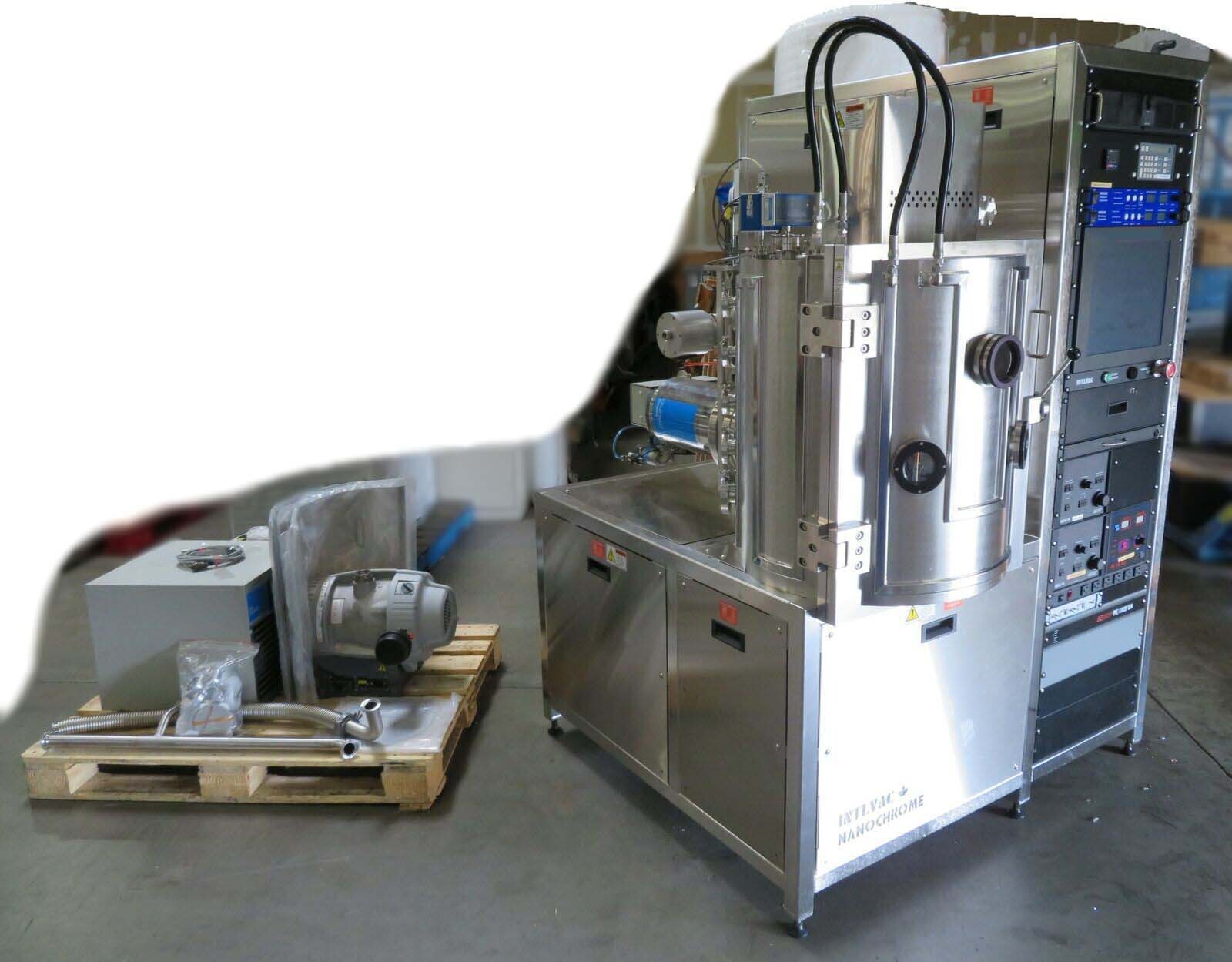

Used INTLVAC Nanochrome #9361948 for sale

URL successfully copied!

