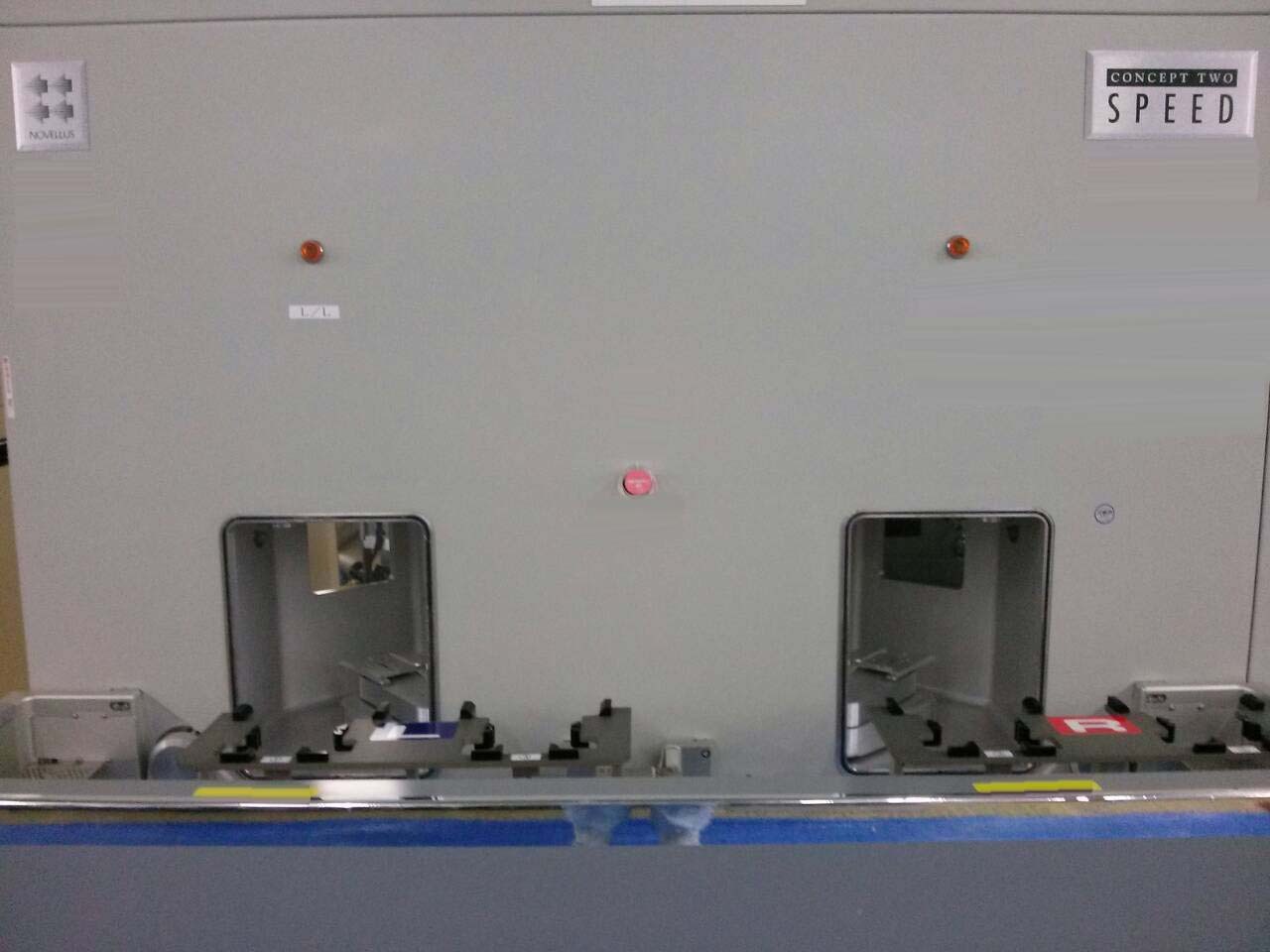

Used NOVELLUS CONCEPT 2 Dual speed-S #9097741 for sale

URL successfully copied!

