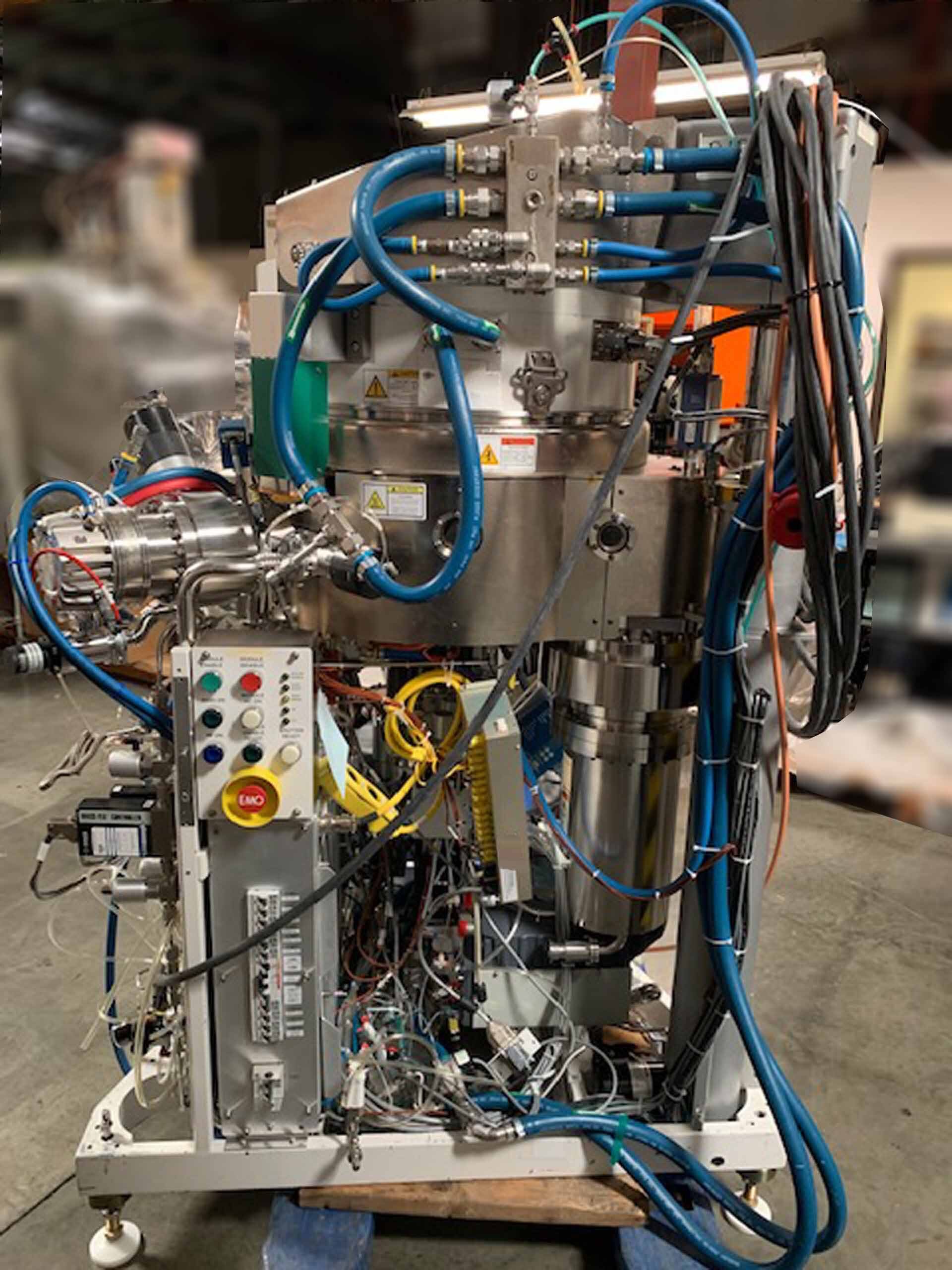

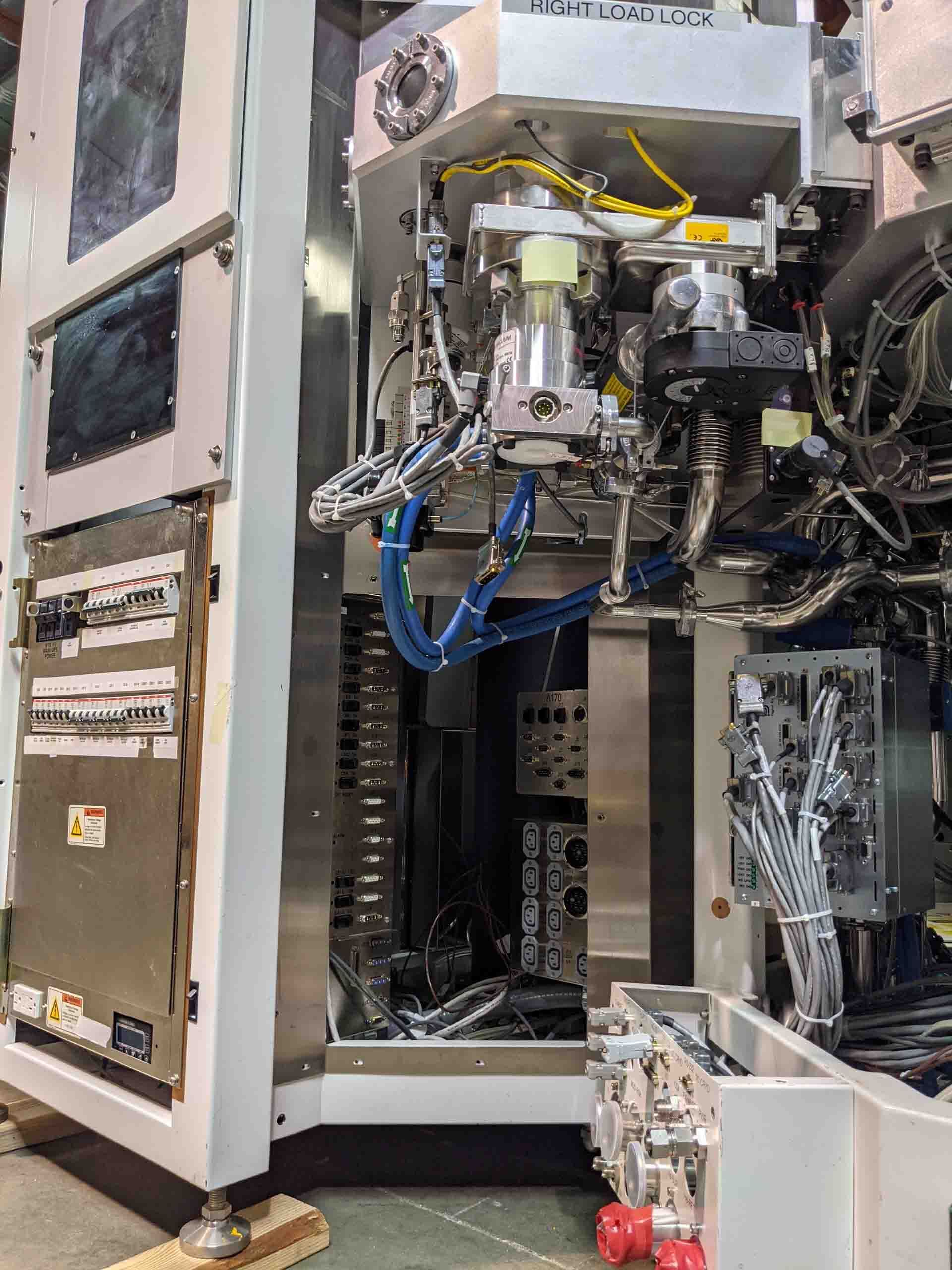

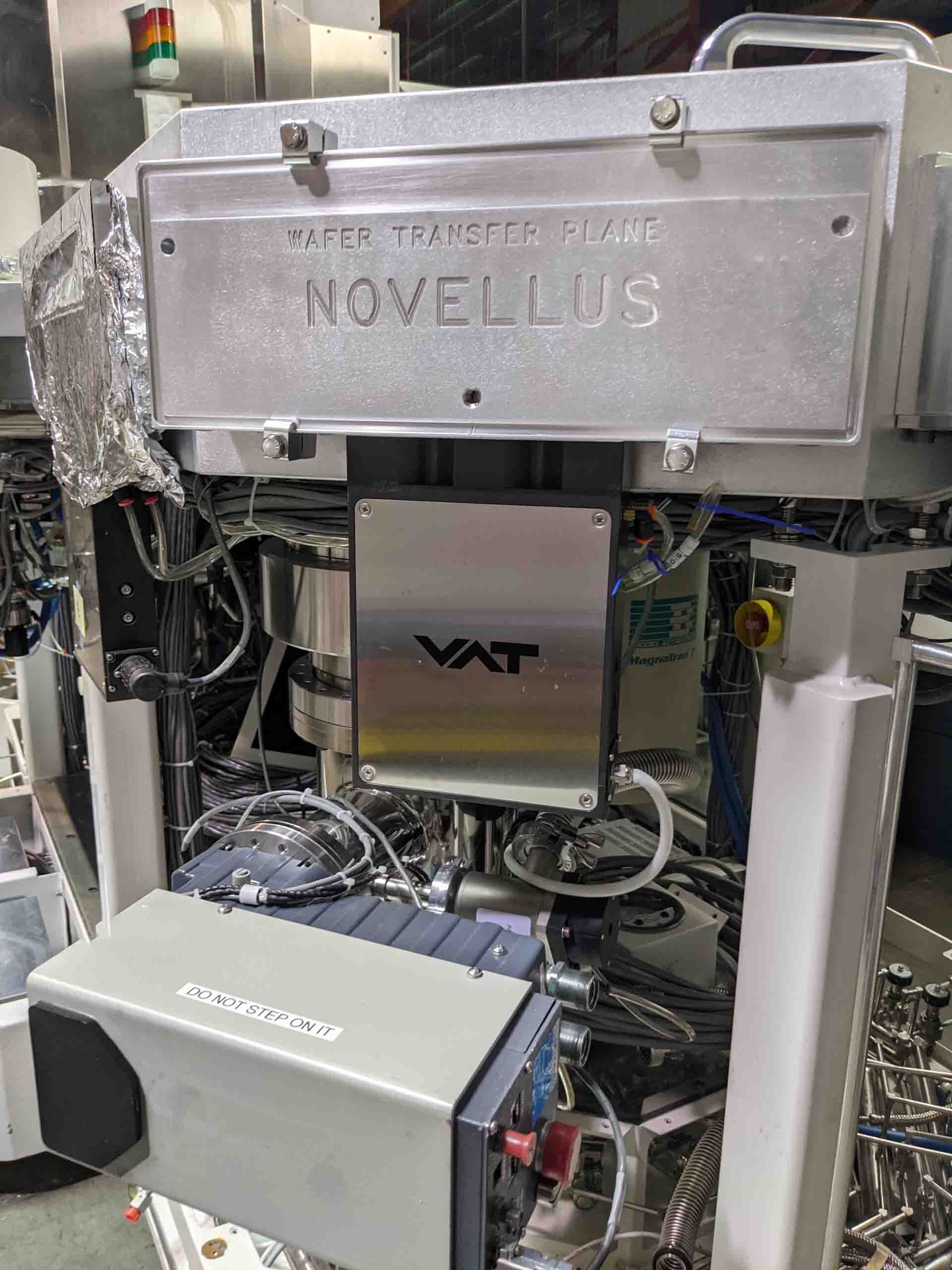

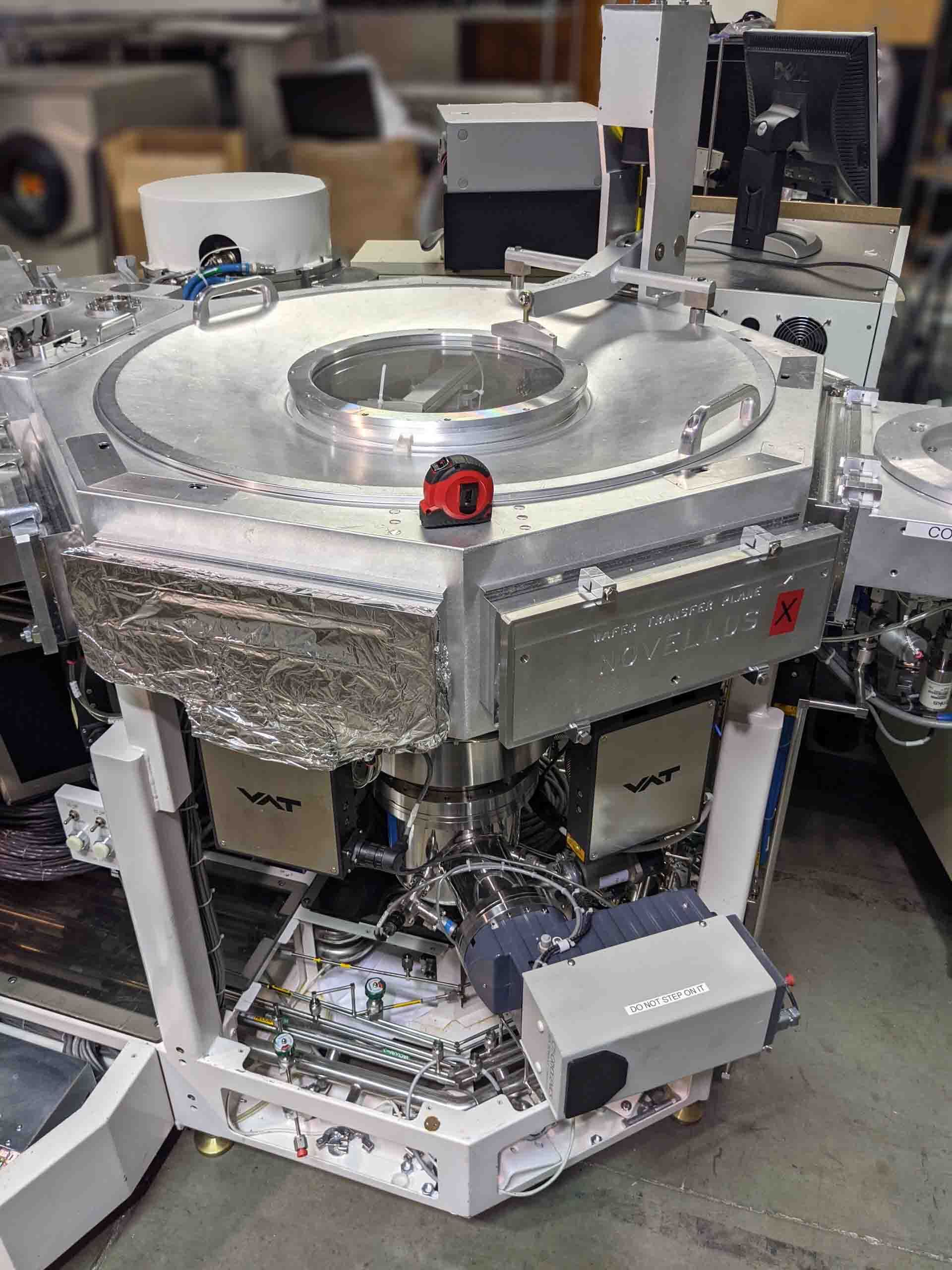

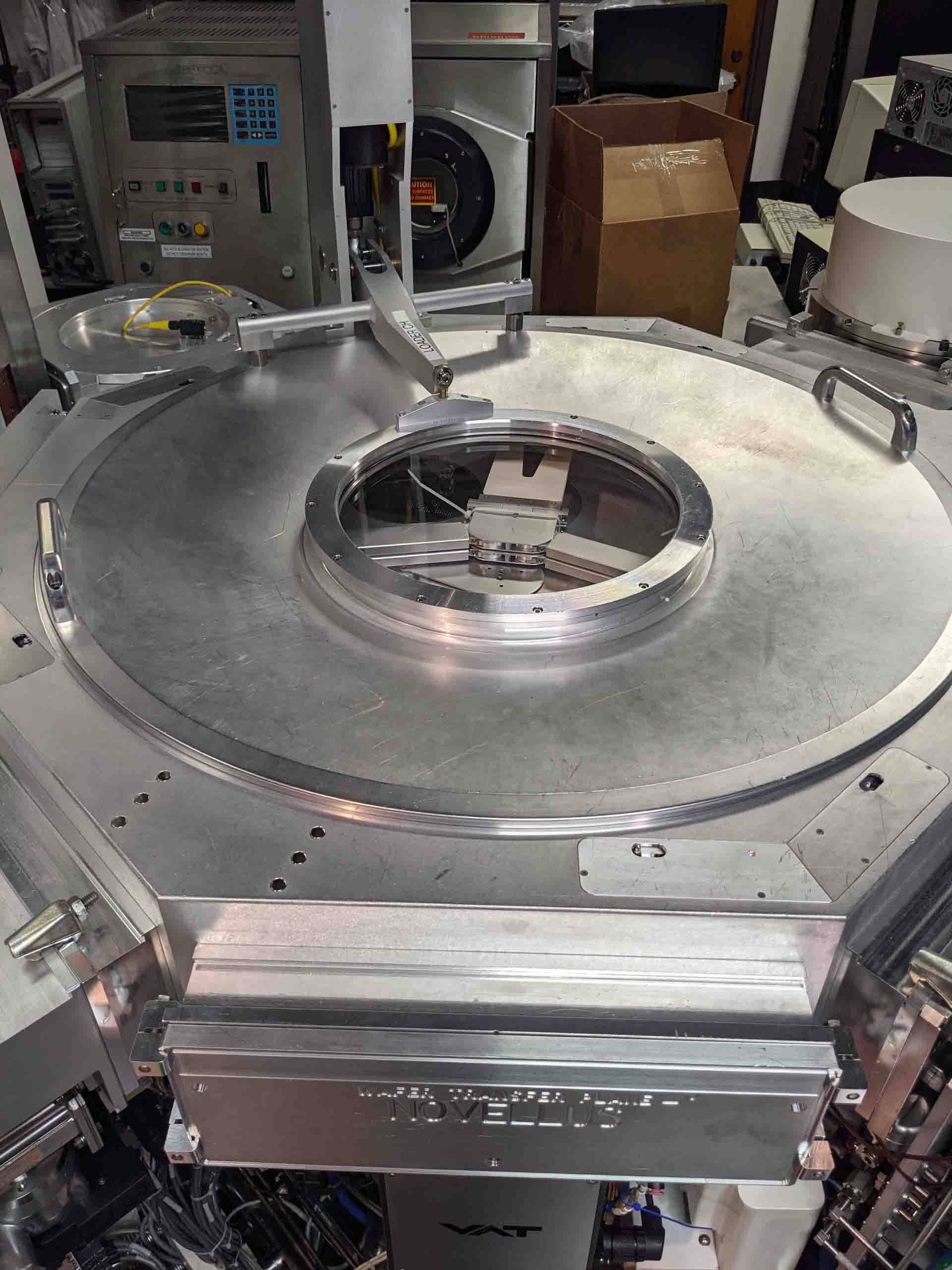

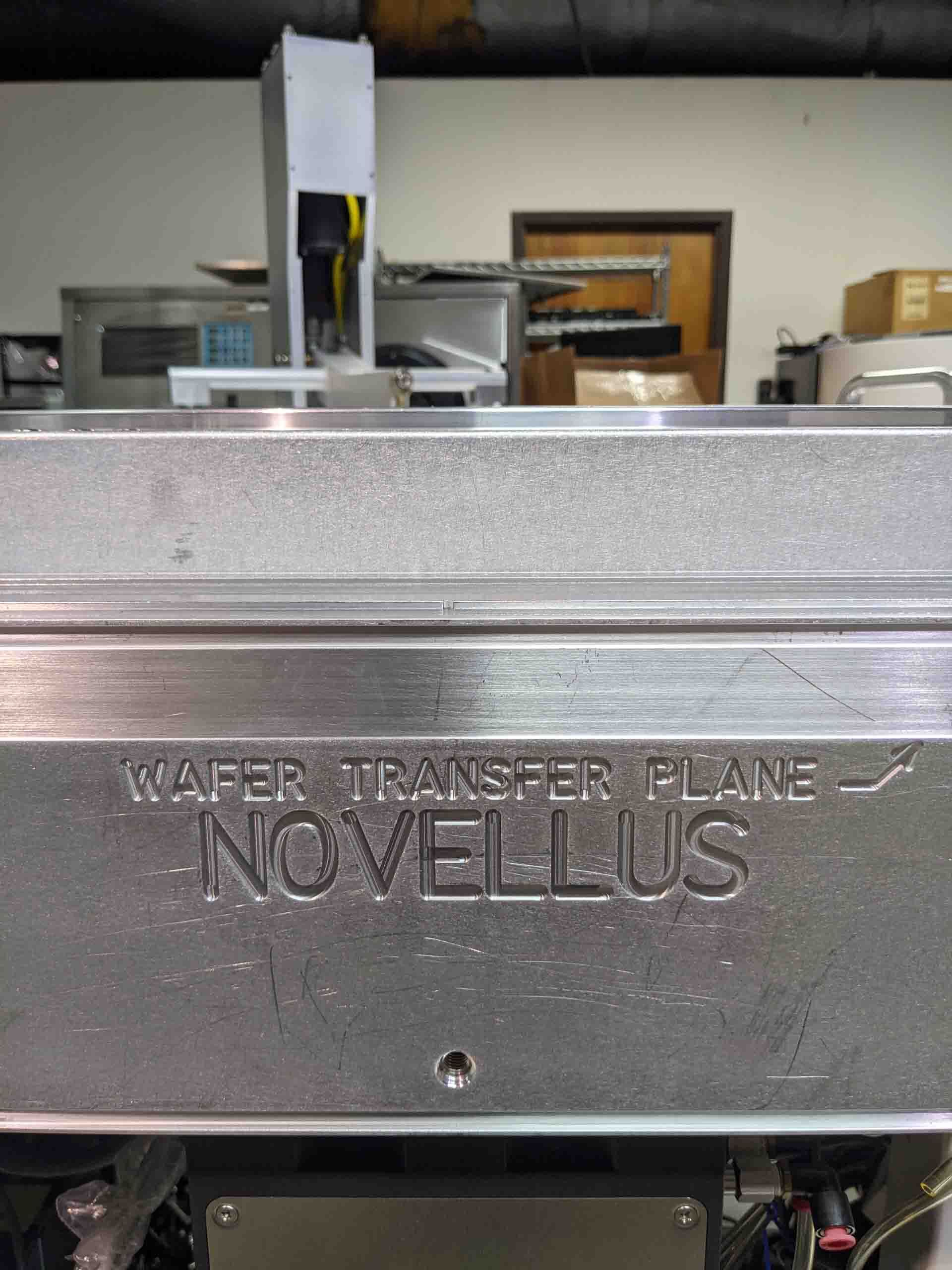