Tap to zoom

ID: 9361948

Wafer Size: 4"-6"

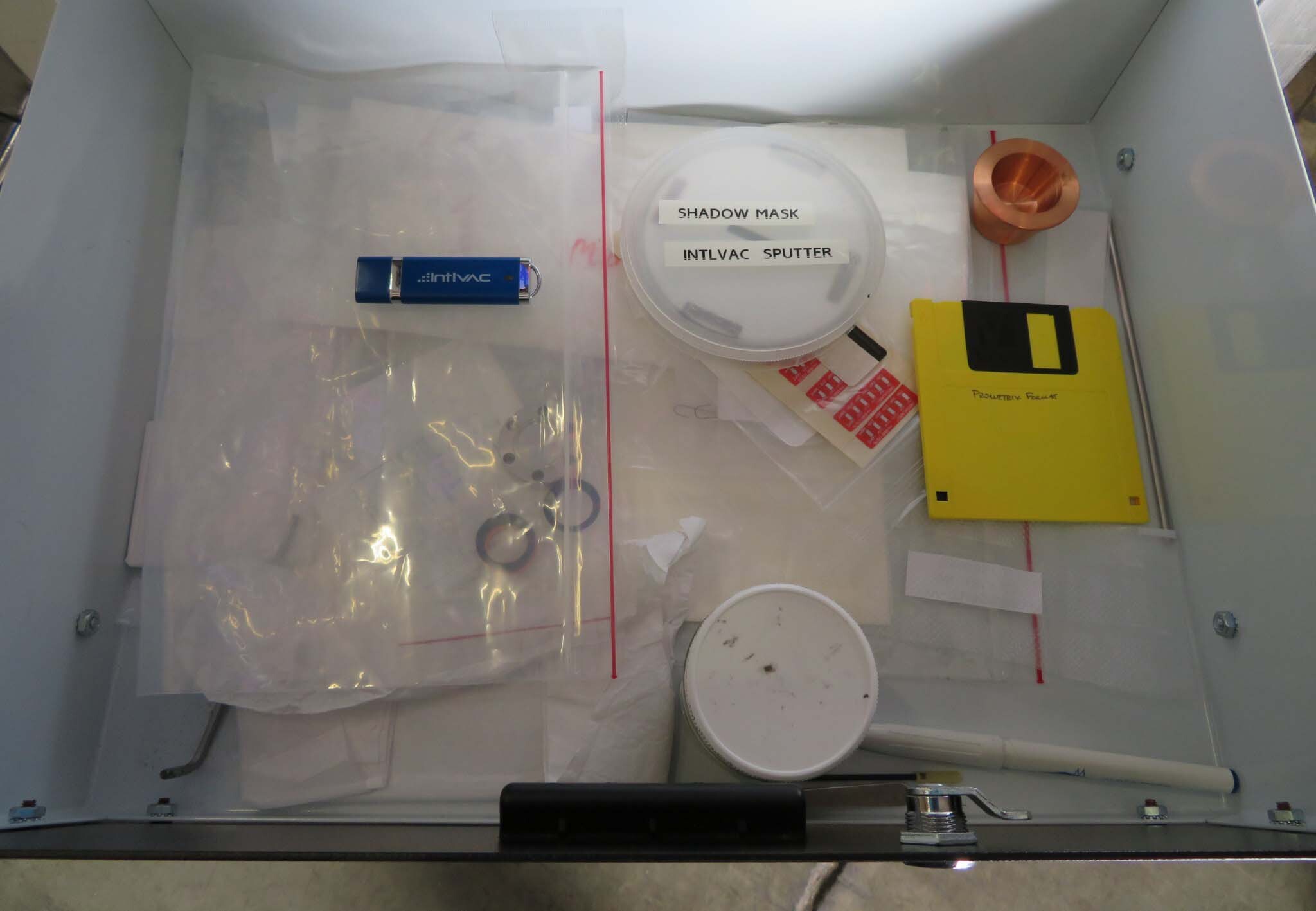

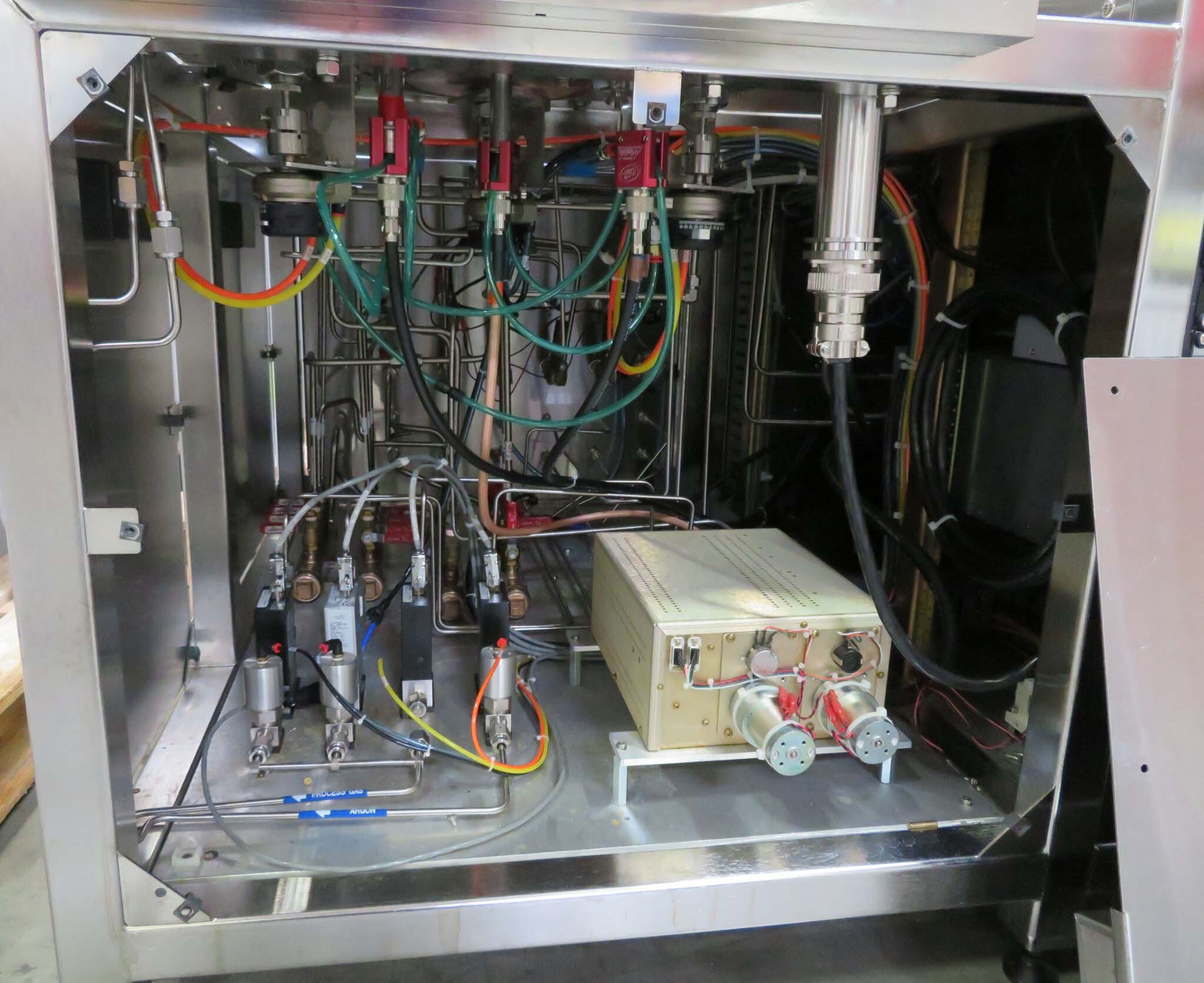

Thin film deposition sputtering system, 4"-6", parts system

Part number: NCI-2AC-DC-RF-EH

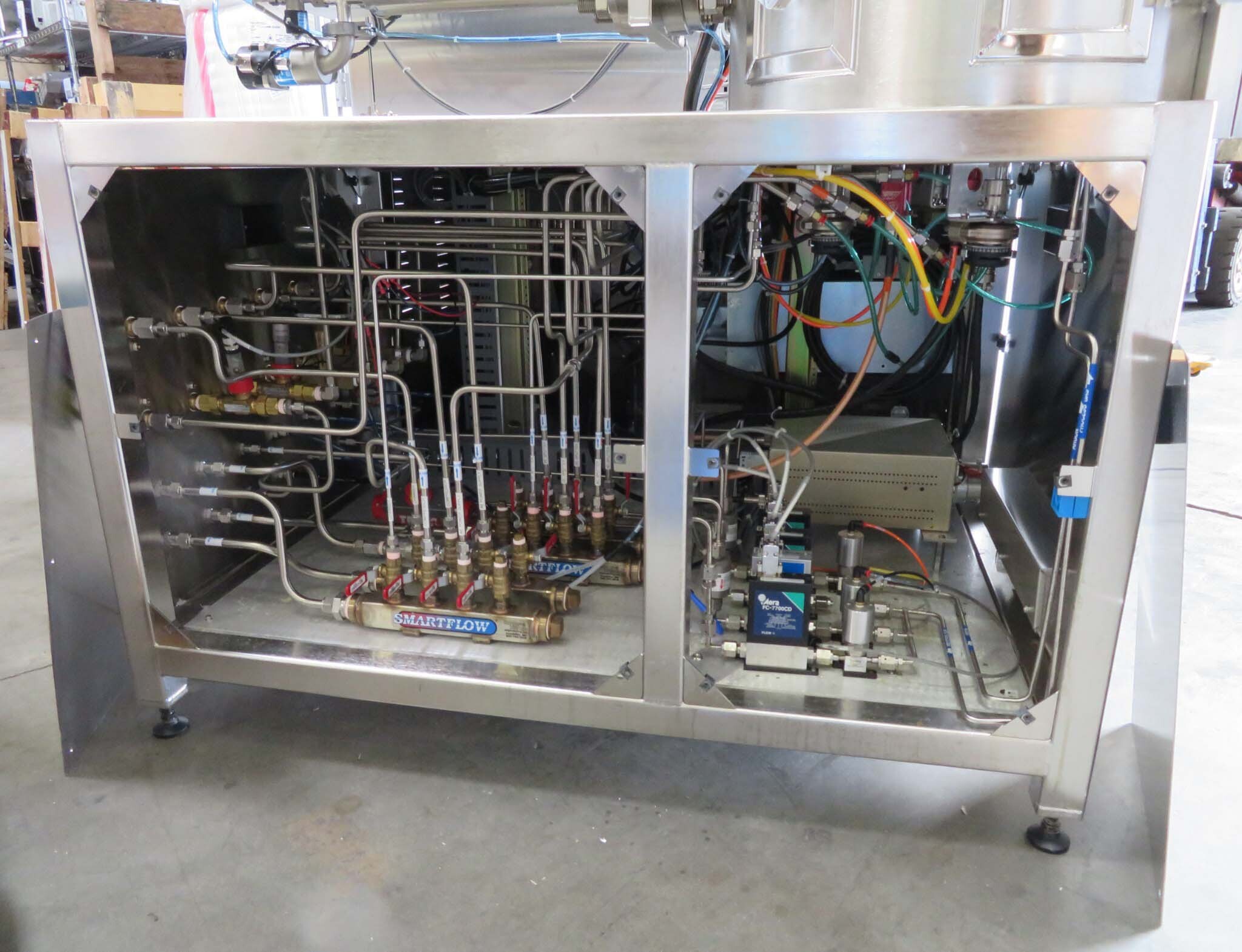

CTI On-Board 8R CP cryo pump with FastRegen controller

8200 Compressor with hoses

(2) ADVANCED ENERGY MDX-1K Power supplies

ADVANCE ENERGY PEII 5K Power supply

RF VII and RF-6 RF Generator

HOPE INDUSTRIAL SYSTEMS HIS-Rl17-CTDE Touch panel display

(2) INTLVAC Filament controllers

EDWARDS XDS35iC Scroll vacuum pump

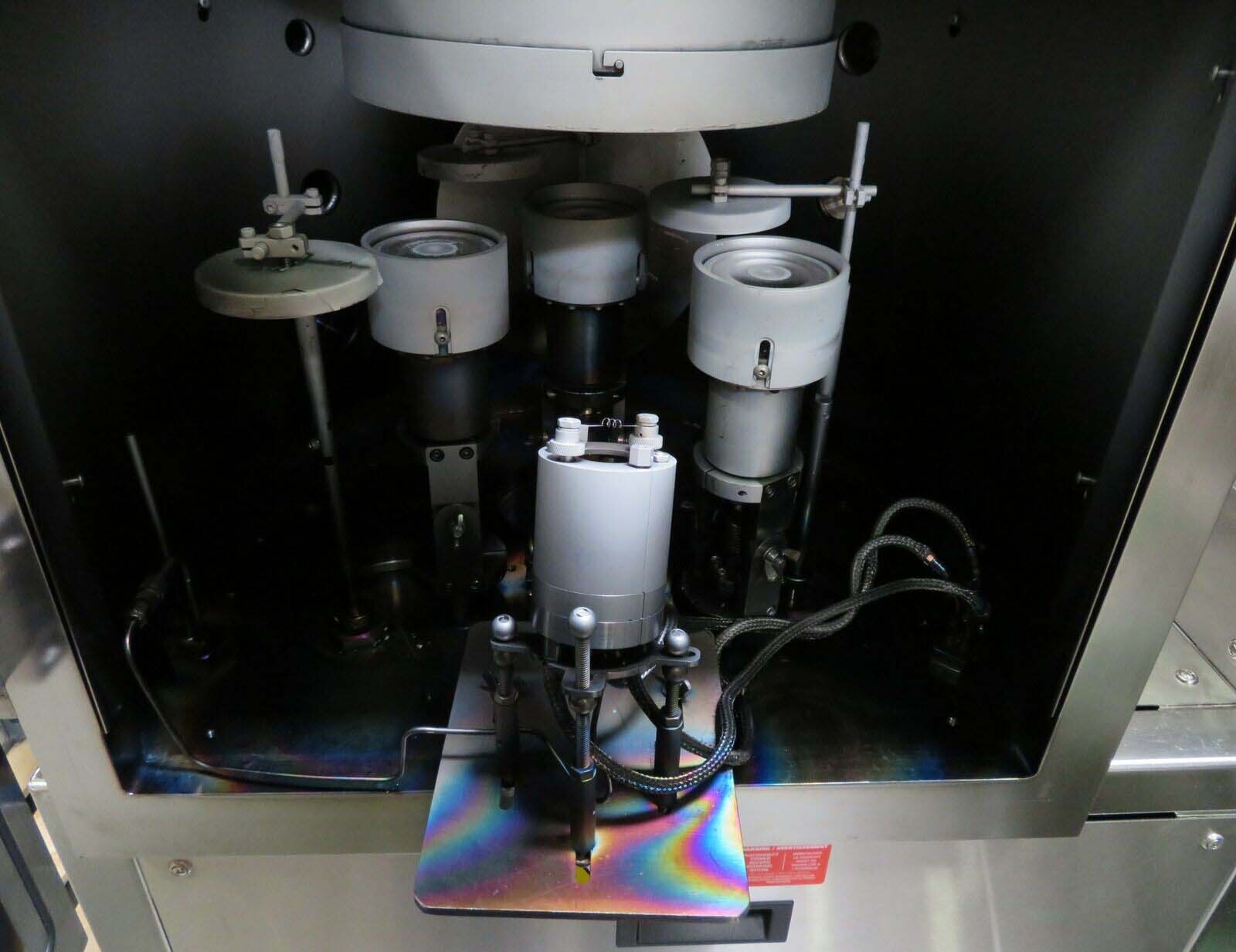

Chamber with (4) sputtering targets.