Tap to zoom

ID: 9097741

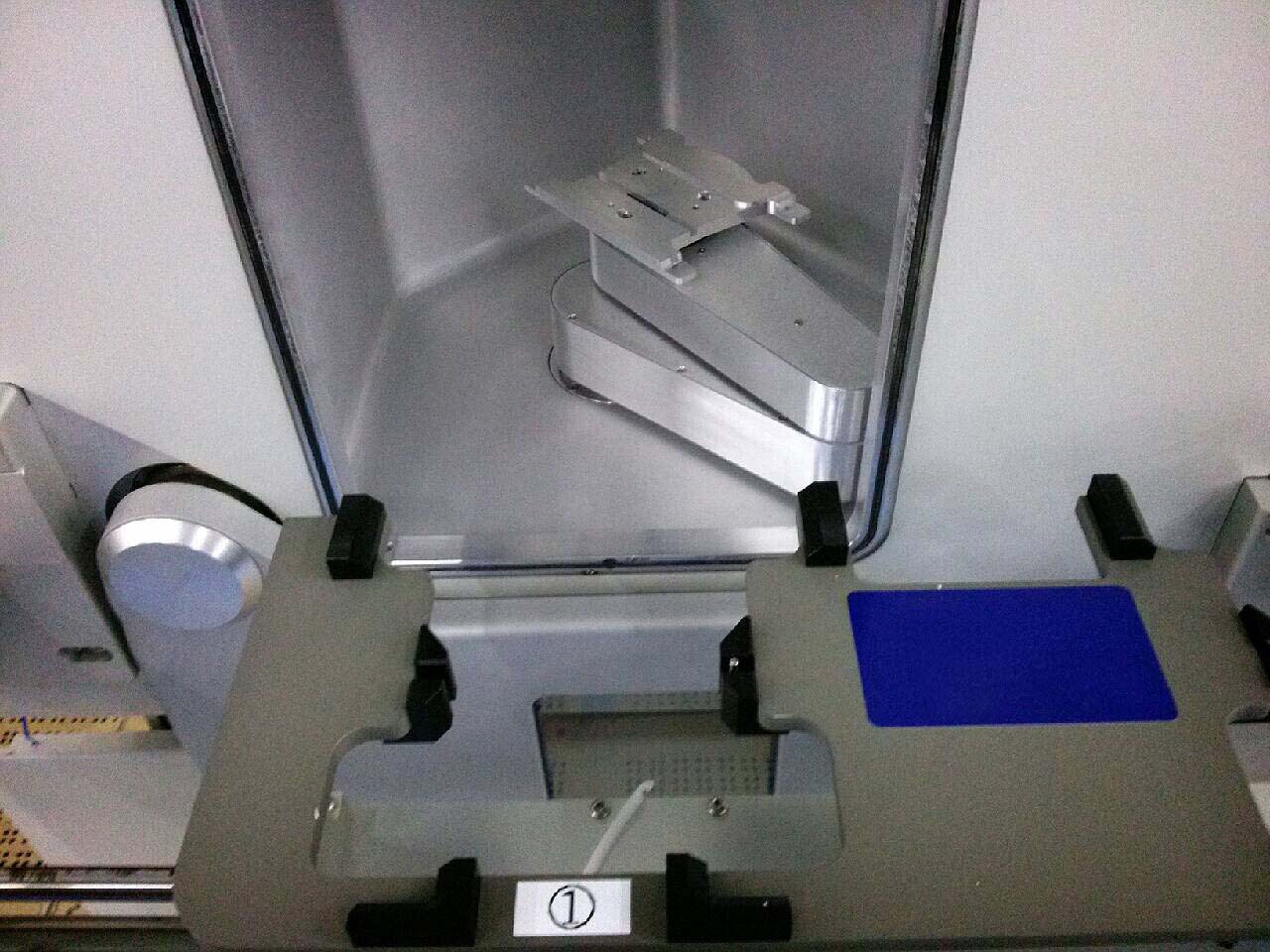

Wafer Size: 6"