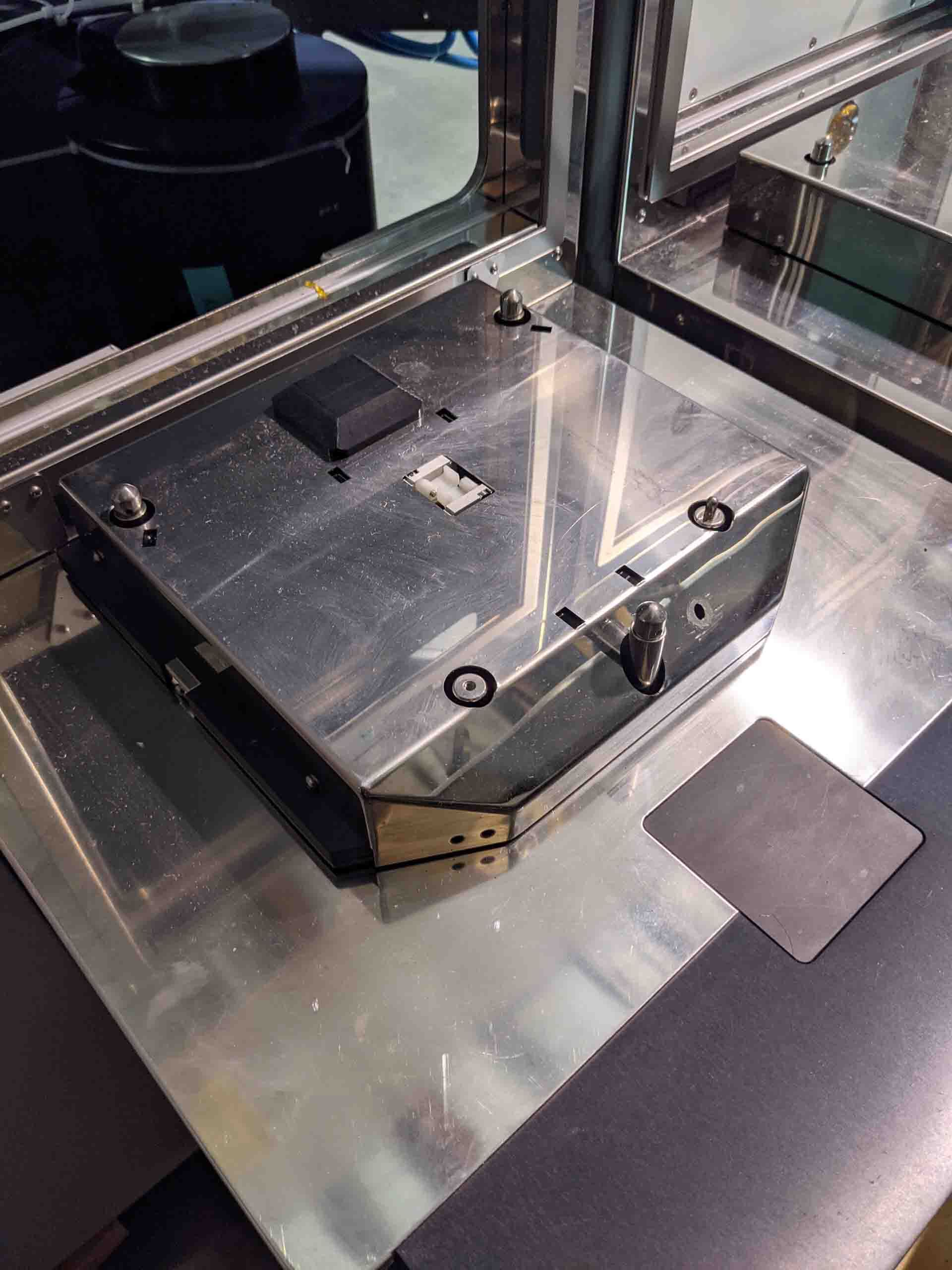

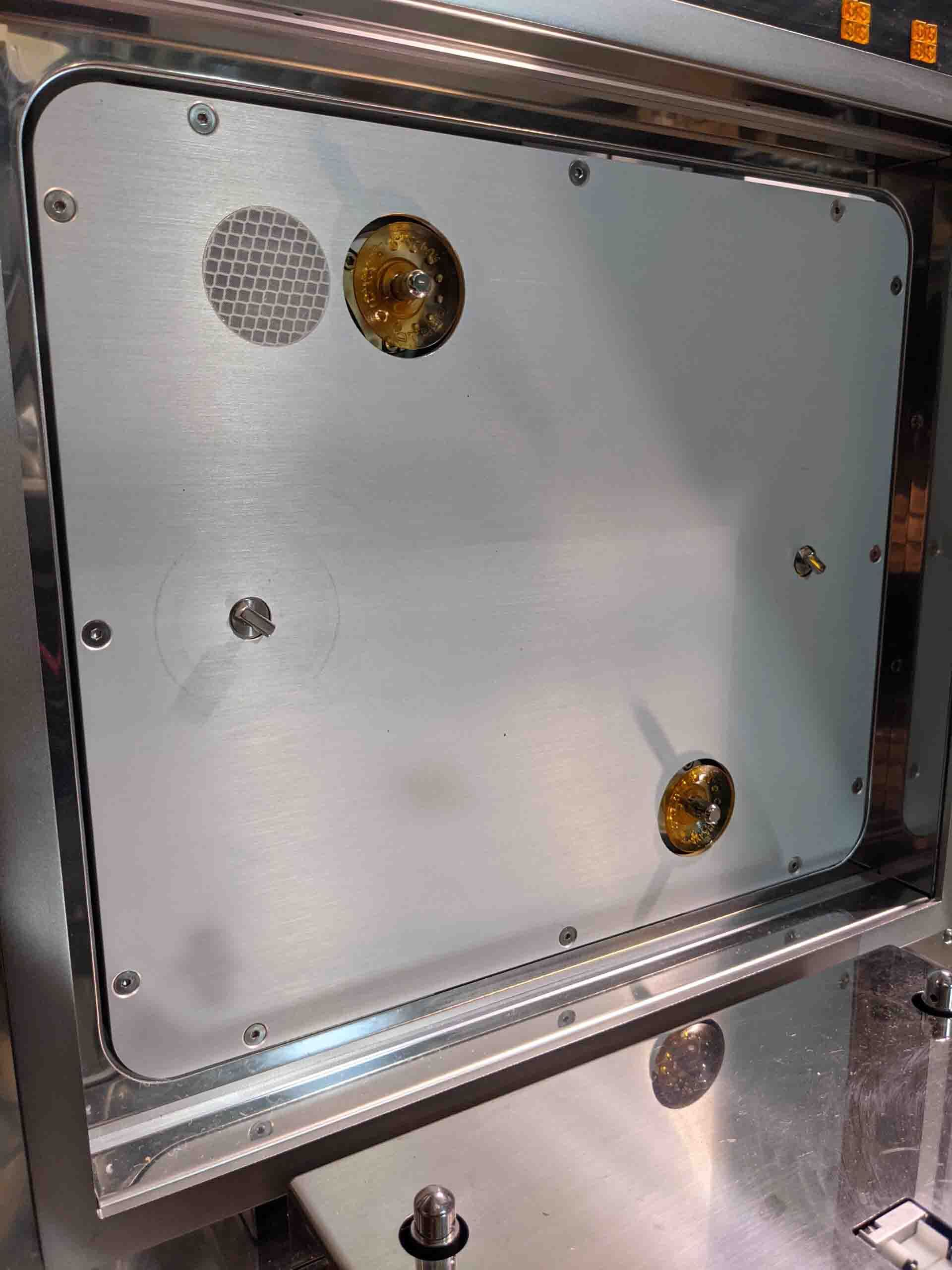

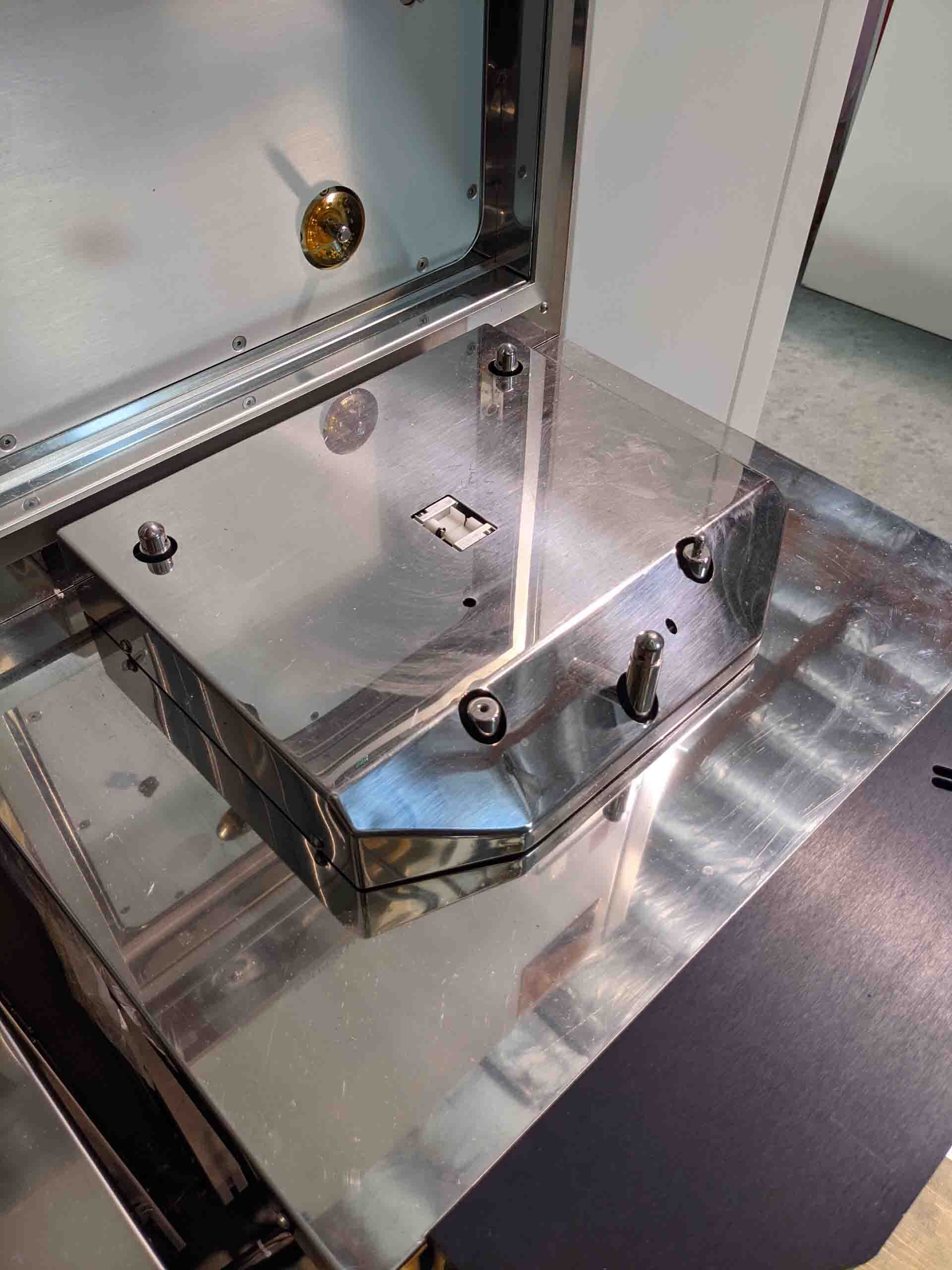

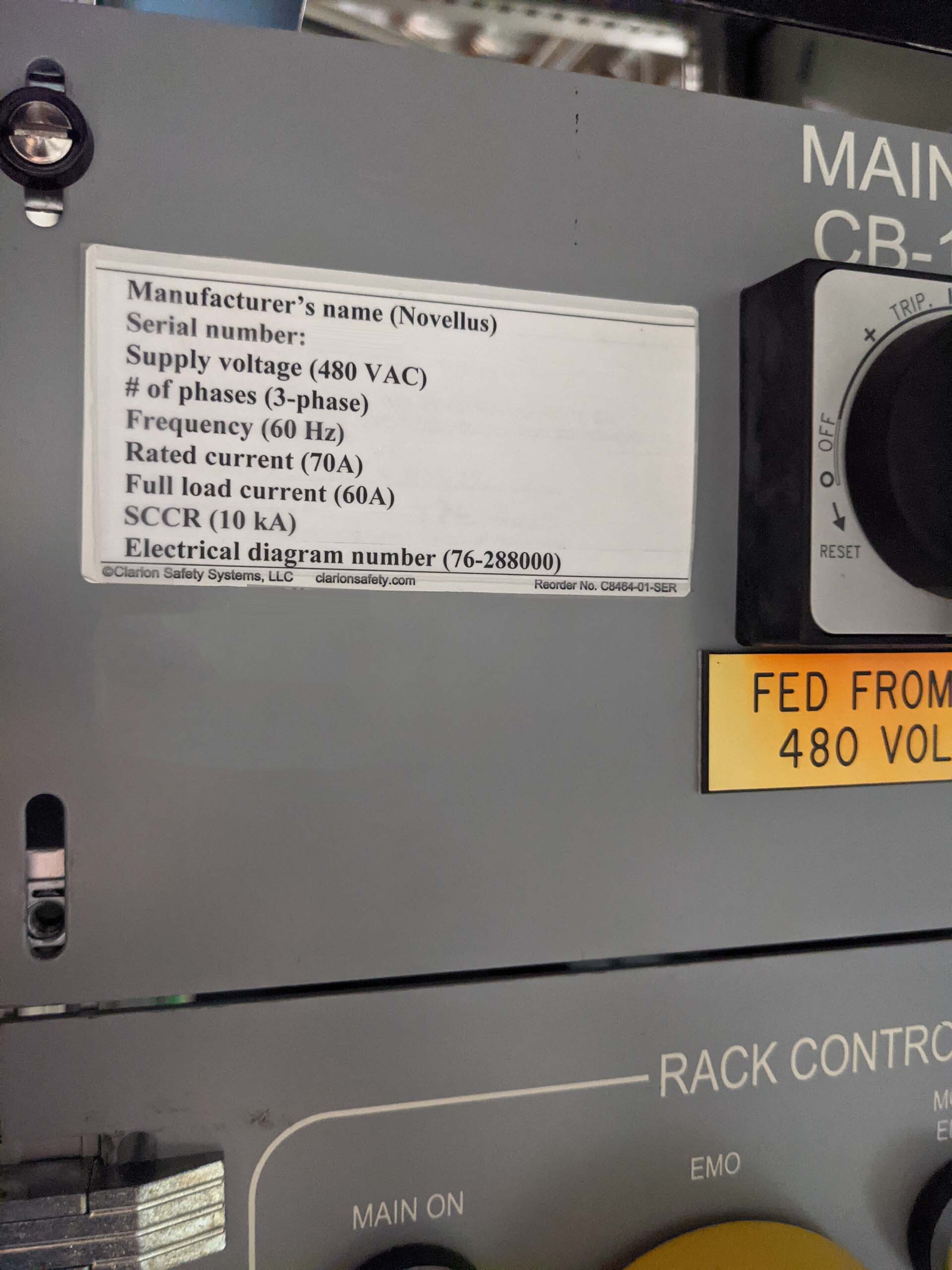

Used NOVELLUS Inova XT #9393590 for sale

URL successfully copied!

