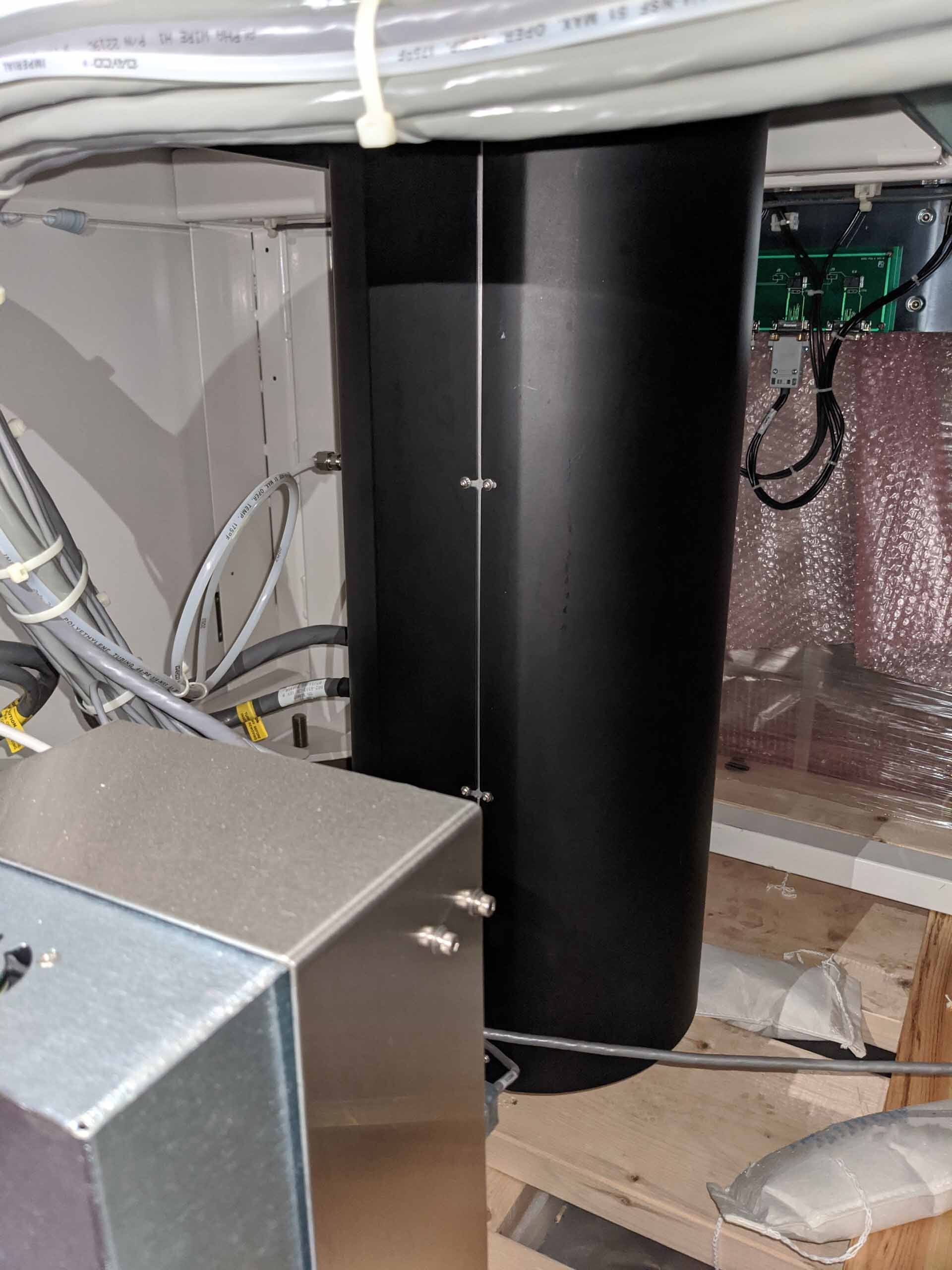

