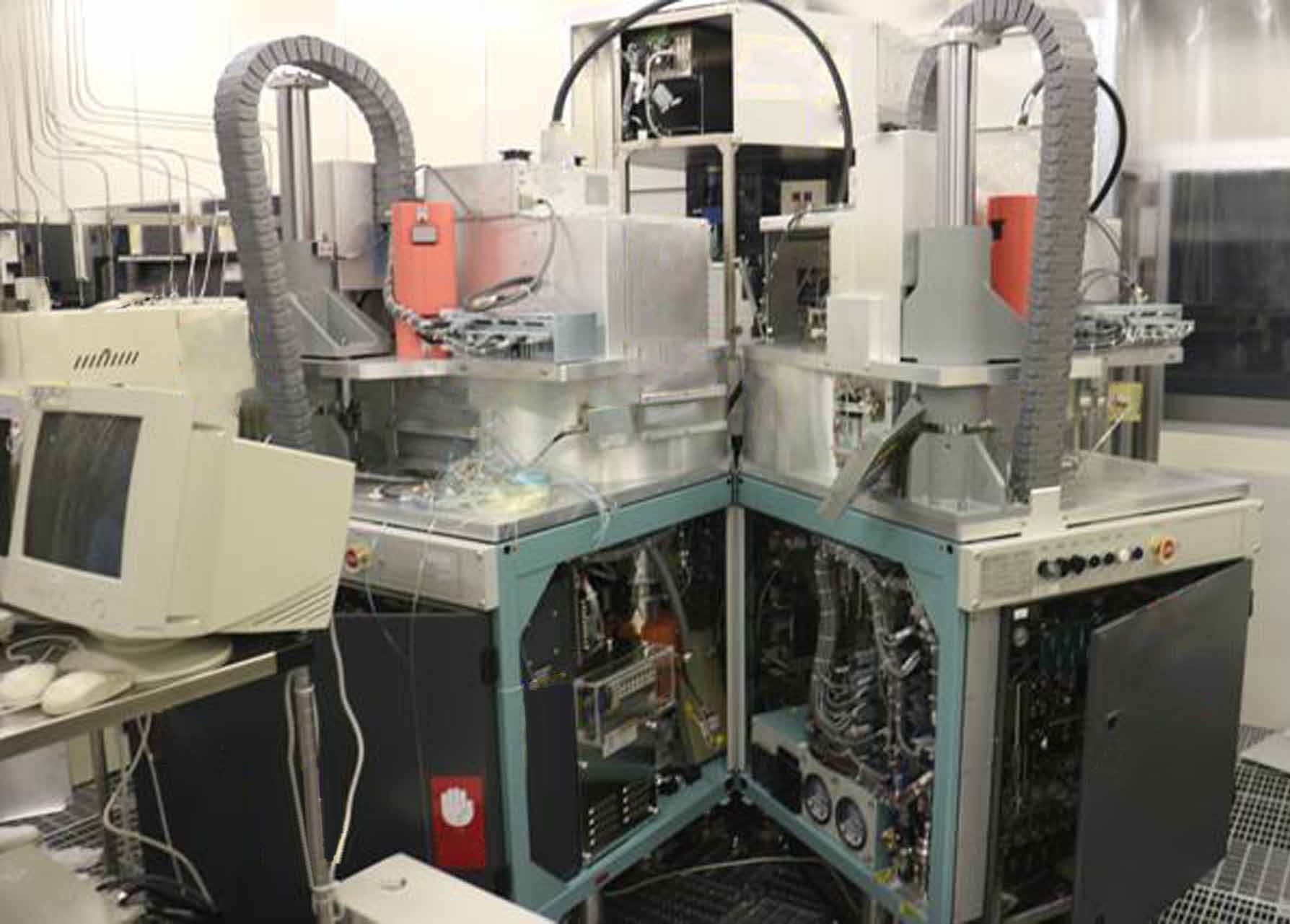

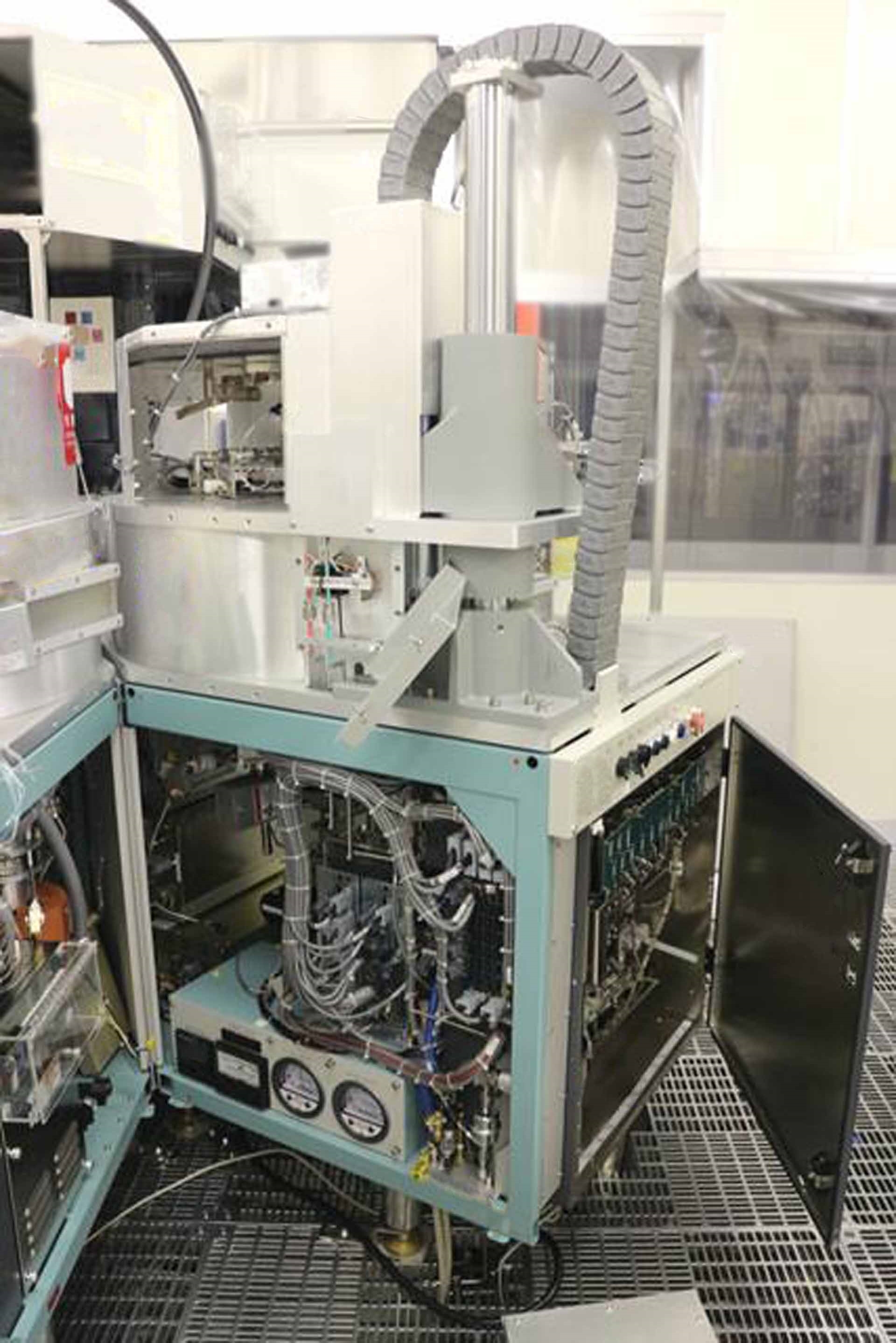

Used NOVELLUS CONCEPT 2 Dual Sequel Express #9223972 for sale

URL successfully copied!

