Used LAM RESEARCH / NOVELLUS Vector Express #9169612 for sale

URL successfully copied!

Tap to zoom

ID: 9169612

Wafer Size: 12"

Vintage: 2007

CVD System, 12"

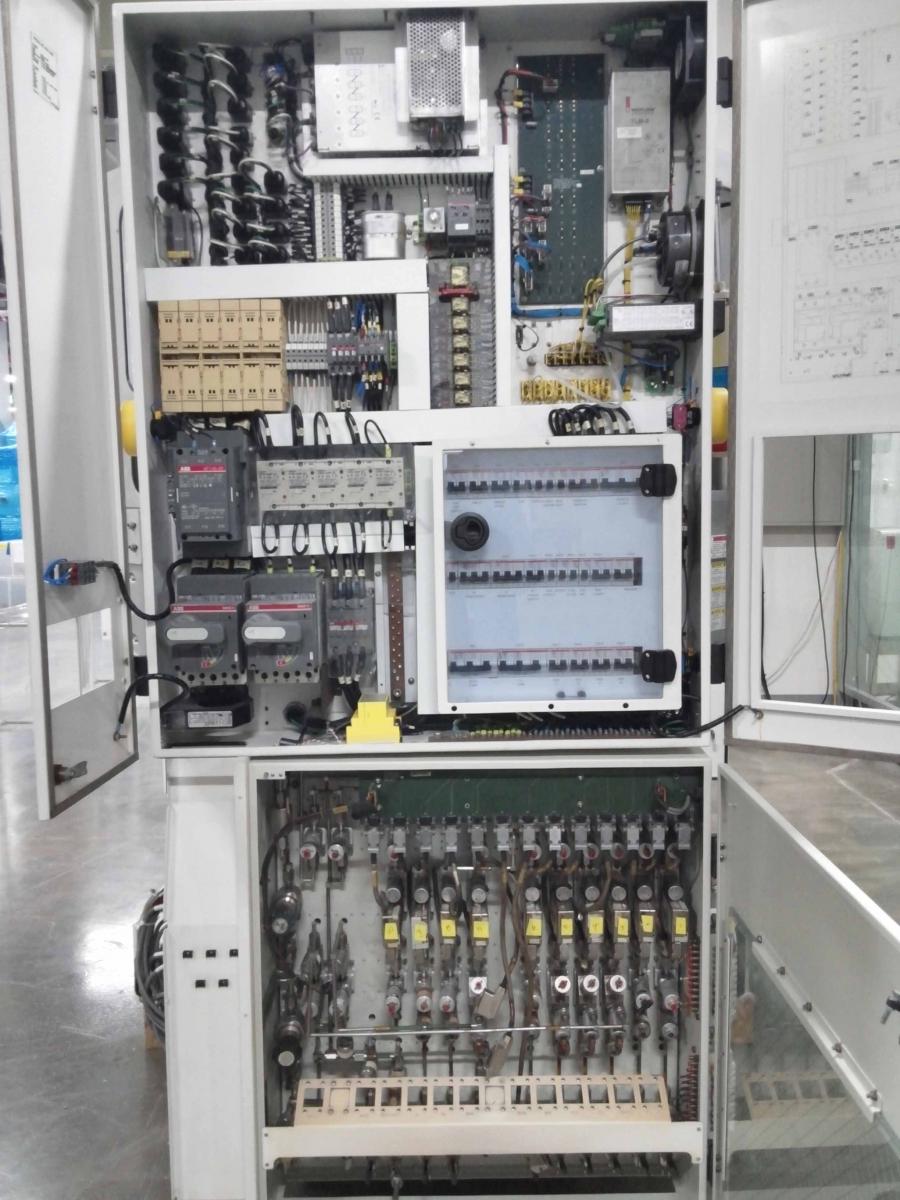