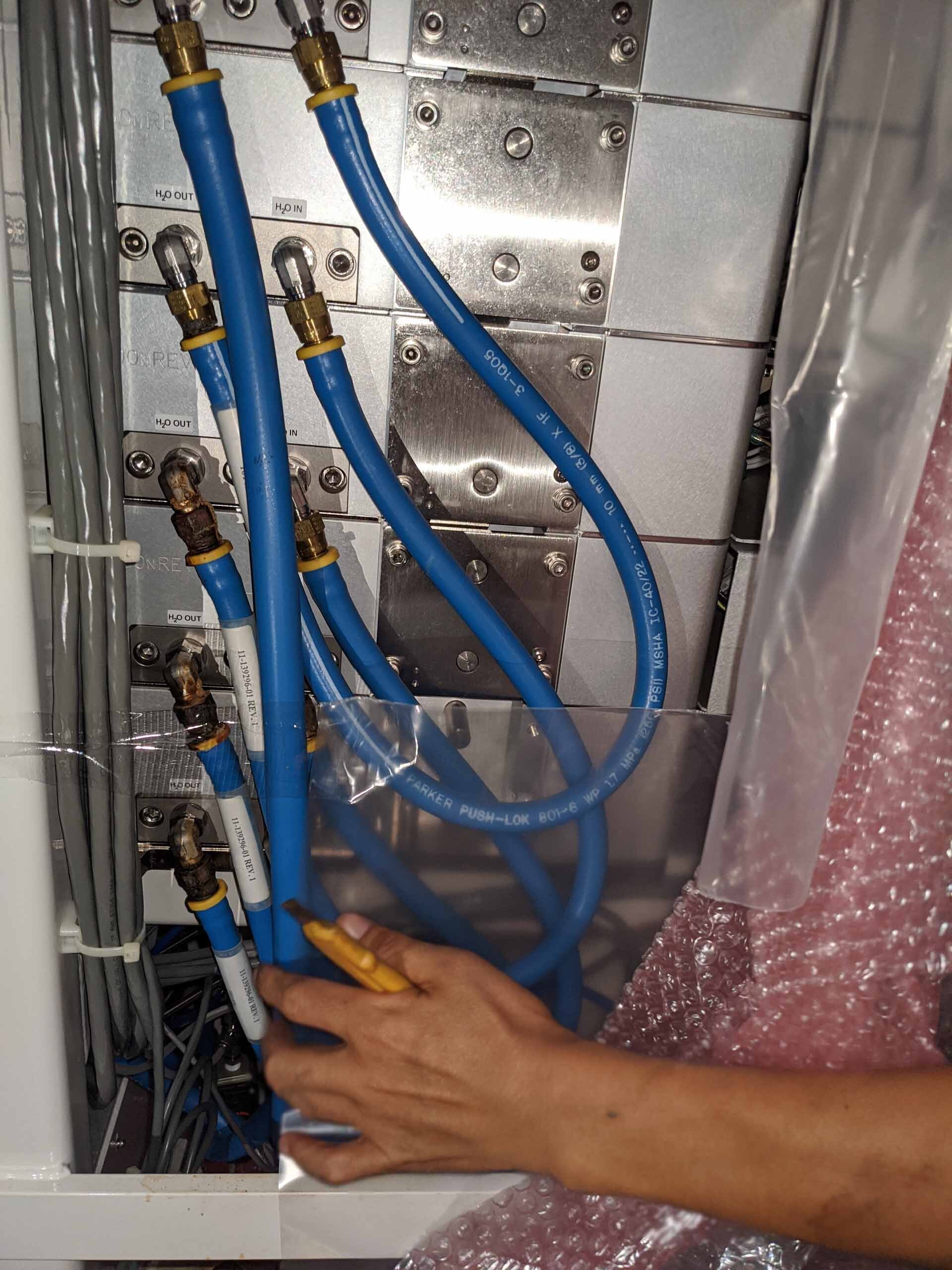

