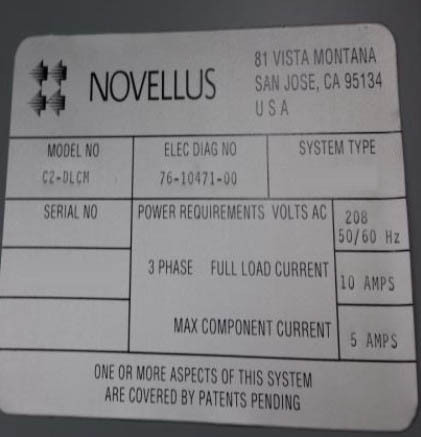

Used NOVELLUS CONCEPT 2 #9069052 for sale

URL successfully copied!

Tap to zoom

ID: 9069052

Wafer Size: 8"

CVD system, 8"

Includes:

Wafer shape: Flat

SMIF Interface: No

Aligner: No

System main power: 3-Ph, 5-wires, 208 V

Module A: Standard

Process A: Sio2

Module B: Standard

Process B: Sio2

TM Throttle valve: TYLAN

TM Robot type: MTR5

TM Robot blade: Ceramic

Wafer sensor: Existence

Loadlock baratro model: 275 Mini convectron

TM Baratron model: Tylan 100 Torr

EMO: Turn to release

DLCM IOC Version: 4.0

Module controller: MC1 P100

Front monitor: Side

Module A:

Chamber type: Standard

Module controller: MC1

Process type: SIO2/SIN

Manometer: Mykrolis, 10 Torr

Manometer: Tylan 1000 Torr

Process clean type: In-Situ

HF Generator: OEM-28

Heater block type: 6-Station

Endpoint option: N/A

Spindle top plate type: (1) Piece

Spindle type: Ferroflo seal

Throttle valve: Tylan

RF Matcher: AMU2-1

IOC Version:

IOC0: 4.1

IOC1: 4.1

IOC2: N/A

LF Generator: PL-2HF

Foreline gate valve: VAT

Chamber gas box:

MFC # | Gas name | MFC size | MFC model

MFC B, N2, 10 SLM, Brooks 5964

MFC A, N2O, 20 SLM, Brooks 5964

MFC 9, C3F8, 2 SLM, Brooks 5964

MFC 8, O2, 3 SLM, Brooks 5964

MFC 6, NH3, 10 SLM, Brooks 5964

MFC 2, N2, 5 SLM, Brooks 5964

MFC 1, SIH4, 1 SLM, Unit UFC 8160

Module B:

Chamber type: Standard

Module controller: MC1

Process type: SIO2/SIN

Manometer: Mykrolis, 10 Torr

Manometer: Tylan 1000 Torr

Process clean type: In-Situ

HF Generator: OEM-28

Heater block type: 6-Station

Endpoint option: N/A

Spindle top plate type: (1) Piece

Spindle type: Ferroflo seal

Throttle valve: Tylan

RF Matcher: AMU2-1

IOC Version:

IOC0: 4.1

IOC1: 4.1

IOC2: N/A

LF Generator: PL-2HF

Foreline gate valve: VAT

Chamber gas box:

MFC # | Gas name | MFC size | MFC model

MFC B, N2, 10 SLM, Brooks 5964

MFC A, N2O, 20 SLM, Brooks 5964

MFC 9, C3F8, 2 SLM, Brooks 5964

MFC 8, O2, 3 SLM, Brooks 5964

MFC 6, NH3, 10 SLM, Brooks 5964

MFC 2, N2, 5 SLM, Brooks 5964

MFC 1, SIH4, 1 SLM, Unit UFC 8160.

NOVELLUS CONCEPT 2 reactor is a chemical vapor deposition (CVD) equipment with a revolutionary process that has been designed to deliver high deposition rates, high quality films, and superior productivity and reliability in an Atomic Layer Deposition (ALD) platform. The KEY FEATURES of CONCEPT 2 reactor include: sub-one nanometer process control for thin film deposition; high deposition rates and good film quality; the ability to precisely control the deposition environment, enabling total process control; advanced substrate temperature control and uniform heating which permits high throughput times; outstanding homogeneity and uniformity. NOVELLUS CONCEPT 2 reactor has a very high deposition rate due to the small chamber size and an exceptional recipe control system which allows for precision deposition of a wide range of materials such as polymers, metal oxides, and metals. The deposition process begins with the introduction of the source material, the gas. This gas is fed into the reaction chamber where the substrate is located. The reaction chamber is then pressurized and heated to the desired temperature. This allows the source material to be evaporated and then carried away by the vacuum. The deposition process is then regulated by the advanced process control unit. This machine can monitor the reaction parameters such as temperature, pressure, gas flow etc. and can adjust them to achieve the desired results. The uniform deposition of thin film is achieved due to the highly uniform heating of the substrate. CONCEPT 2 reactor provides excellent heat uniformity within the chamber, ensuring that the temperature is uniform throughout the reaction process. This ensures homogeneous growth and improved film properties. NOVELLUS CONCEPT 2 reactor is also equipped with a powerful post-process tool that allows for precise film uniformity tuning. This asset permits users to optimize thin film formation, making sure that the product layer meets the product requirements. This model also allows users to quickly test recipes without having to go through the process of each deposition process. In conclusion, CONCEPT 2 reactor is a revolutionary CVD equipment that has been designed to deliver high deposition rates, high quality films, and superior productivity and reliability in an Atomic Layer Deposition (ALD) platform. It has a high deposition rate due to the small chamber size and exceptional recipe control system, while providing excellent heat uniformity within the chamber to ensure homogeneous growth and improved film properties. Additionally, it has a powerful post-process unit that allows for precise film uniformity tuning, making it the ideal machine for thin film deposition.

There are no reviews yet