Vintage: 1996

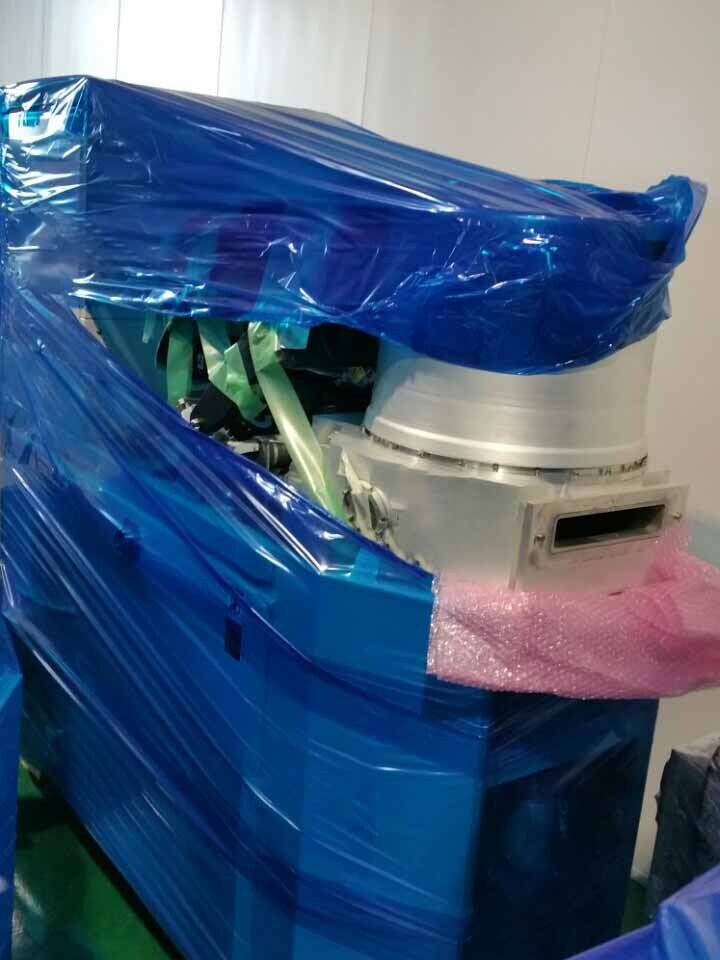

CVD System, 6"

