Used NOVELLUS CONCEPT 2 Dual Sequel #9092631 for sale

URL successfully copied!

Tap to zoom

ID: 9092631

Wafer Size: 6"

CVD system, 6"

Software: C2.SEQ_4.92B15

Operating system: QNX4

SECS GEM: Yes

Free cable length: 75 Ft

RF Cable length: 84 Ft

Indexer firmware: 2.0_G

Transfer robot: Brooks Mag 7

Chamber location: Left

Chamber model: C2-CVDD-S SEQX

EPD: Verity dual wavelength

Shower head: Al 6061 8" 16-033931-00

Handling wafer size: 6"

Heater block: No slot Sequel STN 1 pin 19-00154-04

Spindle speed: Standard

Fork assembly: Ceramic anti-deflect

15-101482-00

15-101482-01

15-00700-00

Fork type: Min Contact

15-053394-02

Spindle feed through: Ferro fluidic

Primary process gauge: 10T

Gate & throttle valve: Heated / Internal

02-260348-00

16210-0403QS-002HJR

MFC Type: Brooks GF100

IOC Software version: 4.2

RF Switching option: Yes

RPC (Remote plasma clean): No

HF RF Generator: AE Apex 5513

LF RF Generator: AE PDX 1400

RF Match AE mercury: 3013

Foreline heated: No

2.0 MFC C Open

MFC B N2 (10000 sccm)

MFC A N2O (20000 sccm)

MFC 9 NF3 (5000 sccm)

MFC 8 O2 (20000 sccm)

MFC 7 Open

MFC 6 NH3 (10000 sccm)

MFC 5 Open

MFC 4 Open

MFC 3 Open

MFC 2 N2 (5000 sccm)

MFC 1 SiH4 (1000 sccm)

Chamber location: Rear

Chamber model: C2-CVDD-S SEQX

EPD: Verity dual wavelength

Shower head: Al 6061 8" 16-033931-00

Handling wafer size: 6"

Heater block: No slot Sequel STN 1 pin 19-00154-04

Spindle speed: Standard

Fork assembly: Ceramic anti-deflect

15-101482-00

15-101482-01

15-00700-00

Fork type: Min Contact

15-053394-02

Spindle feed through: Ferro fluidic

Primary process gauge: 10T

Gate & throttle valve: Heated / Internal

02-260348-00

16210-0403QS-002HJR

MFC Type: Brooks GF100

IOC Software version: 4.2

RF Switching option: Yes

RPC (Remote plasma clean): No

HF RF Generator: AE Apex 5513

LF RF Generator: AE PDX 1400

RF Match AE mercury: 3013

Foreline heated: No

2.0 MFC C Open

MFC B N2 (10000 sccm)

MFC A N2O (20000 sccm)

MFC 9 NF3 (5000 sccm)

MFC 8 O2 (20000 sccm)

MFC 7 Open

MFC 6 NH3 (10000 sccm)

MFC 5 Open

MFC 4 Open

MFC 3 Open

MFC 2 N2 (5000 sccm)

MFC 1 SiH4 (1000 sccm)