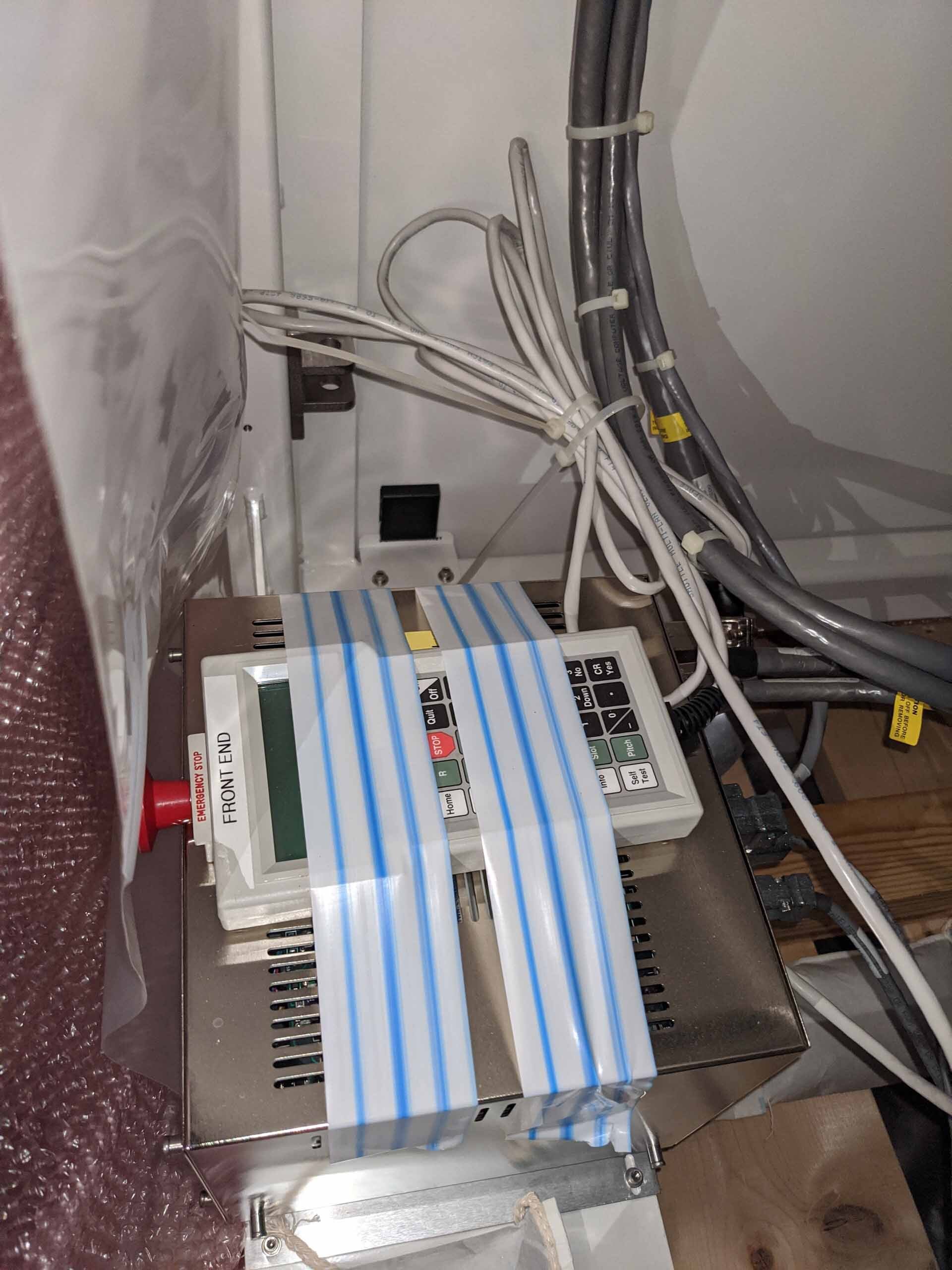