Tap to zoom

ID: 9223972

System

User interface: C2-SCON5995

Wafer shape: Flat / Notch

No SMIF interface

No aligner option

Module A / B: Express

Process A: ARC

Process B: AEC

Load lock baratron model: Convectron

Index robot type: Index 2

TM Robot type: Mac 7

TM Robot blade: Metal

Wafer sensor: Existence

Signal tower

No fab installation

Module controller: MC1

Host interface: SECS

EMO: Push button

Front monitor: System UI LCD

Back monitor: CRT

No load lock dry pump

Slit valve insert

Slit valve type: SMC L-Motion

No TM dry pump

TM Throttle valve model: Millipore

TM Baratron model: MKS

Module A / B:

Chamber type: Express

Module controller: MC1

Chamber process: ARC

IOC Version:

IOC1 / 4.1

IOC2 / 4.1

IOC3 / 4.1

Manometer 1(10T): MKS

Manometer 2(1000T): MKS

Process clean type: Normal

HF Generator: AE RFG5500

LF Generator: AE PDX1400

RF Match: Mercury

Heater block type: (6) Stations

End point option: Dual head

Spindle top plate type: (6) Pieces

Spindle type: Ferrofluidic

Foreline gate heat option

Foreline gate valve: HVA

Throttle valve: MKS 2538-15665

Throttle valve heat option

Liquid IOC version: 4.1

No module dry pump

RF Isolation box missing

Pearl kit missing (N2O Treatment kit)

Gas / MFC Size / MFC / Model

N2 / 5 / SLM / Awra FC7800CD

N2 / 10 / SLM / Awra FC7800CD

N2O / 20 / SLM / Awra FC7800CD

NH3 / 10 / SLM / Awra FC7800CD

SÌH4 / 1 / SLM / Awra FC7800CD

O2/CF/ 20 / SLM / Awra FC7800CD

PH3/N2 / 2 / SLM / Awra FC7800CD

N2O / 1 / SLM / Awra FC7800CD

C2F6 / 5 / SLM / Awra FC7800CD

System:

Main power: 208 V, 3 Phase, 5 wires

UPS power: 120 V, 3 Phase, 3 wires.

NOVELLUS CONCEPT 2 Dual Sequel Express is a reactor that is used for chemical processes and coatings. It is equipped with two inner rotating tubes and a flat downstream deposition chamber. It is designed to maximize throughput while providing maximum performance. The main components of CONCEPT 2 Dual Sequel Express are the upper and lower vapor jet injectors, the concentric ramp and baffle plates, the downstream shower and the high pressure water/gas streams. The upper and lower vapor jet injectors spray atomized precursors into the reaction chamber, which are then heated and reacted upon. The concentric ramp and baffle plates increase the residence time of the reaction mixture, allowing a greater degree of reaction between all the components. The downstream shower is designed to allow for deposition of any reaction product on the inner and outer walls of the reaction chamber. Finally, the high pressure water/gas streams ensure a uniformity of reaction within the chamber. NOVELLUS CONCEPT 2 Dual Sequel Express has the capability to process a variety of materials, such as acrylics, oxides, silicones, nitrides, carbides, and others. It can be used for chemical vapor deposition (CVD), physical and chemical vapor deposition (PECVD), and sputter deposition. CONCEPT 2 Dual Sequel Express also has the ability to process thermal deposition operations. NOVELLUS CONCEPT 2 Dual Sequel Express also offers an advanced level of control, analytics, and safety features. It is equipped with a remote production monitor, allowing users to track the highest process parameters to ensure precision control. It also has an integrated touch screen for improved user interface and data logging. The data acquisition system provides data and analysis of real-time production in the reactor chamber, giving an indication of process uniformity. Finally, CONCEPT 2 Dual Sequel Express also has safety features such as process shut-off valves and emergency shut-down buttons. Overall, NOVELLUS CONCEPT 2 Dual Sequel Express offers an efficient and safe method of chemical processing and coating. The advanced level of control offered ensures precision and uniformity during any process. The remote production monitor and integrated touch screen make the process highly user-friendly, leading to increased efficiency.

There are no reviews yet