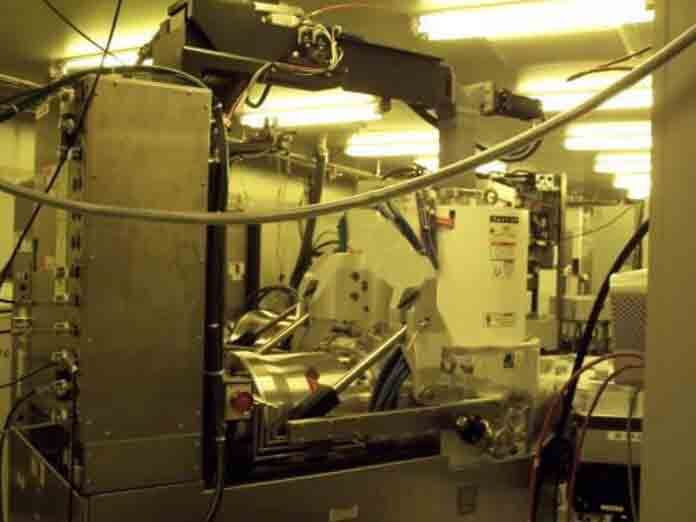

Used LAM RESEARCH DSM 9900 #293587928 for sale

URL successfully copied!

Tap to zoom

ID: 293587928

Wafer Size: 8"

ECR CVD Silicon oxide system, 8"

(2) Process chamber modules

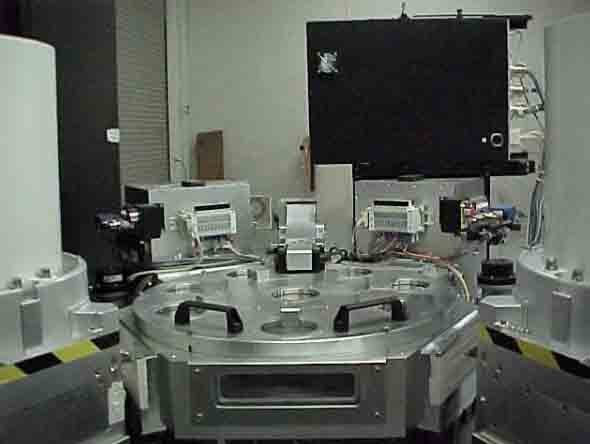

Heating chuck, 8"

BROOKS AUTOMATION Cluster handling system

Supports microwave plasma

With electromagnetic field (ECR Mode)

Gases: Argon, Oxygen, Silane

NF3 For in-situ cleans

RHcP Microwave guide upgrade

Control module

With monitor

BROOKS AUTOMATION Vacuum transfer module

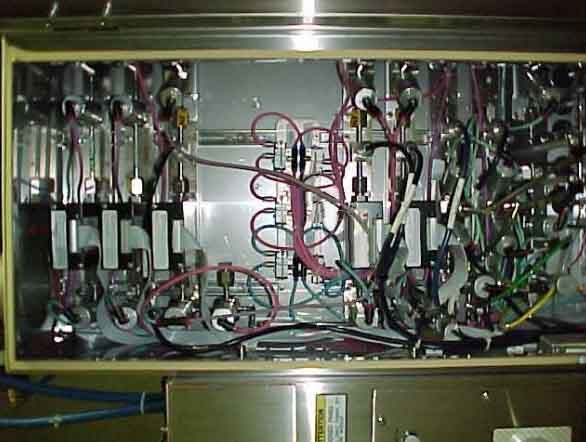

Main power box

(2) Power control deck

With ASTEX 2050 Microwave power

LAM 2080 TCU Chiller / Heat exchanger

ALCATEL ADS 501 Dry pumps.

LAM RESEARCH DSM 9900 is an advanced plasma etch reactor used for processing various materials such as silicon, polyimide, glass, and even certain metals. The unit is constructed using top quality components and manufacturing techniques to ensure high plasma generating capabilities and repeatable, reliable operation. With its unique chemistry capabilities, LAM RESEARCH 9900 is capable of etching a wide range of structures with architecture and micro-topography. LAM RESEARCH 9900 is a 'source-drain' type of proportional etch reactor, utilizing secure closed-loop control systems and cryogenic cooling to allow efficient, high-speed plasma etching of all materials. The unit is designed to run in either low or high frequency modes, providing flexibility and precision during the etching process. The power supply, reactor chamber, and process components such as inert gases, etch species, and dopants are all controlled and optimized independently to ensure accurate and repeatable processing. DSM 9900 reactor is a versatile etching equipment that allows the processing of different substrates and materials with a wide range of geometries. The system incorporates sophisticated gas control, ceramic pumping ports, and monolithic wafer handling components to provide the highest level of stability and uniformity. The unit also offers an advanced monitoring machine with automatic diagnostics, which ensures optimal results. LAM RESEARCH DSM 9900 reactor was developed for customers that require the highest level of yield and throughput for hard materials such as silicon, copper, and even gold. This industrial-grade tool provides complete control and monitoring of all process variables, ensuring the highest yield and accuracy. The asset's wide range of available functions and multiple operating modes make it the ideal solution for any etching application, from basic to complex. Additionally, the model is compatible with a variety of peripheral equipment and can be integrated into a larger process line.

There are no reviews yet