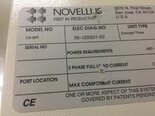

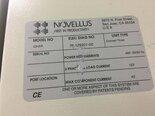

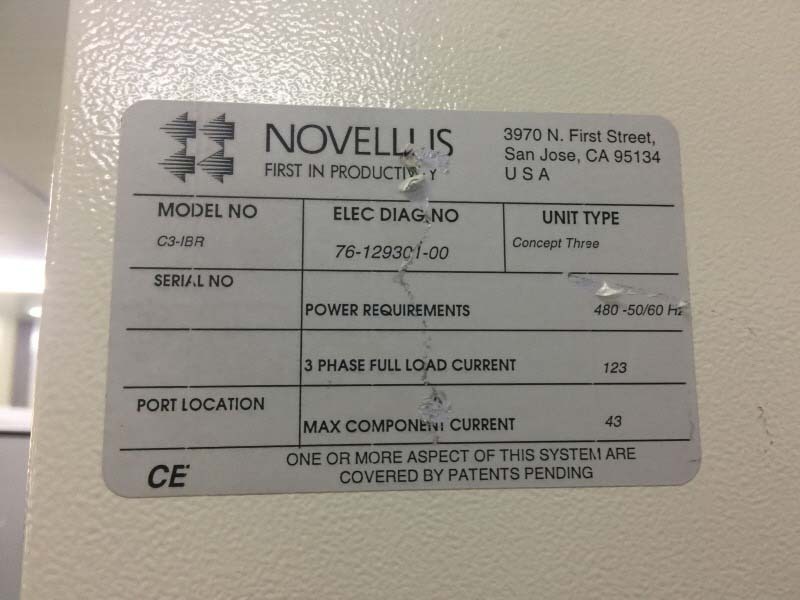

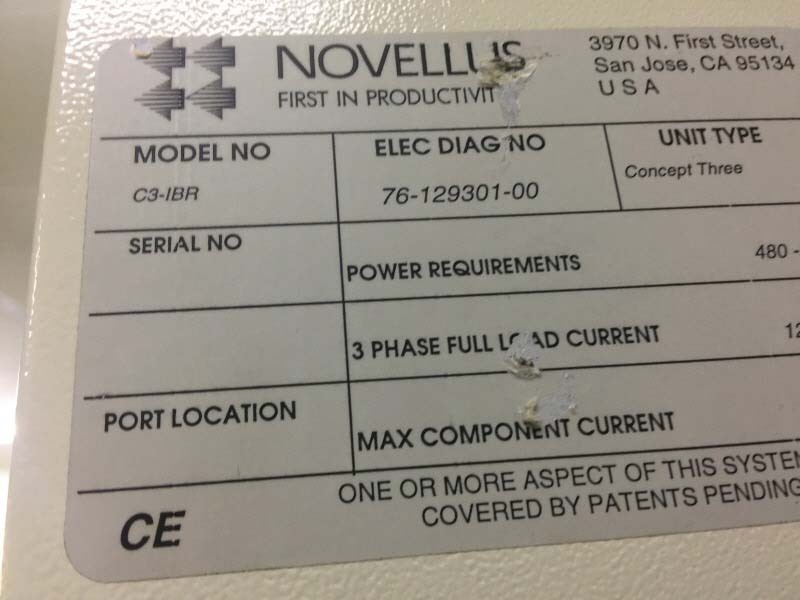

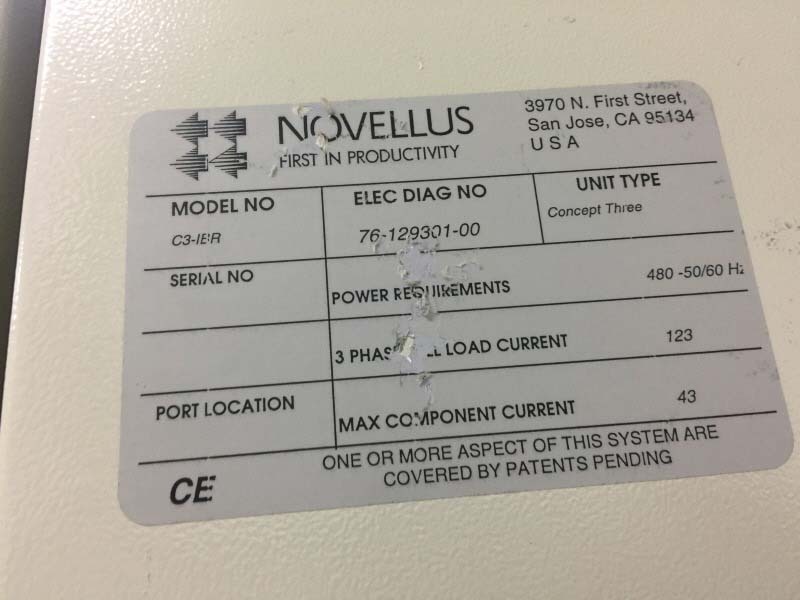

Used NOVELLUS Concept 3 Inova #9259672 for sale

URL successfully copied!

