Used MATTSON EpiPro 3000 #9003702 for sale

URL successfully copied!

Tap to zoom

ID: 9003702

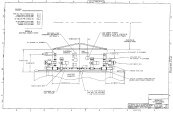

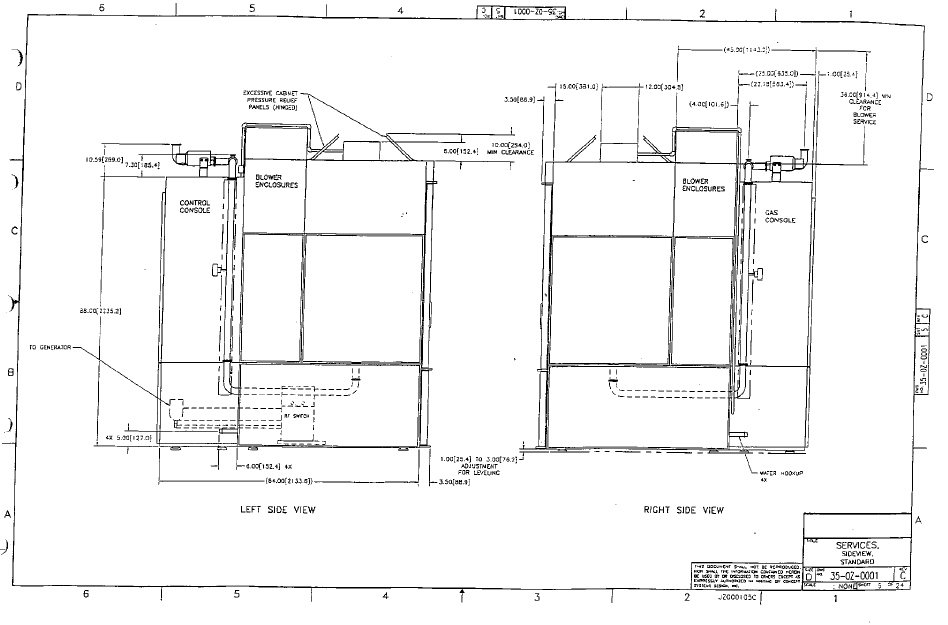

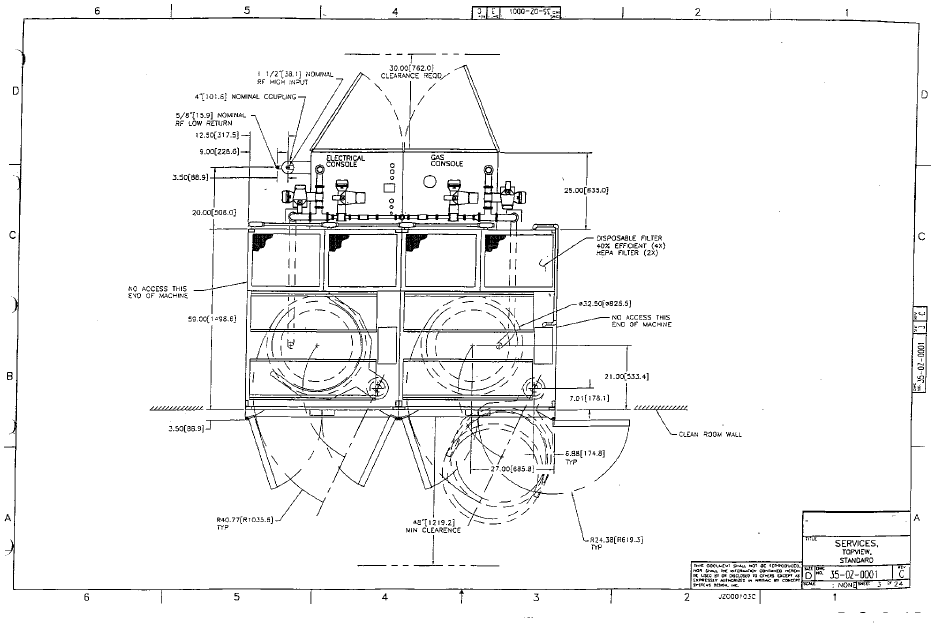

Reactors

Dual station

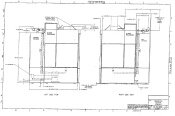

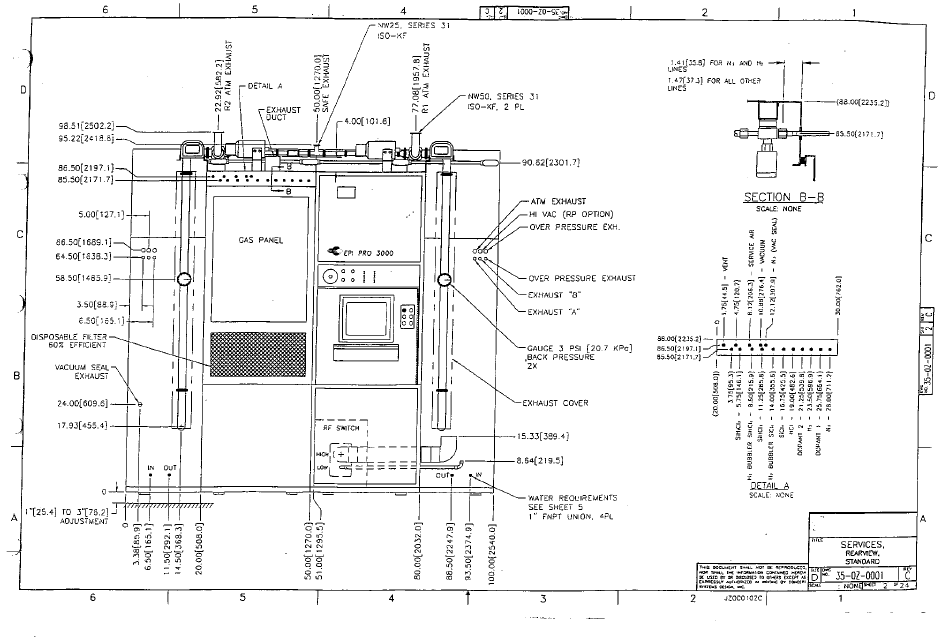