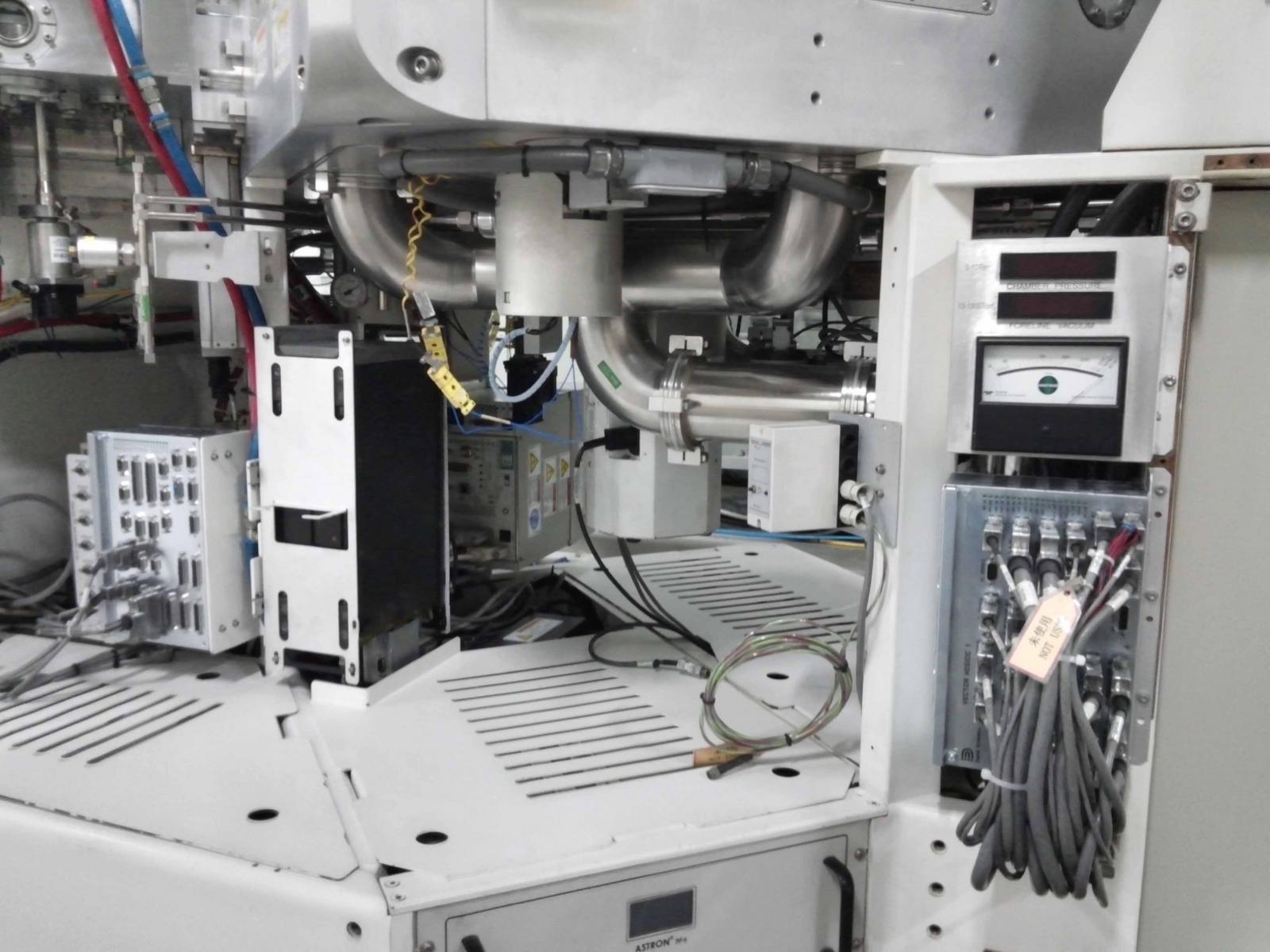

System configuration:

Front UI

Signal tower: Broken

System controller: MC3E, 02-257935-00

Module controller: MC3E, 02-253704-00

IOC: IOC#0,1,2,3 HDSIOC

ATM Robot & controller:

BROOKS RELIANCE 8

Friction type

Controller 129974

Trust controller: C-2027-D01

ULPA Filter

(3) Pod loaders: Fixload 6M

LL / FE Interface PCB: 03-283968-00

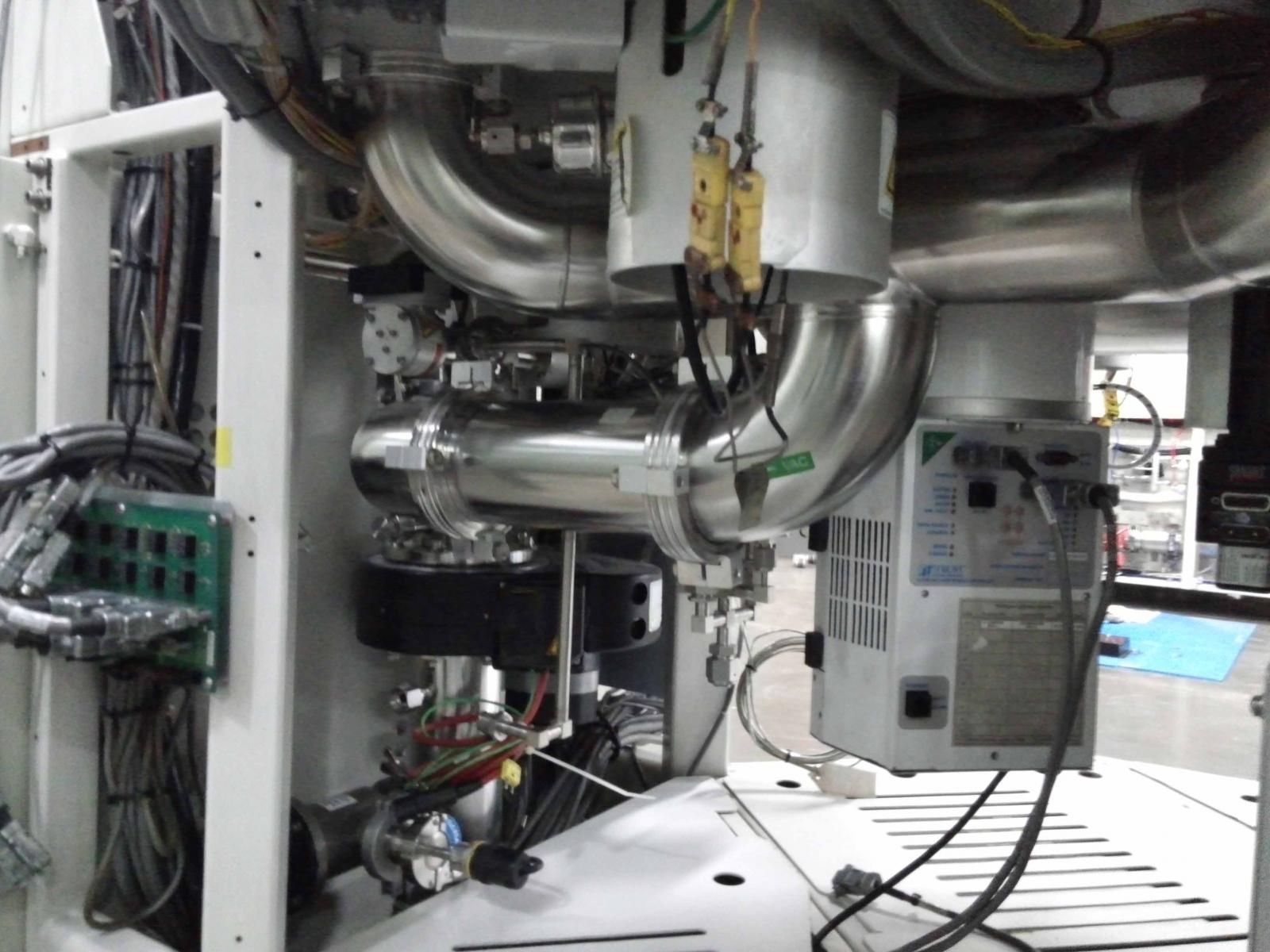

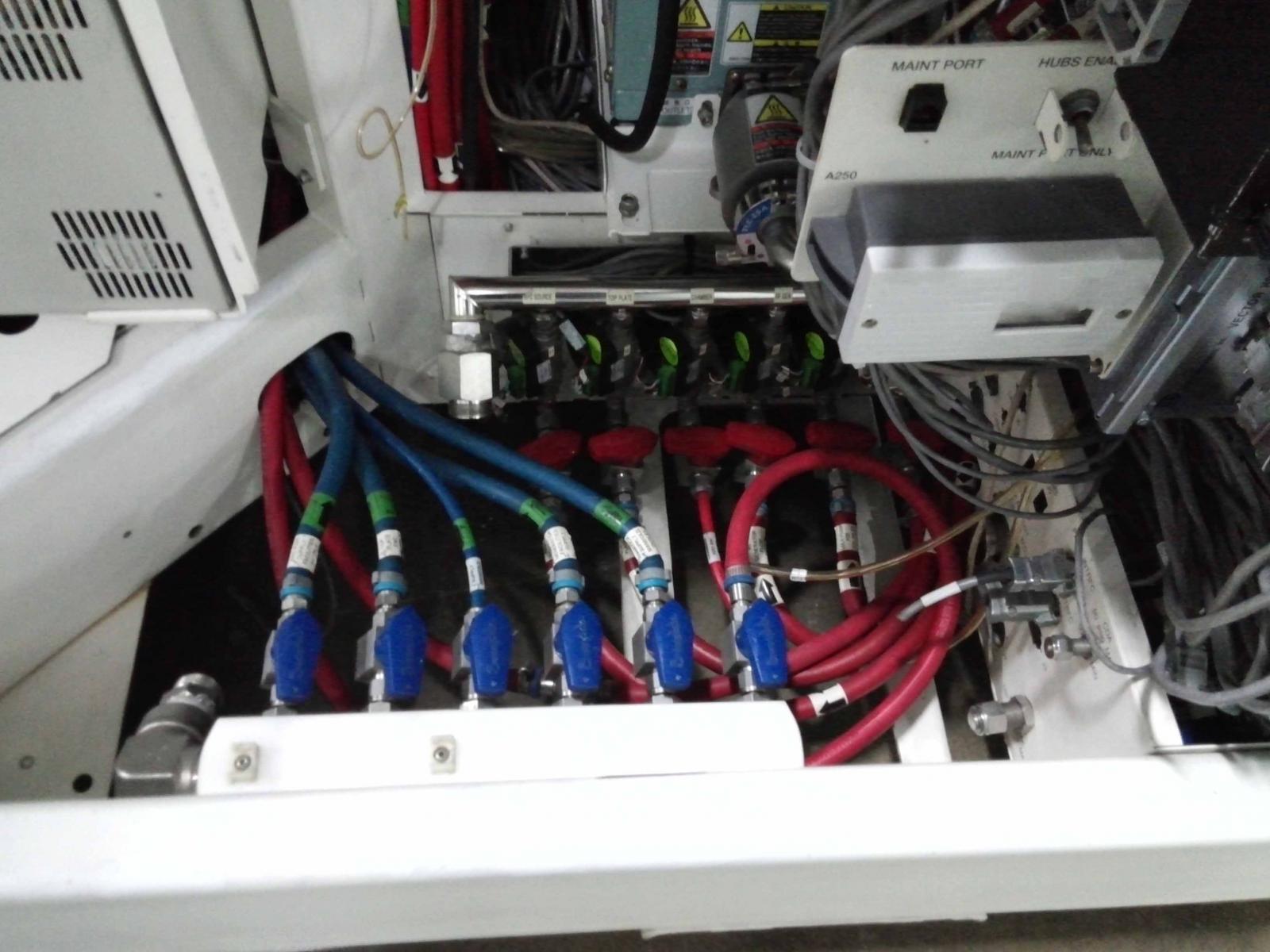

