Used NOVELLUS CONCEPT 2 Altus #9171171 for sale

URL successfully copied!

Tap to zoom

ID: 9171171

Wafer Size: 8"

Vintage: 2001

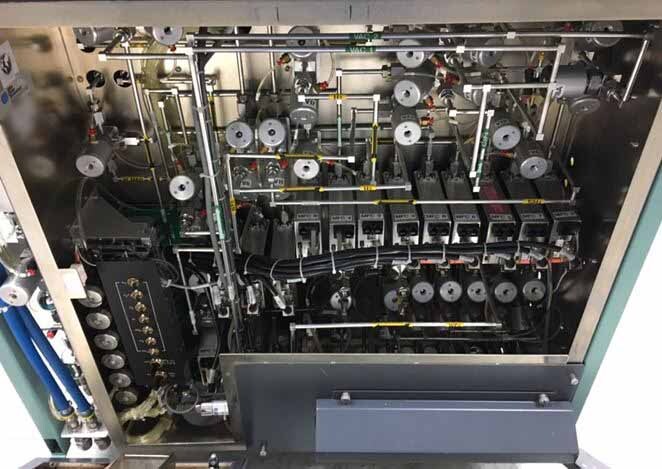

Chemical vapor deposition (CVD) system, 8"

Process: CVD - Tungsten dep

Module configuration: Standard

Wafer type: Notch

Module type: CVDW

SMIF Type

(2) Chambers

Software: QNX2 / 4

Module controller: MC2

Pedestal assembly type: Ped assy, 200mm MORE, D, no flat, SEMI 0

Exclusion ring type: MOER 0

Exclusion ring lift type: 02-054427-01 0

DLCM Configuration:

DLCM Type: Shrink

Cassette interface: Platform

Robot type: Mag7 (P/N: 003-1600-25)

Arm set: Dual arm (P/N: 002-0016-14)

Cool station: 3-Level

Pressure gauge:

Capacitance manometer, MKS (P/N: 750B12TCE2GK), 100Torr

MYCROLIS Throttle valve

MKS 651D-16202 Throttle valve controller

ANIMATICS CDP2407-2 Indexer controller

Slit gate valve (Chamber A, B):

02-121427-00, SMC, XGT-0402AWM-X16 Rev8

Slit gate valve (Loadlock A, B):

02-133793-00, SMC, XGT-0101AWM-X16 Rev1

Chamber configuration:

Chamber A CVD - Tungsten

Chamber B CVD - Tungsten

Pedestals: 200 mm

MOER:

Pedestal 1

Pedestal 2-5

Clean: Insitu

Millipore MDVX-100B Throttle valve

27-053468-00 Throttle valve controller

VAT 14040-PE34-0003 Gate valve

Pressure gauge:

100 Torr (Milipore, CDLD2106E), Backside

100 Torr (Milipore, CDLD2106E)

10 Torr (Milipore, CDLD1106E)

RF Match: Trazer, AMU2-1

RF Configuration:

HF RF Generator type: AE RFG 3000

MFC Size & Gas type:

Chamber A:

MFC1 / SLM / Ar

MFC2 / 50SCCM /SiH4

MFC3 / 20SLM / H2

MFC4 / 20SLM / Ar

MFC5 / 500SCCM/ WF6

MFC6 / 2SLM / C2F6

MFC7 / 2SLM / O2

MFC8 / 10SLM / Ar

MFC9 / 20SLM / H2

MFCC / 2SLM / Ar

MFCD / 20SLM / Ar

MFCE / 500SCCM / WF6

UPC1 / SLM / Ar

Chamber B:

MFC1 / SLM / Ar

MFC2 / 50SCCM /SiH4

MFC3 / 20SLM / H2

MFC4 / 20SLM / Ar

MFC5 / 500SCCM/ WF6

MFC6 / 2SLM / C2F6

MFC7 / 2SLM / O2

MFC8 / 10SLM / Ar

MFC9 / 20SLM / H2

MFCC / 2SLM / Ar

MFCD / 20SLM / Ar

MFCE / 500SCCM / WF6

UPC1 / SLM / Ar

2001 vintage.

NOVELLUS CONCEPT 2 Altus Reactor is a state-of-the-art tool that enables users to perform advanced semiconductor materials processing in an advanced etch environment. The Altus Reactor is an all-in-one system designed to offer high-quality, high-throughput etching capabilities for all types of related applications. CONCEPT 2 Altus Reactor is particularly designed to improve the performance of etching as well as other processing steps, such as thermal oxidation and relamination. It utilizes a revolutionary advanced etch technology that combines inductively coupled plasma (ICP) with high precision reactive ion etching (RIE) and directional ion beam etching (DIBE). This advanced etch technology provides ultimate step coverage, advanced control of etch parameters, high throughput, uniform etch rates over large wafer areas, and low damage of the wafer surface. The main feature of NOVELLUS CONCEPT 2 Altus Reactor is its advanced etch processor, which enables users to take full advantage of the advanced etch technology offered by the system. This processor not only allows for high precision of etch conditions, but also provides insight into etch process optimization with flexible parameters and real-time feedback. This allows users to optimize their etch recipes quickly and accurately, ensuring the best possible end results of their applications. CONCEPT 2 Altus Reactor is easy to use and maintain, thanks to its advanced auto-calibration feature. This feature allows users to calibrate the etch chamber quickly and accurately, ensuring that all etch processes are conducted with maximum precision and accuracy. Combined with its advanced auto-cleaning function and advanced diagnostics, NOVELLUS CONCEPT 2 Altus Reactor offers a highly reliable and efficient etching system. CONCEPT 2 Altus Reactor stands out from the competition thanks to its advanced etch technology, unique processor and easy-to-use features, which make it an ideal choice for any semiconductor etch application. Its advanced etch technology ensures the best possible results for any related etching applications, making it an effective, reliable, and high-quality solution for advanced semiconductor materials processing.

There are no reviews yet