Tap to zoom

ID: 9393590

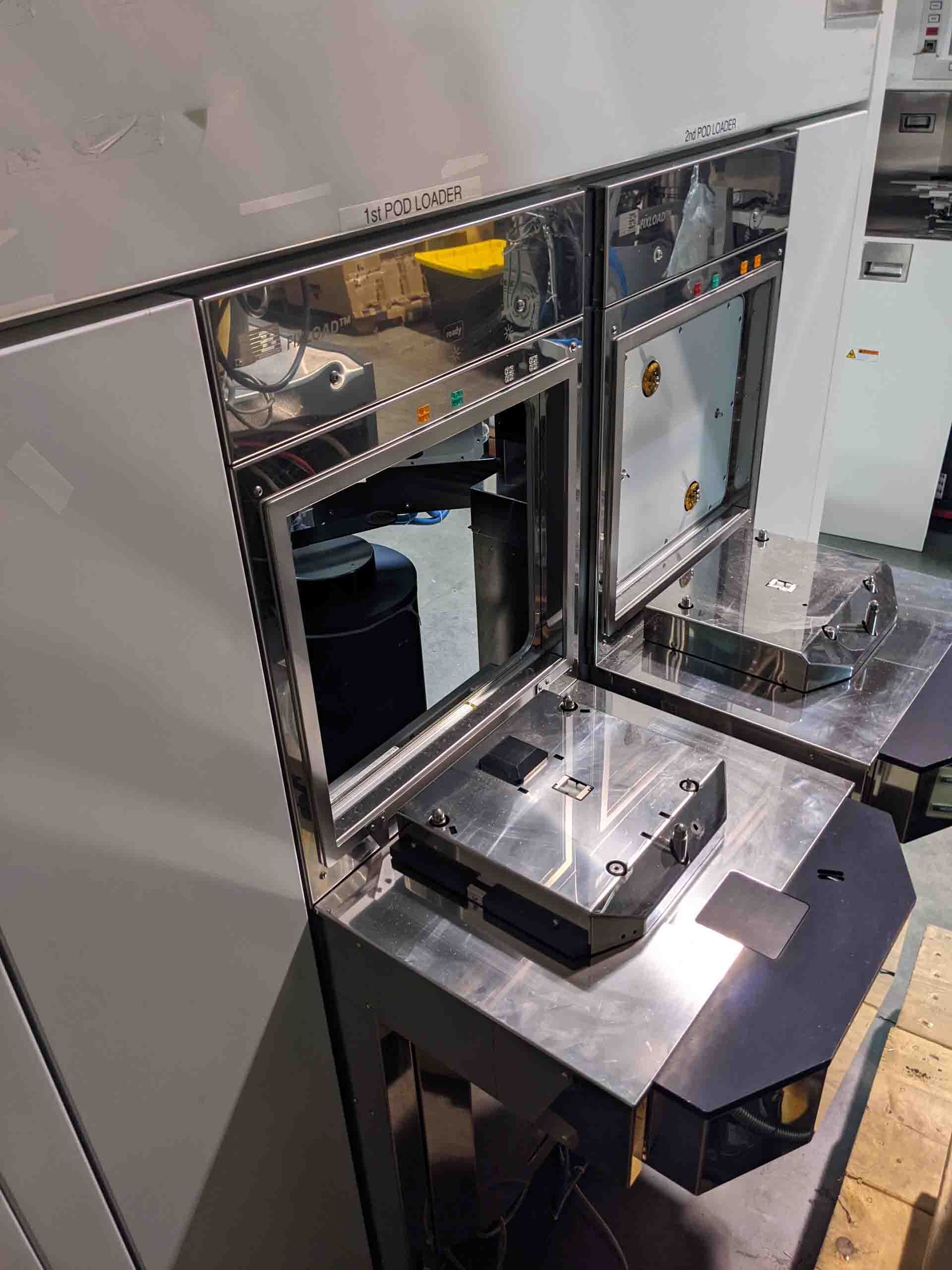

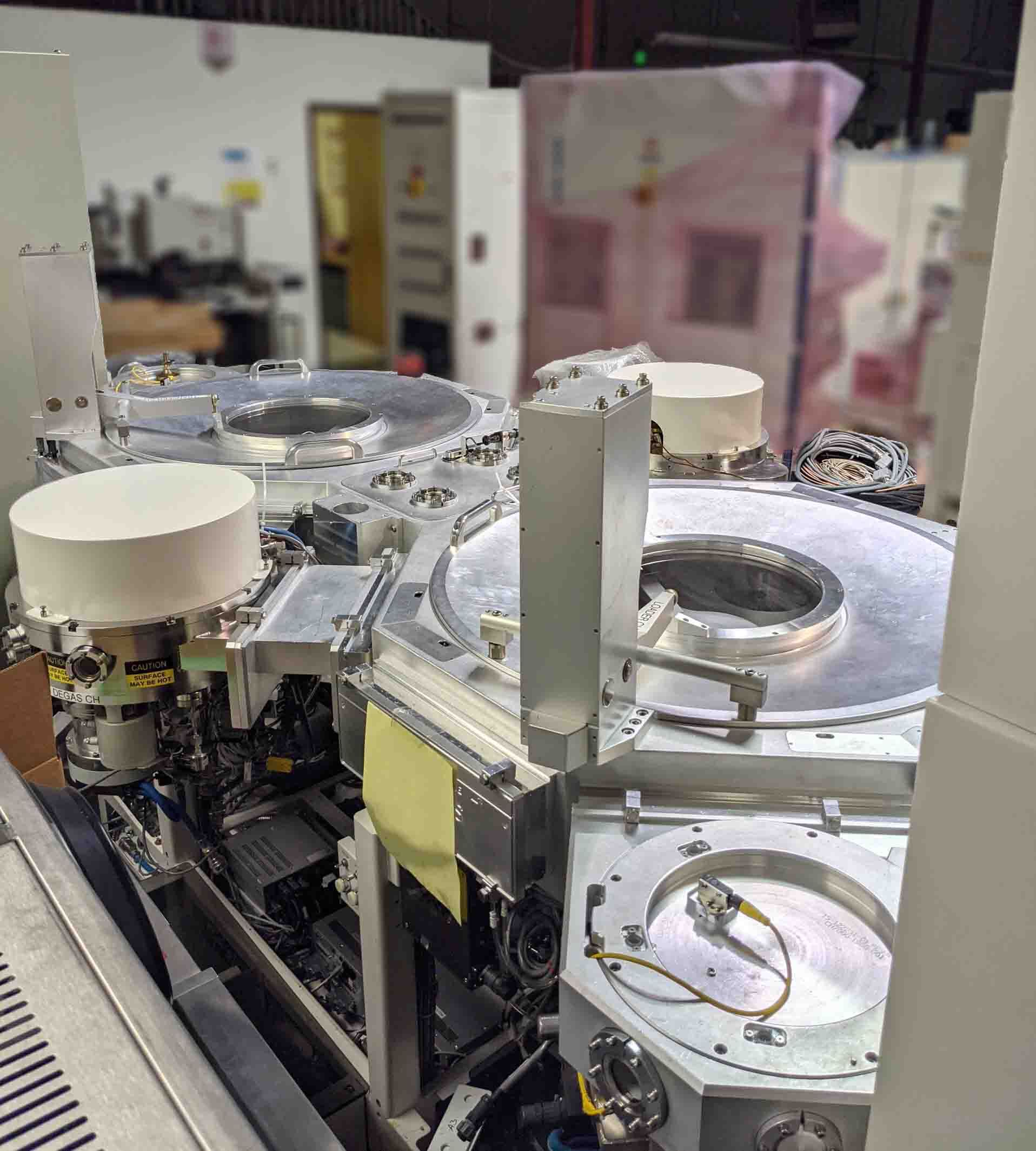

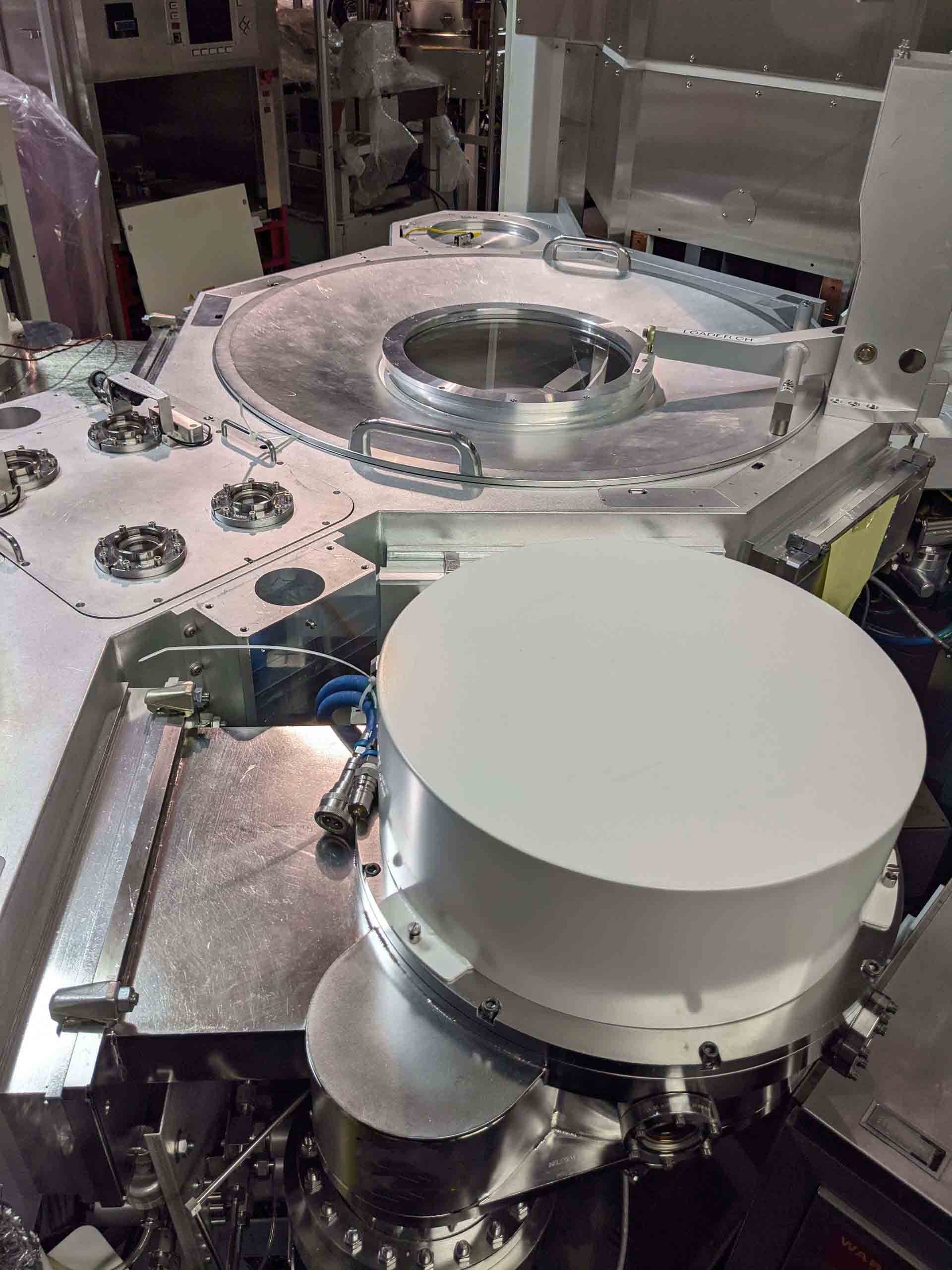

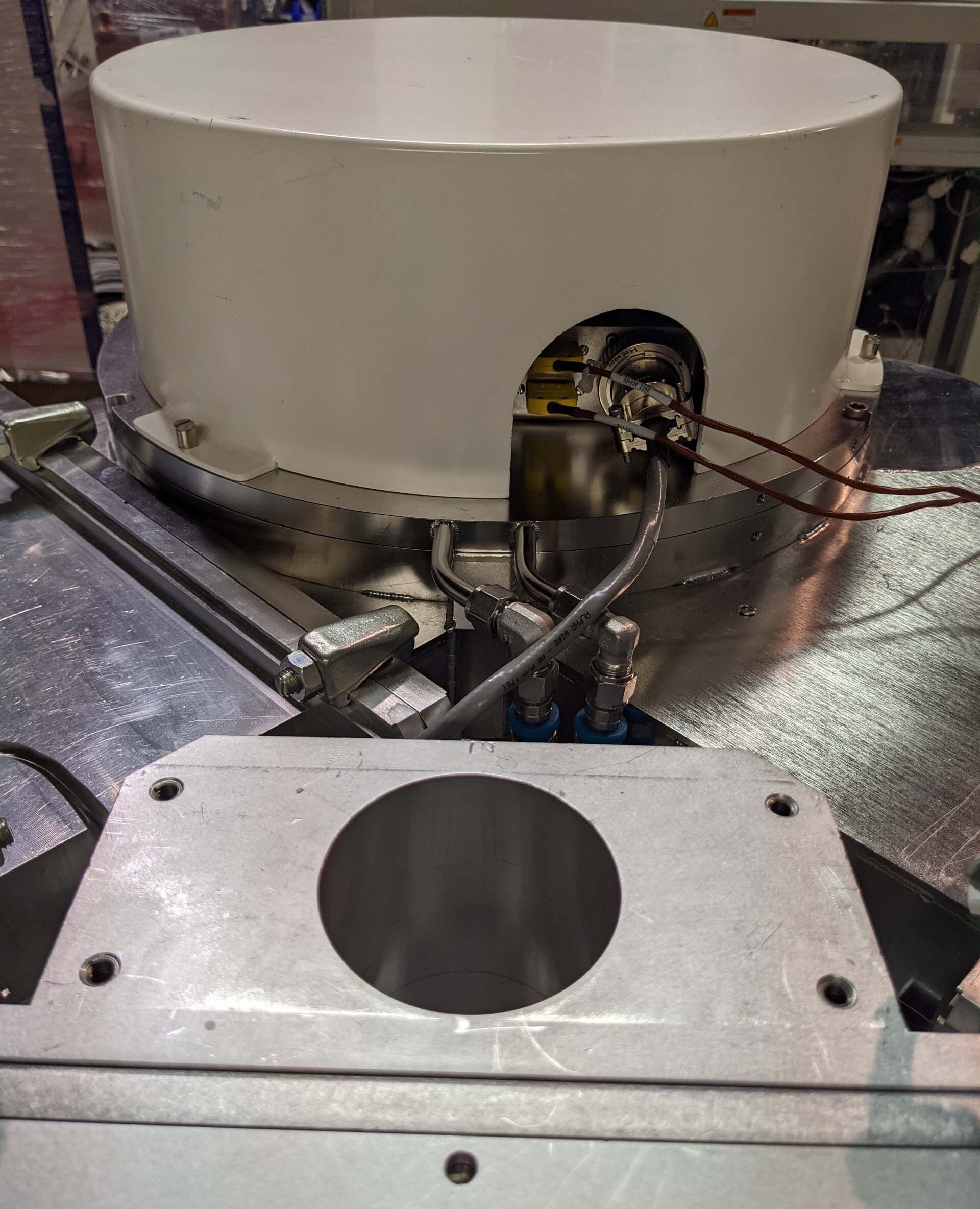

Wafer Size: 12"

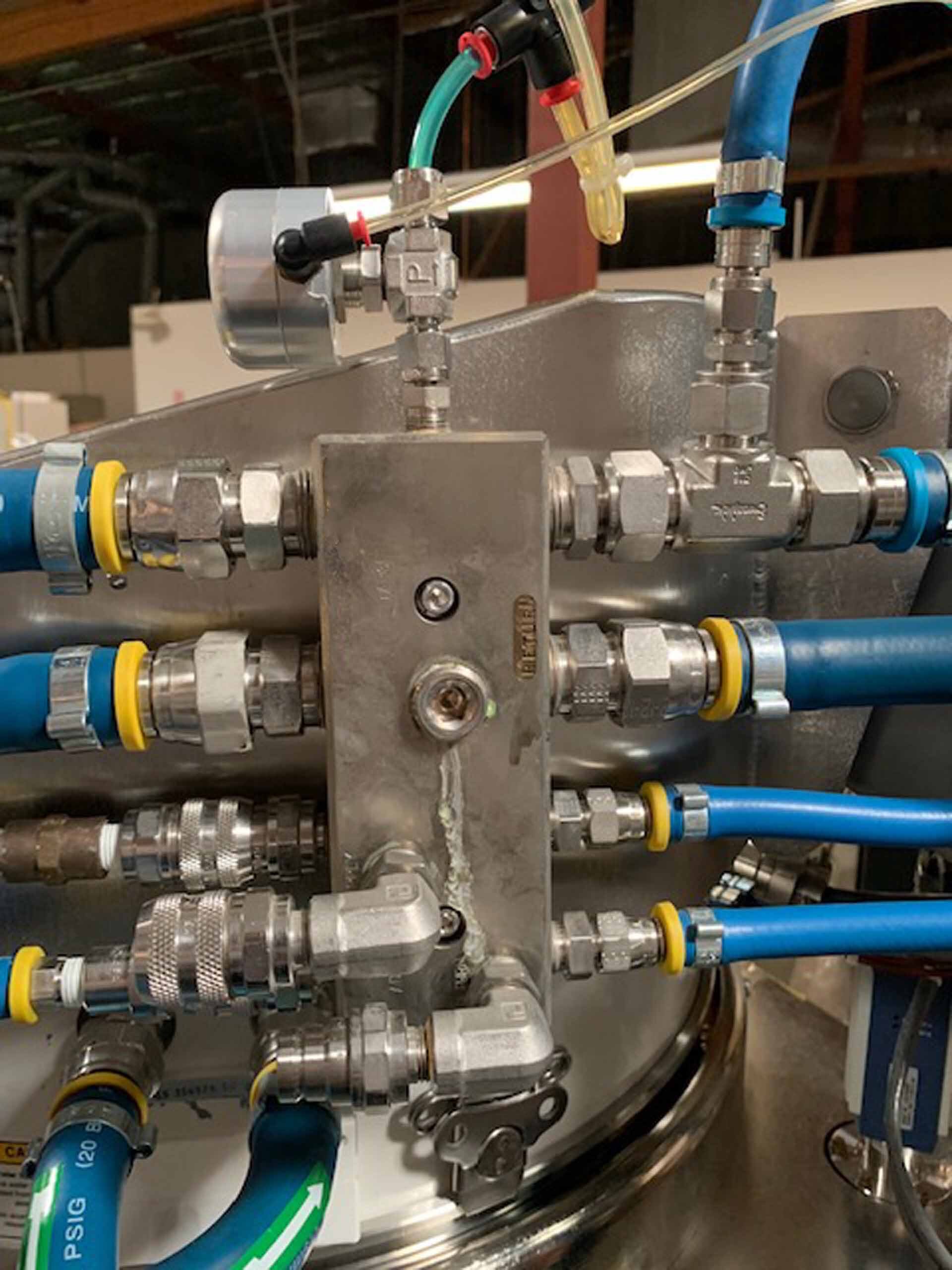

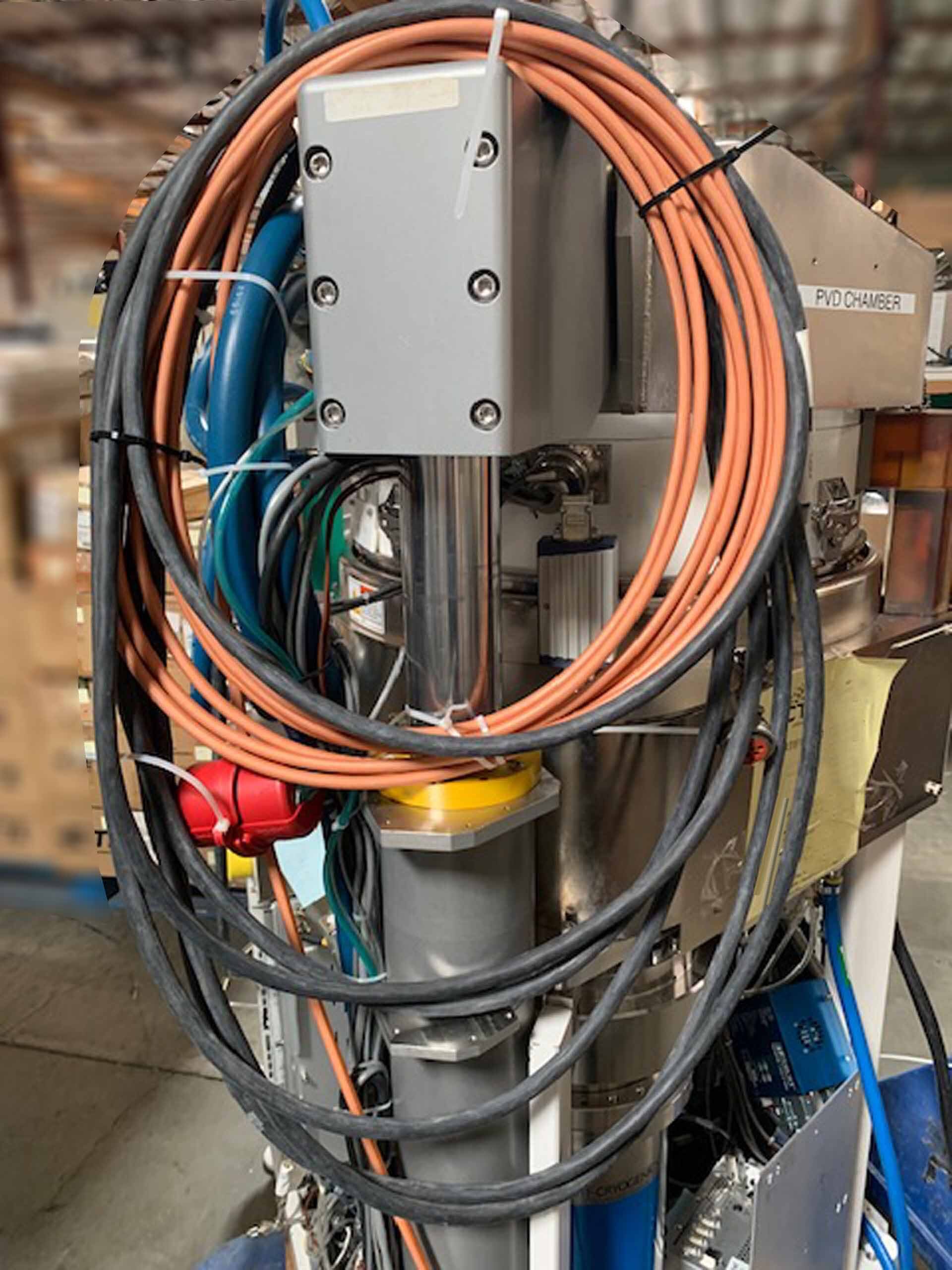

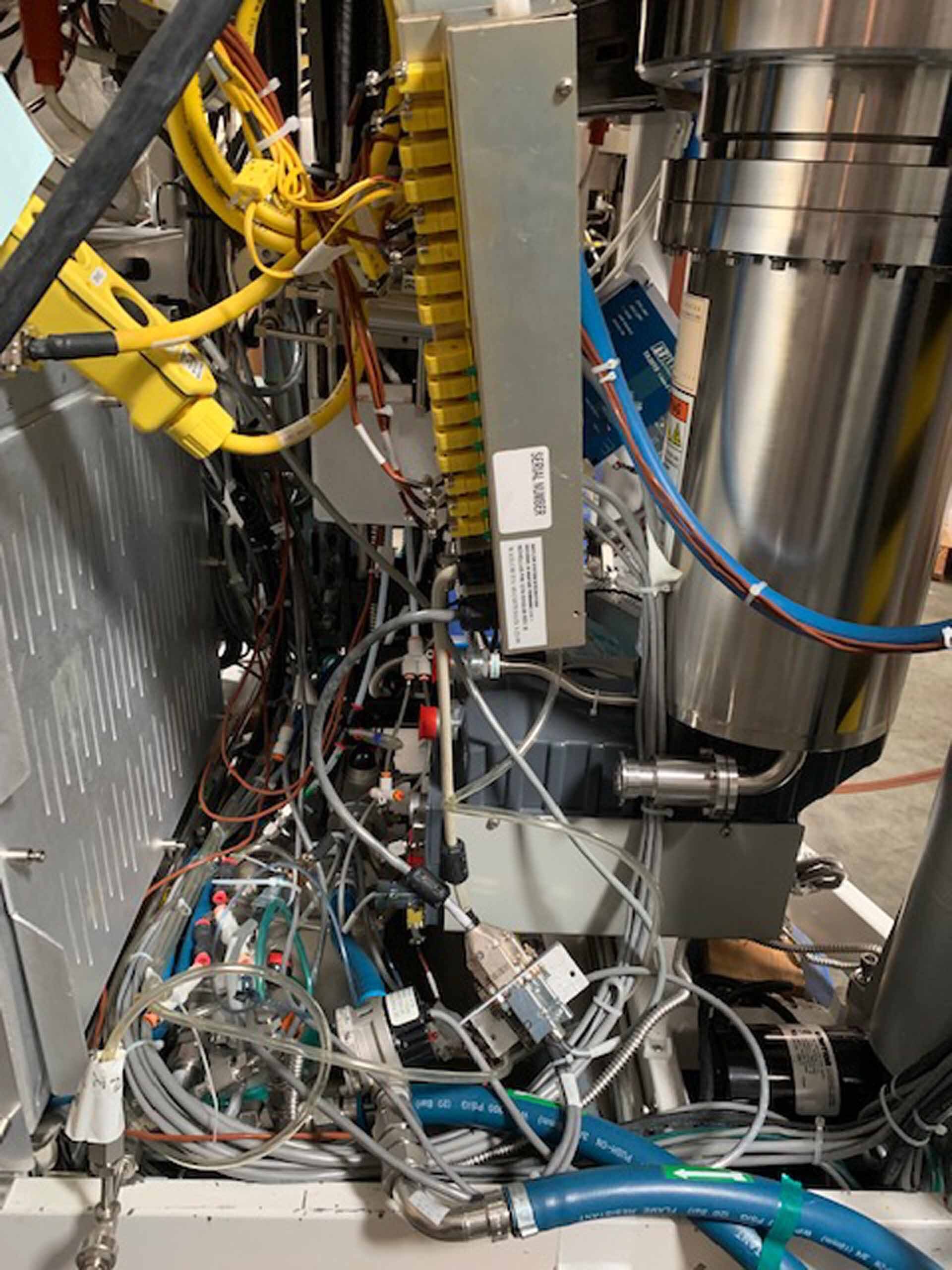

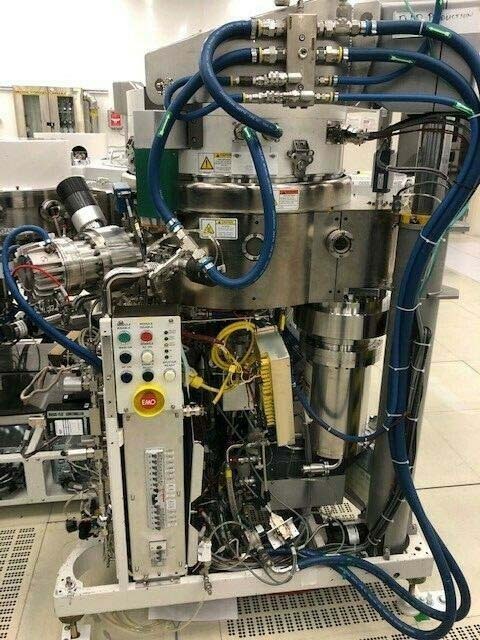

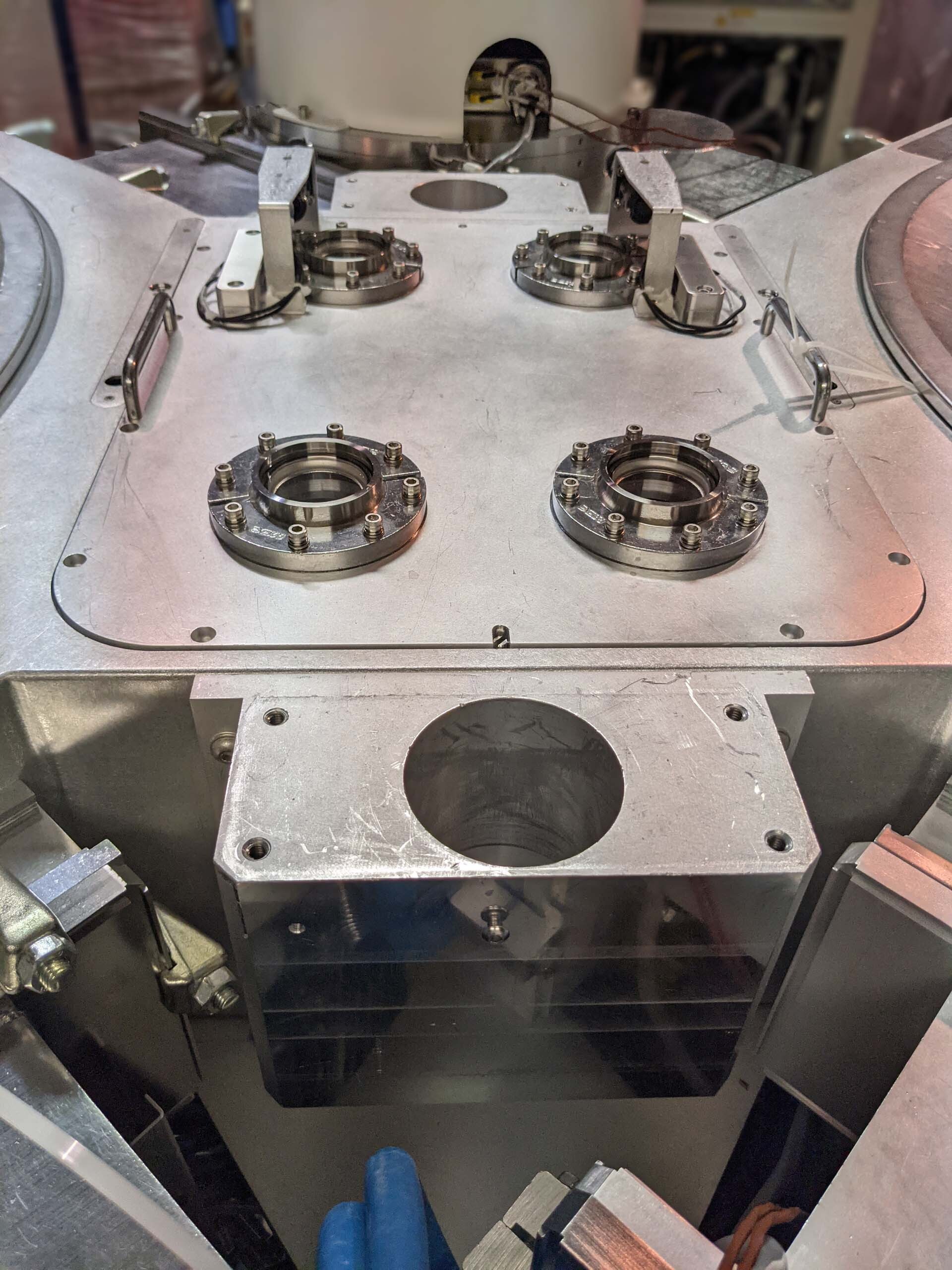

PVD System, 12"