Tap to zoom

ID: 9259672

Wafer Size: 12"

Vintage: 2000

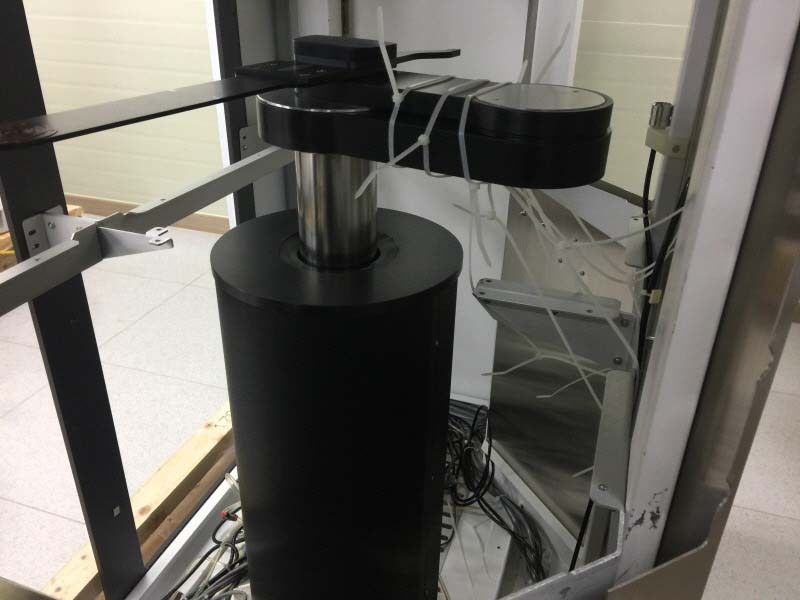

PVD Systems, 12"

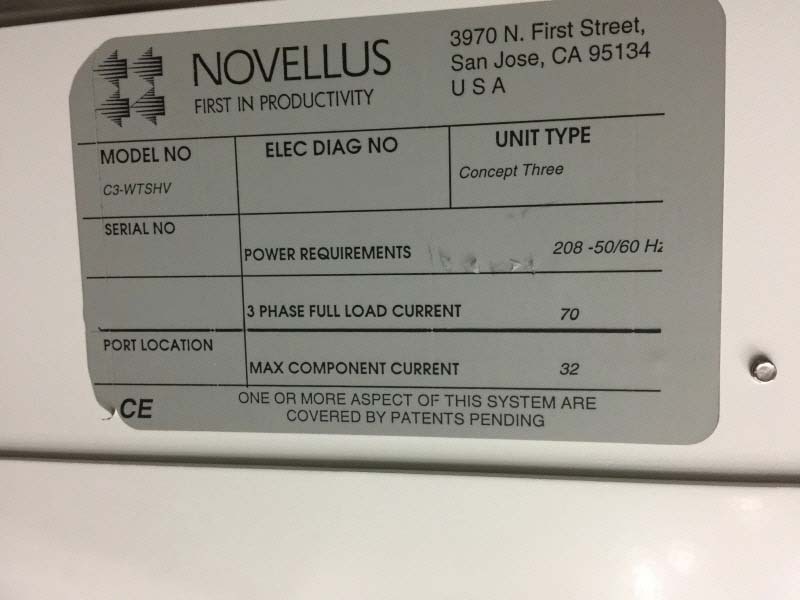

Process: MPD (WTS-HV)