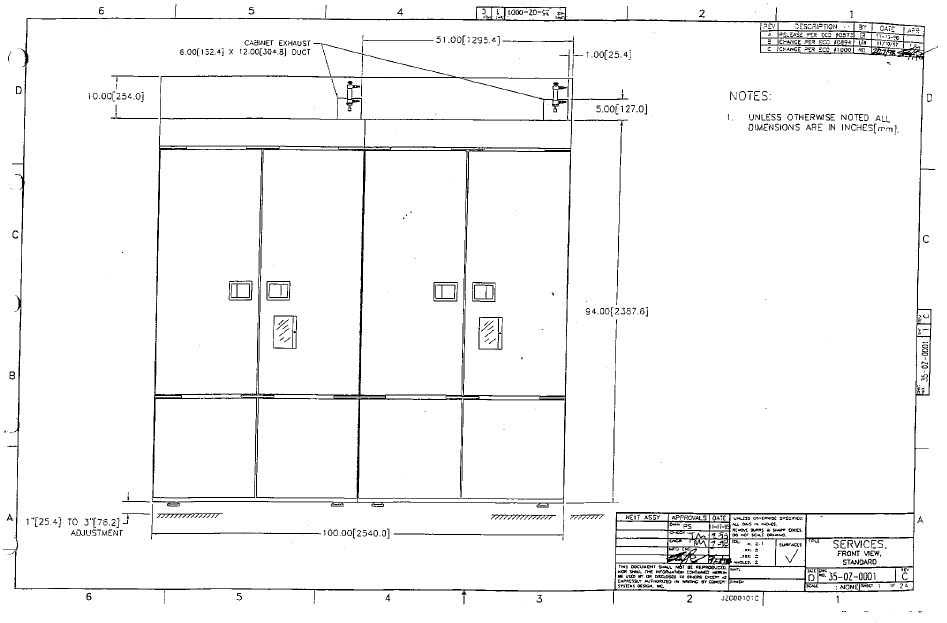

Chamber: 94" x 50" x 62"

R2 Reactor chamber: 94" x 50" x 62"

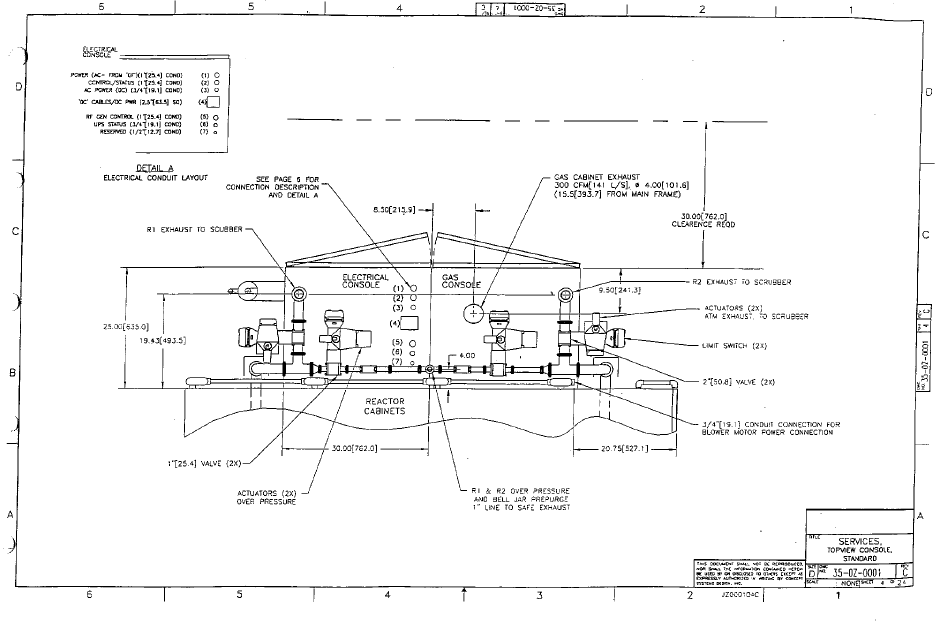

Electrical console

AC Power module

Remote interface module

UPS Module

Pillar vacuum tube oscillator RF generators, 125 kW

Generator pump module: (Pillar only)