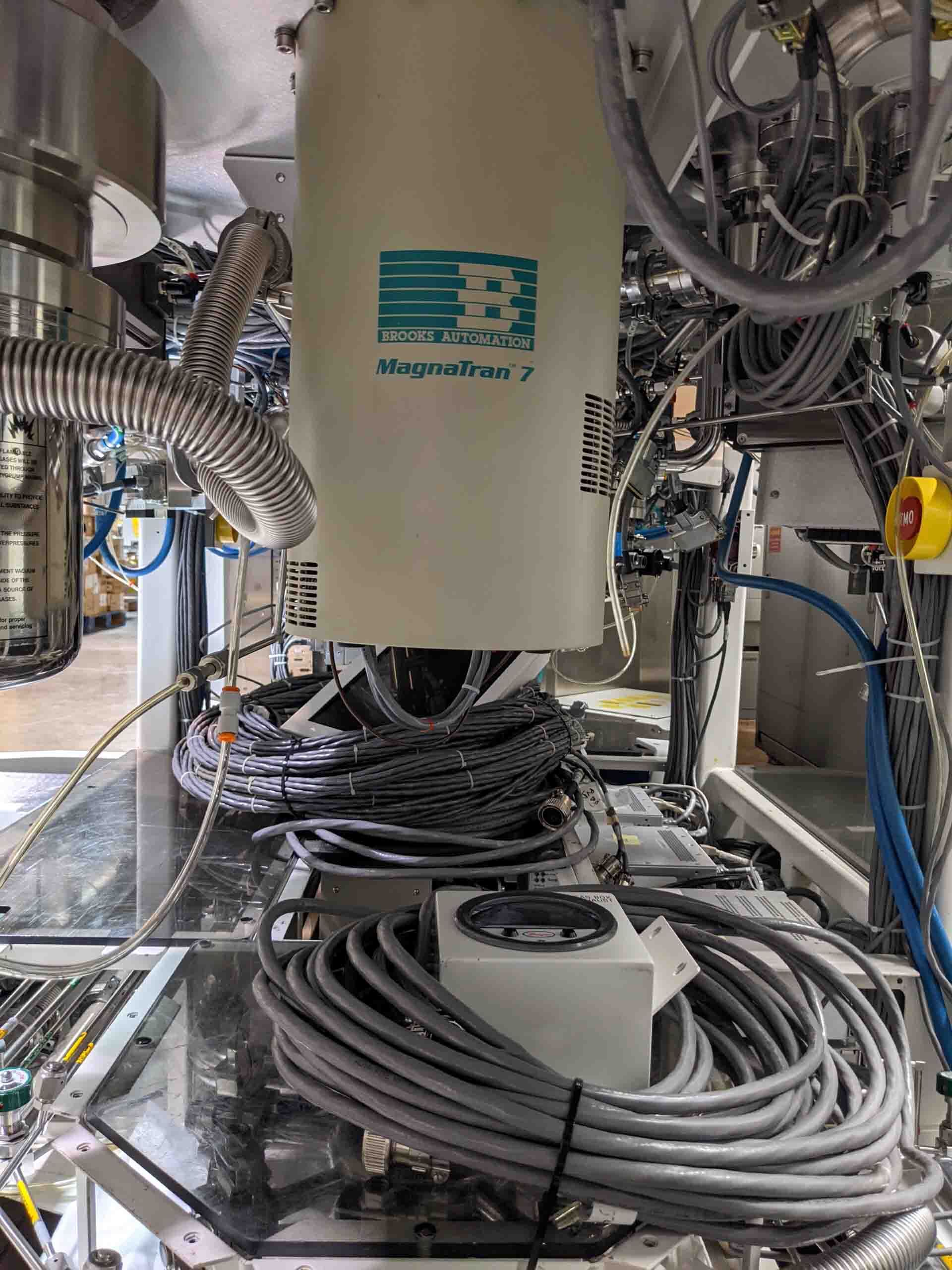

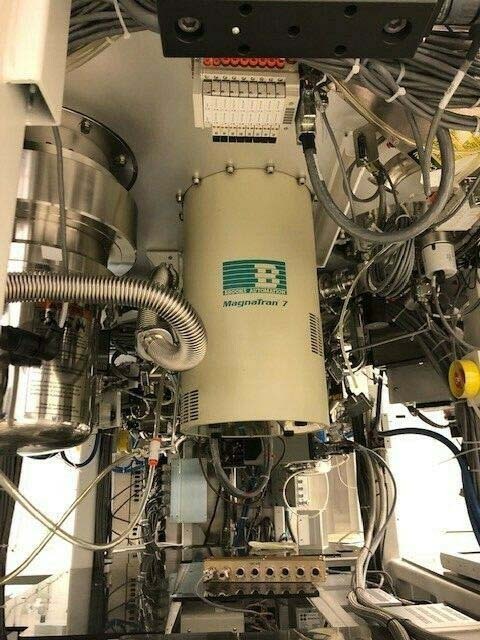

BROOKS MAG7 Robot

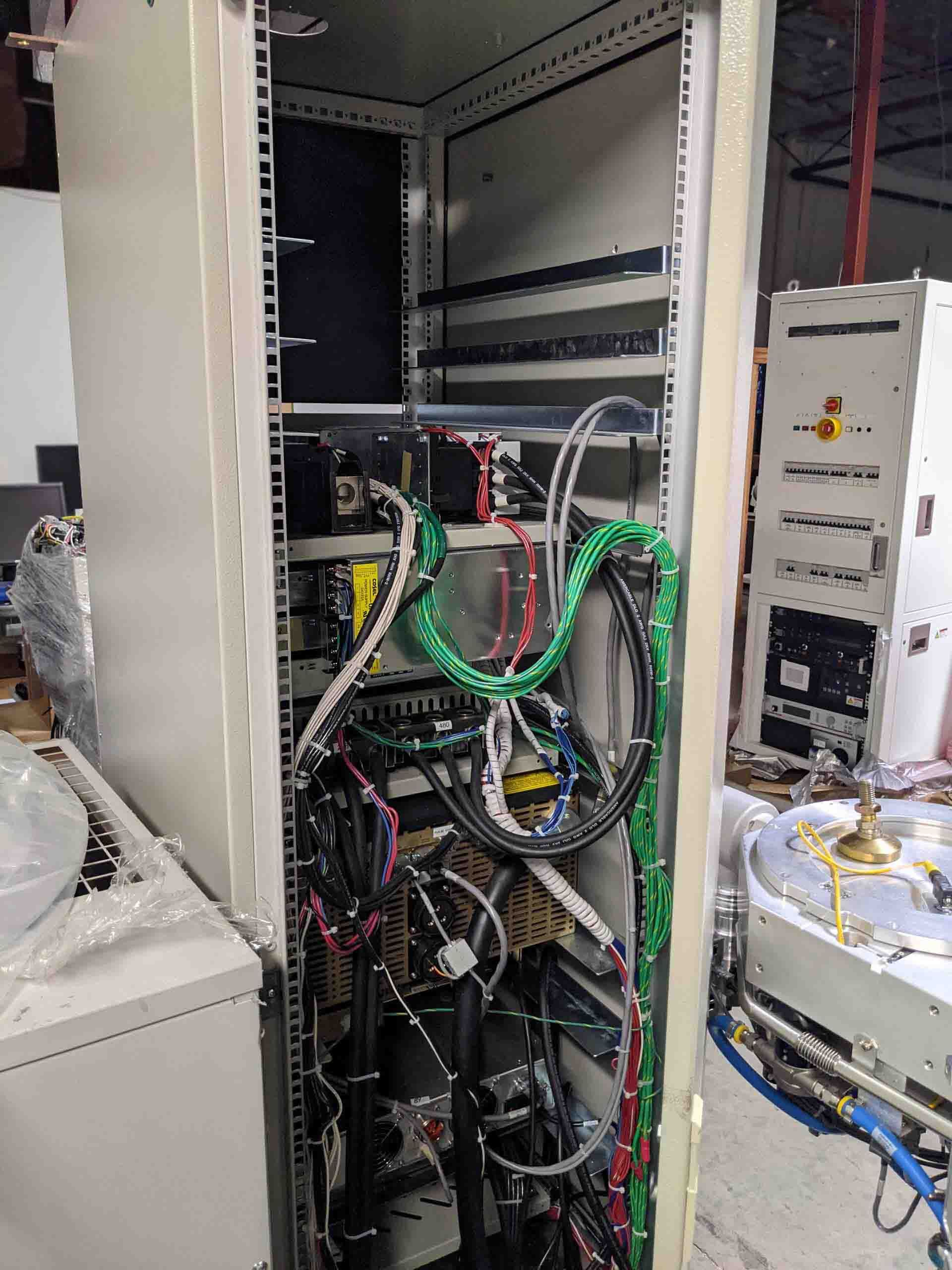

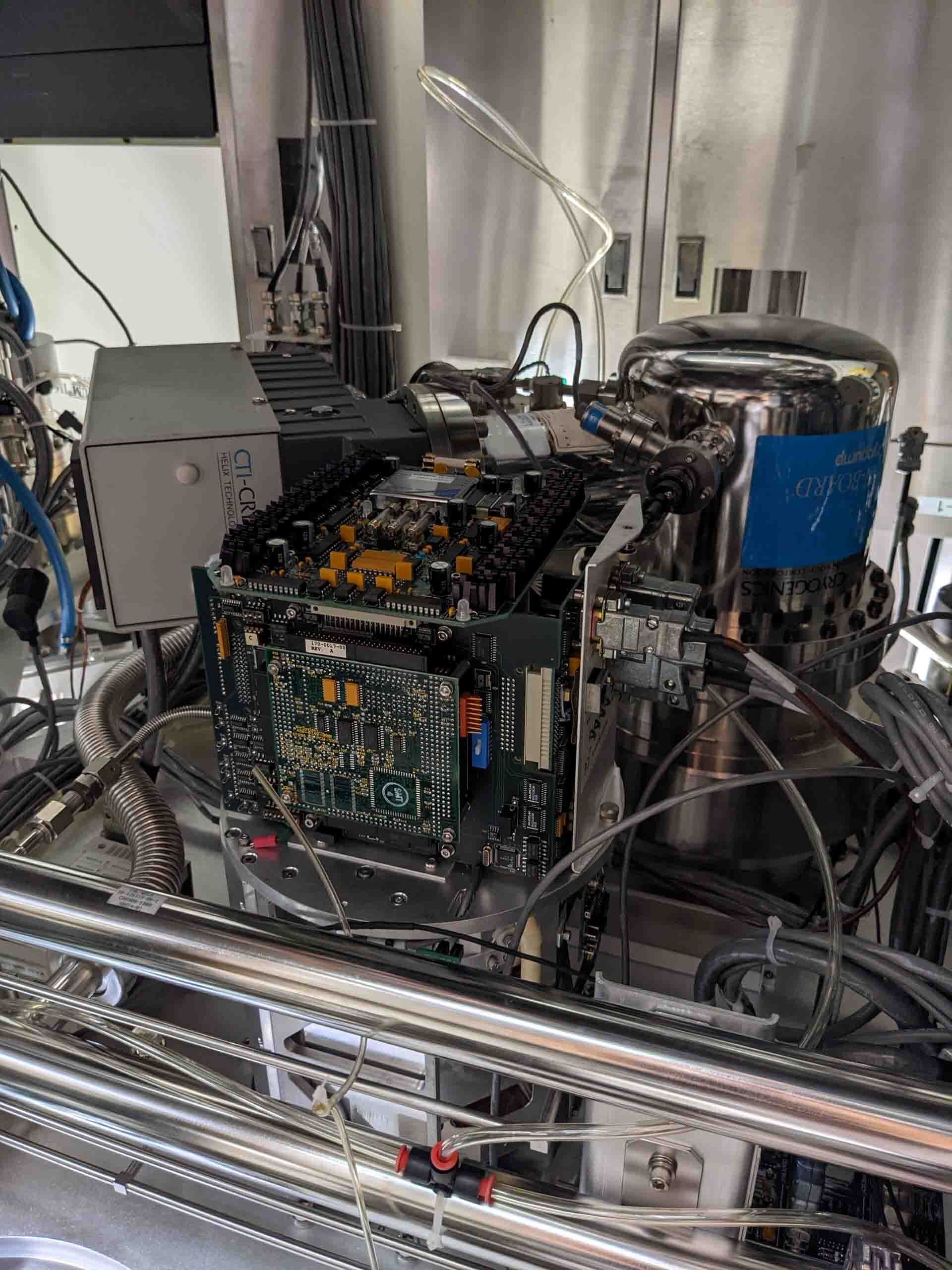

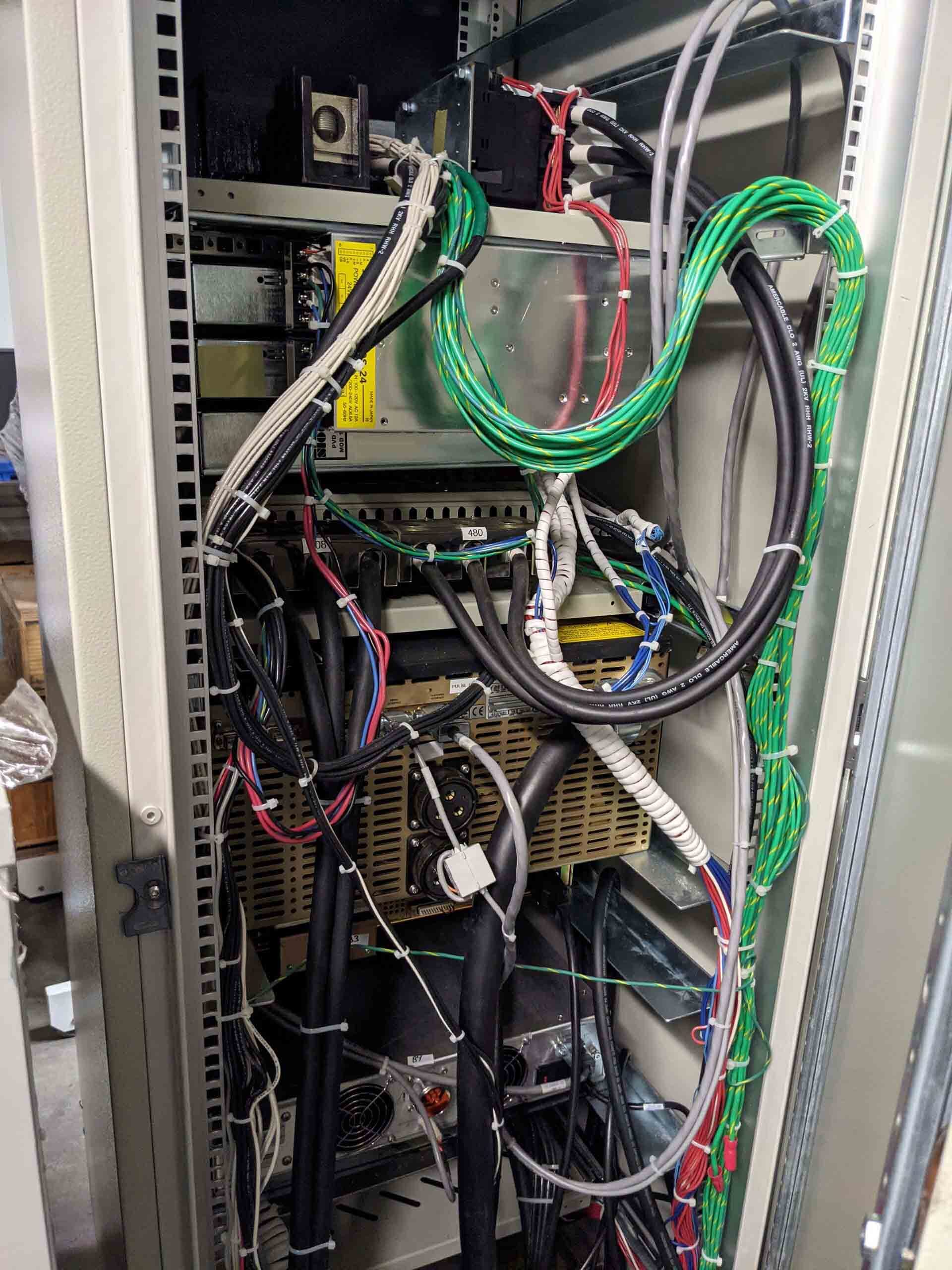

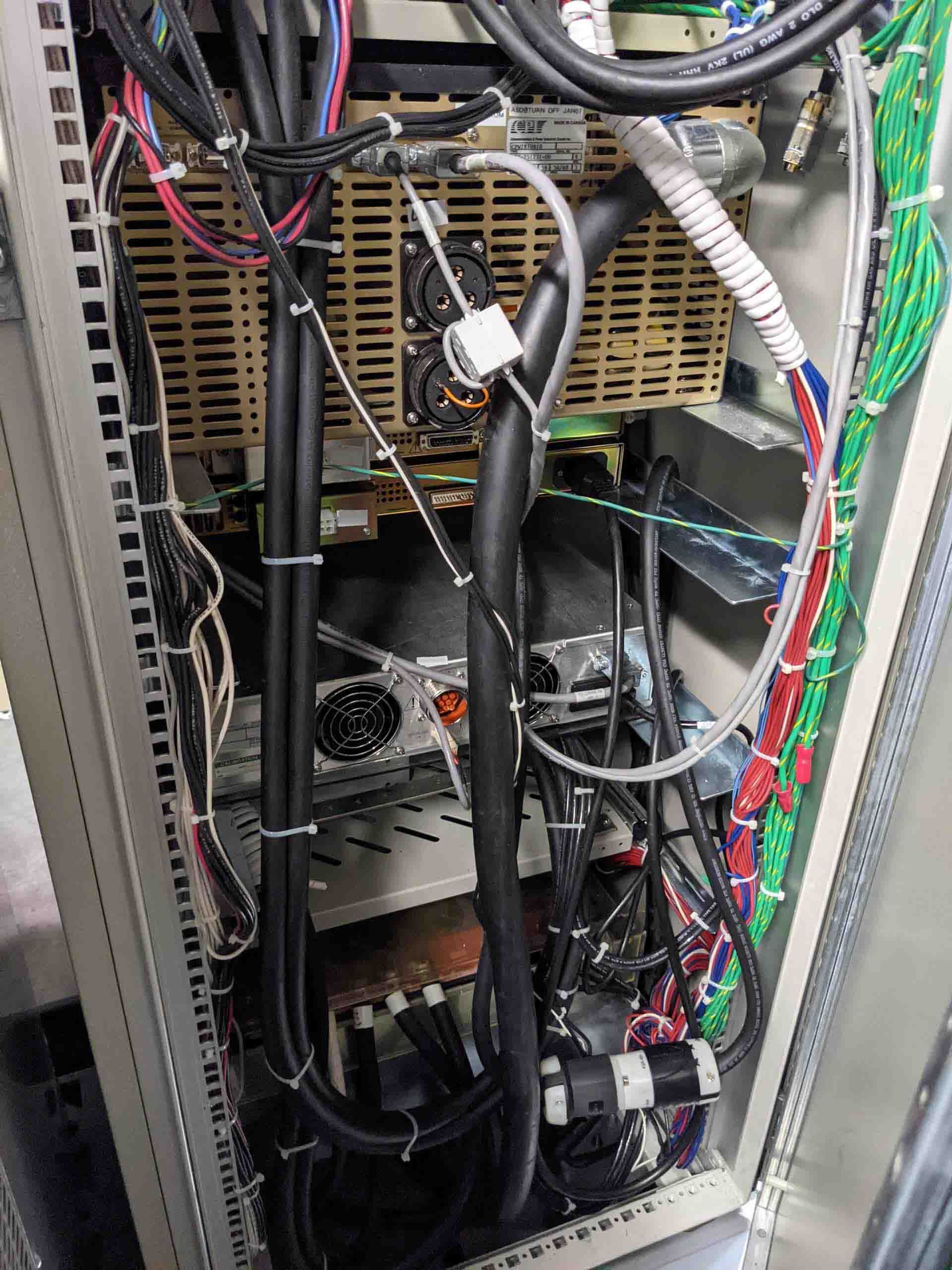

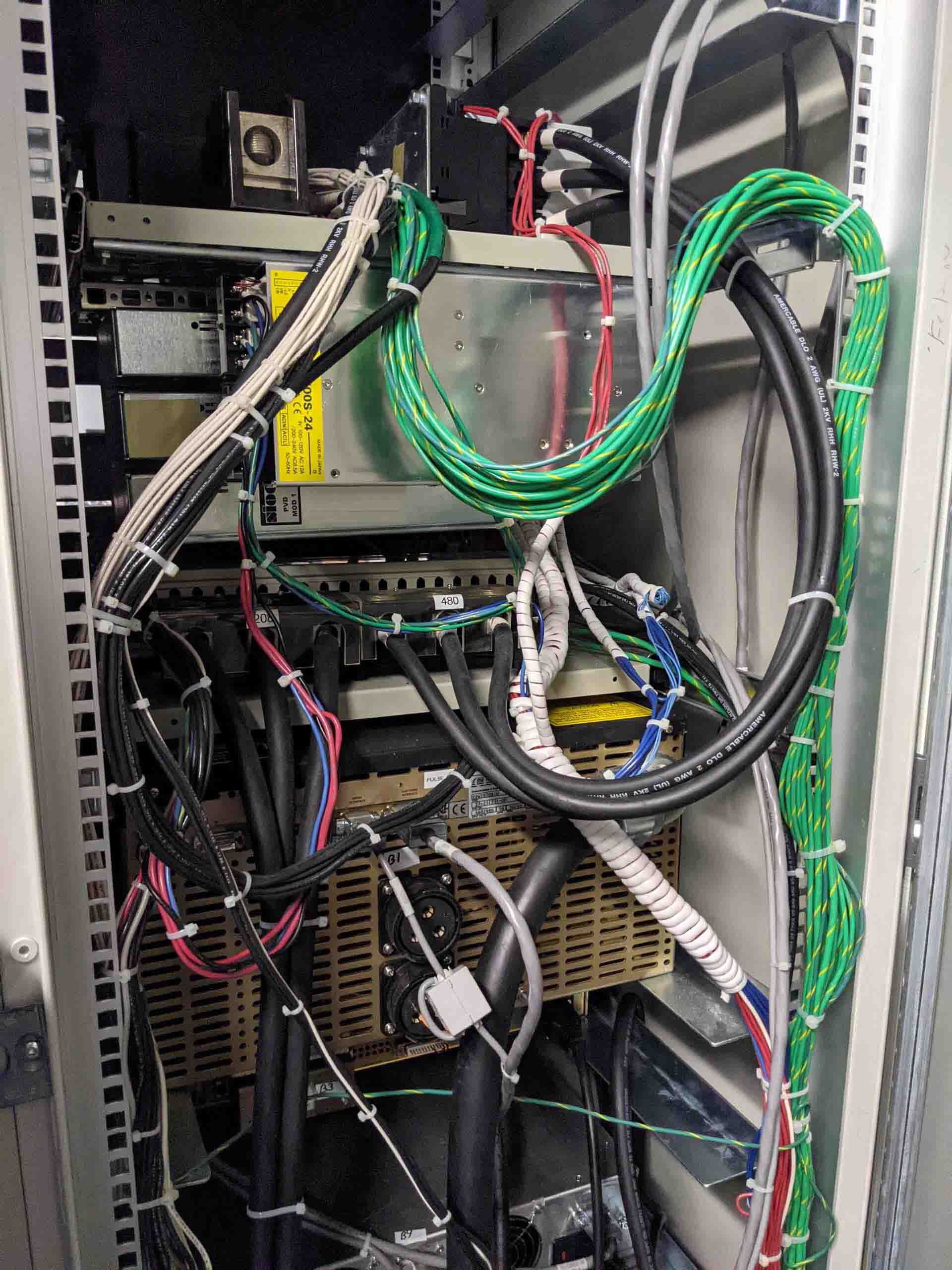

NOVELLUS MC3 Module controller

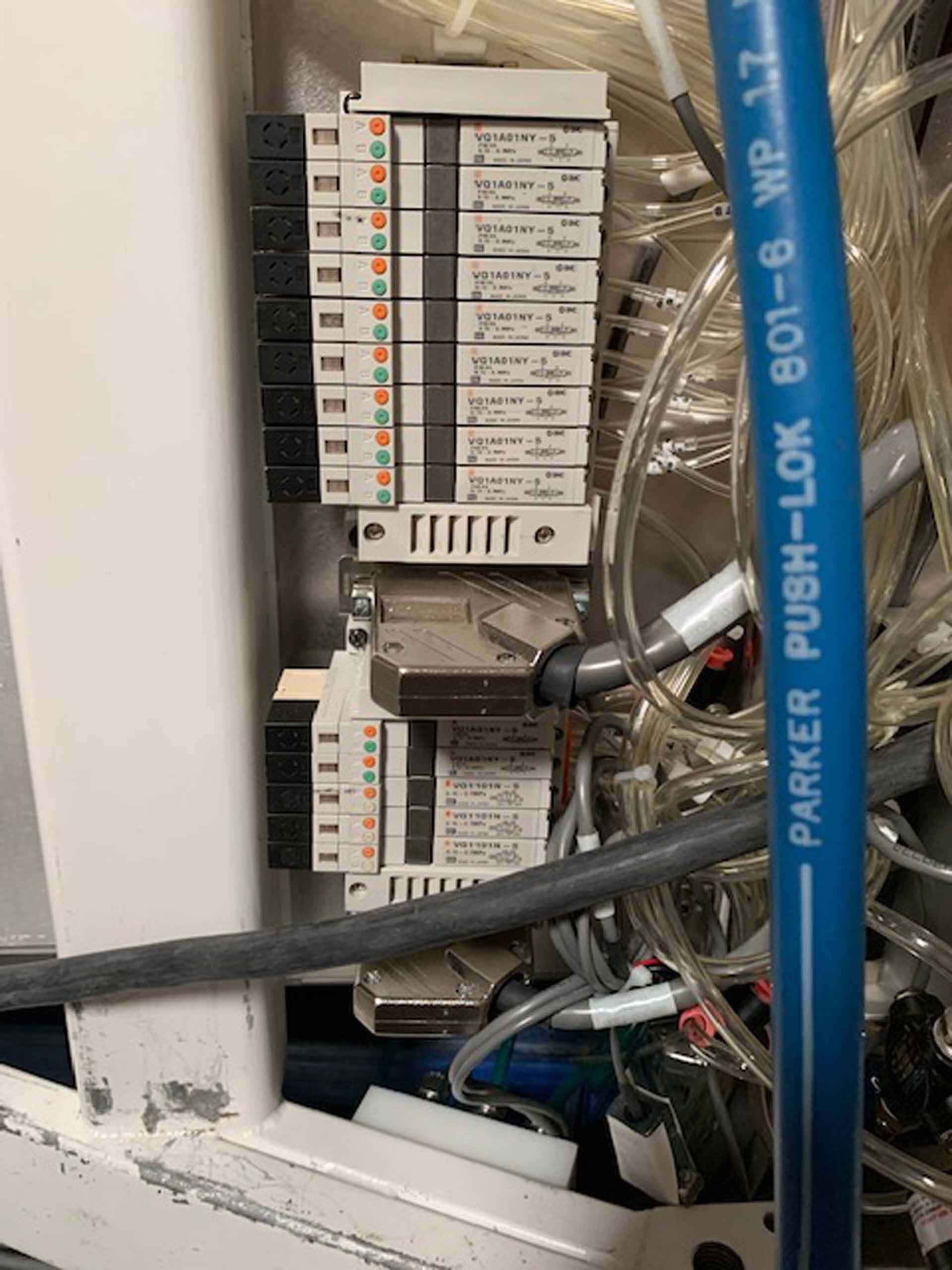

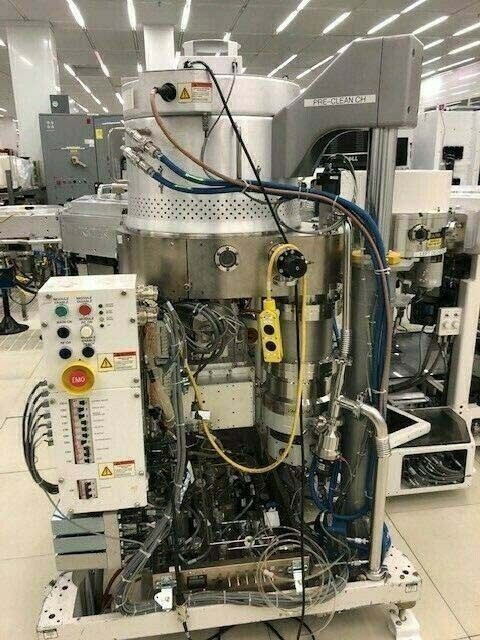

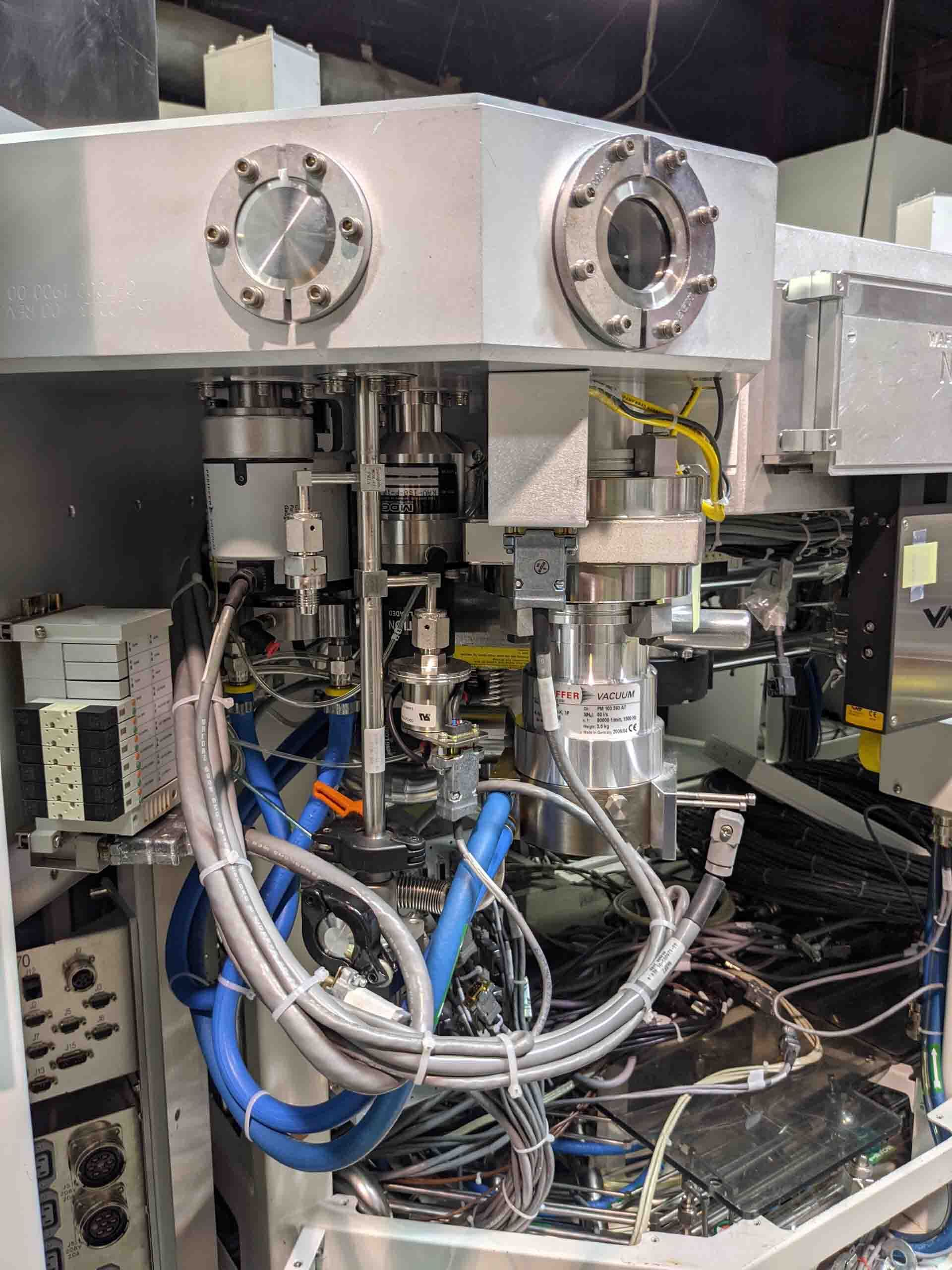

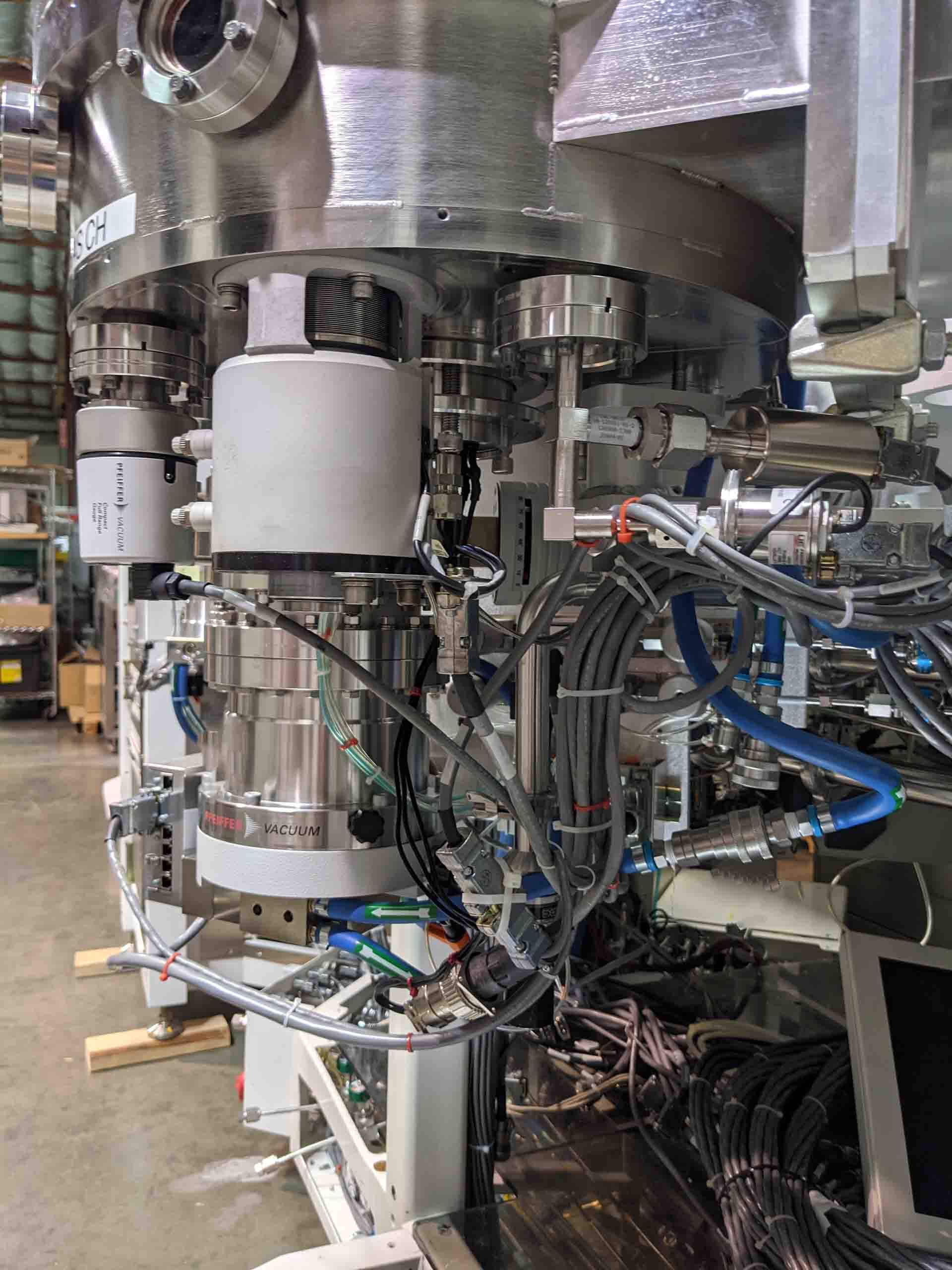

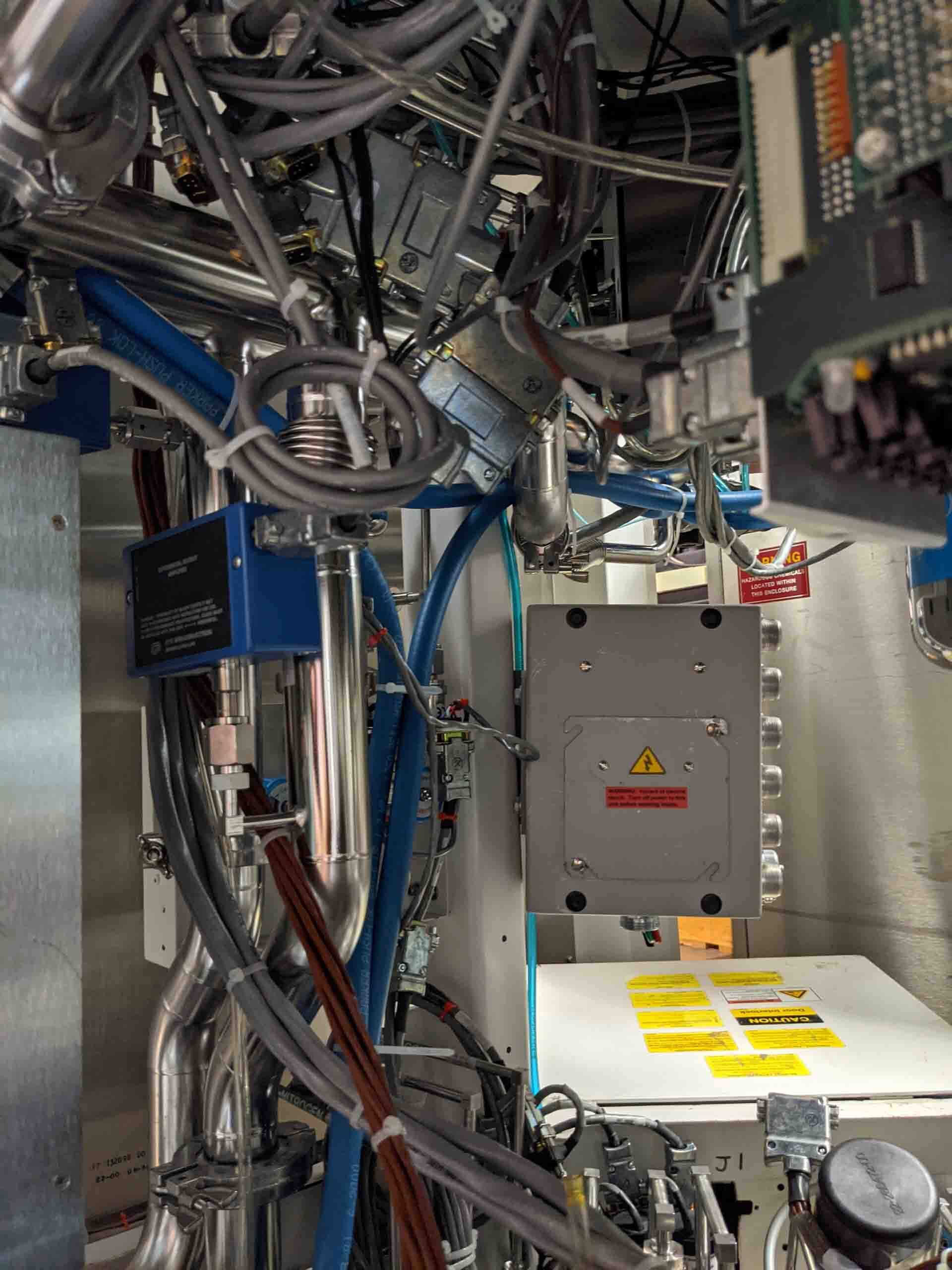

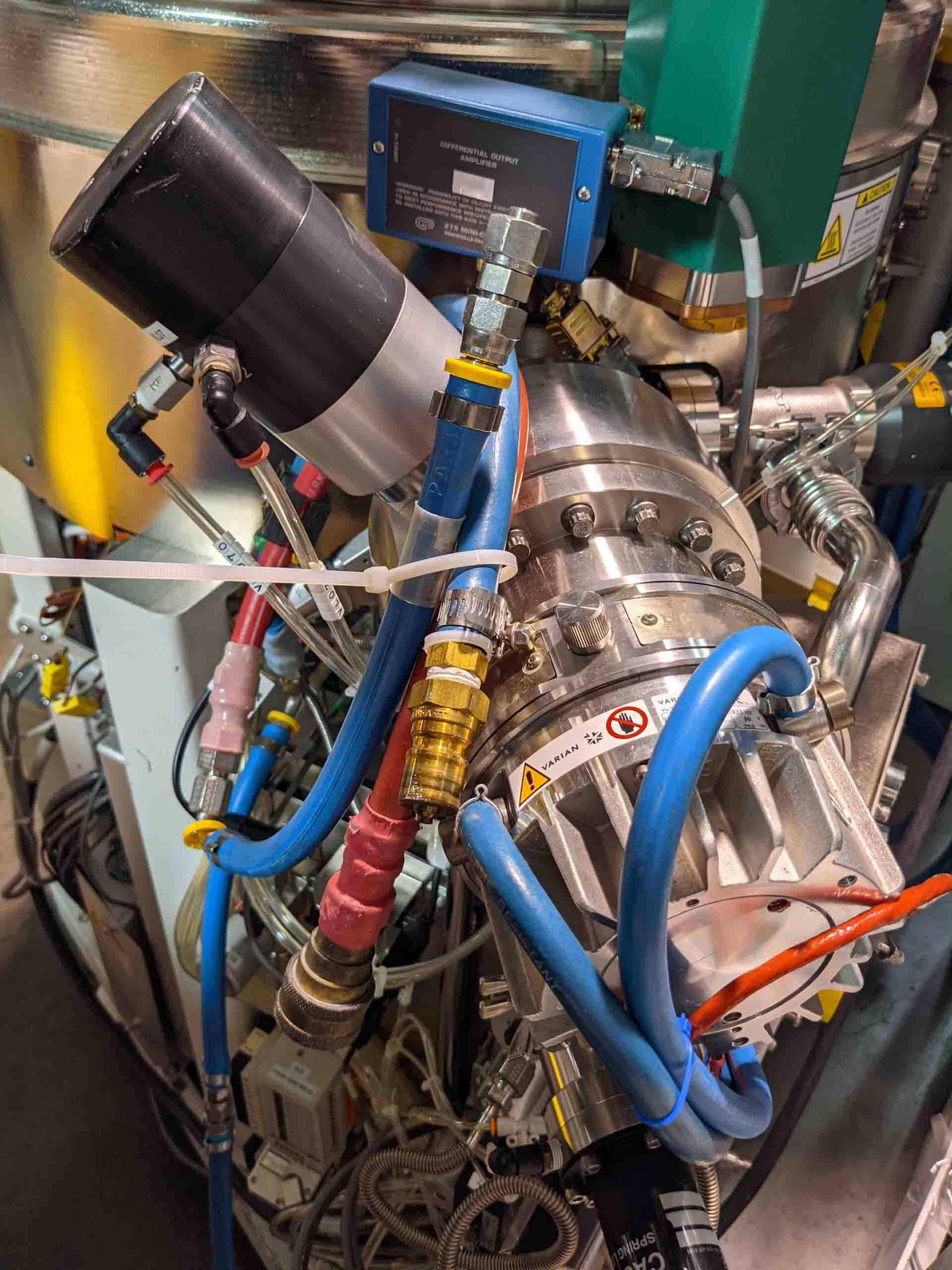

PFEIFFER Turbo and controller

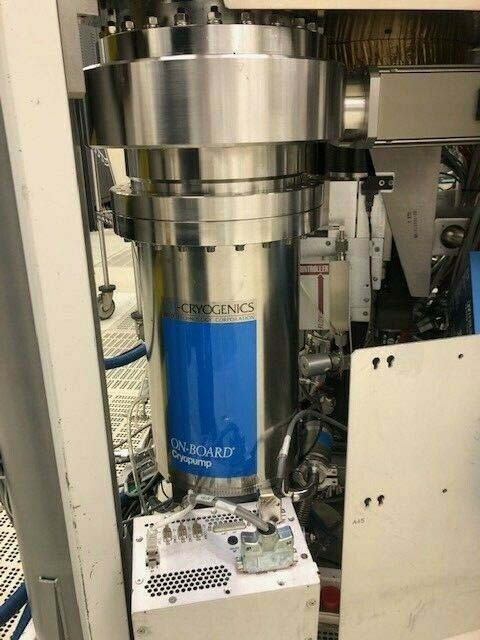

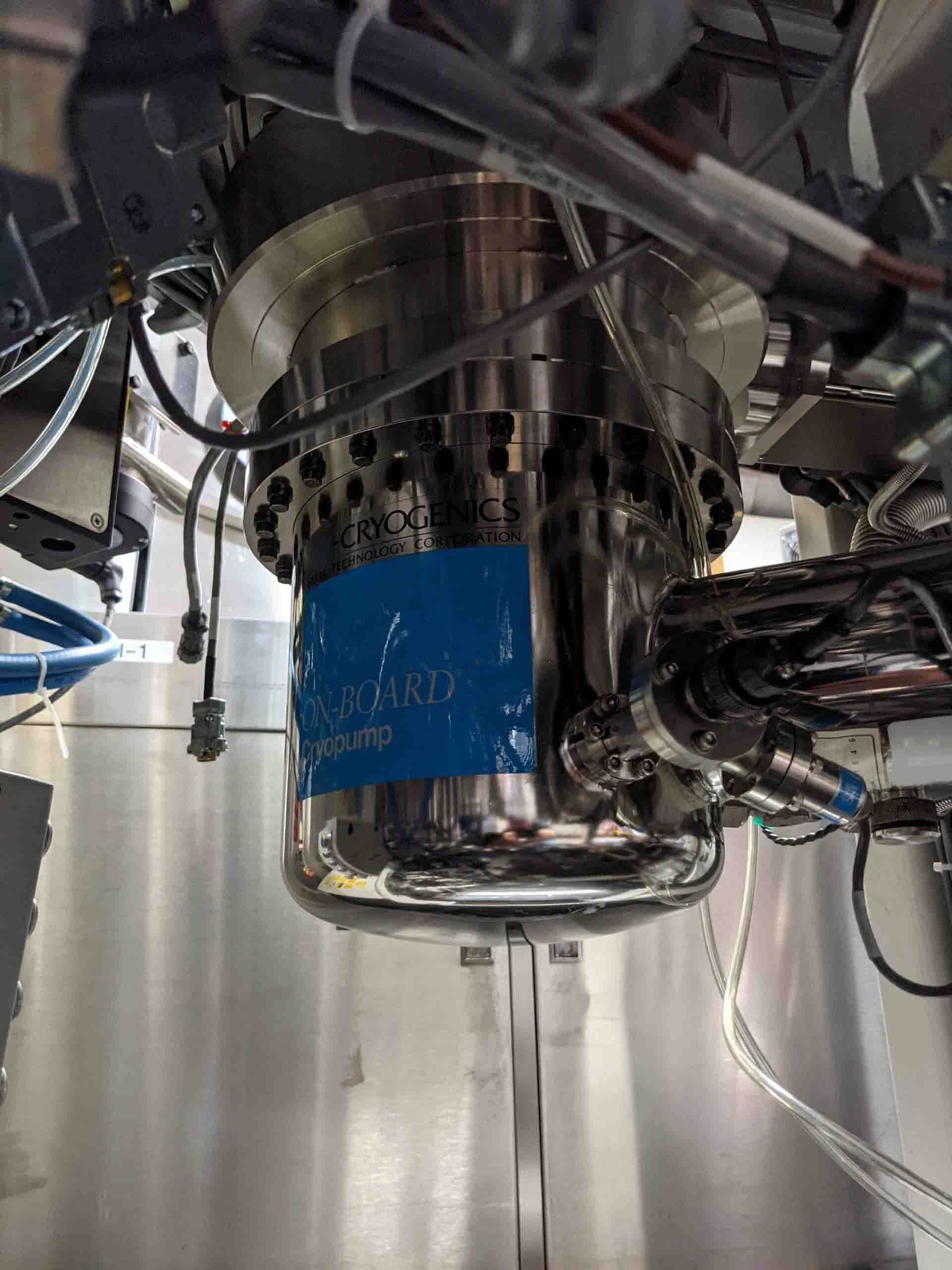

(3) CTI / HILEX / BROOKS Cryo pumps

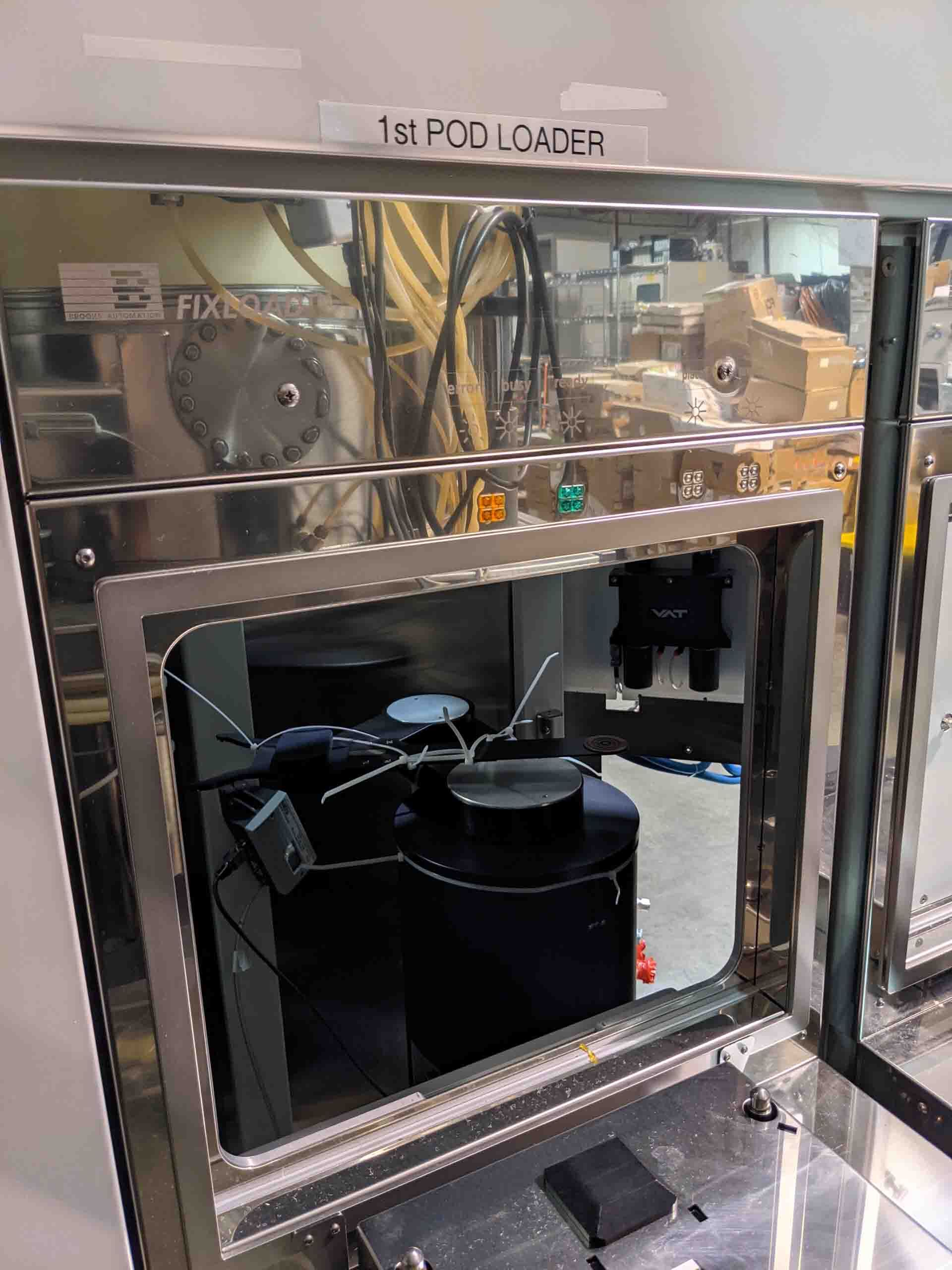

(4) BROOKS FOUP Cassette wafer loaders

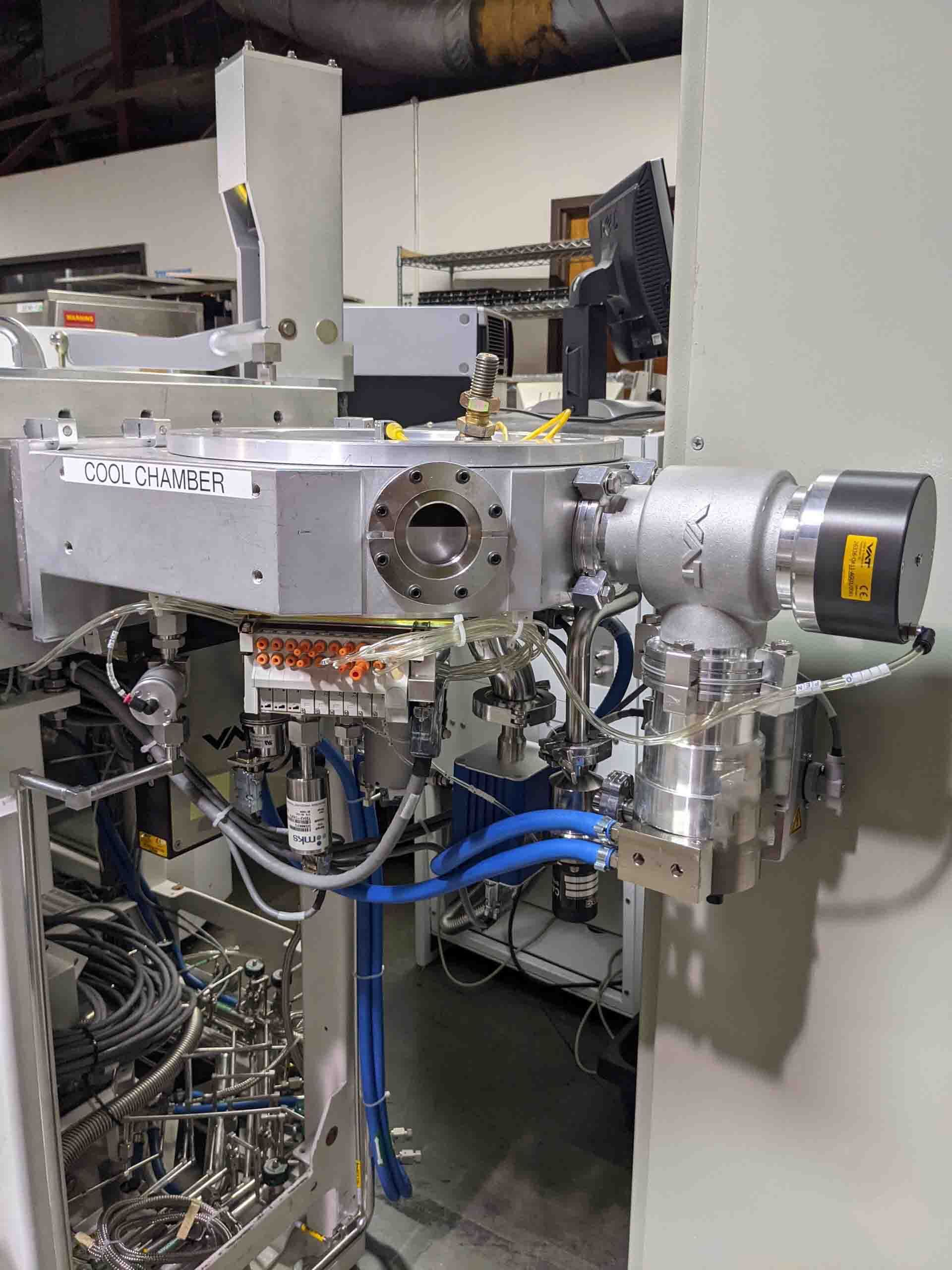

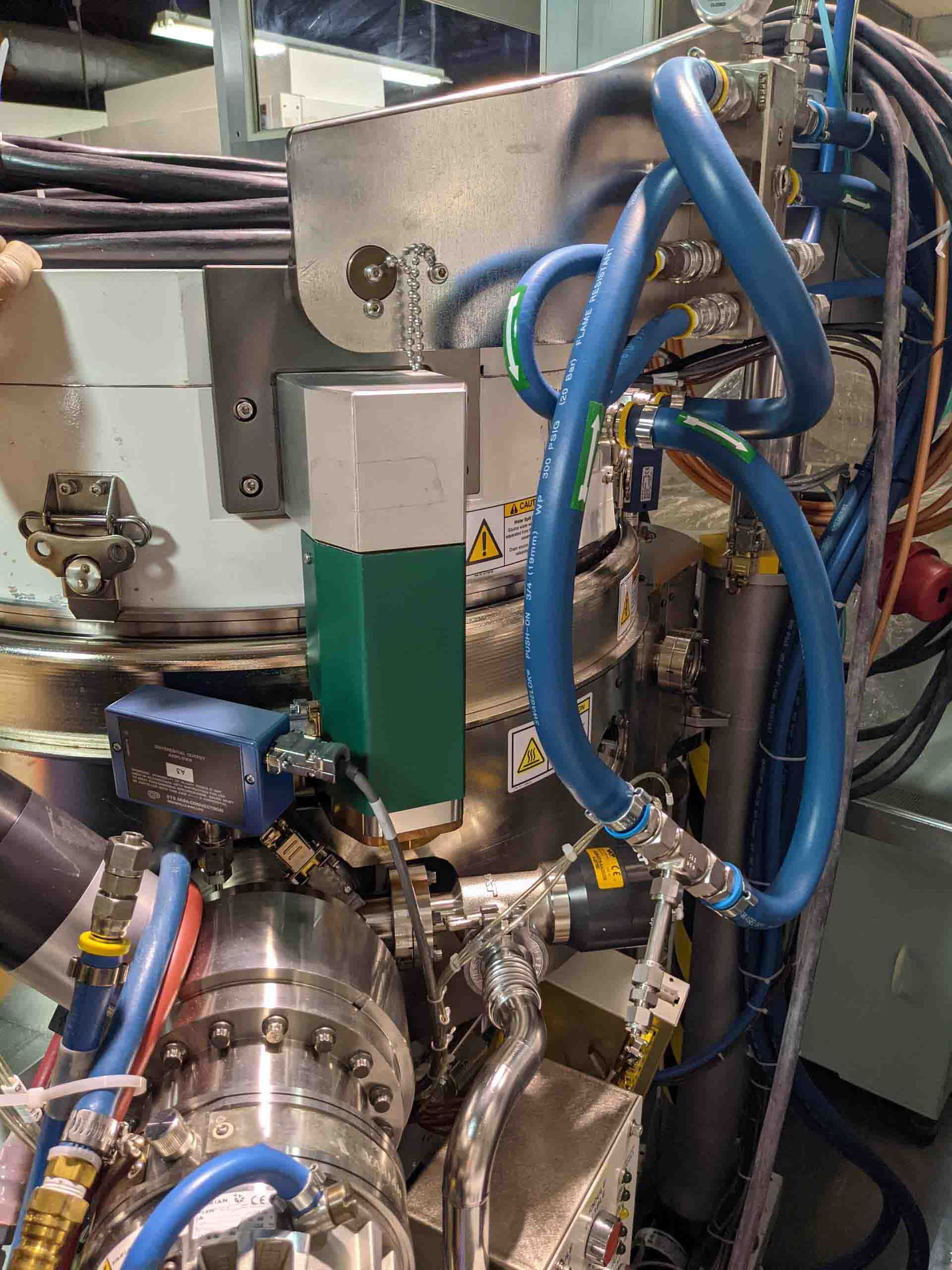

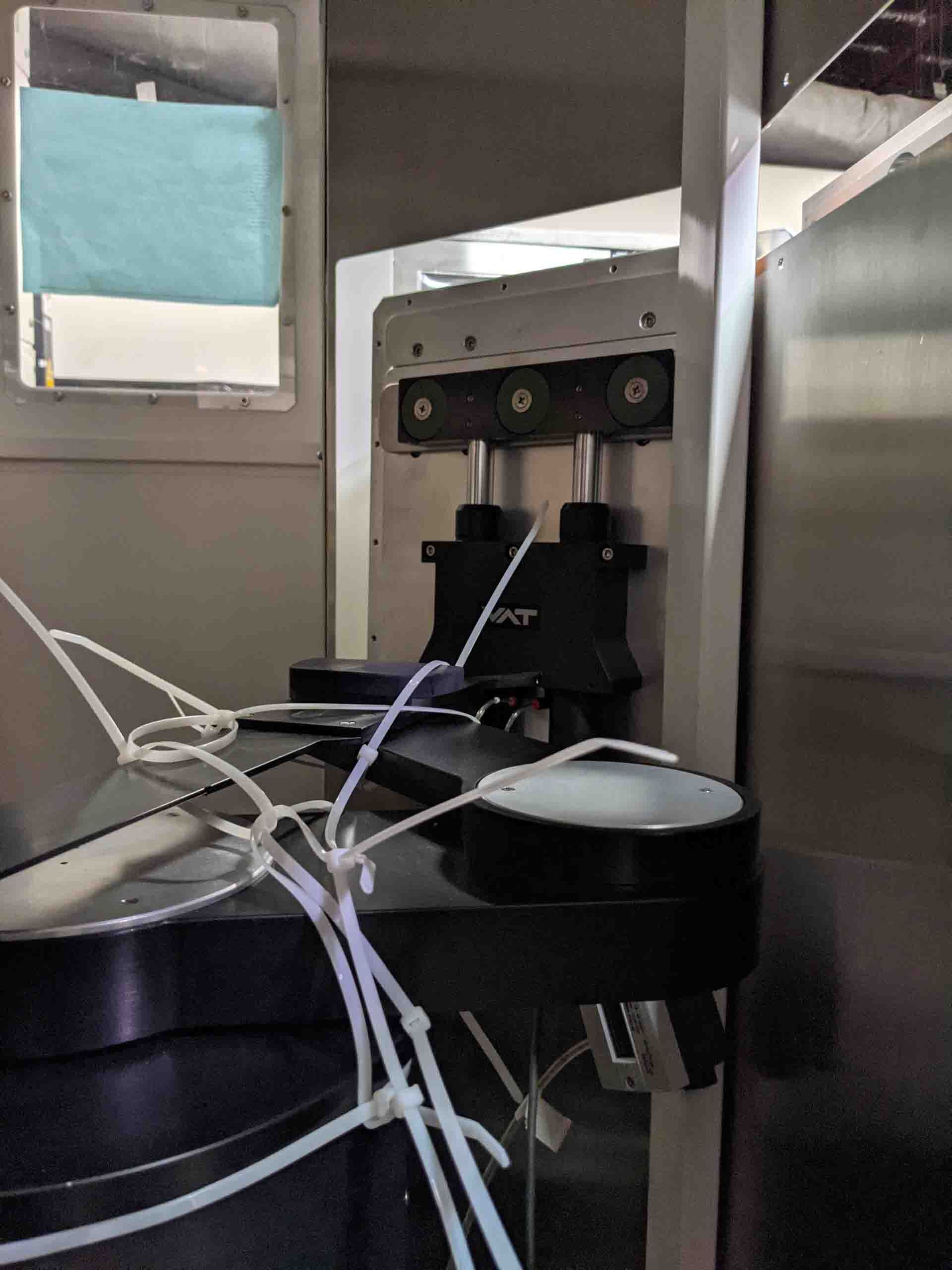

VAT Throttle valve and controller

ADVANCED ENERGY PDX 5000 RF Generator

ADVANCED ENERGY RFG 5500 RF Generator

MKS RF Generator

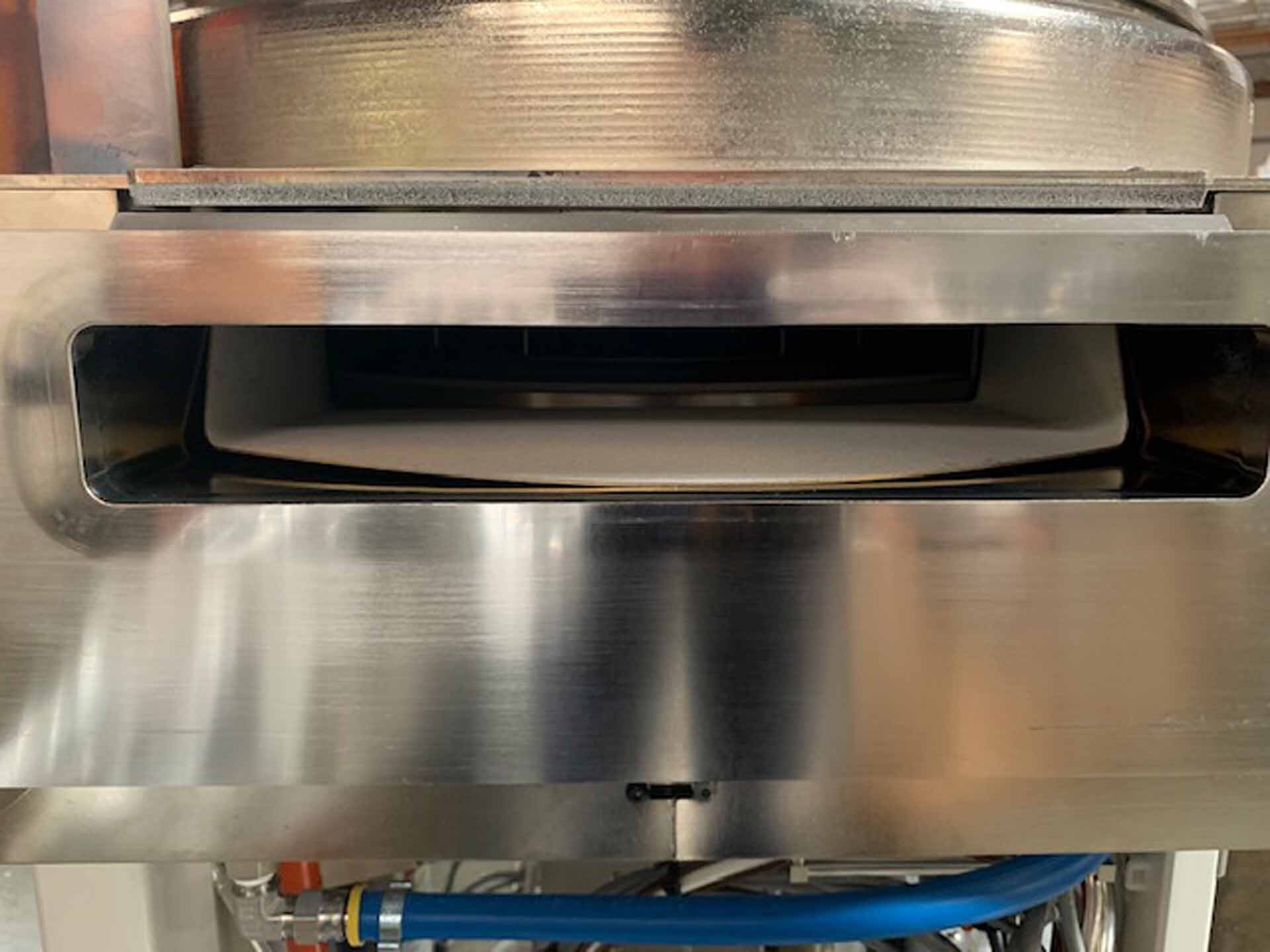

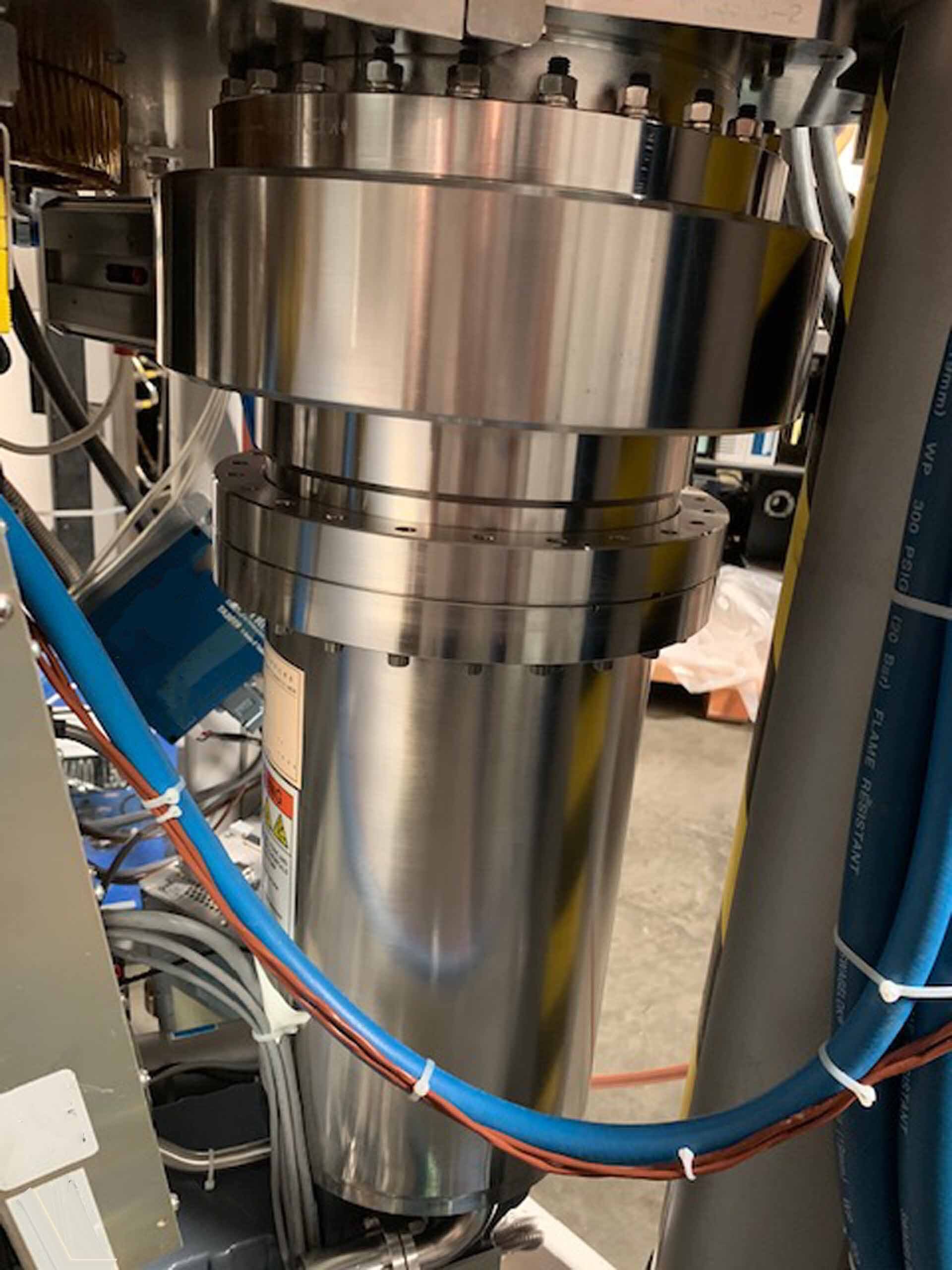

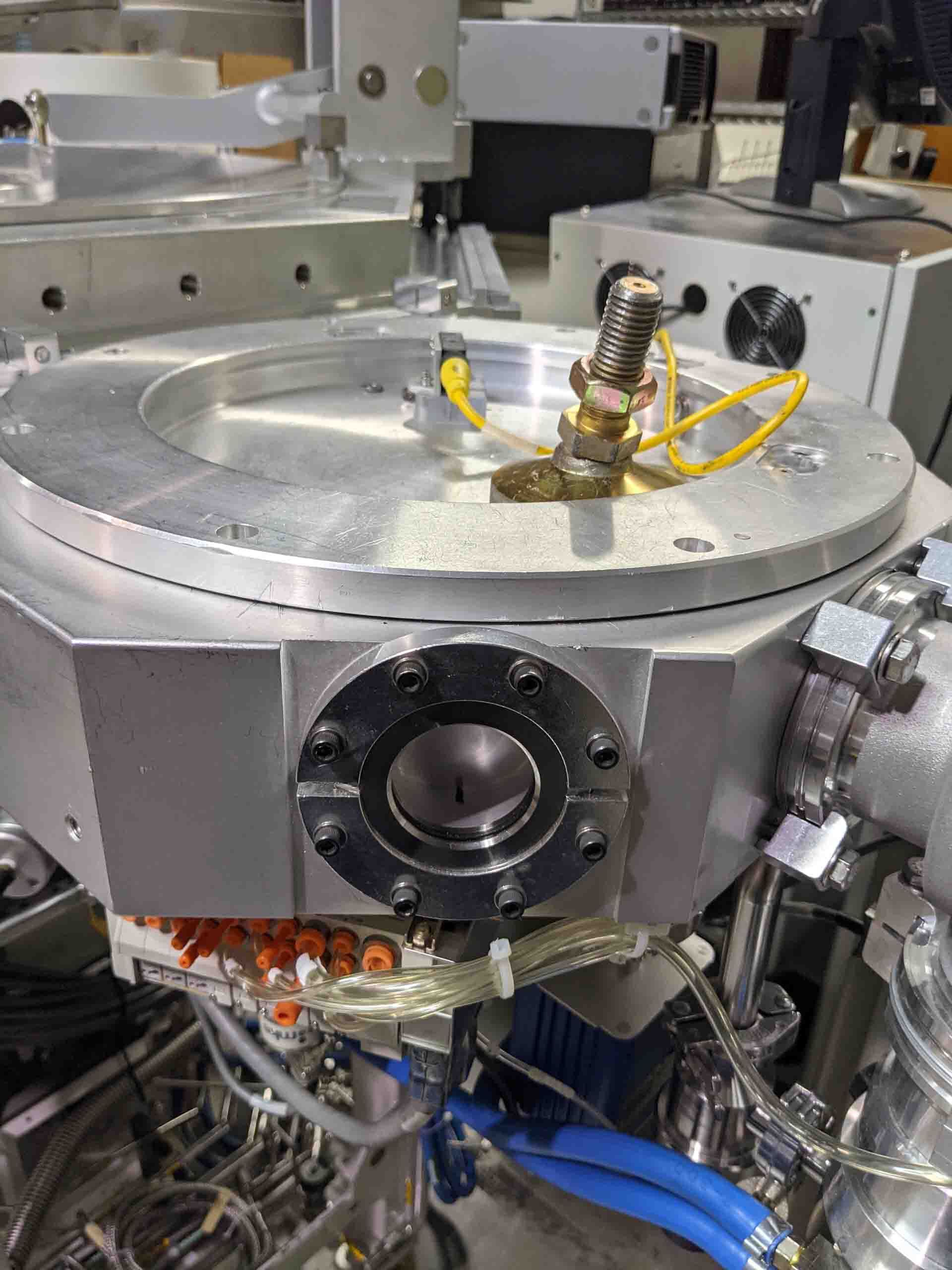

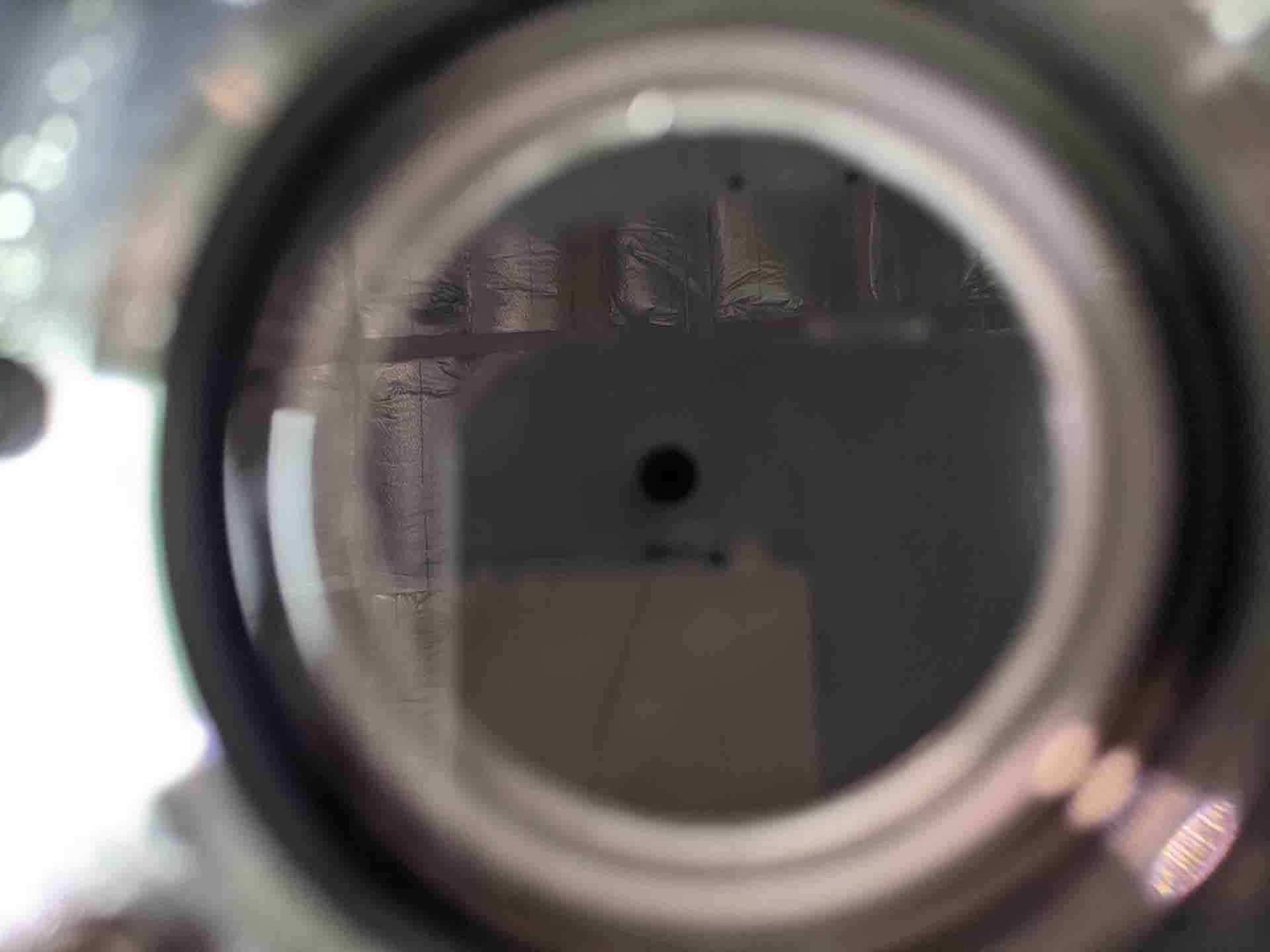

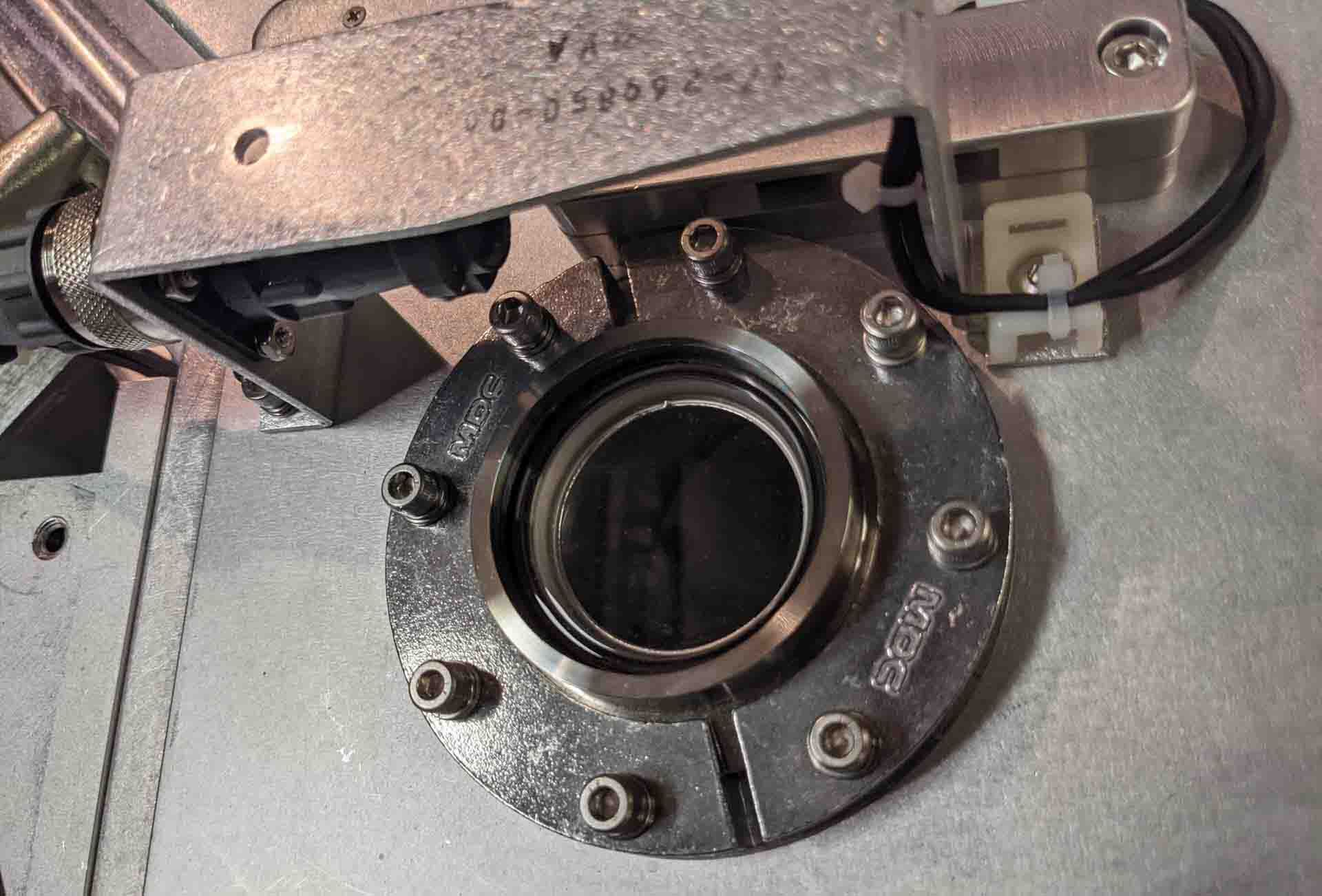

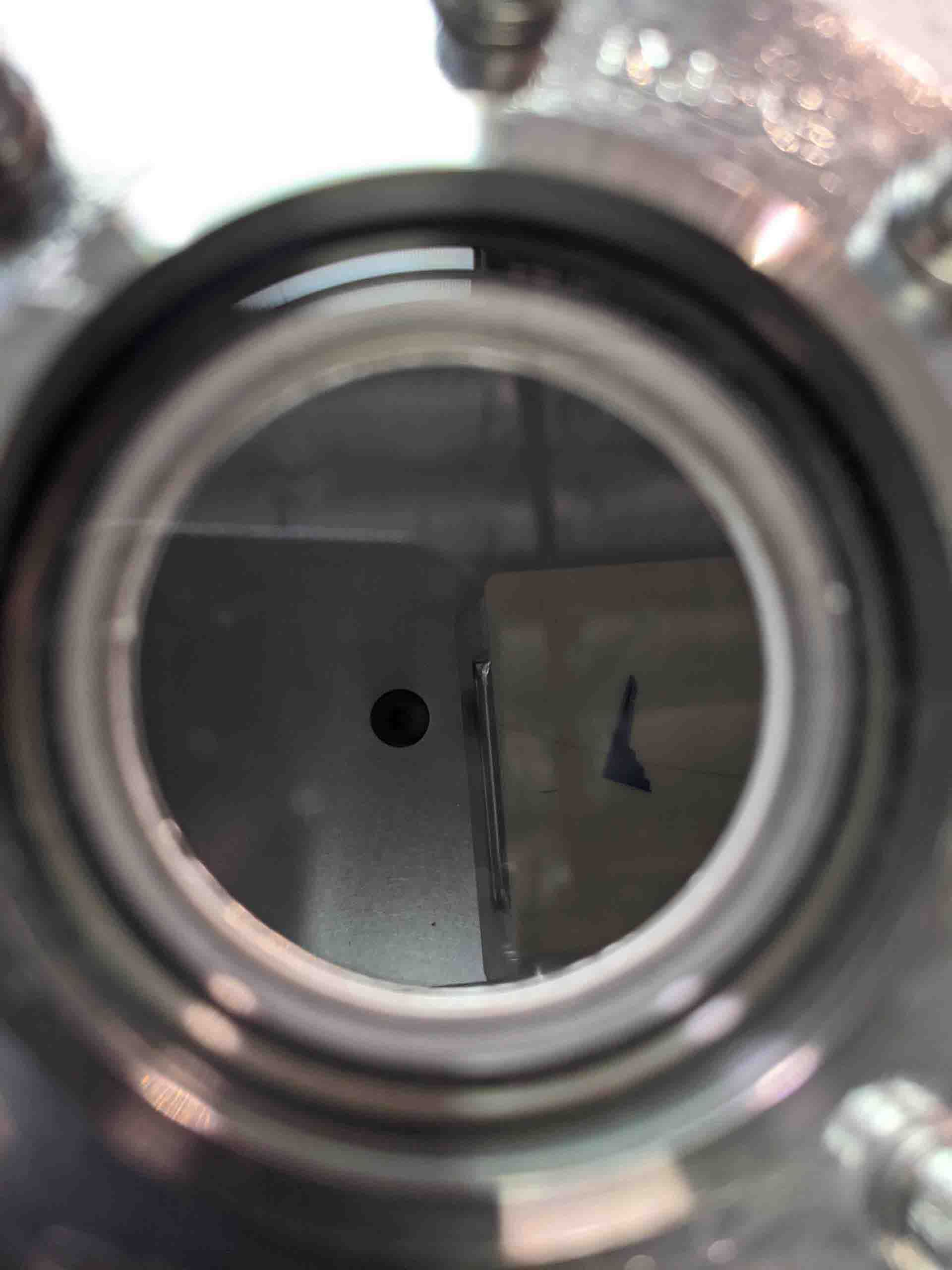

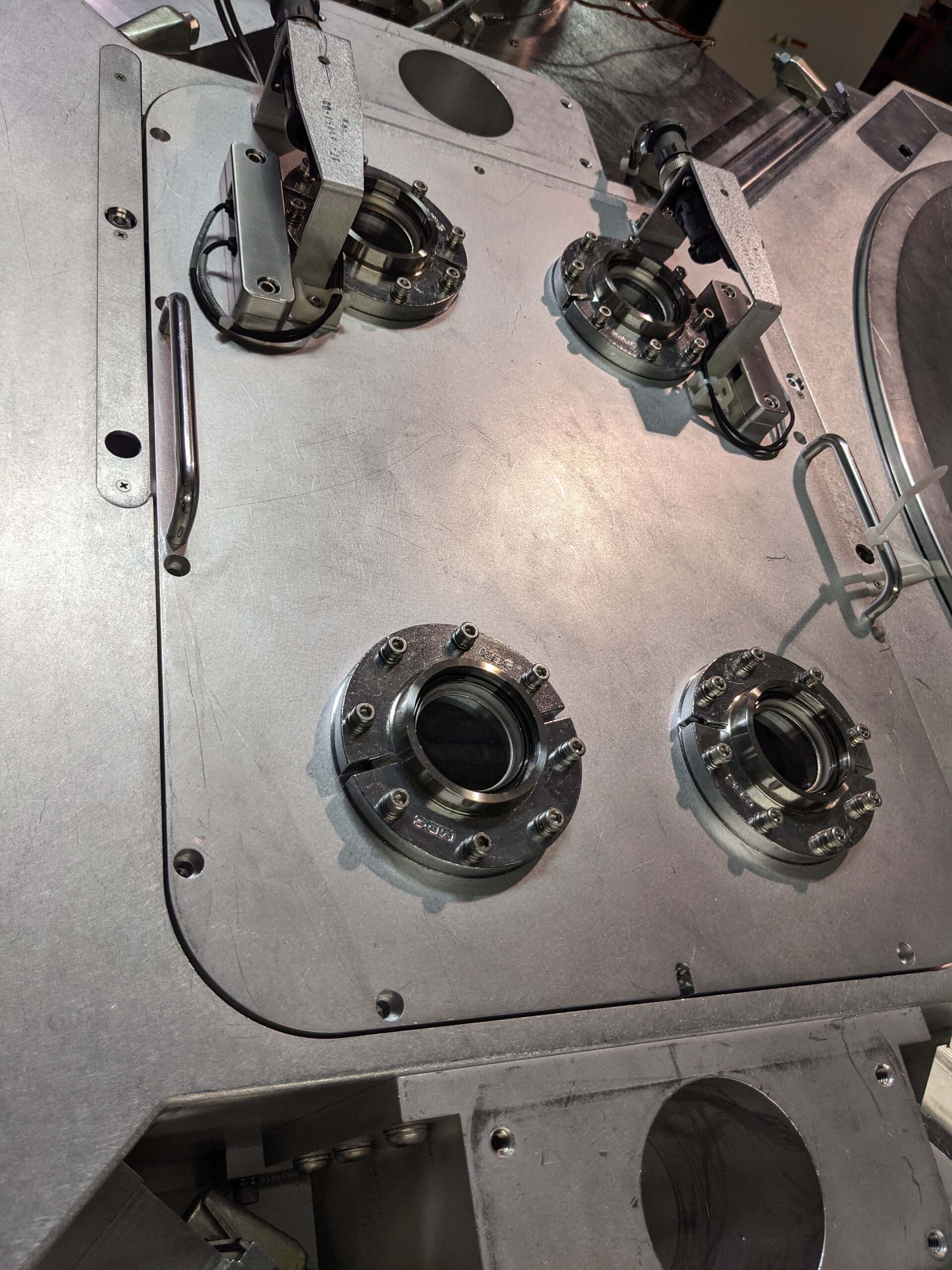

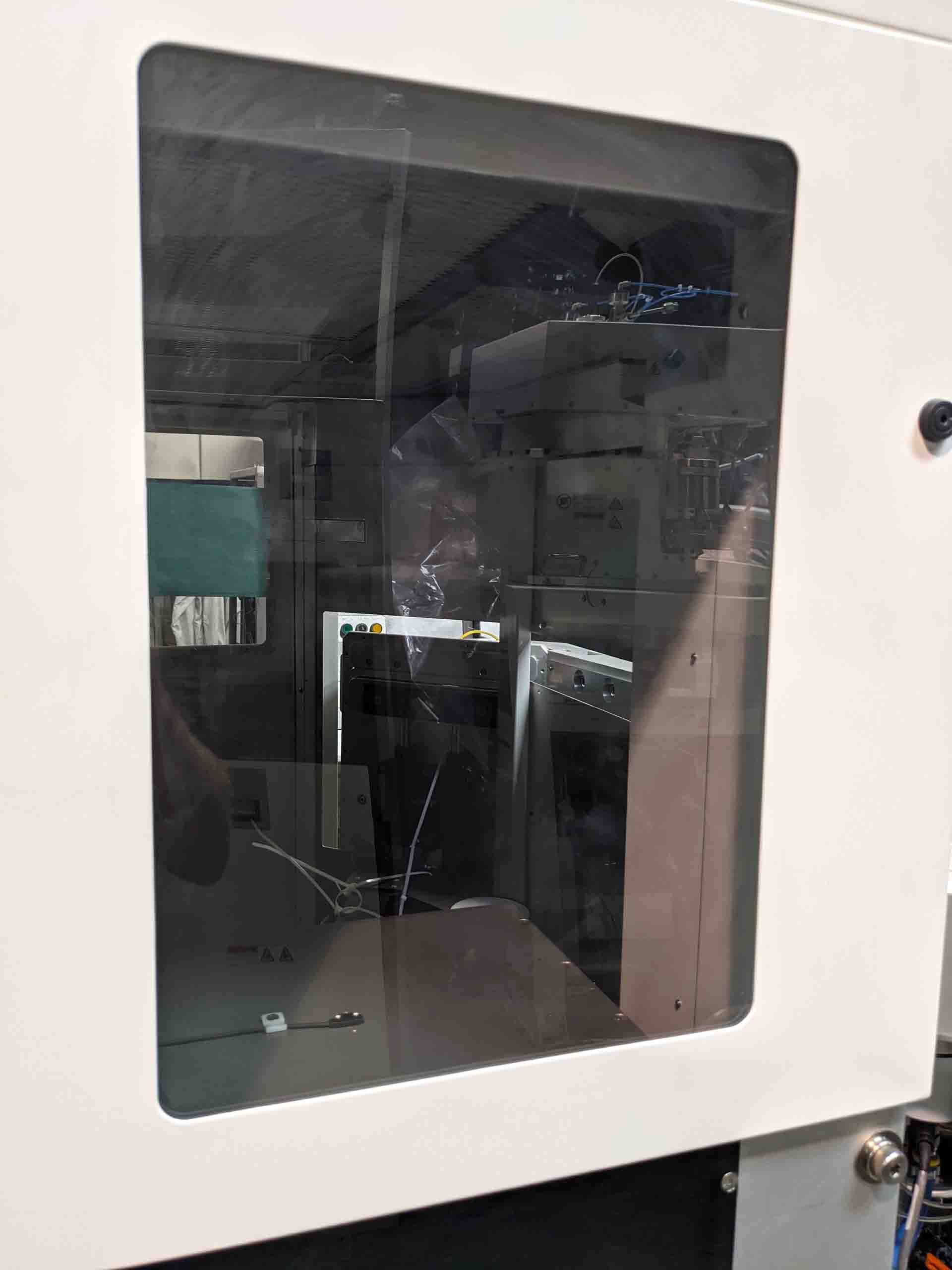