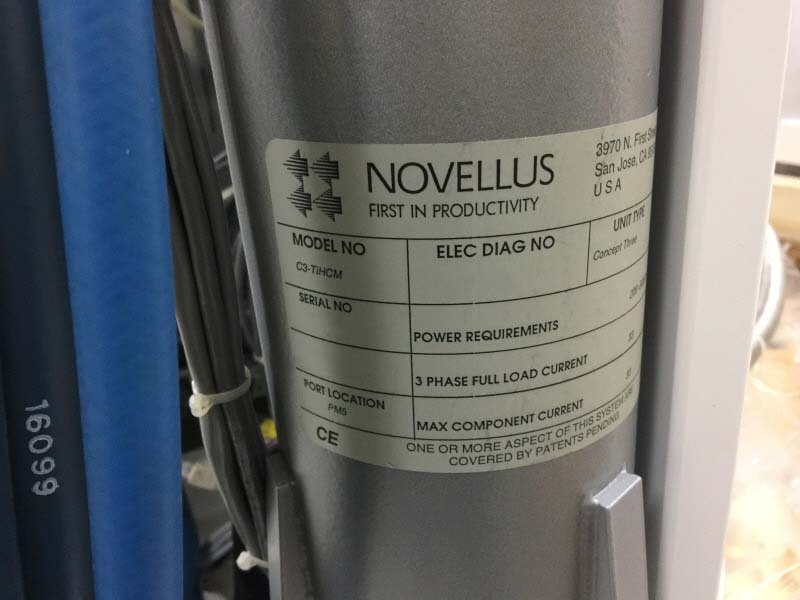

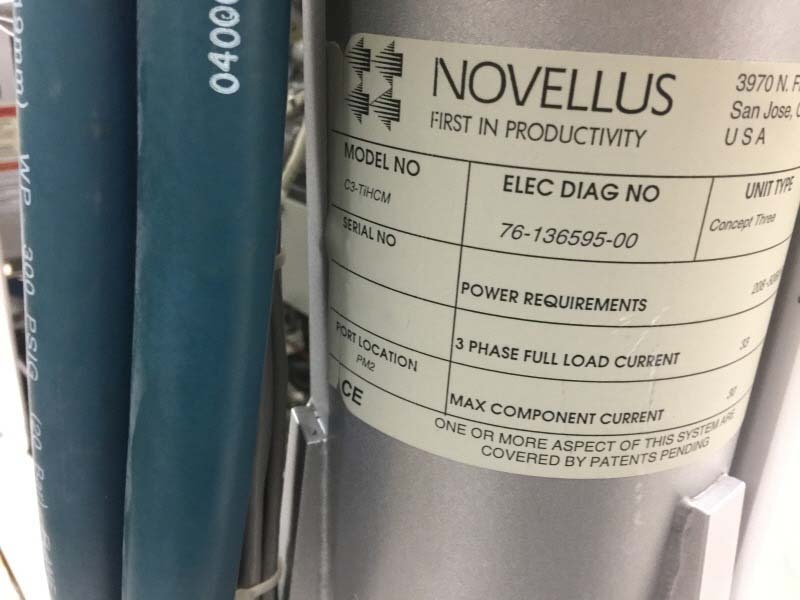

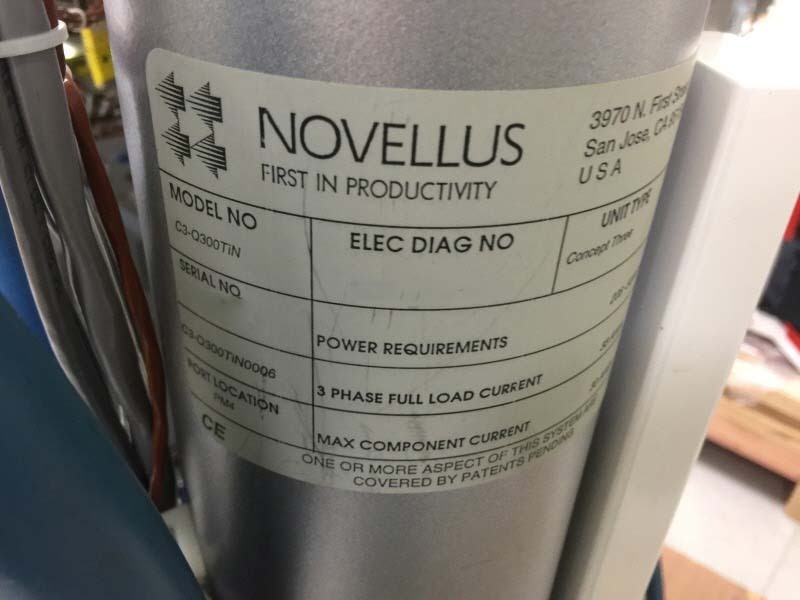

(4) Chamber: Q300 AL, Q300 TiN, (2) TiHCM

EFEM:

Load port: (2) FOUPs

Right with keyboard, mouse and monitor

Clean room wall interface

Wafer / FOUP: 25

BROOKS AUTOMATION ATM Robot

PEC Station

17-PEC Slots

ATM

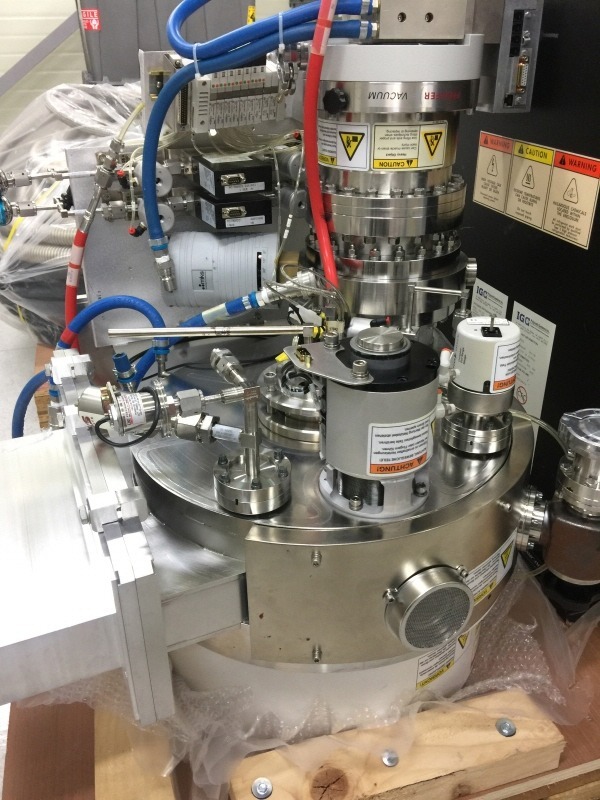

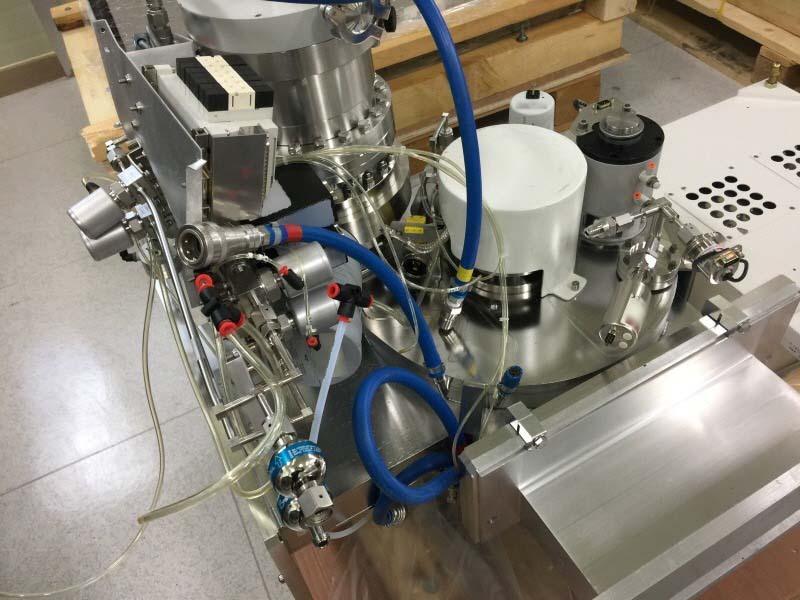

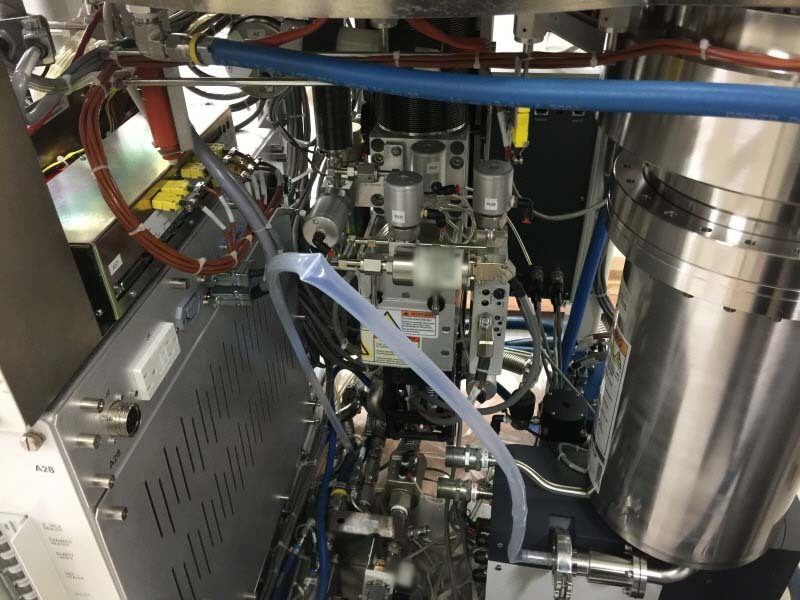

WTS-HV:

(2) BROOKS AUTOMATION Magnatran 7 Robots

Robot blade: Ceramic, dual

SIOC: 0-4

Cryo HUB

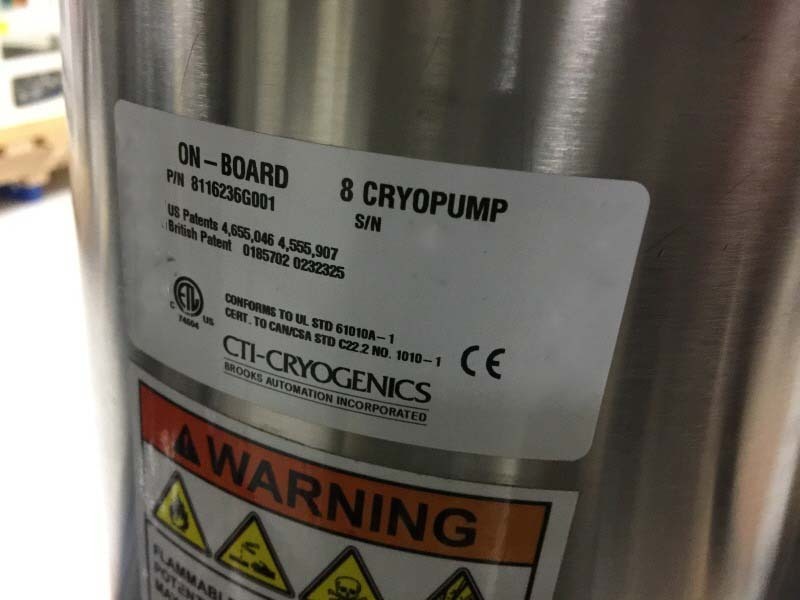

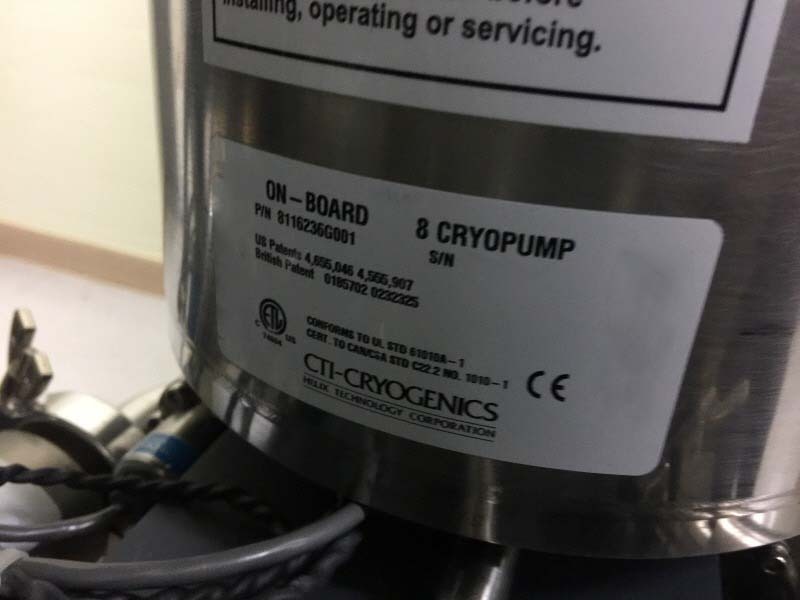

IS-8F (On-Board) Cryo pump

(6) VAT Isolation valves

No MC3 System controller

No MC3 Handler controller

Left and right load lock:

TMH 071P Turbo pump

VAT Isolation valve

Left and right degas:

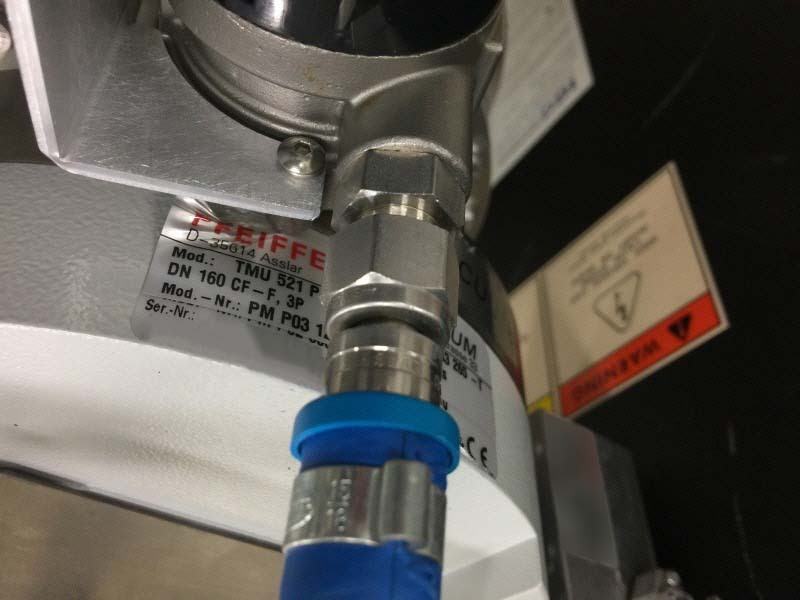

TMU 521P Turbo pump

VAT Isolation valve

Cool:

TMH 071P Turbo pump

Q300 AL and Q300 TIN:

No module controller

On-Board Cryo pump

V250 Turbo pump

On-Board Controller

Trust controller

MKS 649 Pressure controller

LPB

SIOC

ESC Pedestal

MFC (Ar, 200 SCCM)

MKS MFC (N2, 200 SCCM)

AERA UPC (300 SCCM)

INFICON Ion gauge

Anafazer Module

(2) HCM TI:

No module controller

On-Board Cryo pump

V250 Turbo pump

On-Board Controller

Trust controller

MKS 649 Pressure controller

LPB

SIOC

ESC Pedestal

MFC (Ar, 200 SCCM)

MKS MFC (N2, 200 SCCM)

MYKROLIS UPC (300 SCCM)

MYKROLIS Ion gauge

Anafazer Module

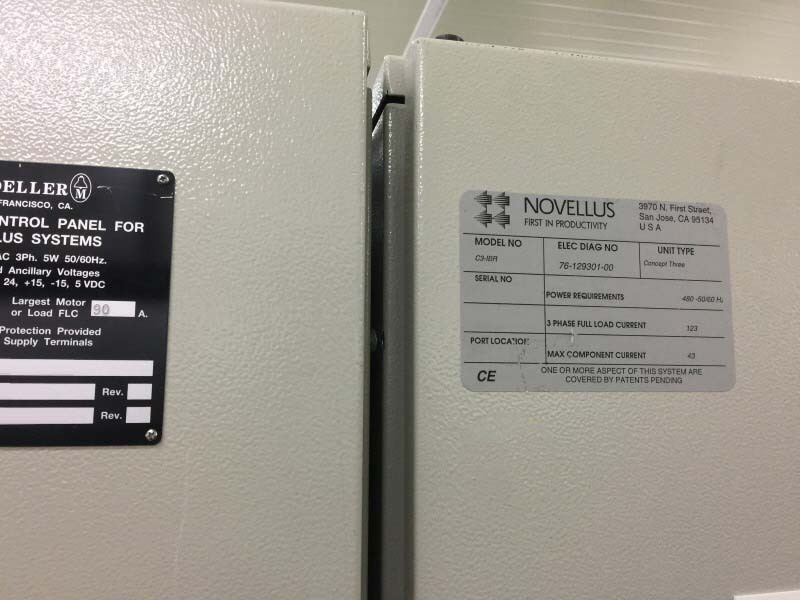

Electric cabinet rack (AL / TIN):

TREK 684-1 ESC Power supply

CPW2870B10 CPI DC Power supply

Electric cabinet rack:

TREK 684-1 ESC Power supply

(2) CPW2870B10 CPI DC Power supplies

(8) DCS80-13E EM Coil power supplies

Miscellaneous parts:

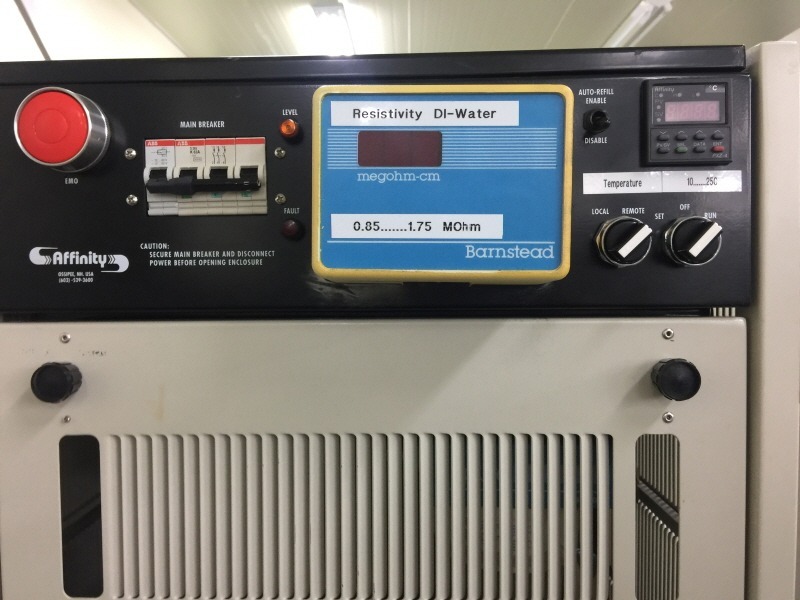

AFFINITY EWA-23DK-HE04CBC Chiller

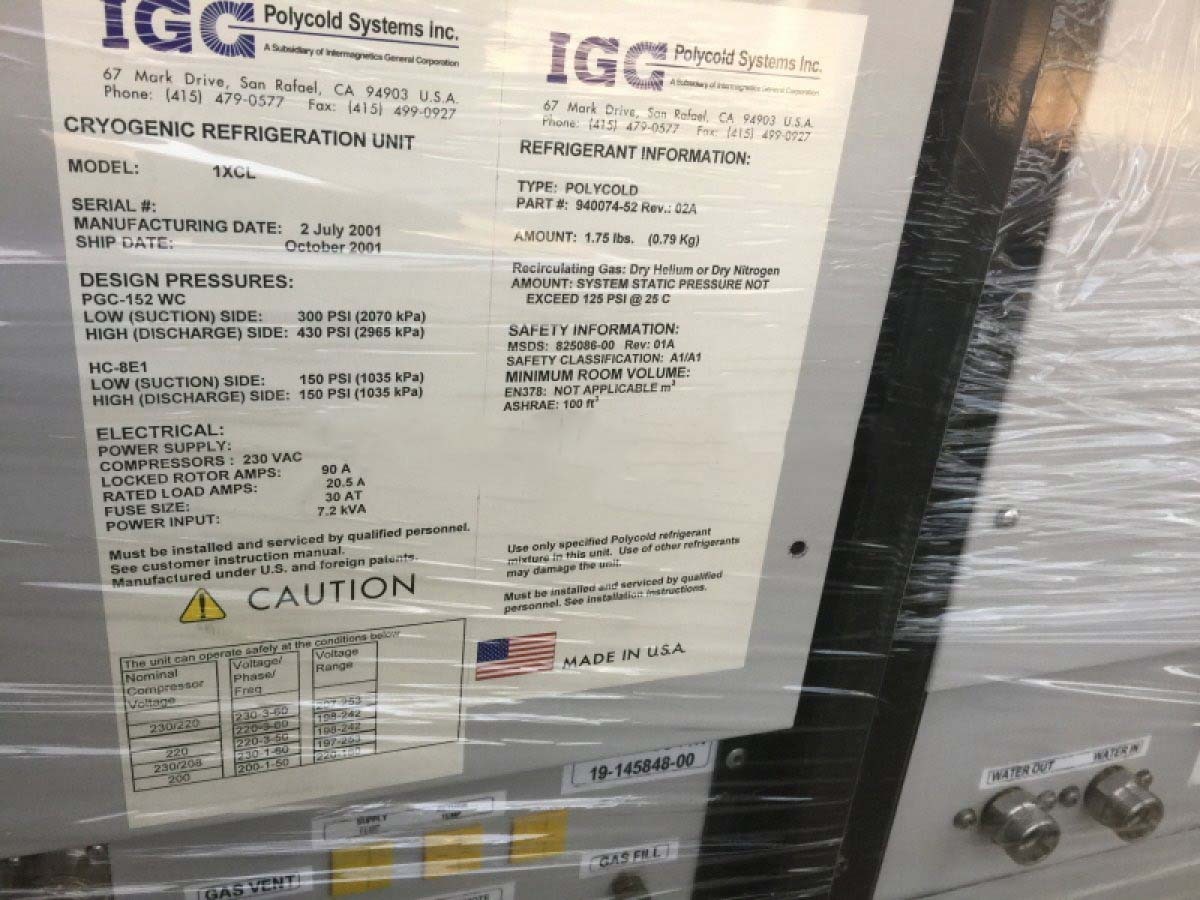

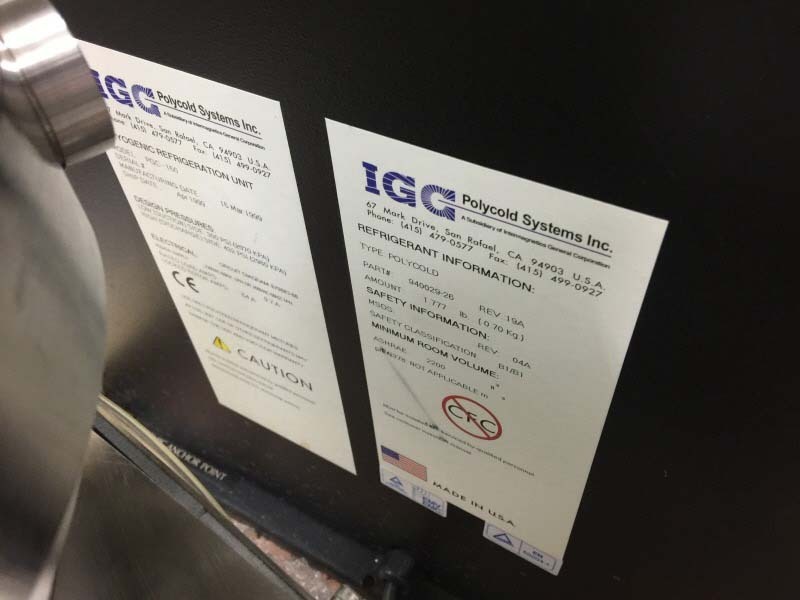

POLYCOLD PGC-150 Chiller

POLYCOLD 1XCL Chiller

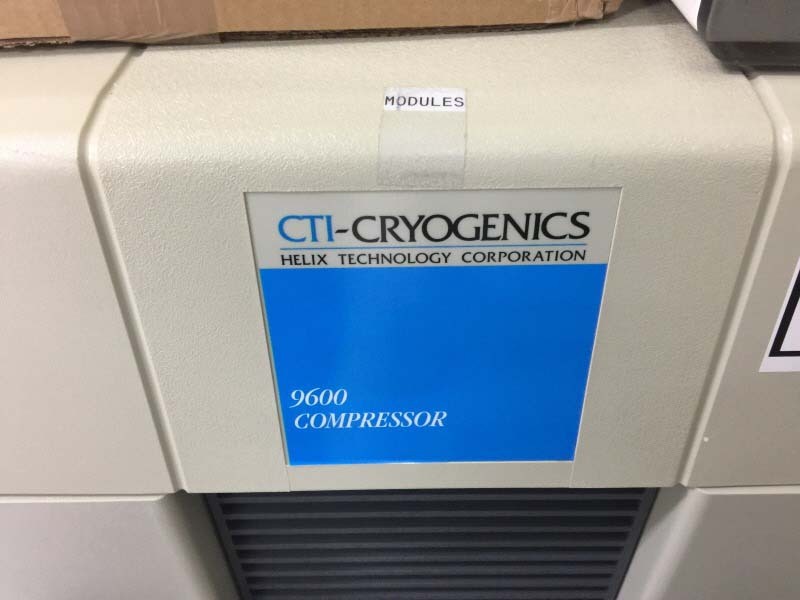

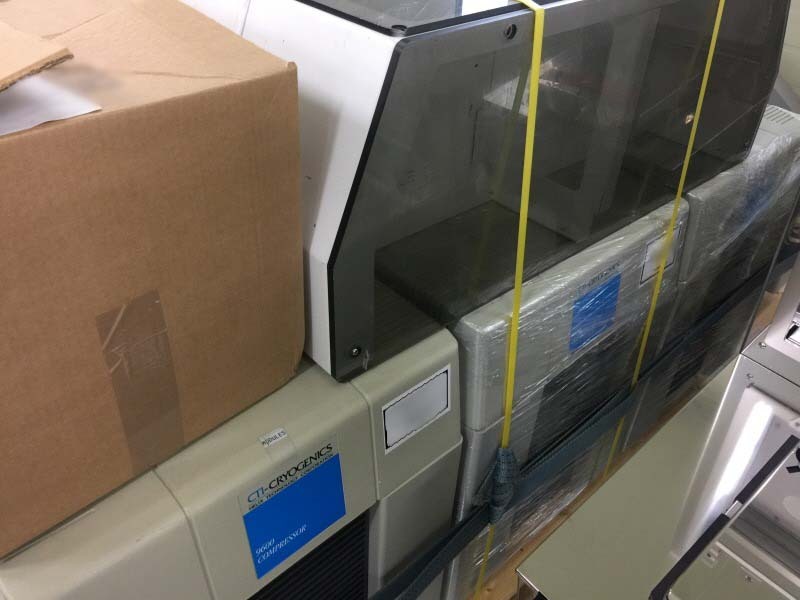

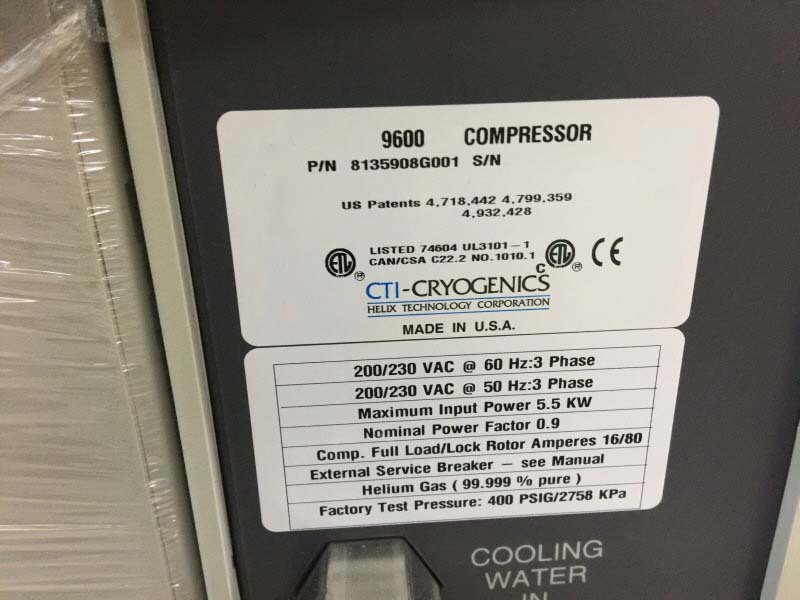

CTI 9600 Compressor

SPUD Gas box

Vacuum jacket lines

Cable box

Shield box

Spare parts

Missing parts:

MC3 Controllers for system and module

MKS 651D-16202 Throttle valve controller

(4) Z-Table movement controllers, P/N: 19-131418-00

POLYCOLD 1XCL Closed loop gas chiller

VAT Valve, P/N: 07512-UA24-0001

TMP Controller, P/N: 19-126817-00 Rev B and 88-30620-000

CTI-CRYOGENICS Controller, P/N: 823247G001

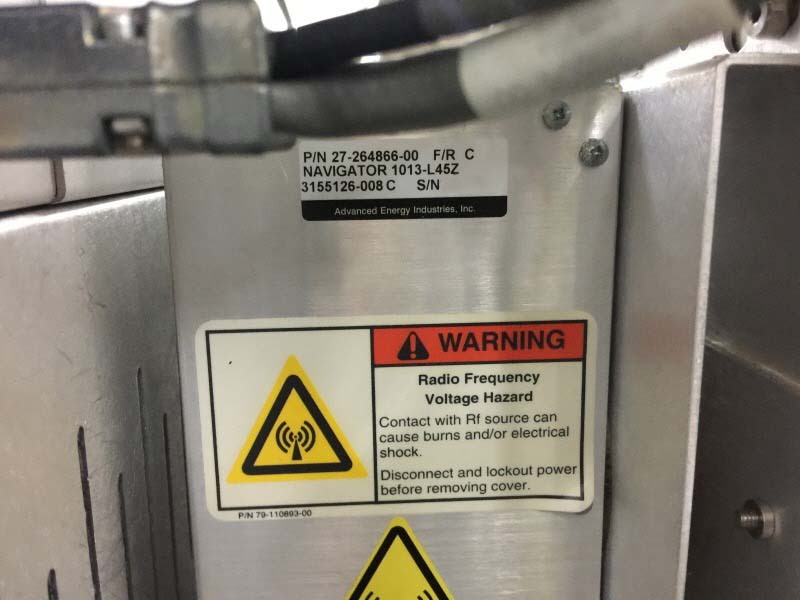

(2) ADVANCED ENERGY RFG 1251 Generators

VERIFLO SQMICRO302PFSFF Manual valve, 1/4 VCR, 2-way female

(3) CTI-CRYOGENICS 9600 Compressors

MAG7 Robot

2000 vintage.

NOVELLUS Concept 3 Inova Reactor is a high-throughput, continuous-flow reactor equipment for the synthesis of fine chemicals. It is designed to be used in R&D and scale-up applications. The system can be used to synthesize