INTLVAC Nanochrome is a compact, ultra-high vacuum (UHV) thermal evaporation reactor that provides a precise, efficient method of depositing thin films onto substrates. It utilizes microwave energy to vaporize materials, allowing for deposition of thin films with uniform thickness and excellent homogeneity. Nanochrome is designed for applications requiring high-temperature processing. It can be used to deposit pure metals and alloys, semiconductors such as silicon, insulators, and oxides such as SiO2. INTLVAC Nanochrome consists of a cylindrical vacuum chamber, mounted on a motorized three-axis manipulator. The vacuum chamber is filled with an inert gas such as argon or nitrogen, and has a pump attached for evacuating the chamber and maintaining a UHV pressure. The evaporation source and substrate holder are located inside the vacuum chamber and are mounted on the manipulator. The evaporation source is typically made from a graphite boats and can hold the materials to be deposited. The substrate holder, with the substrate placed on top, is mounted to the manipulator, allowing for precise positioning of the substrate. Nanochrome features a microwave generator, coupled to the evaporation source for rapid material processing. The generator entrains the material and creates plasma forms which can then be directed onto the substrate. The generator is coupled with low ESR capacitors to ensure efficient and precise processing. INTLVAC Nanochrome also incorporates numerous safeguards, such as arcing and overheating protection, to ensure safe operation. Additionally, the vacuum pump is equipped with oil-free diaphragm pumps and a gas ballast valve to ensure a clean and efficient operation. Nanochrome provides a fast and efficient method of depositing thin film materials onto substrates, offering producers a reliable and cost-effective solution for their needs. It can be used for a variety of applications, including solar cell production, optical coatings, metallizing, and nanofabrication. INTLVAC Nanochrome is a robust and reliable system that is designed to maximize efficiency and reduce production costs.

There are no reviews yet