PVD Chamber

Preclean chamber

Right degas chamber

Left degas chamber

Sputter

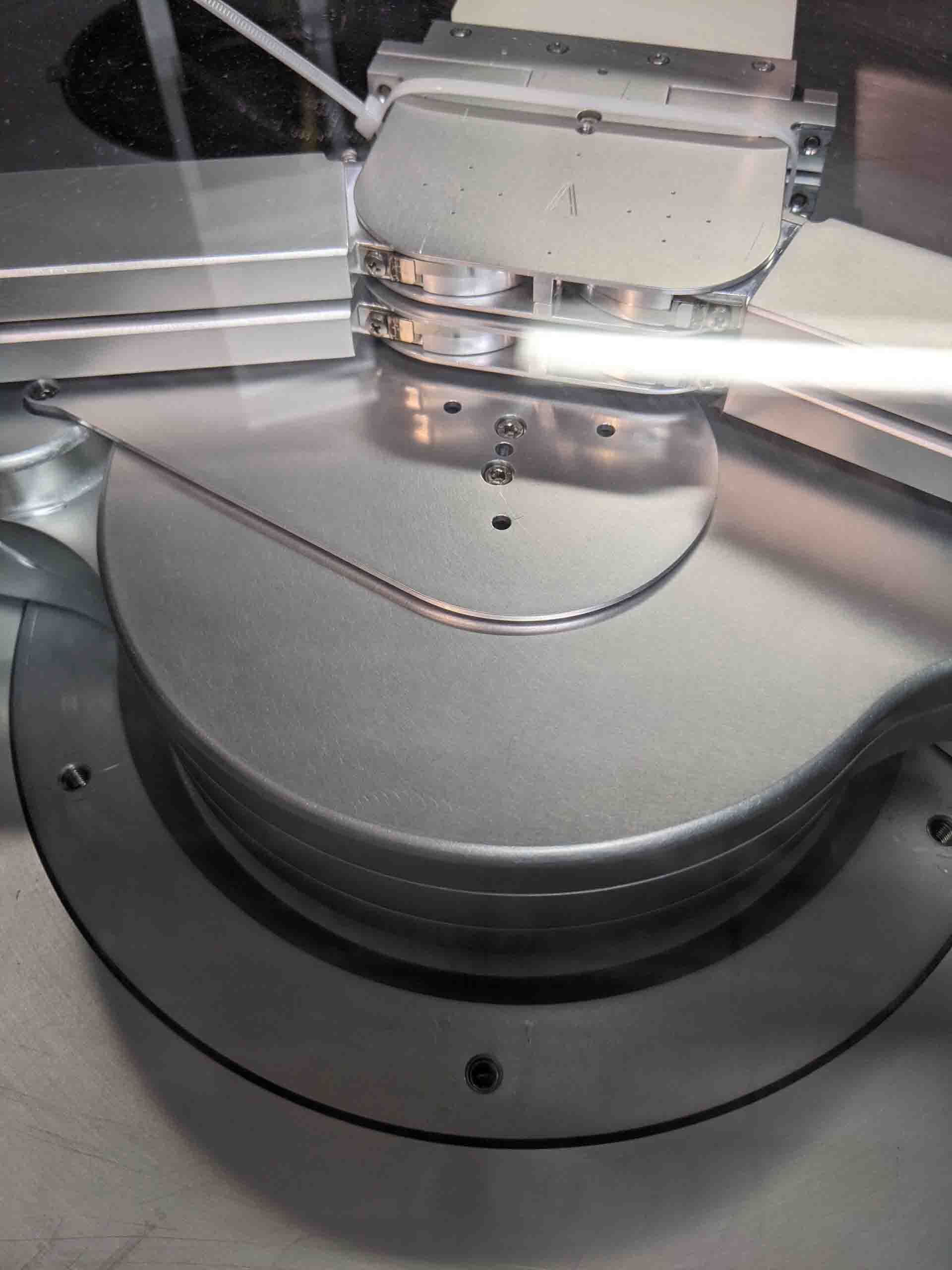

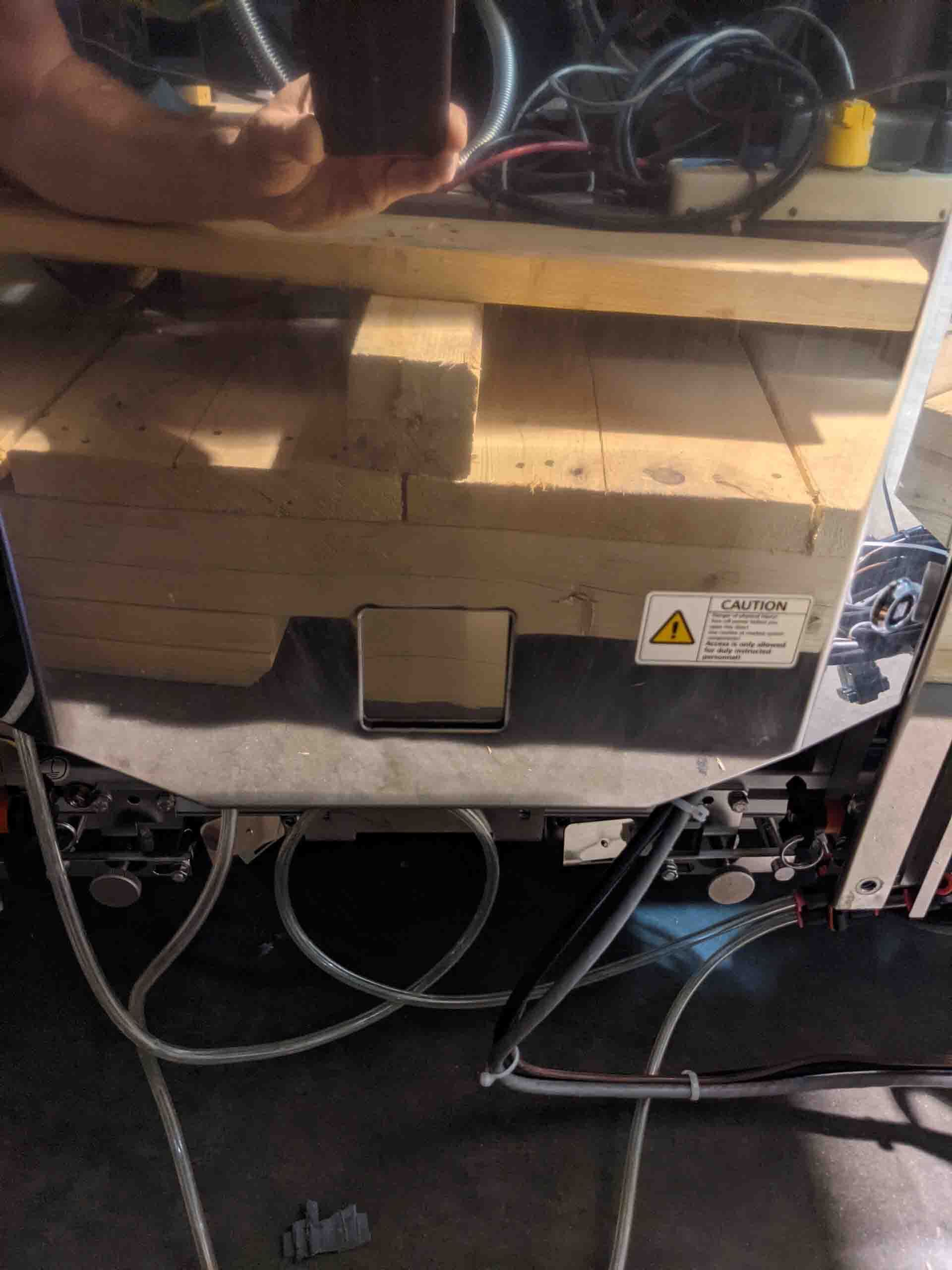

Transfer module with dual blade

Dual brooks robot transfer

DC power supply

Qty / Part number / Make / Model / Description

(1) / PA07060 / TREK / - / Power supply

(2) / DCS80-13E / SORENSEN / - / DC Power supplies: 0-80 V, 0-13 A / 1000 W

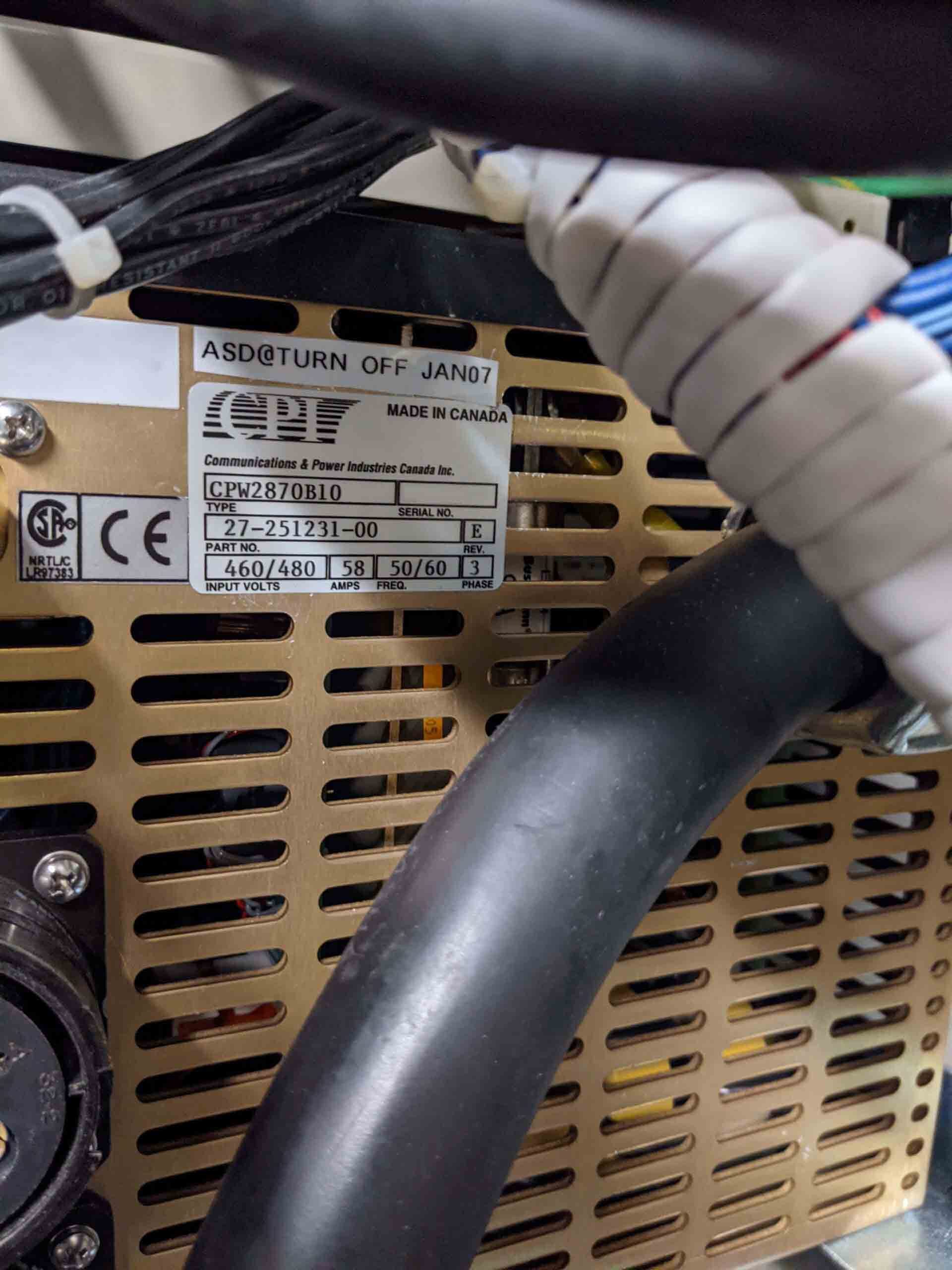

(1) / CPW2870B10 / CPI / - / 27-251231-00 DC Sputtering power supply

(1) / 3155051-015A / ADVANCED ENERGY / RFG 5500 / M/N: 3155051-015A RF Generator

(1) / 684-1 / TREK / - / NOVELLUS R19-137359-00, 416092, ESC Power supply: 6 Phase

(1) / RPG-50 / MKS / ENI / RPG-50A / Bipolar pulsed DC Generator

(1) / 27-156757-00 / ADVANCED ENERGY / PDX 5000 / RF Generator, M/N: 3156043-204

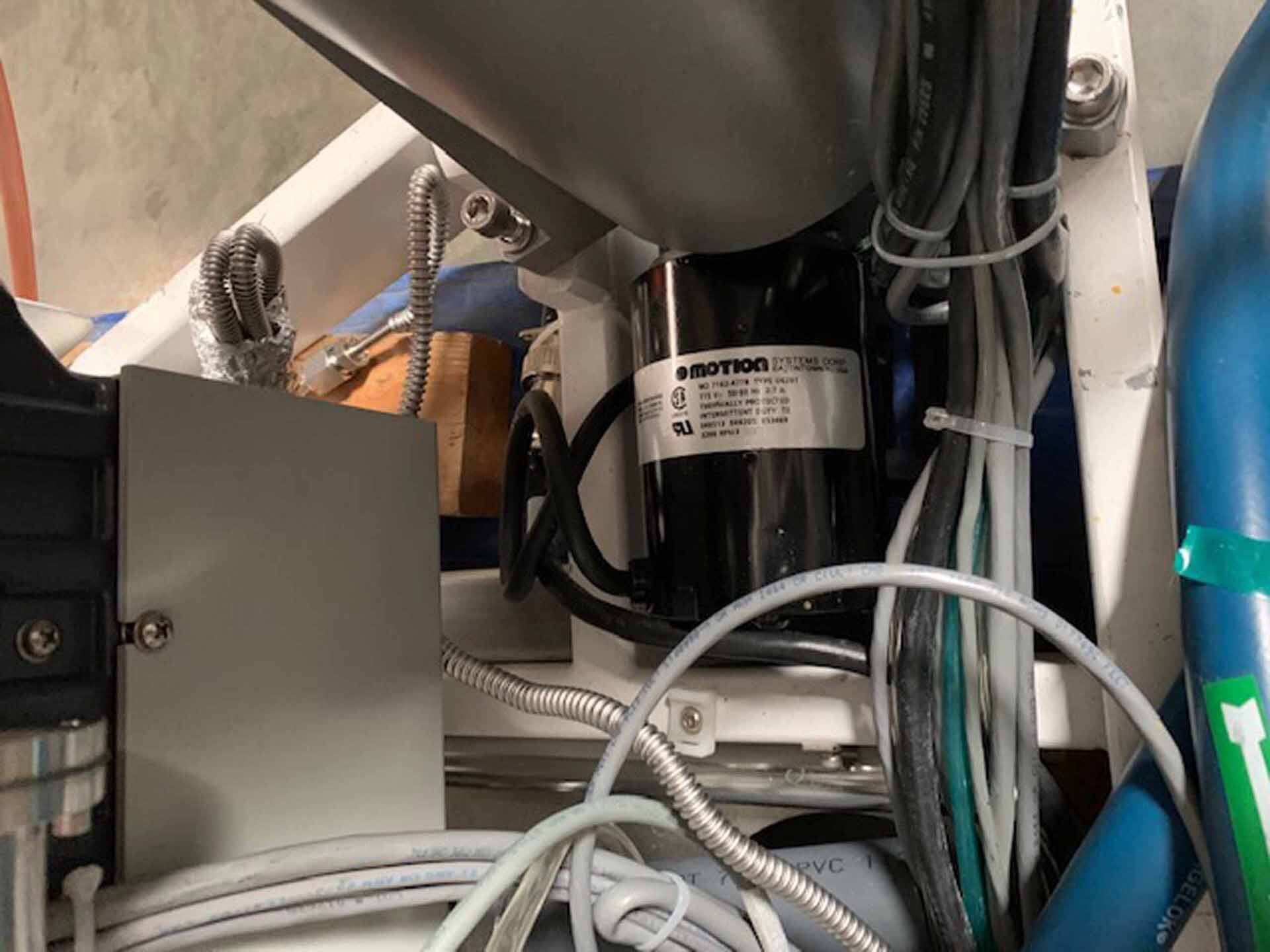

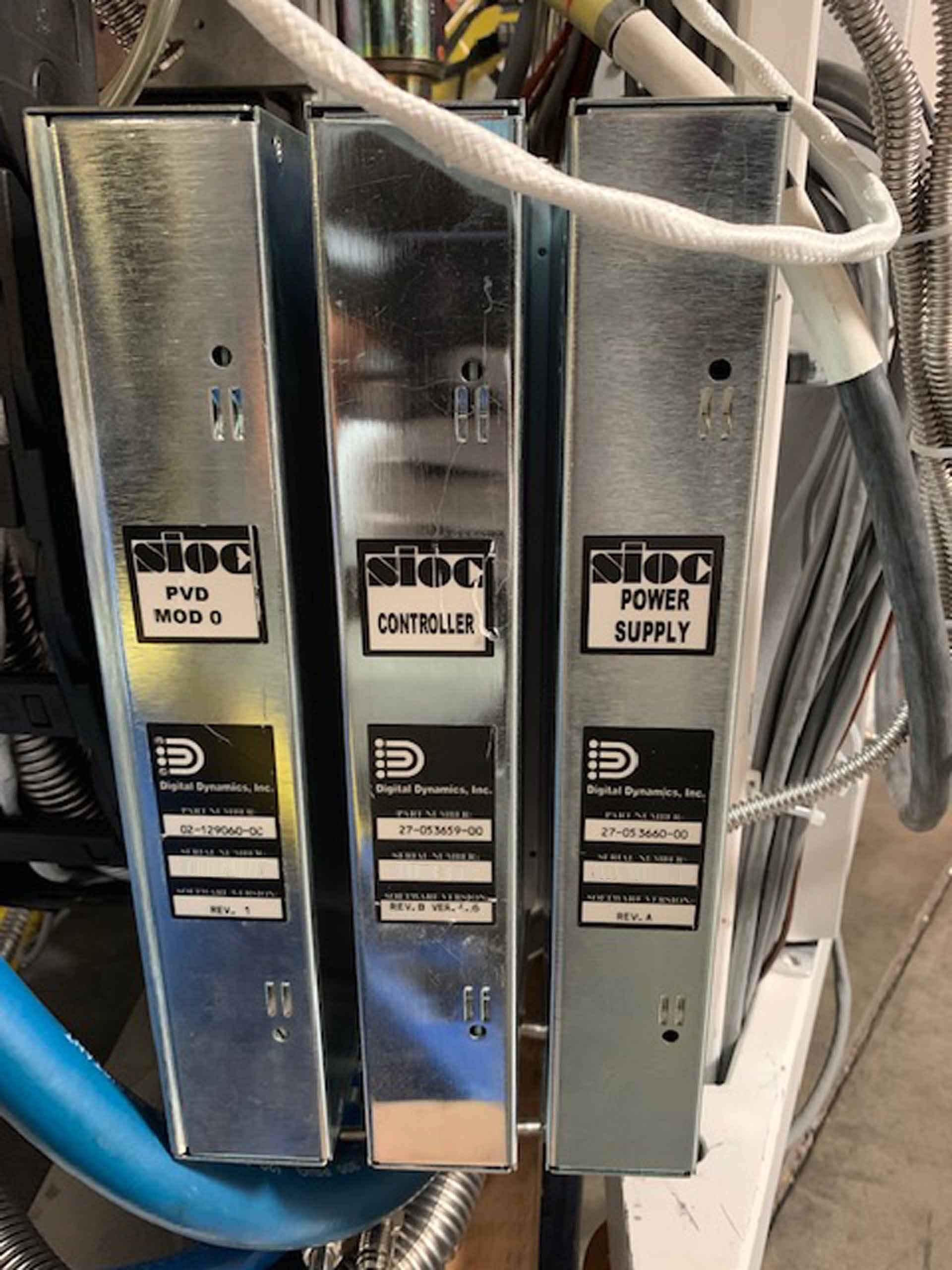

(1) / 03-12785-00 / NOVELLUS / - / 02-128733-00 PVD Assy SIOC Controller

(1) / 02-288084-00 / NOVELLUS / - / WTS-HV Sesioc 0, Rev.A

(1) / 02-271697-00 / NOVELLUS / - / WTS-HV Sesioc 3 IXT, Rev.A

(1) / 02-266875-00 / NOVELLUS / - / 02-266875-00 4 IXT WTS HV 4

(1) / 02-253704-00 / NOVELLUS / - / ASSY MC3E Controller with Ethernet 75-261867-00

(1) / 02-257935-00 / NOVELLUS / - / MC3E Platform controller with Ethernet 79-257795-00

(2) / 651D-16202 / MKS / - / Throttle valve controllers