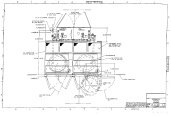

(2) Bell jars

RF Coils assy and quartz

Heat exchanger: Water to water

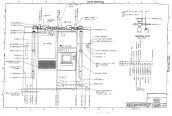

Gas inlet requirements:

Gas / Inlet pressure / Tubing diameter x wall thickness

N2 / 50-100 PSIG (1) / 3/8" x 0.035"

H2 / 50-80 PSIG (2) / 3/8" x 0.035"

HCL / 15 PSIG Regulated (3) / 1/4" x 0.035"

Dopants / 35 PSIG Regulated / 1/4" x 0.035"

SiCl4 / 20 PSIG Regulated / 3/8" x 0.035"

SiHCl3 / 20 PSIG Regulated / 3/8" x 0.035"

SiH2Cl2 / 7 PSIG Minimum / 3/8" x 0.035"

Pneumatic Air/N2 / 90-100 PSIG Regulated / 3/8" x 0.035"

N2 (Vacuum seal) / 80-100 PSIG (3) / 1/4" x 0.035"(1)

Gas purity:

H2: Greater than 99.95% minimum assay

Oxygen content must be less than 2 ppm

Water content must be less than 2 ppm

HCl: Greater than 99.99% (semiconductor grade)

Silicon sources – Greater than 100 ohm/cm intrinsic

Dopants: Greater than 99.99% H2 free basis

Maximum gas flows and volumes:

System / H2 / N2 / H2 / N2

Mainstream / 300 / 70 (2) / 300 / 70

High flow bypass (Fixed) / 200 / 100 (1) / 200 / 100 (1)

SiCl4 / SiHCl3 Carrier / 30 / - / - / -

Dopants dilution / 30 / - / - / -

RF Coil / Lower reactor purges / 30 / 10 / 30 / 10

Gas panel purges (Fixed) / 12 / 4 / - / -

Rotation purges (Fixed) / 10 / 2 / 10 / 2

Total N2/H2 flows / 612 / 186 / 540 / 182 (1) N2 flow rate during pre-post purge

Quartz cleaning facility:

Pedestal / 30-0R-281 / 4 1/2" diameter x 12" long

Support rod / 30-0R-139 / 1" diameter x 5" long

Coil cover / 30-0Z-000 / 25" diameter x 2" thick

Insulator, high Side / 30-0Z-857 / 3" diameter x 6" long

Insulator, bottom / 30-0Z-766 / 4 1/2" diameter x 1/4" thick

Insulator, top / 30-0Z-791 / 4 1/2" diameter x 1/4" thick

Insulator, high side / 30-0Z-793 / 5" x 4"

Insulator, middle / 30-0Z-794 / 5" x 4"

Inject tube / 30-0Z-758 / 1/2" diameter x 11" long

Tube cover / 30-0Z-1037 / 1/2" diameter x 9" long

Rod, fiber optic / 30-0Z-1037 / 1/4" diameter x 13"

Power requirements:

RF Generator: 480 VAC, 400 A, 3-Phase, +GND

Water system: 480 VAC, 30 A, 3-Phase, +GND

Electrical service: 10 KVA at 200-240 VAC, 50 amps, 50/60 Hz, single phase, 3 wire (6 ga) plus ground.

MATTSON EpiPro 3000 is an advanced semiconductor deposition reactor designed for large-area epitaxy and deposition. This reactor offers reliable production with reduced cost of ownership. It features high-temperature and high-precision operation for up to 500 mm wafers, providing repeatable process uniformity at a highly reduced cost of ownership. EpiPro 3000 utilizes advanced designs and features to ensure repeatability and accuracy in each semiconductor deposition process. It features a low-vibration collisionless gas source allowing for truly uniform processing results. The wafer stage is driven by an ultra-precise motion control equipment that offers maximum stability and repeatability. The high-temperature operation of this reactor is optimized through the use of high-efficient, metal-ceramics clad insulation. The patented enclosed electrode drive system eliminates the need for vibration and drift compensation and ensures precise electrode timing and utmost stability. MATTSON EpiPro 3000 offers a variety of performance-enhancing features, such as programmable recipe management, in-situ analysis and monitoring, and distributed networking. These features provide users with greater control and enhanced accuracy over each deposition process. The reactor's user-friendliness is further enhanced by its integrated control unit that requires minimal operator intervention. In addition, EpiPro 3000 provides a full suite of environmental protection features, such as gas purge and scrubber units. This ensures that the reactor meets regional safety standards. The reactor is built with safety and reliability in mind and is equipped with an effective preventive maintenance machine to maximize uptime and process stability. MATTSON EpiPro 3000 is an advanced and high-performance deposition reactor that offers superior process repeatability and accuracy. Its low-cost of ownership and user-friendly design make it an ideal choice for a wide range of applications involving large-area semiconductor deposition processes.

There are no reviews yet