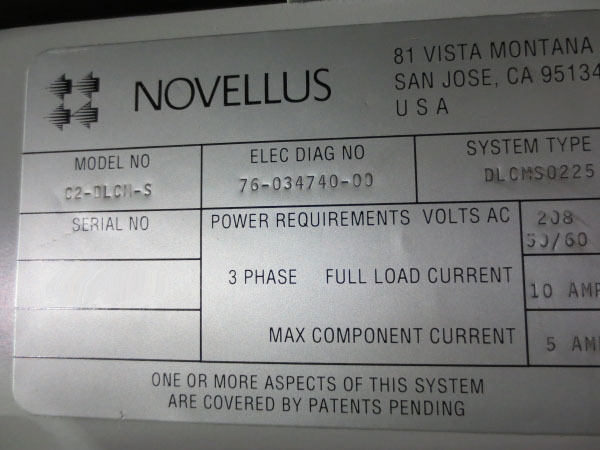

Used NOVELLUS CONCEPT 2 Altus #181297 for sale

URL successfully copied!

Tap to zoom

ID: 181297

Wafer Size: 8"

Vintage: 1996

Dual Shrink W-CVD Chemical vapor deposition system, 8"

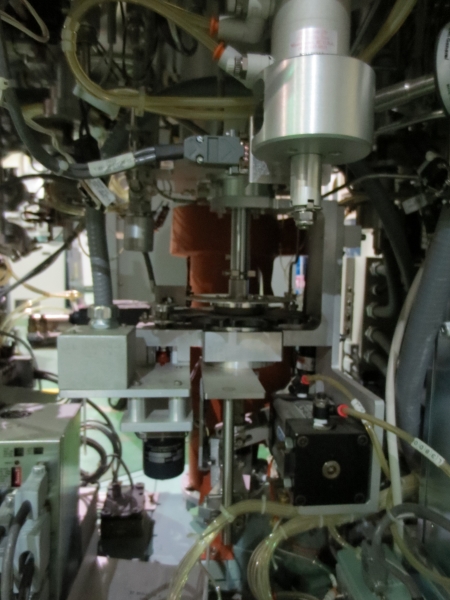

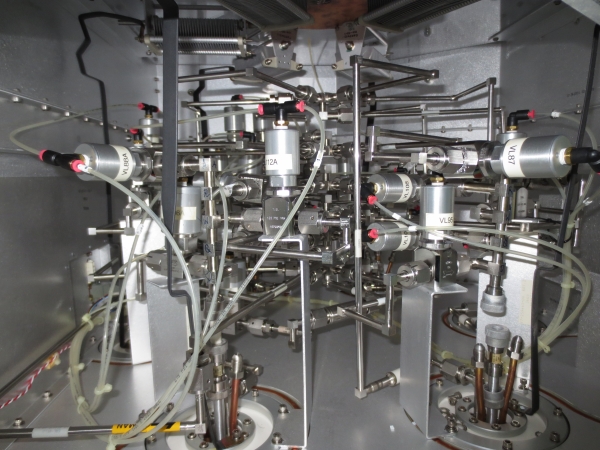

Chamber Location

1 Station Left Loadlock

2 station Process Module

3 station Process Module

4 station Right Loadlock

5 Station Cooling Sation

Electrical Requirements

AC power Voltage 208 VAC

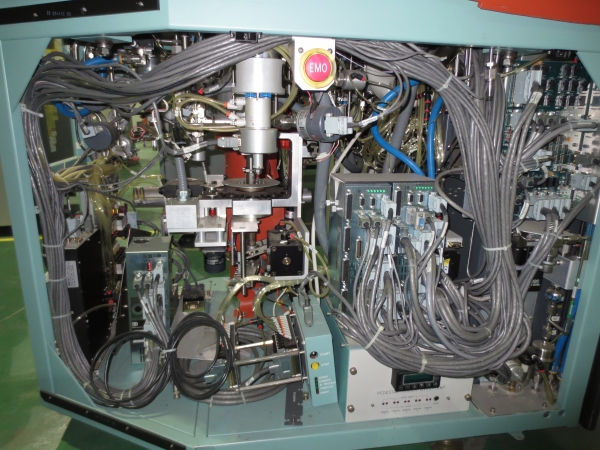

DLCM Configuration

Indexer Type: Animatic Controller

Brooks Robot Type: Mag7

Host Interface: GEN/SECS

Controller Type : P166/64M/QNX4

DLCMS Type: Only Hi

Module Interface Type: Arc-net Type

IOC : Ver 4.1

TM Manometer 1 torr/ 100mtorr: Tylan General

L/L Manometer 100torr: Tylan General

L/L Convectron: Not Install

Module Door Type: SMC L-Motion

Chamber A:

Process Option BLKT

Clean Option Insuts Clean

MOER Ceramic M/A / M/B (Not Used)