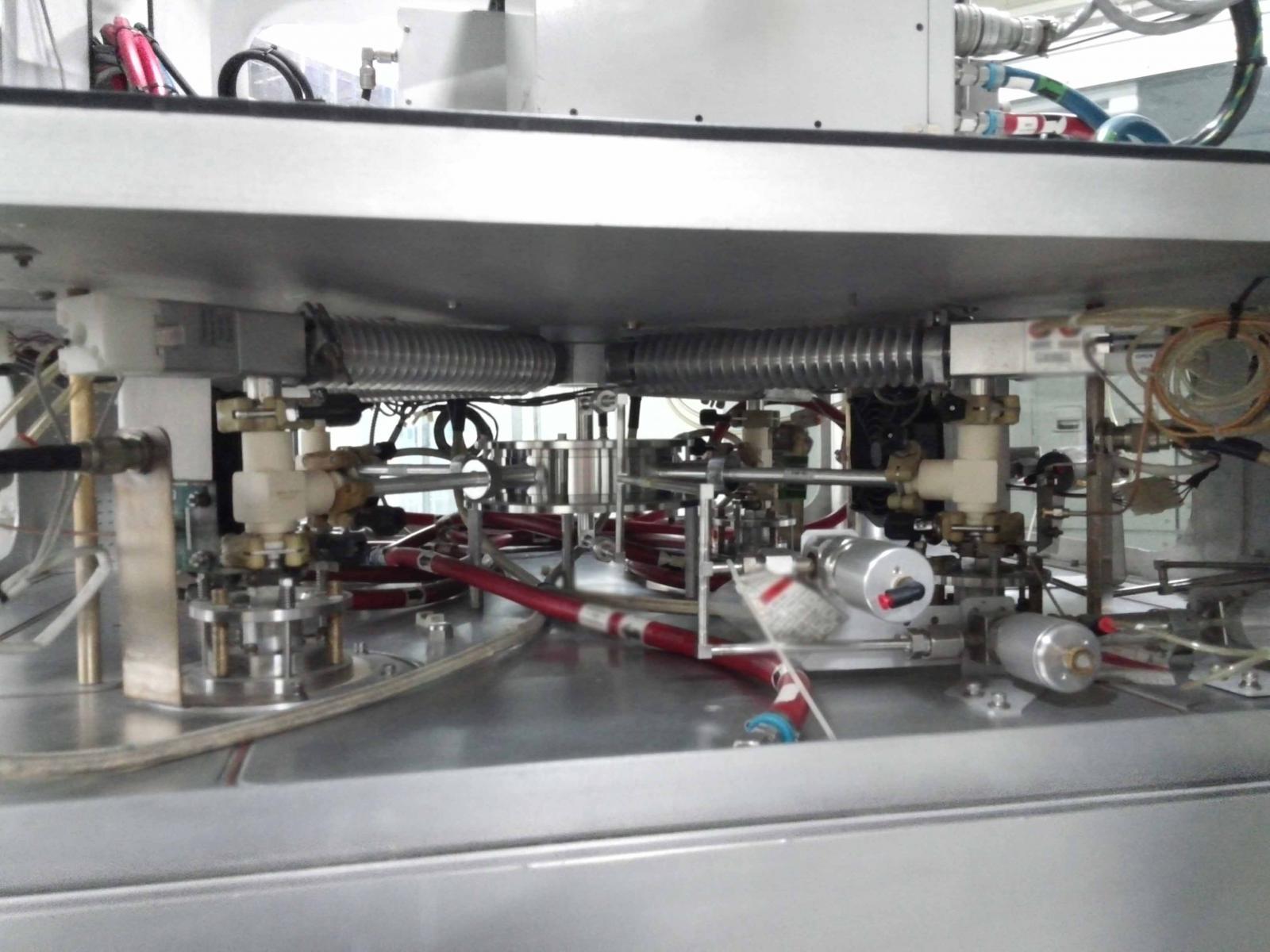

Loadlock configuration:

(2) ATM Door valves: VAT

(2) Chamber slit valves: SMC

L/L Manometer: (10) Torr 750B 11TCE2GK

Vacuum switch

LTM Type: LTM II

Preheat pedestal

Pedestal lift type: Servo motor (Both)