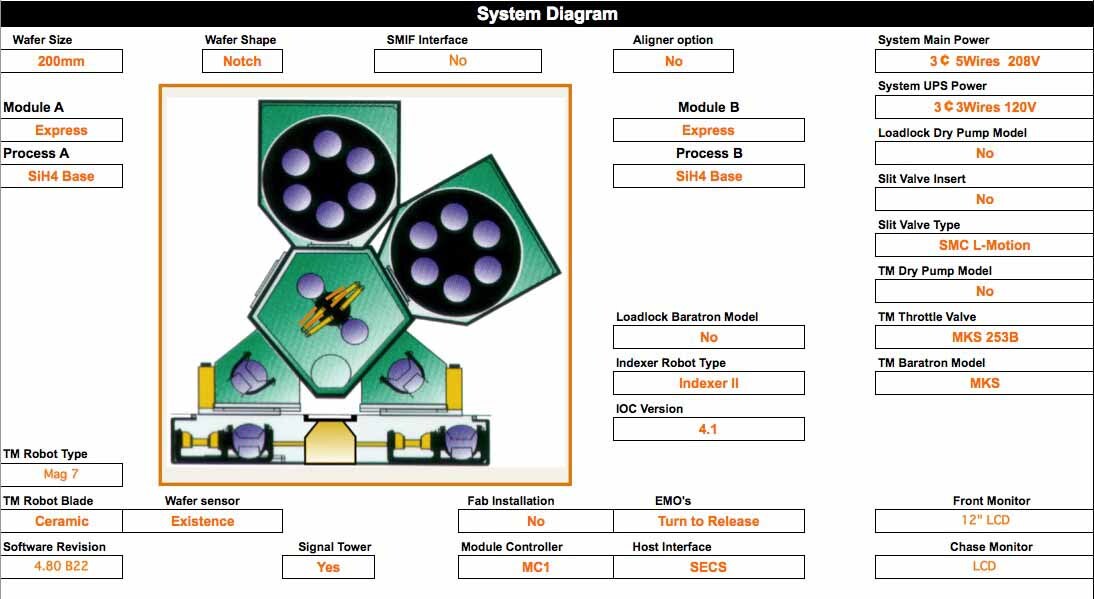

System main power: 3ϕ 5Wires 208V

System UPS power: 3ϕ 3Wires 120V

SMIF Interface: No

Aligner option: No

Loadlock dry pump model: No

Slit valve insert: No

Slit valve type: SMC L-Motion

TM Dry pump model: No

TM Throttle valve: MKS 253B

TM BARATRON model: MKS

Front monitor: 12" LCD

Chase monitor : LCD

Loadlock BARATRON model: No

Indexer robot type: Indexer II

IOC Version: 4.1

TM Robot type: Mag 7

TM Robot blade: Ceramic

Software revision: 4.80 B22

Signal tower: Yes

Module controller: MC1

Host interface: SECS

Module A: Express

Process A: SiH4 Base

Module B: Express

Process B: SiH4 Base

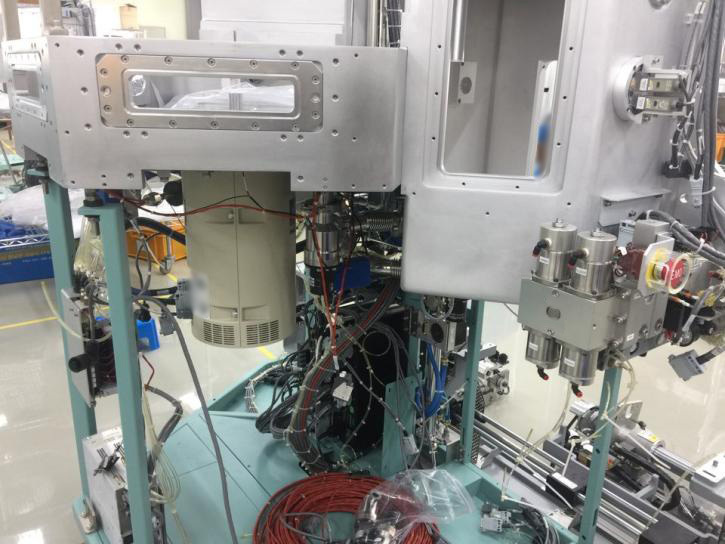

System and DLCM:

MC1 (P166 64M) System

DLCM Module controller

MSSD (2 Sequel configuration) power rack

Upgrade 4 cool station

SiH4 Base oxide process

Signal cables

RF Coaxial cables

MKS 253B throttle valve

651D Throttle valve controller

MAG 7 Transfer robot

Dual arm

Indexer robot

Animatics controller

Standard shuttle assy

Chase PC and table

Generator rack

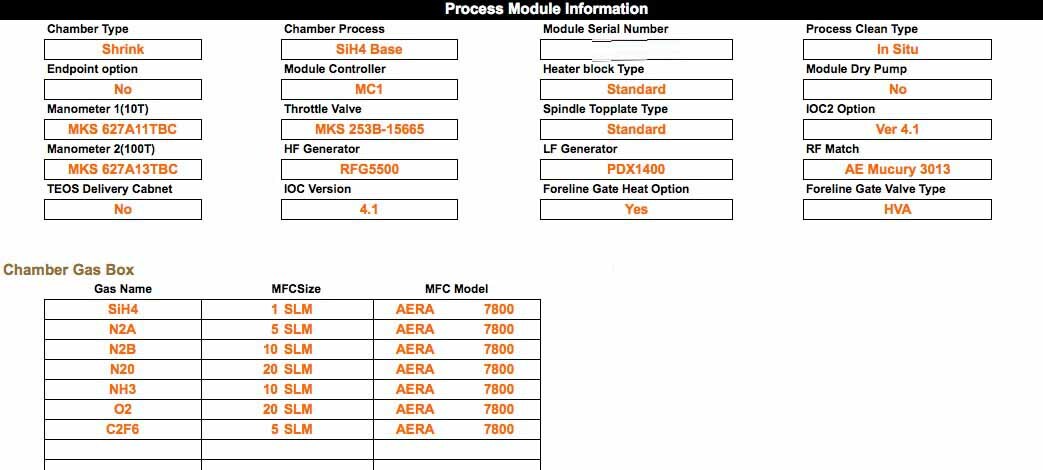

Process module:

Chamber type: Shrink

Chamber process: SiH4 base

Process clean type: In Situ

Endpoint option: No

Module controller: MC1

Heater block type: Standard

Module dry pump: No

Manometer 1(10T): MKS 627A11TBC

Throttle valve: MKS 253B-15665

Spindle topplate type: Standard

IOC2 option: Ver 4.1

Manometer 2(100T): MKS 627A13TBC

HF Generator: RFG5500

LF Generator: PDX1400

RF Match: AE Mercury 3013

TEOS Delivery cabinet: No

IOC Version: 4.1

Foreline gate heat option: Yes

Foreline gate valve type: HVA

Chamber gas box:

Gas name MFC Size MFC Model

SiH4 1 SLM AERA 7800

N2A 5 SLM AERA 7800

N2B 10 SLM AERA 7800

N20 20 SLM AERA 7800

NH3 10 SLM AERA 7800

O2 20 SLM AERA 7800

C2F6 5 SLM AERA 7800

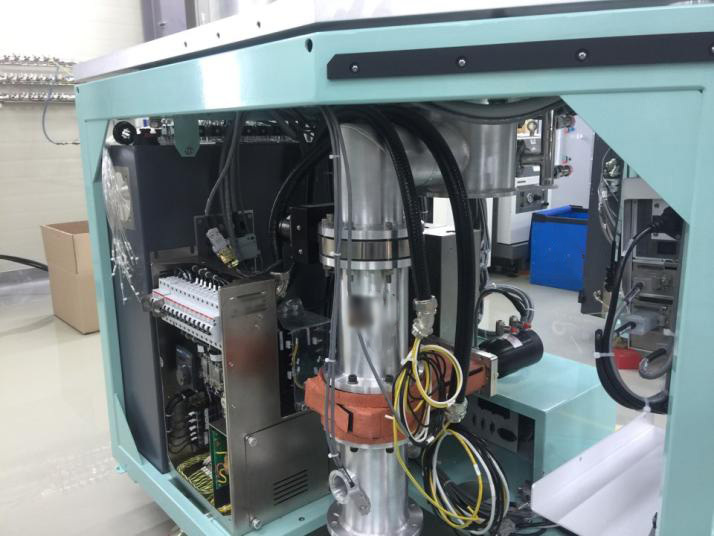

Module A :

Gas filters

Gas box

HF and LF RF Generators

RF Matching network

Lower spindle assy

Ferrofluidic spindle Assy

Bottom and top plates

10Torr and 1000Torr manometer

Heated type HVA gate and MKS throttle valves

Throttle valve controller

Upgrade MC1 (P166 64M) module controller

Ceramic type spindle fork assy

O-Rings

Metal parts in chamber

Watlow temp controller

Window shappire

Heater ISO box

TC gauge

MFC's

Heater block (OPM)

Shower head

RF and heater feedthru

2000-2001 vintage.

NOVELLUS CONCEPT 2 Dual Sequel is a reactor designed and manufactured by NOVELLUS Systems, Inc., a leading provider of plasma-based chemical vapor deposition (CVD) systems. The reactor is used in the fabrication of semiconductor devices in the sub- and ultra-micron sizes, and is well-suited for high-volume production of these components. This reactor includes a unique dual-chamber design that utilizes two separate chambers to deposit materials onto a substrate. The Dual Sequel reactor utilizes a chamber pressure of up to 10 Torr for deposition processes, ranging from very low to high film thicknesses. It also includes a detector unit for constant monitoring of the deposition process. For retaining thermal uniformity across the wafer, the reactor includes a wafer cooling feature designed to reduce detrimental effects from changes in wall temperature. Furthermore, this feature also helps to eliminate impurities from the process. The Dual Sequel reactor comes with a unique interlock equipment, which works by connecting the process chambers with one another via a shared vacuum line. This interlock ensures that both the chambers are working in tandem, thereby delivering reliable and consistent performance. The interlock also helps in regulating pressure throughout the system, allowing the chamber pressure to remain in the intended range. Other features include a highly-efficient gas delivery unit which helps in minimizing the use of process gases. The machine also operates in a special 'half-on' mode which can be used to speed up the process by performing a series of processes simultaneously. In addition, the Dual Sequel also provides a higher level of safety due to its advanced safety features like an emergency pump tool and a safety interlock. Overall, CONCEPT 2 Dual Sequel reactor is an advanced, high- throughput, and reliable CVD tool that is well-suited for high-volume production of small-sized semiconductor components. Its unique dual-chamber design offers greater levels of deposition and temperature control, while its interlock asset allows for a more unified and efficient process. It also boasts a range of features designed to enhance safety, minimize process gases, and boost throughput.

There are no reviews yet