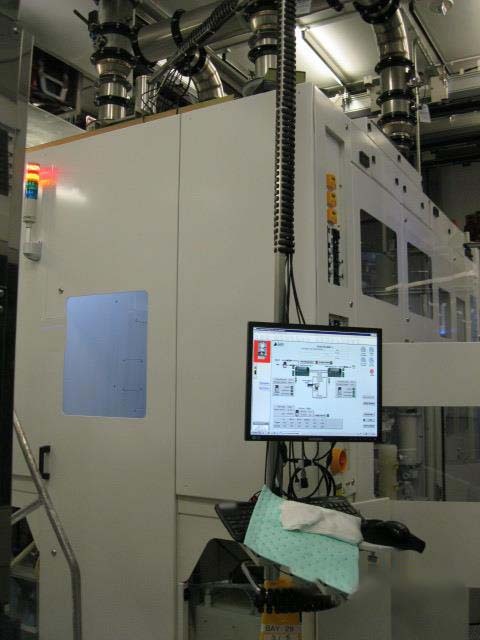

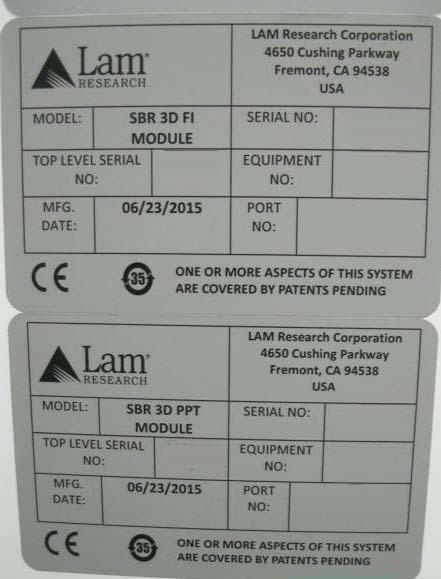

Used NOVELLUS Sabre 3D #9179871 for sale

URL successfully copied!

Tap to zoom

ID: 9179871

Wafer Size: 12"

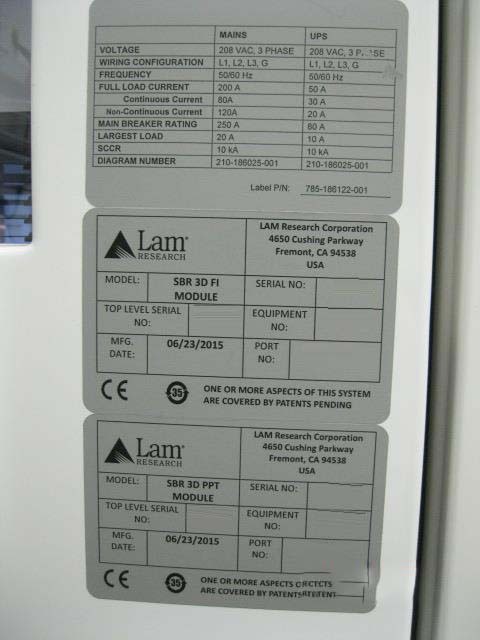

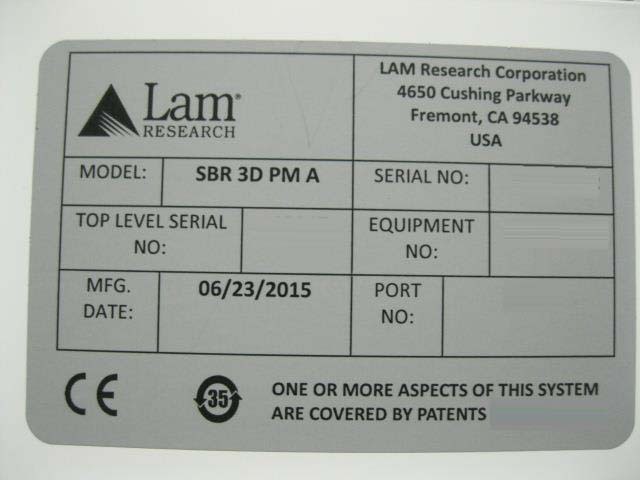

Vintage: 2015

Electro chemical deposition (ECD), 12"

Single module

Configuration:

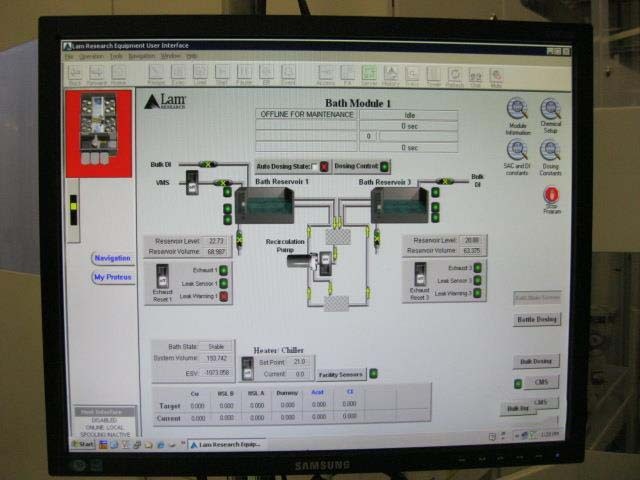

(1) PVC-4910 (SABRE 3D Single module)

(1) KB & Athena remote

(1) Additional (Third) FOUP - 300 mm

(1) RFID Reader (3) FOUP

(1) OHV CA Head-On transmission

(1) LT Front & rear (4) colors

(1) Aligner

(1) (2) APT Duets (4910)

(1) Chemical ADM (TSV Only)

(1) EBR 4910, (2) Duets

(1) TSV Copper

(1) 8 x 0 Config 1 Ba

(1) TF10000 With heater

(4) 300 mm, 1.00 EE, 0.40 mm Cont

(4) Copper TSV process package

(4) Degasser

(1) SABRE 3D Single, 2 APT, 2 EBR/SRD

(4) Cell specific flow meters

(1) NSR 17, NSR 1087310 Pneumatic flow switch

(1) NSR 18, Tool ladder 71-299012-00

(4) 9.5A, 750W Serial

(1) NSR 1, 845-154096-001 Trough vent, ver C

(1) NSR 2, 845-211454-001,KIT,SBR-3D,Bath R

(1) NSR 3, SW CESPTC53073A, Plate, leveling F

(1) NSR 4, Blue900109 BE Robot 8 cell

(1) NSR 5,CESPTC52432A Factory int ionizer

(1) NSR 6, 845-175917-001 8c Video monitor

(4) NSR 7, SW 856-155785-001 Kit UPGRD, TR 4

(1) NSR 8, 845-192680-001 KIT,SBR-3D,1087310

(1) NSR 9, Blue900137, Aligner, vortex,300 mm

(1) NSR 10, SW, 02-414924-02, ASSY,Drip pan,P

(1) NSR 11, SW, 02-443139-02, ASSY,Drip pan

(1) NSR 12, SW, 27-403019-00, Pump DI water

(1) NSR 13, SW, 857-170700-101, KIT,CNTCTR R

(1) NSR 14, SW, 857-170700-102, KIT,CNTCTR R

(1) NSR 15, SW, 856-200391-001, KIT,UPGRD,AI

(1) NSR 16, SW, 856-200391-002, KIT,UPGRD,AI

Currently installed

2015 vintage.

NOVELLUS Sabre 3D is a revolutionary semiconductor processing reactor that combines two key technologies - chemical vapor deposition (CVD) and atomic layer deposition (ALD). It is designed to facilitate the fabrication of ultra-thin layers of materials used in the manufacturing of semiconductors. This equipment offers unmatched precision and control in deposition processes, significantly reducing cycle times and other process costs that can impact yield. Sabre 3D provides a fast, reliable and repeatable process by using the combination of CVD and ALD for both deposition and etch operations. It utilizes a high-powered gas source, consisting of oxygen and various other inert gases, to create a 'monochromatic' and 'superclean' environment. This allows for ultra-thin films with no surface defects or contamination, thus providing exceptional control of the deposition process. NOVELLUS Sabre 3D reactor consists of three basic modules - a plasma generator, a chamber and a power supply. The plasma generator is a microwave unit that generates a pyrogenic, non-thermal plasma. This is responsible for molecular activation and deposition of thin films on the substrate. The chamber is a vacuum-sealed enclosure housing the plasma and reactor portions of the system. It is designed to maintain a consistent, clean environment to sustain a repeatable process. The power supply unit provides the correct electrical current to ignite and maintain the plasma. Sabre 3D reactor has an extensive temperature range (from 90°C to 500°C), allowing it to be used for multiple processes. It also features advanced automation and controls, including a high precision, integrated optical unit for in-situ process monitoring. This helps to quickly identify process issues and provide prompt feedback for process improvement. Finally, NOVELLUS Sabre 3D reactor features an easy connection to any process control machine. This allows for data collection, analysis, and process optimization for maximum uptime and yield. Sabre 3D reactor is efficient, cost effective and provides reliable and repeatable deposit characteristics. It is an ideal solution for high-volume, high-quality semiconductor fabrication.

There are no reviews yet