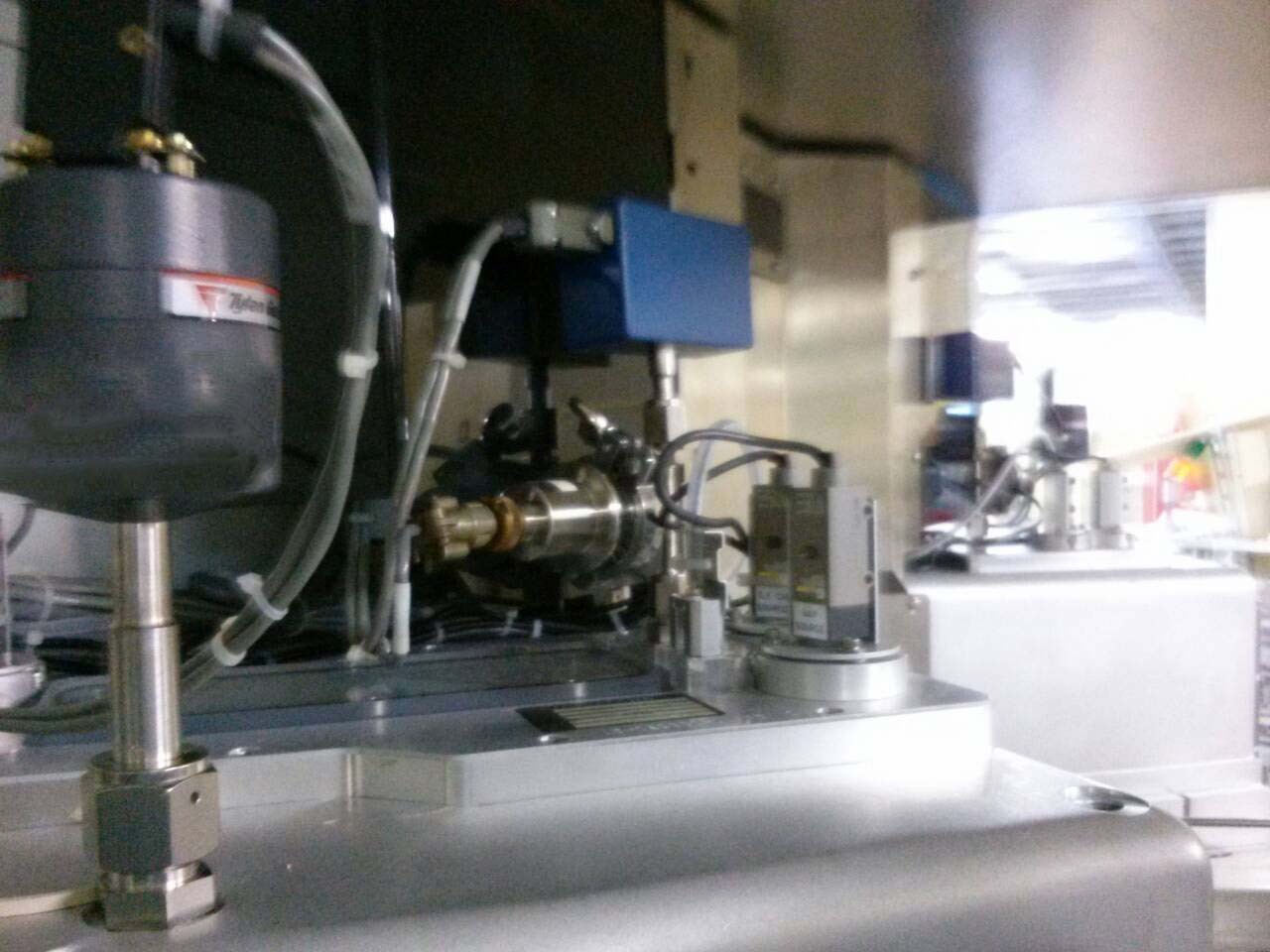

Loadlock baratron: Tyran general

Loadlock dry pump: EDWARDS QDP40

Slit valve: SMC L-motion

TM Dry pump: EDWARDS QDP40

TM Throttle valve: Tyran general

TM Baratron model: Tyran general

TM Robot: MTR 5

TM Robot blade: Metal

Wafer sensor: Existence

Host interface: SECS

Module controller: MC1

12" LCD Front monitor

Module A: Shrink, STI/IMD

Manometer 1: Tyran general

Manometer 2: Tyran general

TMP Pump right: TG1113MBW-09

TMP Pump left: Osaka vac TG1113M

TMP Controller: TD 701/1101

Throttle valve: VAT 14046-PE24-0005

HF Generator: ENI OEM-50N-11601

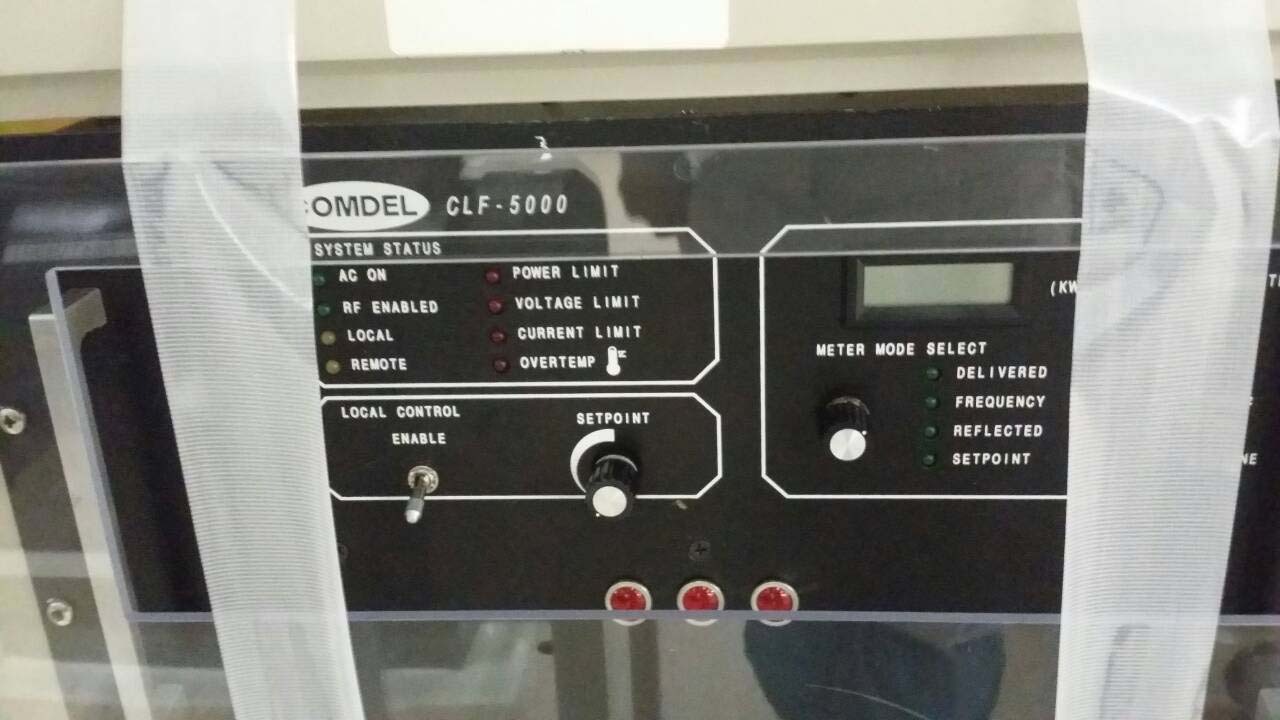

LF Generator: ENI CLF-5000/400

Module dry pump: EDWARDS QDP80

Pump booster: EDWARDS EH1200

RF Match: TRAZAR AMU10E-1

Chamber gas box:

MFC 1 Ar 500 SCCM BROOKS 5964

MFC 2 O2 500 SCCM BROOKS 5964

MFC 3 NF3 1 SLM BROOKS 5964

MFC 4 SIH4 200 SCCM BROOKS 5964

MFC 5 SIF4 200 SCCM BROOKS 5964

Module B: Shrink, STI/IMD

Manometer 1: Tyran general

Manometer 2: Tyran general

TMP Pump right: TG1113MBW-09

TMP Pump left: Osaka vac TG1113M

TMP Controller: TD 701/1101

Throttle valve: VAT 14046-PE24-0005

HF Generator: ENI OEM-50N-11601

LF Generator: ENI CLF-5000/400

Module dry pump: EDWARDS QDP80

Pump booster: EDWARDS EH1200

RF Match: TRAZAR AMU10E-1

Chamber gas box:

MFC 1 Ar 500 SCCM BROOKS 5964

MFC 2 O2 500 SCCM BROOKS 5964

MFC 3 NF3 1 SLM BROOKS 5964

MFC 4 SIH4 200 SCCM BROOKS 5964

MFC 5 SIF4 200 SCCM BROOKS 5964

DLCM Gas MFC

MFC1: UPC, Ar/He, 1 SLM, BROOKS 5866 RT

MFC2: UPC, Ar/He, 1 SLM, BROOKS 5866 RT

MFC3: Ar/He, 500 SLM, BROOKS 5964

SMIF Interface: No

PET Module: No

UPS Power: 120 V, 3 Ph, 3 wires

Main system: 208 V, 3 Ph, 5 wires

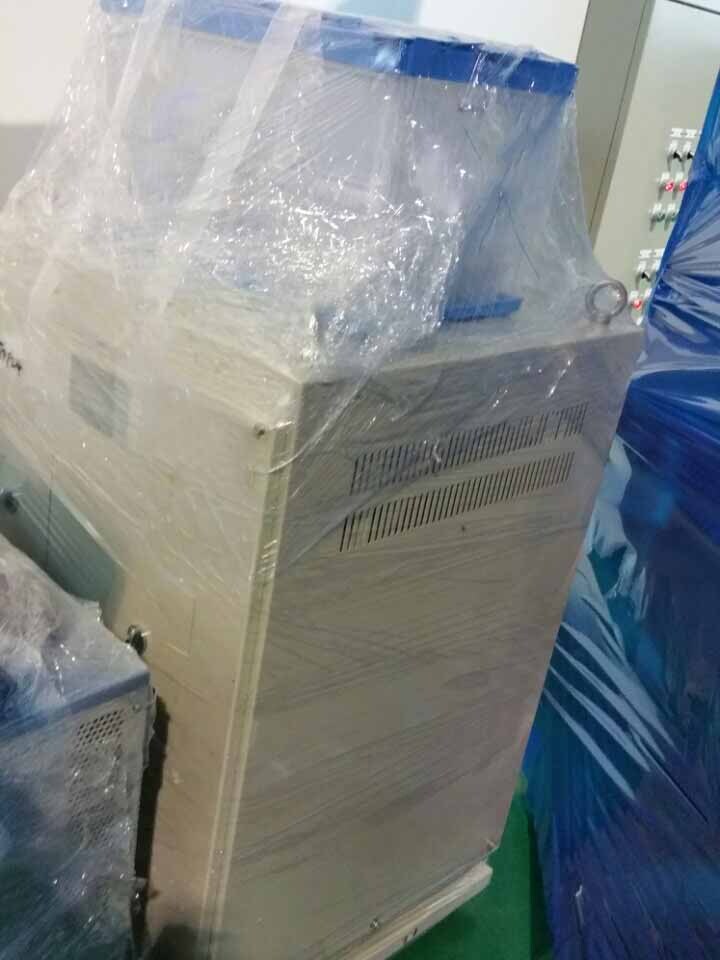

Currently de-installed

1996 vintage.