a range of compounds, including pharmaceuticals, agrochemicals, flavors and fragrances, and polymers. The unit features a three-stage continuous-flow reactor design, which allows for reliable and consistent synthesis of a variety of materials. The first stage is an injection-molded reactor where a heated liquid stream containing reactants and catalyst is mixed. The heater monitors the temperature of the stream and can heat the stream to temperatures between 50-400°C. The second stage is an agitated vessel where homogenous mixing occurs to allow efficient and complete conversion of the reactants. The third stage is a separator where the reaction products are separated and collected. Concept 3 Inova Reactor is designed with a variety of safety features, including an onboard gas monitoring machine, automated shutdown in case of an overpressure, automatic lockout of hazardous gases, and emergency shut off devices. The reactor is also equipped with a computer-based control tool, which allows for monitoring and control of the asset parameters. It can be interfaced with computers or programmable logic controllers (PLC) for efficient process monitoring, control, automation, and data logging. The reactor is also equipped with an electrical heater that can be used to control the reaction temperature. This heater is adjustable within a range of -50 to +250°C. In addition, the model is designed to be used with a variety of catalysts and can accommodate changes in reaction conditions and operating variables. In order to reduce the amount of time and effort required for reactor cleaning, NOVELLUS Concept 3 Inova Reactor features automated cleaning systems. These systems use a combination of mechanical and chemical treating methods to automatically and thoroughly clean the reactor chamber. The cleaning time necessary can be reduced by up to 90%, thus speeding up the rate of process cycle completion. Concept 3 Inova Reactor is a highly efficient and cost-effective tool for the production of small molecules and fine chemicals in research, development, and scale-up applications. Its three-stage continuous-flow reactor design, safety features, computer-based control equipment, and automated cleaning systems all contribute to the system's efficiency and effectiveness and make it a preferred choice for many applications.

There are no reviews yet