Used NOVELLUS CONCEPT 2 Speed #9093692 for sale

URL successfully copied!

Tap to zoom

ID: 9093692

Wafer Size: 8"

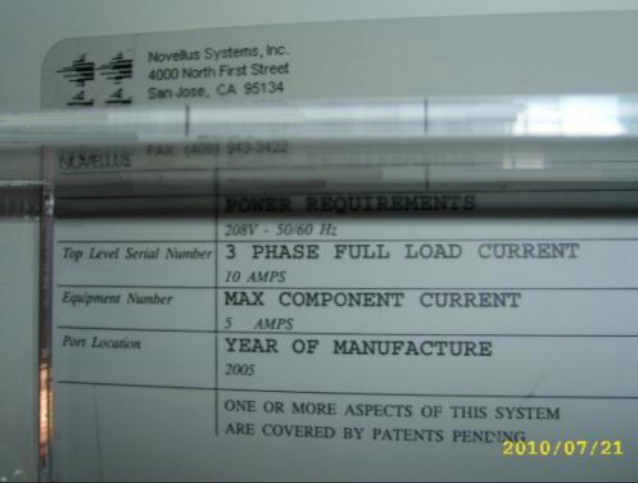

Vintage: 2005

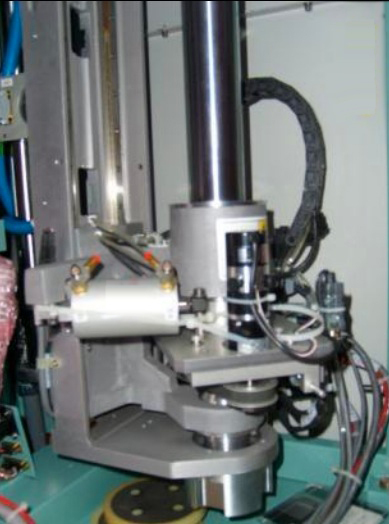

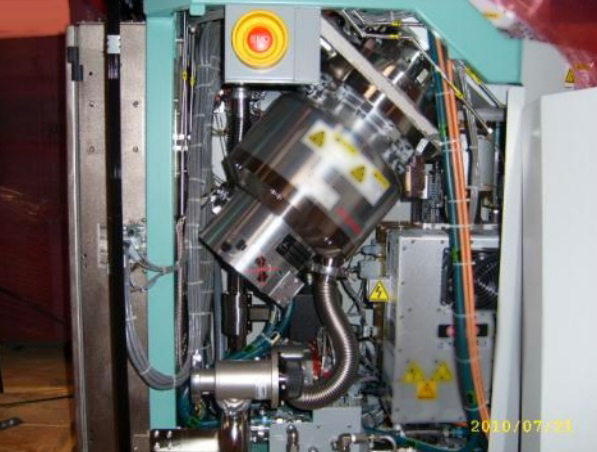

CVD, HDP System, 8".

Wafer shape: Flat

SMIF Interface: No

PET Module: Yes

Aligner option: No

System main power:

208 V, 50/60 Hz, 3 phase, 5 wires

3-Phase full load current: 10 amps

Max component current: 5 amps

System UPS Power: Yes

Silt valve insert: No

Silt valve type: SMC L-Motion

TM Turbo pump bodel: Pfeiffer TMH260

TM Throttle valve model: MKS

TM Baratron model: MKS

Loadlock baratron model: MKS

IOC Version: V 4.1

TM Robot type: Mag 7

TM Robot blade: Ceramic

Wafer sensor: Existence

Signal tower: Yes

EMO's: Push button

Module controller: MC1

Host interface: SECS

Front monitor: LCD Monitor

MFC1, Ar/He, 1 SLM, Brooks 5964

MFC2, Ar/He, 1 SLM, Brooks 5964

MFC3, Ar/H2, 500 Sccm, Brooks 5964

Sys con: C2-SCON-6582

Signal cable

Chase computer

Module A, B, and C:

Chamber type: Shrink

Chamber process: ILD

Process clean type: In situ

Module controller: MC1

Module turbo pump: Pfeiffer TPH2101 PCX

Manometer 1 (10 T): MKS

Throttle valve: MKS

ESC / Dome cooling: PCW

Temp monitoring: NTM500C

Manometer 2 (10 T): MKS

HF Generator: AE RFG5500

LF Generator: AE PDX 5000

RF Match: Trazar AMU10E-2

Manometer 3 (100 m): MKS

IOC Version: 4.2

Dual clean injector kit: Yes

Injector type: Single

Louvered screen: No

Pedestal lift type: Dual position

Foreline type: Standard

NF3, 1 slm, Aera FC-D980C

Ar, 500 sccm, Aera FC-D980C

O2, 500 sccm, Aera FC-D980C

H2, 2 slm, Aera FC-D980C

HE, 500 sccm, Aera FC-D980C

SiH4, 200 sccm, Aera FC-D980C

Deinstalled

2005 vintage.

NOVELLUS CONCEPT 2 Speed (C2S) is a two-chamber chemical vapor deposition (CVD) reactor designed specifically for deposition of thin films for the semiconductor industry. It is used to deposit metals and compounds such as silicon, tungsten, and nitrides onto integrated circuits, or ICs. The C2S is designed to provide users with a reliable, high-rate tool that is tailored specifically for advanced process optimization. The C2S reactor has two chambers, separated by a divide wall, and uses a chemical vapor injection equipment to introduce reactants into the processing chamber. The two chambers are designed to operate at different pressures, temperatures, and flow rates simultaneously. This allows for the optimization of all the parameters necessary to obtain the desired thin-film deposition rate and uniformity of coverage. The C2S utilizes ultra-high purity argon to pressurize the chamber and to promote smooth gas flow, as well as a heated (2200°C) substrate and susceptor system to achieve the highest deposition rates. The unit is designed to be extremely precise, with process control provided at multiple points to ensure the highest level of uniformity on the substrate surface. A computerized controller is also provided to allow users to easily monitor and adjust the pressure, temperature, and flow-rate parameters as needed. The C2S is equipped with several advanced technologies to enhance the process, including NOVELLUS Close Space Sublimation (CSS) technology. This technology allows users to directly deposit multiple layers of tungsten, and other refractory metal films, at a higher deposition rate than traditional CVD processes. It also eliminates the need for etching steps, resulting in both a lower cost and shorter cycle time. In addition, the C2S can be integrated with NOVELLUS Endura CVD Machine, which is designed to provide uniform coverage at higher deposition rates with improved process control accuracy. This tool also allows users to to monitor, control, and optimize the deposition parameters and processes in real time, resulting in better defect control and yield increases. The high cost/performance ratio and customizable features offered by the C2S make it an ideal choice for a wide range of advanced manufacturing applications. The added process control allow users to run the asset at higher speeds while still maintaining the desired uniformity on the substrate surface. With its reliable performance and customization features, CONCEPT 2 Speed reactor provides users with an efficient and cost-effective solution for producing advanced thin-film devices.

There are no reviews yet