Vent / Purge valve

L/L On-board pump: KAWASAKI 27-283364-00 NV60N-2

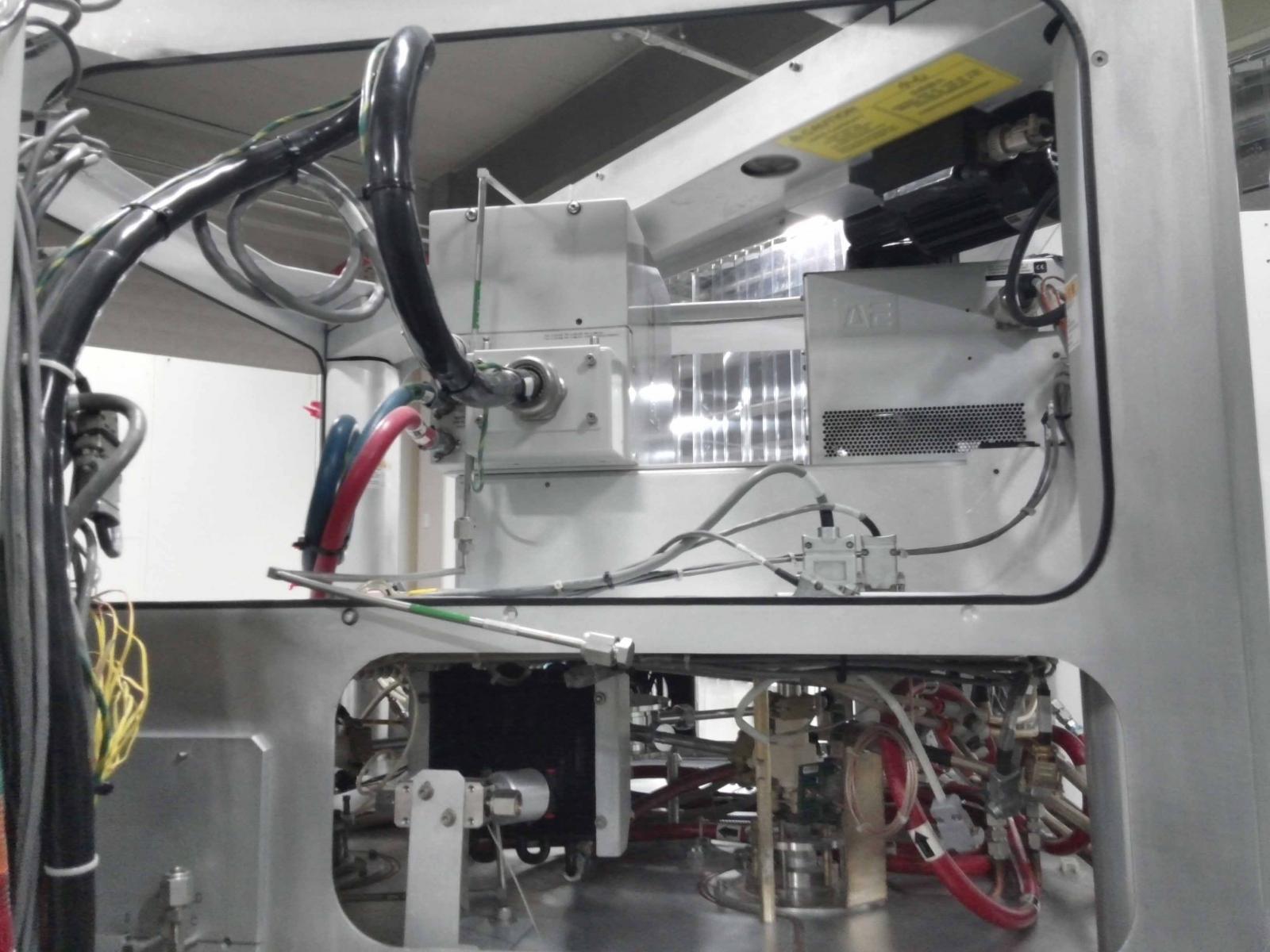

