HANKUK ATTO SEC-Z512MGX

Dry pump 1: EDWARD QDP 80

Dry pump 2: EDWARD QDP 40

Buster pump: EDWARD

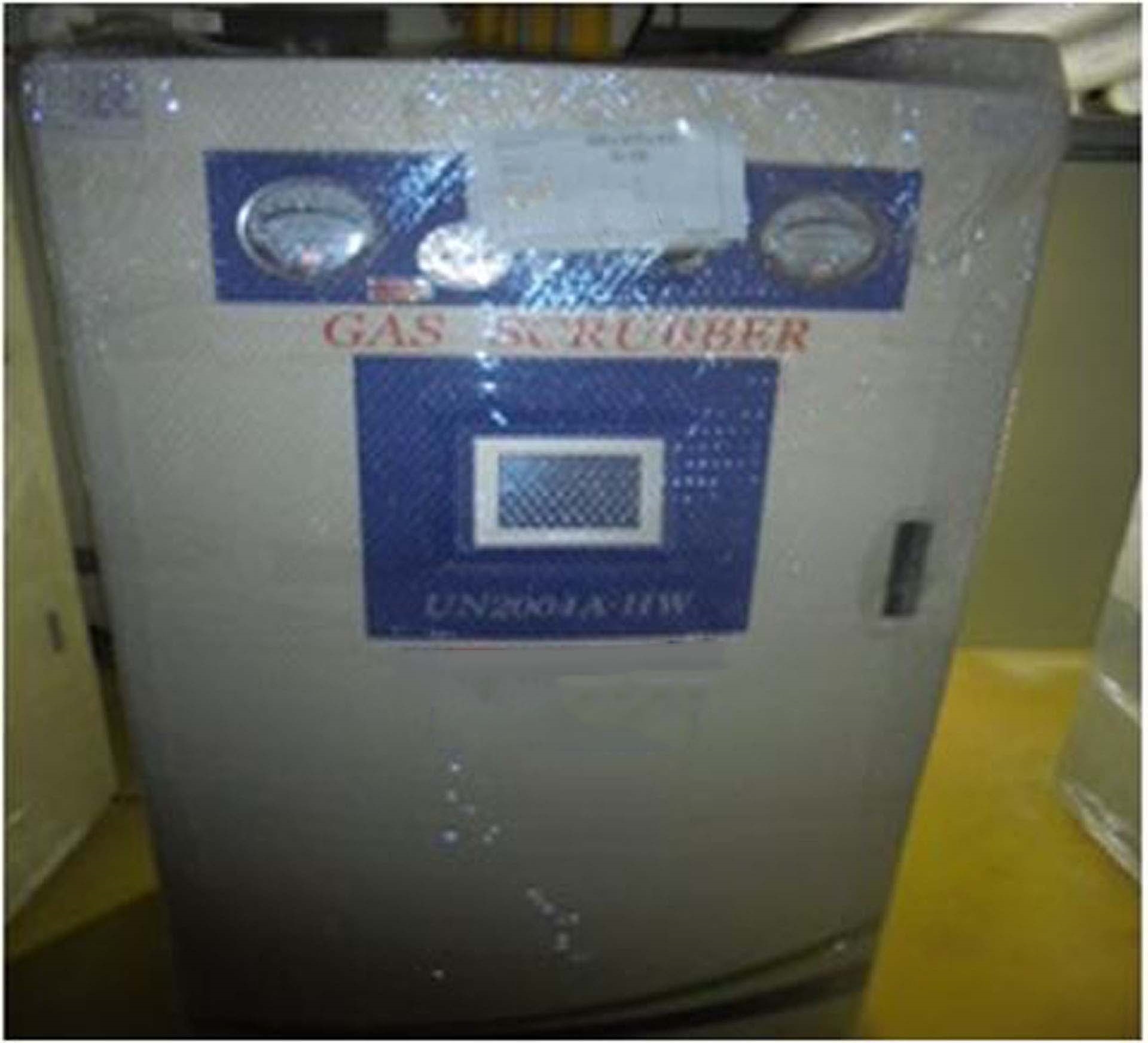

Gas scrubber 1: UNISEM UN200AA-HW

Gas scrubber 2: UNISEM UN200AA-HW

Gas flow control:

Unit Maker Model Range

O2 TAYLAN FC-261 10 SLM

N2 TAYLAN FC-260 6 SLM

N3 TAYLAN FC-261 7 SLM

N4 TAYLAN FC-262 8 SLM

N5 TAYLAN FC-263 9 SLM

N2 TAYLAN FC-260 20 SLM

Power: 208 VAC, 60 Hz, 3 Phase

1989 vintage.

GENUS 8712 DCS is a two-stage reactor equipment for industrial and specialty chemical production. This particular reactor offers a three-zone heating system that provides uniform heating of the reaction zone, reducing the risk of temperature related issues in the manufacturing process. The reactor design provides a larger boiling pot, so less refluxing is required and larger yields can be achieved. The jacketed design of the reactor, coupled with the circulation of the material inside the reactor prevents overheat and yield disruptions due to localized heat spots. 8712 DCS is a double-walled jacketed reactor with a coil-shaped combined baffle-magnetic separator with a power rating of up to 40kW. The temperature of the reactor is monitored and controlled with programmable logic controllers (PLC). This reactor utilizes a single variable speed combined speed motor along with overspeed as well as soft stop protection in order to ensure a safe and continuous operation. The central features of this reactor include a SS316L construct, which provides excellent strength and resistance to corrosion, a removable dry film coating, which prevents the reaction mix from sticking to or damaging the internal surfaces, a variable speed combined speed motor, which provides smooth operation and results in optimal yield and a double walled design, which provides uniform heating of the reaction mix. This reactor also features an overspeed as well as soft stops protection unit, which safeguards against high frequency operations and reduces wear and tear of sensitive instrumentation components. GENUS 8712 DCS reactor also offers an optimal balance between reactivity and selectivity, and can be used with a wide range of catalyst plates and materials, increasing the variety of reactions that can be undertaken. It also offers speed control, which allows for efficient control of reaction rate and reactant feed rate. The machine is designed to reduce labor costs and man-power requirements of production process, achieving enhanced safety, efficiency and productivity. Overall, 8712 DCS reactor offers superior performance, increased yield and consistent quality of products with a wide range of capabilities for industrial and specialty product production.

There are no reviews yet