(1) / TMH 071 P / PFEIFFER / BALZERS / - / Turbomolecular

(1) / 02112-BA24-APN1/0022 / VAT / - / Rectangular gate valve pneumatic actuator A-290319

(1) / 02112-BA24-APN1/0017 / VAT / - / Rectangular gate valve pneumatic actuator A-276468

(1) / 02112-BA24-APN1/0018 / VAT / - / Rectangular gate valve pneumatic actuator A-276468

(1) / 02112-BA24-APN1/0002 / VAT / - / Rectangular gate valve pneumatic actuator A-335571

(1) / 02112-BA24-APN1/0008 / VAT / - / Rectangular gate valve pneumatic actuator A-276468

(1) / 02112-BA24-APN1/0016 / VAT / - / Rectangular gate valve pneumatic actuator A-276468

(1) / 02112-BA24-APN1/0024 / VAT / - / Rectangular gate valve pneumatic actuator A-290319

(1) / 02112-BA24-APN1/0019 / VAT / - / Rectangular gate valve pneumatic actuator A-288644

(1) / 02112-BA24-APN1/0004 / VAT / - / Rectangular gate valve pneumatic actuator A-276468

(1) / 02112-BA24-APN1/0002 / VAT / - / Rectangular gate valve pneumatic actuator A-276468

(1) / 02112-BA24-APN1/0434 / VAT / - / Rectangular gate valve pneumatic actuator A-529666

(1) / 02112-BA24-APN1/0023 / VAT / - / Rectangular gate valve pneumatic actuator A-290319

(1) / - / PFEIFFER / TMU521P / PM P03 120H, PM P03 120 C with TC750-E74, PM C01 712, Turbo pump

(1) / - / PFEIFFER / TMU521P / PM P03 855 with TC750 Special DS15, PM C01 711, Turbo pump

(1) / - / PFEIFFER / TMH 071 P/ Turbomolecular pump with TC750-E74, PM C01 712