Throttle Valve Type Tylan General 1ea

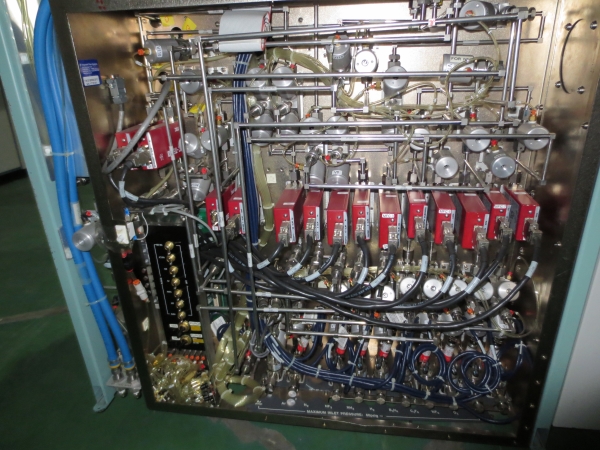

MFC Type & Size

Brooks 5964:

Ar (5000Sccm)

Ar (10000Sccm)

Area FC980C:

NH3 (150Sccm)

Brooks 5964:

Ar (10000Sccm)

Ar (20000Sccm)

Ar (20000Sccm)

H2 (20000Sccm)

H2 (20000Sccm)

Area FC980C:

B2H6, N2 (750Sccm)

Brooks 5964:

C2F6 (2000Sccm)

SAM MC4VLZ24:

WF6 (1000Sccm)

Brooks 5964:

O2 (2000Sccm)

SiH4 (1500Sccm)

SFC1480FPD:

SiH4 (300Sccm)

Slip Valve Type: SMC L-Motion

Chamber B:

Process Option BLKT

Clean Option Insuts Clean

MOER Ceramic M/A / M/B (Not Used)

Throttle Valve Type Tylan General 1ea

MFC Type & Size

SPEC 7330:

Ar (5000Sccm)

Ar (5000Sccm)

NH3 (1000Sccm)

NH3 (1000Sccm)

Ar (20000Sccm)

Ar (5000Sccm)

Ar (15000Sccm)

H2 (5000Sccm)

H2 (20000Sccm)

B2H6, N2 (750Sccm)

C2F6 (2000Sccm)

WF6 (750Sccm)

O2 (2000Sccm)

SiH4 (1000Sccm)

Slip Valve Type SMC:

L-Motion

1996 vintage.

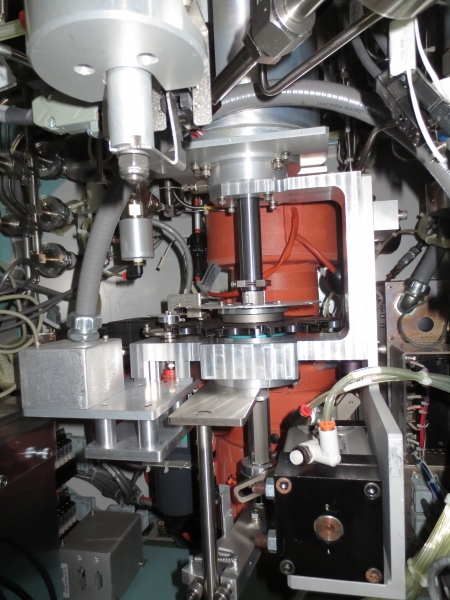

NOVELLUS CONCEPT 2 Altus is a highly specialized and advanced PVD (Physical Vapor Deposition) reactor equipment. It is commonly used to apply thin films of deposited material onto large-scale substrates such as silicon wafers for use in semiconductor, optoelectronic and microelectronic devices. CONCEPT 2 Altus system is designed to provide a high level of process control, uniformity and flexibility with the goal of optimizing process yield. The PVD chamber is driven by a linear motor which provides a steady, stable environment for uniform deposition. It also features variable substrate sizes, adjustable gun positions, multiple zones and two sources of deposition materials, which help to maximize process uniformity and throughput. The chamber also features a fast, high-precision robotic arm which moves and loads materials into the chamber quickly and accurately. NOVELLUS CONCEPT 2 Altus unit is equipped with a variety of sensors and controllers which continually monitor the process and provide detailed feedback on the uniformity of the reaction. This ensures that the highest possible quality and repeatability of the thin films is achieved. The machine also includes proprietary software which can be used to monitor, evaluate and adjust the deposition process in real time. CONCEPT 2 Altus tool offers users greater control of process parameters, greater accuracy and repeatability, and improved process stability. It is an ideal asset for those looking to apply high-quality thin films to large-scale substrates quickly and efficiently. The combination of superior performance, repeatability and flexibility make NOVELLUS CONCEPT 2 Altus model the perfect choice for high-volume PVD applications.

There are no reviews yet