Used NOVELLUS CONCEPT 2 #9315488 for sale

URL successfully copied!

Tap to zoom

ID: 9315488

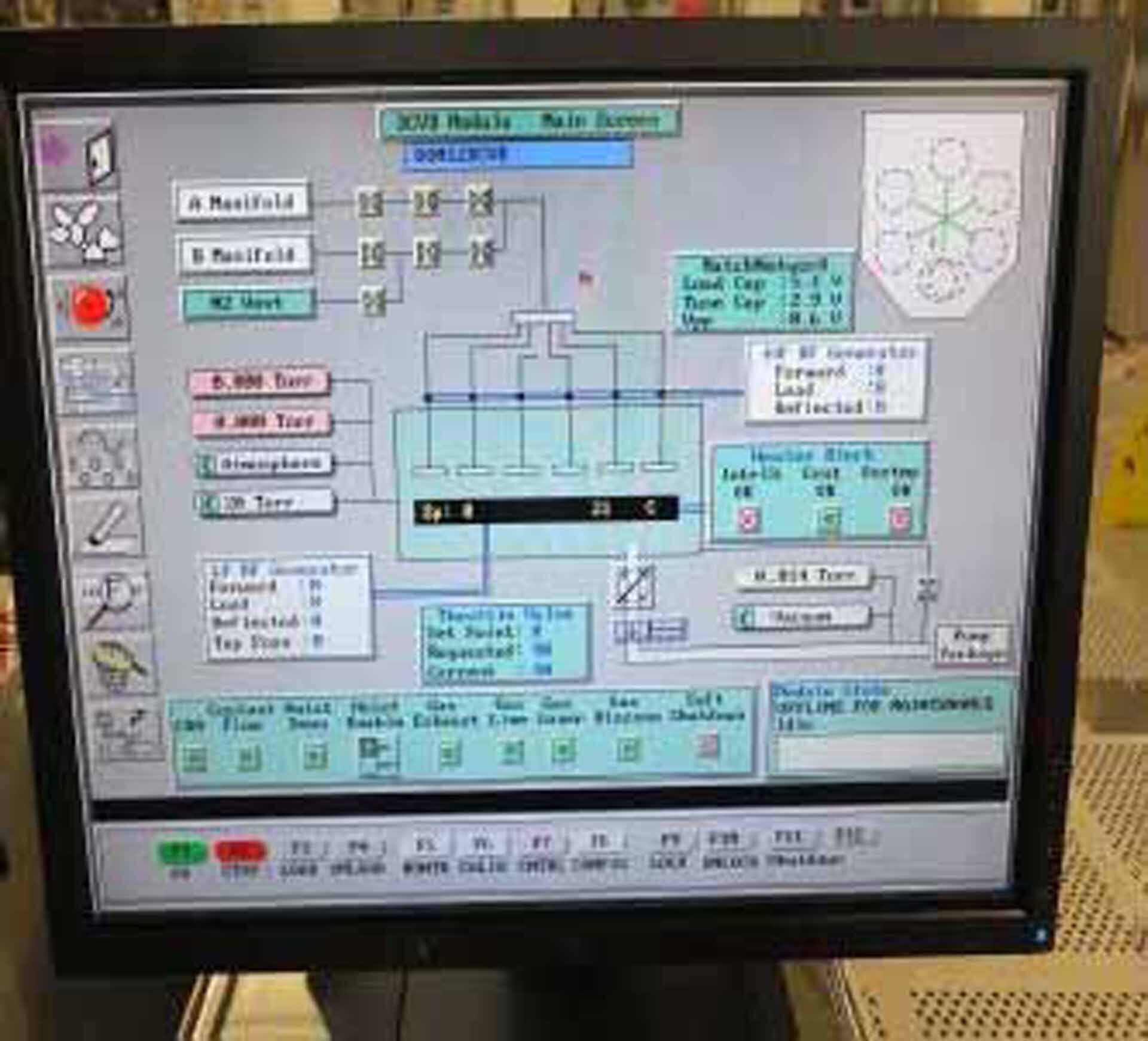

CVD System, 8"

Mainframe

Wafer type: Notch

System and module controller: MC1

SSD

Index robot: Type II

Magnetron 7 Transfer robot

Endpoint detector

Sequel chamber:

Sequel express

DLCM: S1253

Process type: SION

IOC Version: 4.2

Gas box configurations:

Gas line / Gas flow (SCCM) / MFC Make / MFC Model

SiH4 / 750 / HORIBA / Z512

N2 / 5000 / UNIT / UFC1661

SiH4 350 HORIBA / Z512

He / 10000 / UNIT / UFC1661

NH3 / 10000 / UNIT / UFC1661

He (Aux) / 1000 / UNIT / UFC1661

NF3 / 5000 / UNIT / UFC1661

N2O / 20000 / UNIT / UFC1661

N2 / 12000 / UNIT / UFC1661

CO2 / 20000 / UNIT / UFC1661

CE Marked

2001 vintage.

NOVELLUS CONCEPT 2 reactor is an advanced technology chemical etch equipment that meets the needs of the manufacturing sector by offering a superior level of process control and productivity. This highly successful etch system was created to deliver the very highest levels of productivity, precision, and quality assurance. It is based on a robust design that combines advanced features from NOVELLUS Concept 1tm feature set, alongside other state-of-the-art technologies. CONCEPT 2 reactor is an integrated chemical-etch unit that includes multiple features designed to provide superior process control and productivity. The machine utilizes advanced engineering features that are designed to ensure a consistent etch depth for each pattern location and to support the most complex etching operations. Its feed back loop control tool offers an enhanced level of process control and accuracy, allowing it to meet exacting requirements in production and for prototypes. NOVELLUS CONCEPT 2 reactor is designed to operate in a temperature controlled environment, ranging from 10° to 80° Celsius, and is ideal for use with a variety of substrates, such as silicon, tungsten, gold, and others. This reactor also includes a laser detection asset that is used to identify and prevent damage to the material being etched. The model also incorporates a variety of process capabilities that are designed to improve productivity, such as adjustable power levels up to 2000 W, optimized process parameters for detail etching, the ability to transfer etching parameters from one job to the next, and support for multiple samples per chamber. The advanced features of this equipment also include the ability to precisely control the in situ temperature of the substrate. In addition, CONCEPT 2 reactor has a wide range of safety features, such as an emergency stop button, interlock contacts, and over temperature control systems. The reactor also utilizes a range of chemical delivery systems and sensor technology that is used for precise metering and monitoring of the etch process. This highly advanced etch system has been designed to provide the very highest levels of productivity and precision, while also assuring product quality and safety. By combining these cutting-edge features and superior process control capabilities, NOVELLUS CONCEPT 2 reactor is suitable for use in any production environment.

There are no reviews yet