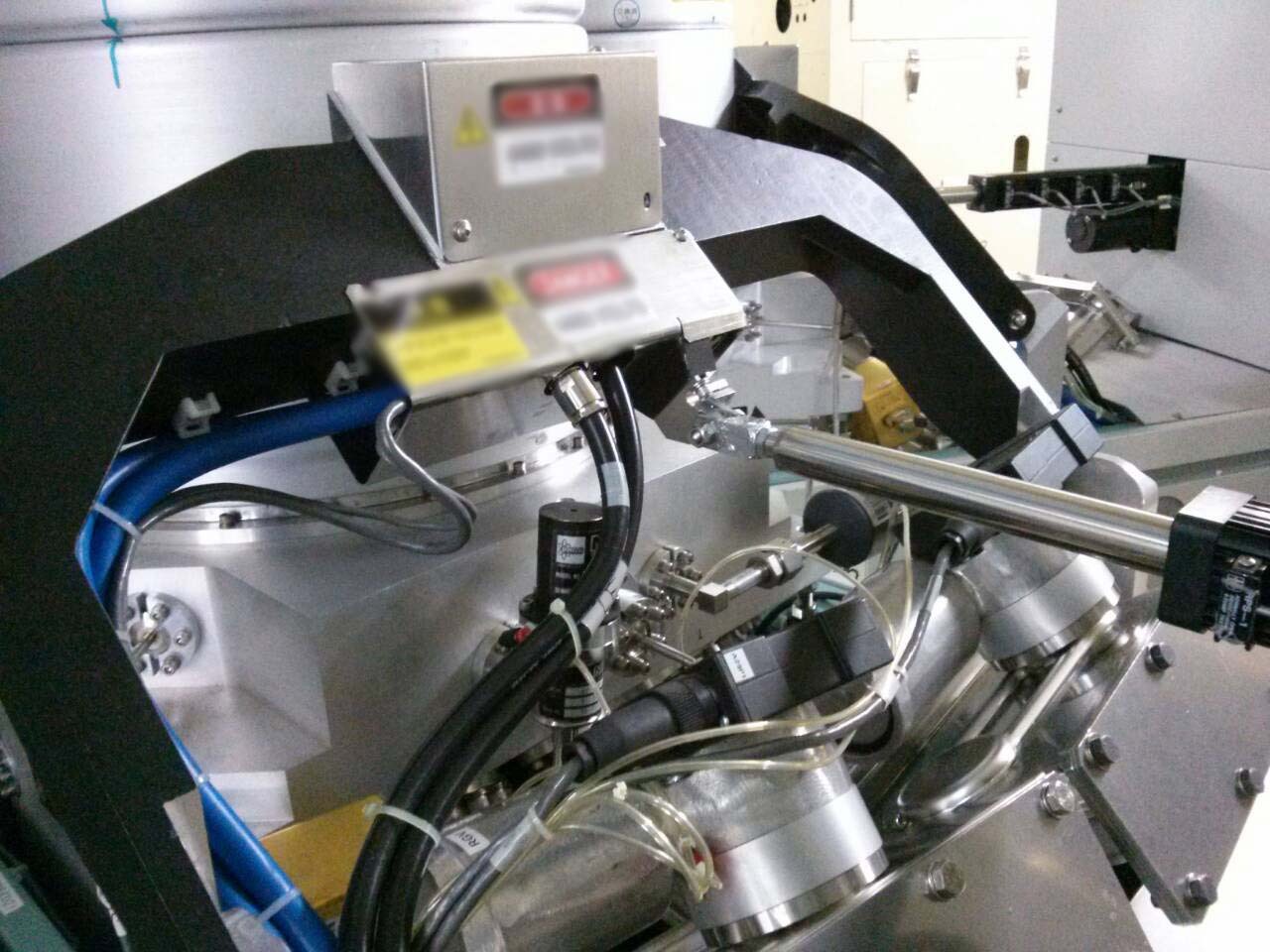

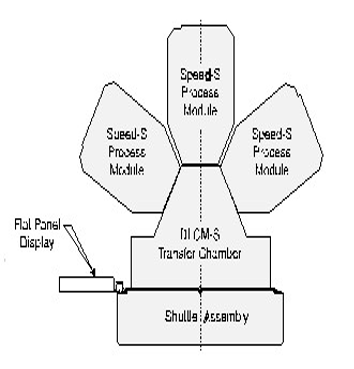

NOVELLUS CONCEPT 2 Dual speed-S Reactor is a chemical deposition chamber used in semiconductor fabrication. It is capable of delivering both low- and high-temperature chemical vapor deposition (CVD) processes, enabling processing of a wide range of dielectric, oxynitride and metal films. The dual chamber design allowsusers to run two applications (high and low temperature) simultaneously or independently, enabling batch precursor delivery and deposition while maximizing process throughput. CONCEPT 2 Dual speed-S Reactor features a versatile high temperature CVD chamber which can process dielectric and metal films at temperatures up to 1000°C. It also features a low temperature CVD chamber which can process oxynitride and dielectric films at temperatures up to 450 ˚C. Both chambers are designed for use with a variety of starting precursors, and feature multiple recipe post-processing options. NOVELLUS CONCEPT 2 Dual speed-S Reactor is built with advanced, robust technological components that provide accuracy, sampling and control. The low temperature CVD chamber uses patented forwardDirect™ injection technology, which enables faster and more efficient deposition, as well as uniform film deposition and high yields. The high temperature CVD chamber is designed with a uniquely designed gas manifold for tight temperature control and uniform deposition across a wide area. Another feature of CONCEPT 2 Dual speed-S Reactor is its automated processes. The patented robotic conveyor system allows the reactor to automatically move wafers, substrates, materials and components through the system, while the robotic assist arm ensures accurate and uniform loading of the pre-processing chamber and the process vessels. The pre-processing chamber also allows for blanket processing before loading the substrates into the process vessel, in order to ensure uniform film deposition. Overall, NOVELLUS CONCEPT 2 Dual speed-S Reactor is a reliable, efficient and versatile chemical deposition chamber. The ability to perform both low and high temperature CVD processes makes it the ideal choice for a variety of semiconductor fabrication processes. Its advanced technological components, automated processes and forwardDirect™ injection technology provide an accurate, uniform and high yield operation.

There are no reviews yet