(1) / 8116079G001 / CTI-CRYOGENICS / - / Cryo pump, HELIX Control sputtering

(1) / 14036-PE24-0004 / VAT / - / Gate valve 14036-PE24-0004

(1) / 003-1600-25 / BROOKS / Magmatran 7 / Wafer transfer robot

(1) / 002-7090-03 / BROOKS / - / Wafer transfer robot

(1) / - / PFEIFFER / TMU 1001 P / Turbo pump PM P02 875, DN 200CF-F, 3P With TC-750 SPECIAL DS15 PMC01 711

(1) 27-265775-00 / NOVELLUS / AE Mercury 3013 Match, 3150274-009.

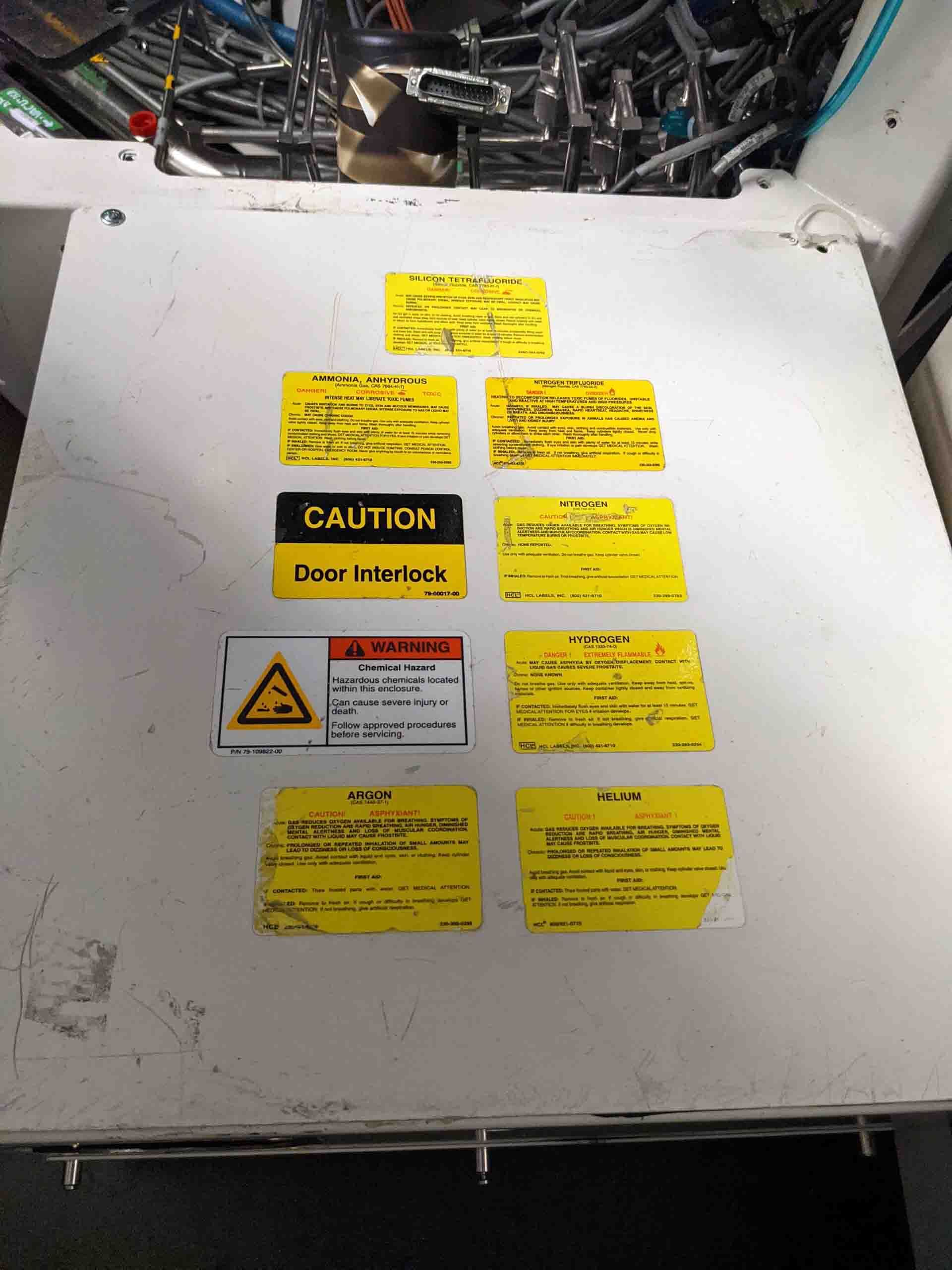

NOVELLUS Inova XT is a multi-chamber semiconductor processing equipment designed for next-generation device fabrication. The system is equipped with three chemically-isolated chambers, each with distinct process modules, that can be configured to meet the specific requirements of any application. It features superior thermal processing, etch, deposition, and clean applications, all with minimal risk of cross-contamination. The first chamber of Inova XT is dedicated to deposition processes. This includes plasma-enhanced chemical vapor deposition (PECVD), atomic layer deposition (ALD), or physical vapor deposition (PVD). This chamber is also capable of using Chemi-Etch™ or spray processes for dry etching. It is also compatible with various source materials, and its flexibility allows it to be used for applications such as dielectric, metal, barrier, and three-dimensional (3D) deposition. The second and third chambers are both used for etch processes. The second chamber is designed specifically for shallow trench isolation and local oxidation of silicon (STI/LOCOS) etching processes. NOVELLUS Inova XT is engineered to precisely control etch-depth and feature transfers with wide-ranging process gases, variable RF outputs, and direct-down wafer sensing for minimal particle generation. The third chamber is also equipped to perform dry etching processes utilizing both ionized cluster beams (ICB) and reactive ion etching (RIE). It offers precision etch processes for multiple metals, dielectrics, and other materials. Inova XT provides high-precision process control with its advanced process engineering software. This automated unit can track gas flows, temperatures, pressures, power levels, and other parameters in real time. It is also equipped with stability and safety features such as fast turnaround time, robust control, error monitoring, built-in safety alarms, and automatic machine shut-down to ensure a high-quality end product. Overall, NOVELLUS Inova XT is a powerful and reliable tool built specifically for advanced semiconductor processing applications. Its multiple-chamber architecture and broad range of deposition and etch capabilities make it an ideal choice for a wide variety of applications. Its advanced process software and safety features make it a reliable and economical solution for any user looking to achieve maximum results.

There are no reviews yet