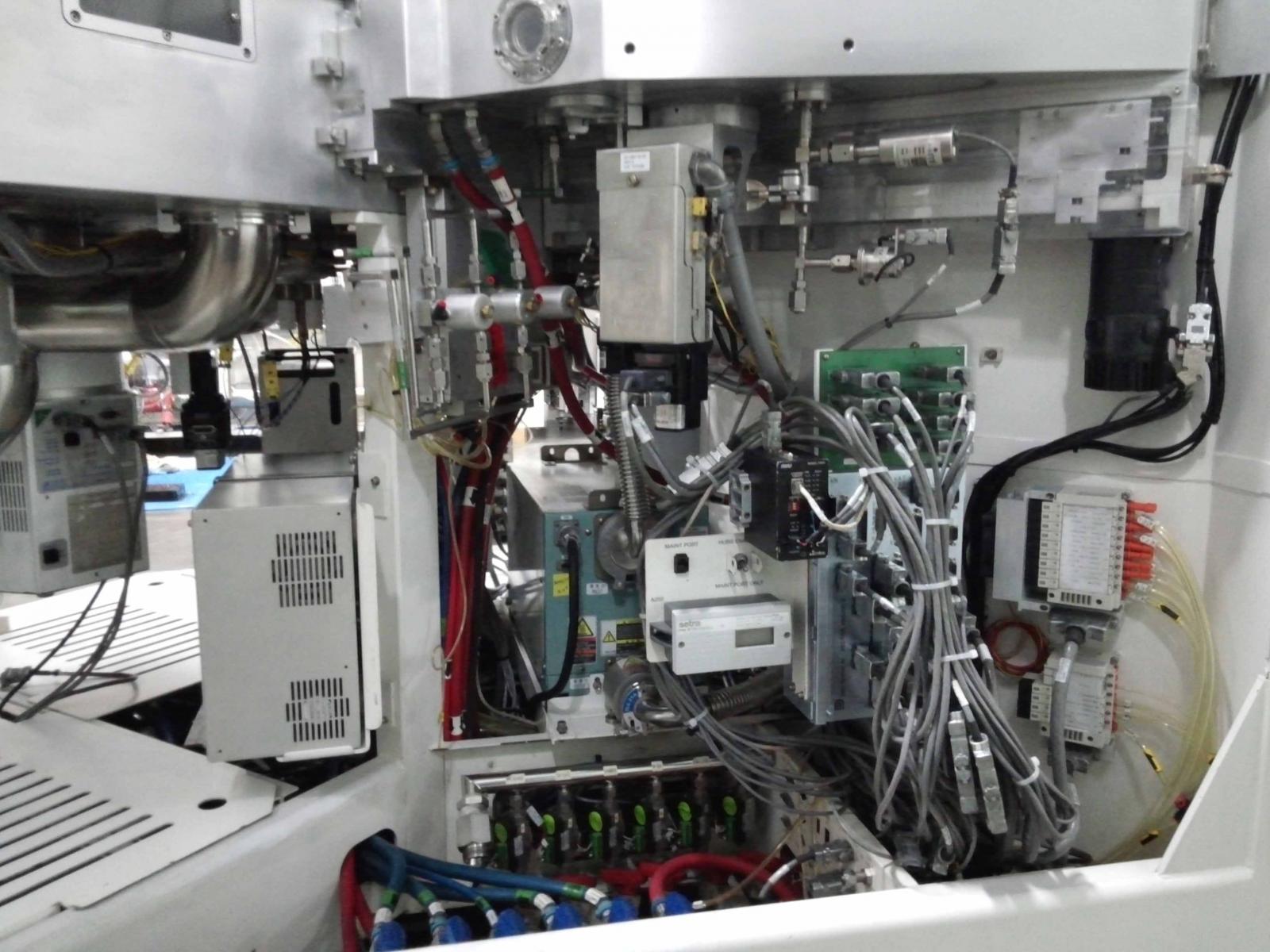

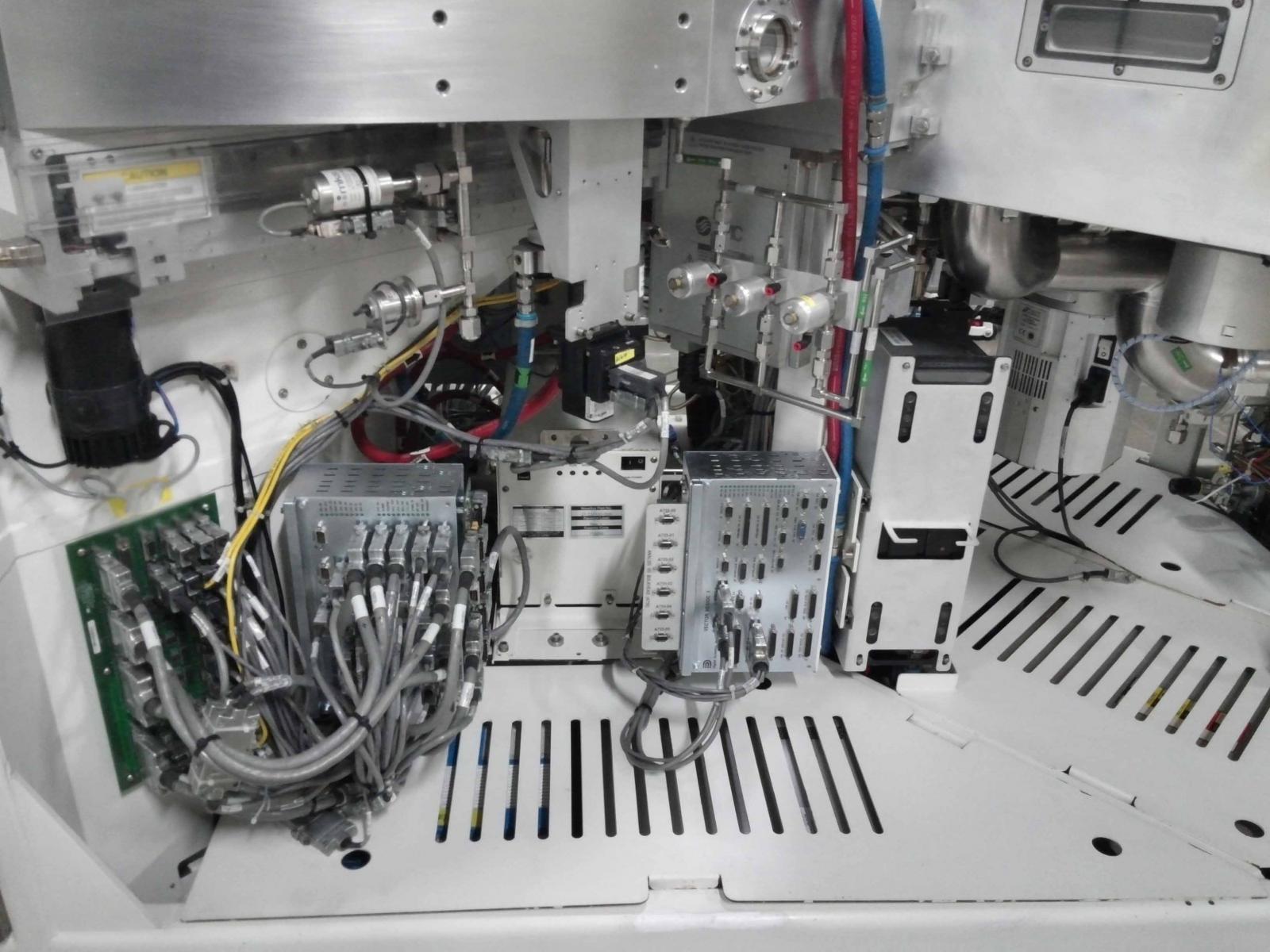

PM Configuration:

Module type: PSIN

HF Generator: Apex 3013

LF Generator: PDX2500

HF Auto matcher 27-279938-00

Navigator: 10013-L80MFI 3155162-002 D

RF Distribution type: Balance kit

RPC Source:

Large RPC / Astron hf-s / 27-282770-00

RPC Power supply: AX7645

Pendulum valve: VAT / PM7 controller X

Pedestal: Standard type

Shower head

Endpoint detector: IREPD - MKS

10 Torr process gauge

Vacuum switch

20 Torr switch

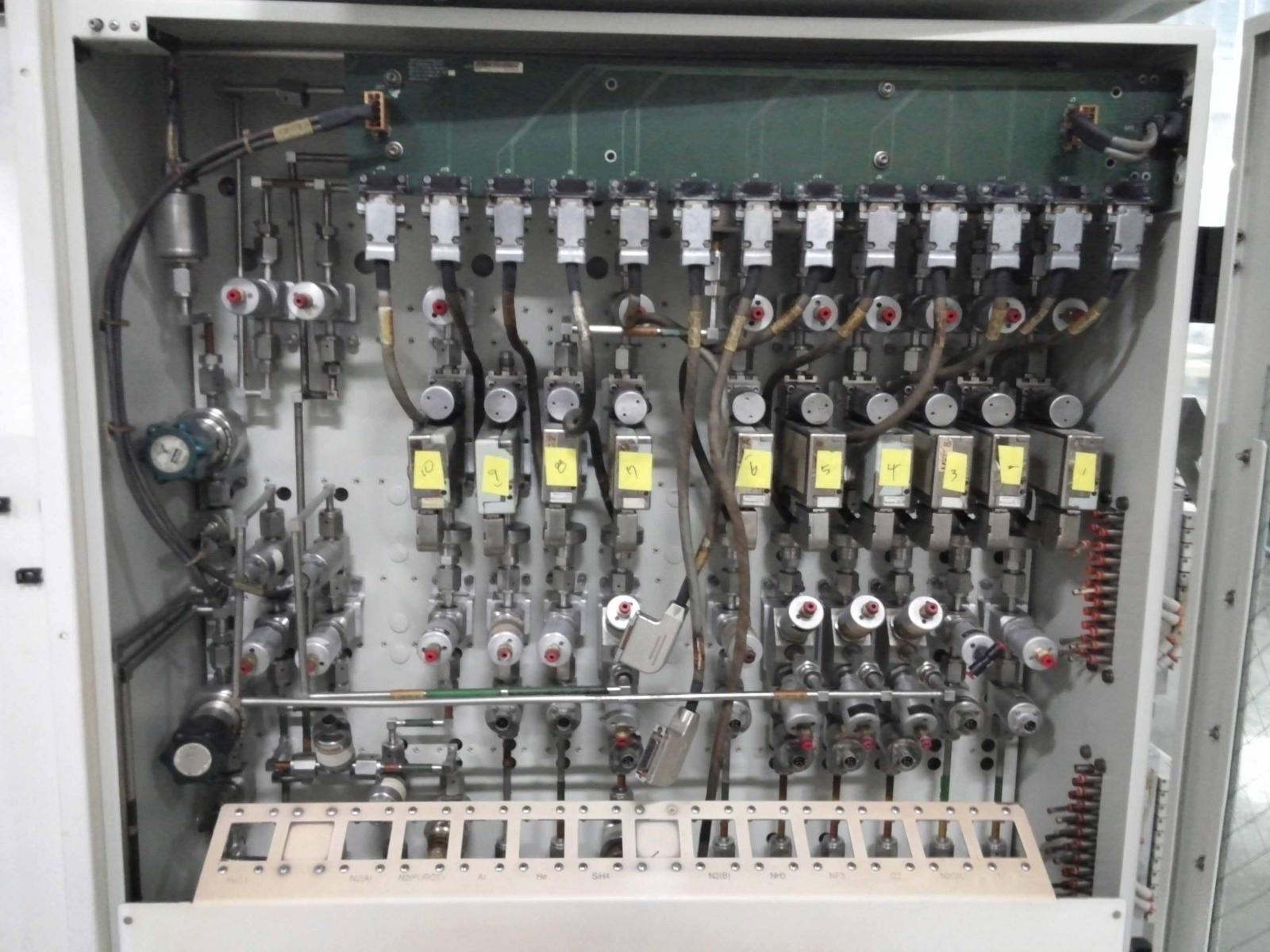

MFC:

BROOKS SLA7950S

N2A

N2B

Ar

He

SiH4

NH3

NF3

O2

N2O(L)

N2O(H)

Arm position detector

Gauge monitoring kit

Spindle type: Servo motor, 27-278697-00

Right L/L top cooling

Stn#1 pin lift type: Servo motor

Missing parts:

PM7 Controller

Signal tower: Broken

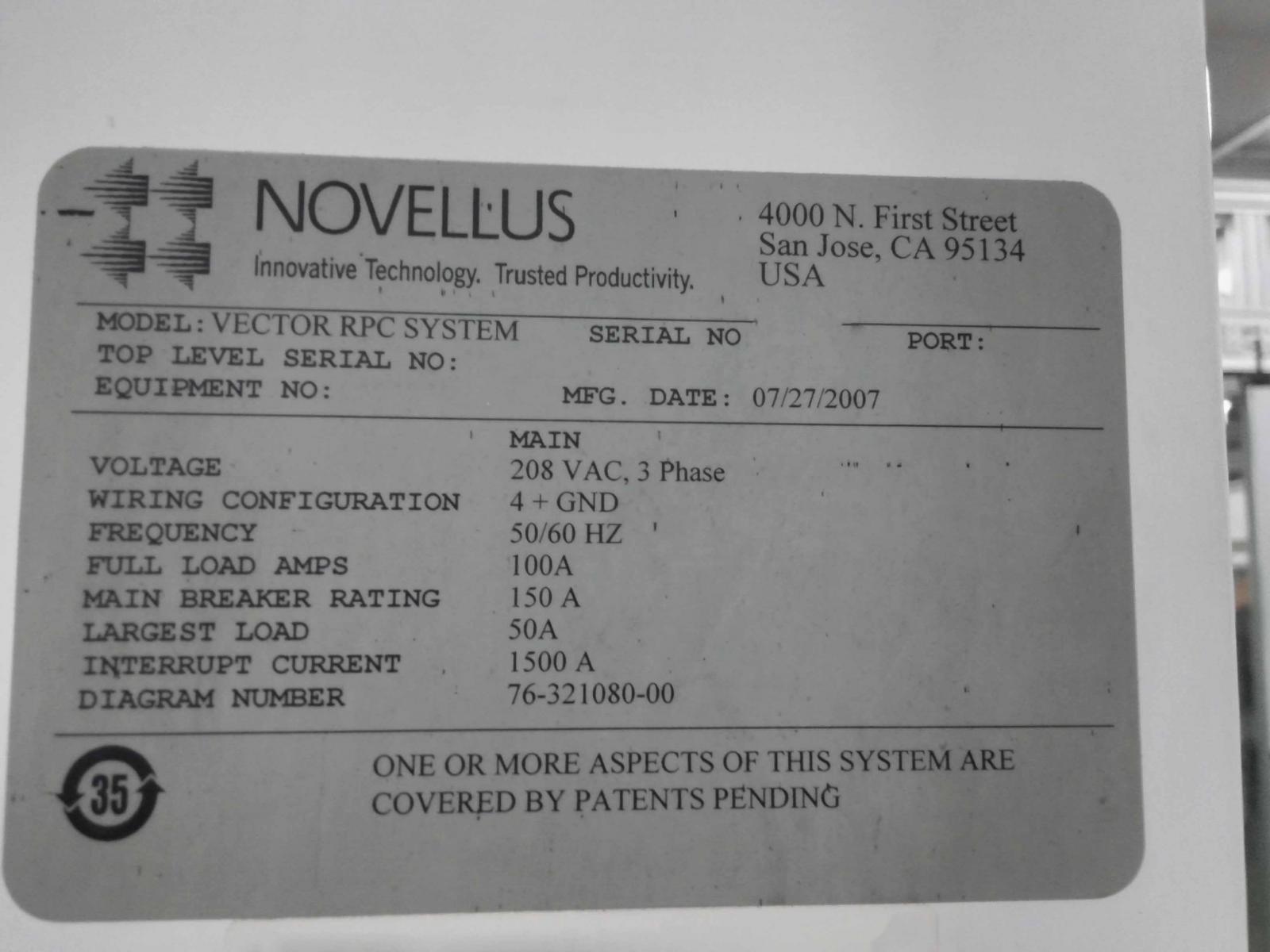

Power:

208 VAC, 3 Phase

Main 150 A

Full load 100 A

2007 vintage.

LAM RESEARCH / NOVELLUS Vector Express is a high-performance, efficient etching equipment used in the semiconductor and related industries. It is designed to provide high precision, reliable, and fast etching of substrates such as quartz wafers, silicon substrates, and other conducting and non-conducting materials in a high-temperature environment. NOVELLUS Vector Express is capable of etching aspect ratios of up to 1:25 and offers a high throughput of up to 1.5 wafers per minute. LAM RESEARCH Vector Express utilizes multiple high-performance etching chambers, each with an independently controlled process chamber and dedicated pumping systems. This system is designed to reduce deposition time, minimize wafer damages, and provide superior process uniformity. The unit also offers fine-tuned control over the etching process, allowing for precise control over critical features. Within each etching chamber, the machine employs a multi-zone temperature and pressure control to create a consistent environment throughout each chamber. This tool features integrated heating and cooling for high-reliability etching. Additionally, the etching chamber utilizes a dedicated gas mixing asset that precisely injects fluorine-based reactive gases (e.g. SF6, NF3, and CF4) into the etching chamber with precision and control. Vector Express also features an Advanced Chamber Impedance Control (CIC) model that provides a uniform plasma for improved etching performance. LAM RESEARCH / NOVELLUS Vector Express utilizes an advanced user-friendly and intuitive graphical interface for ease of control and program development. This equipment also allows seamless integration with all standard etching control systems for maximum flexibility and productivity. It is designed for minimal maintenance and up-time, and is certified for SEMI safety standards for maximum operator safety. NOVELLUS Vector Express is capable of producing excellent etching quality and performance in a variety of materials and applications, making it a reliable and efficient choice for high-volume etching applications. It is a quick and cost effective solution that offers superior reliability, efficiency, and uniformity.

There are no reviews yet