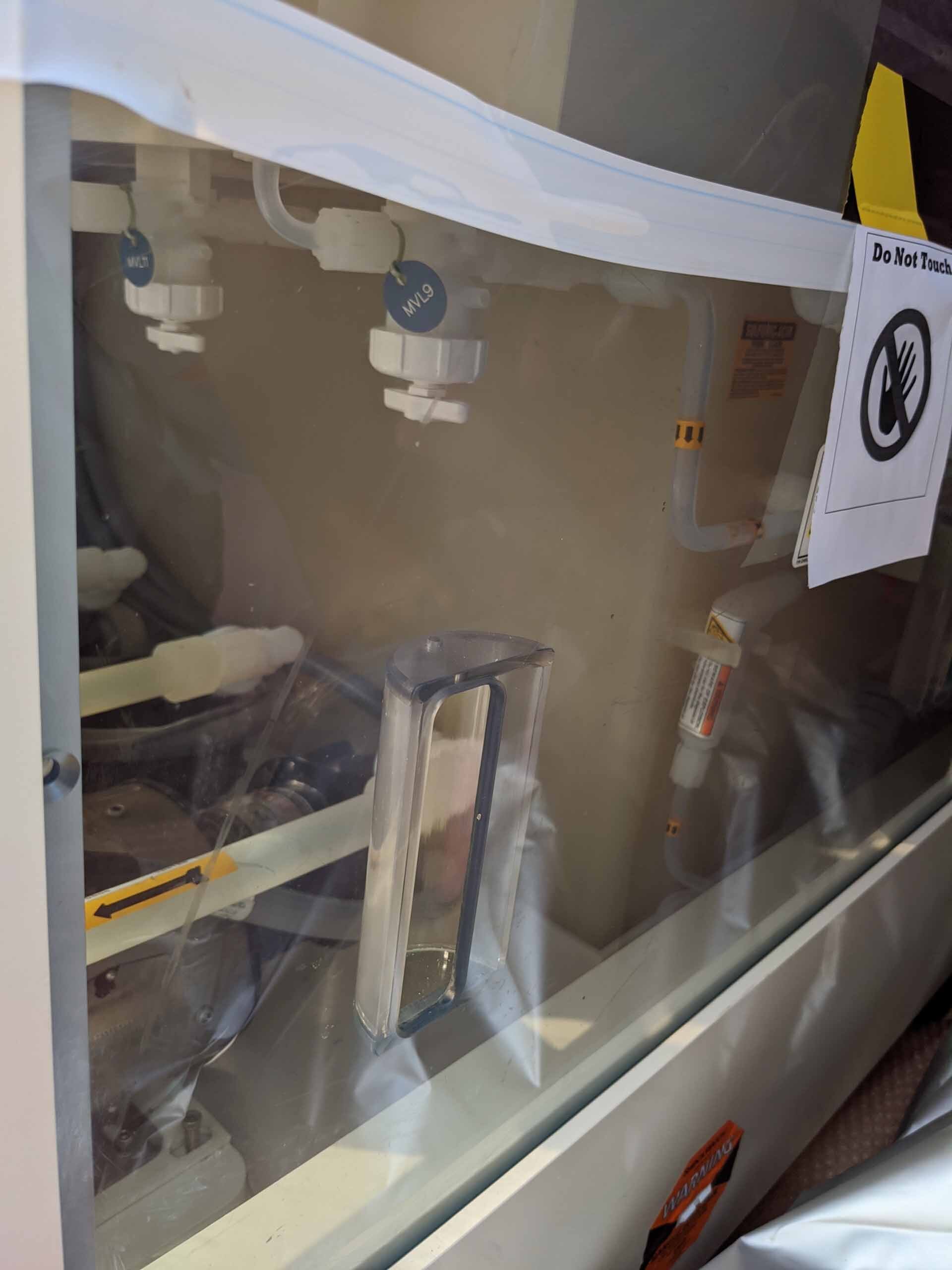

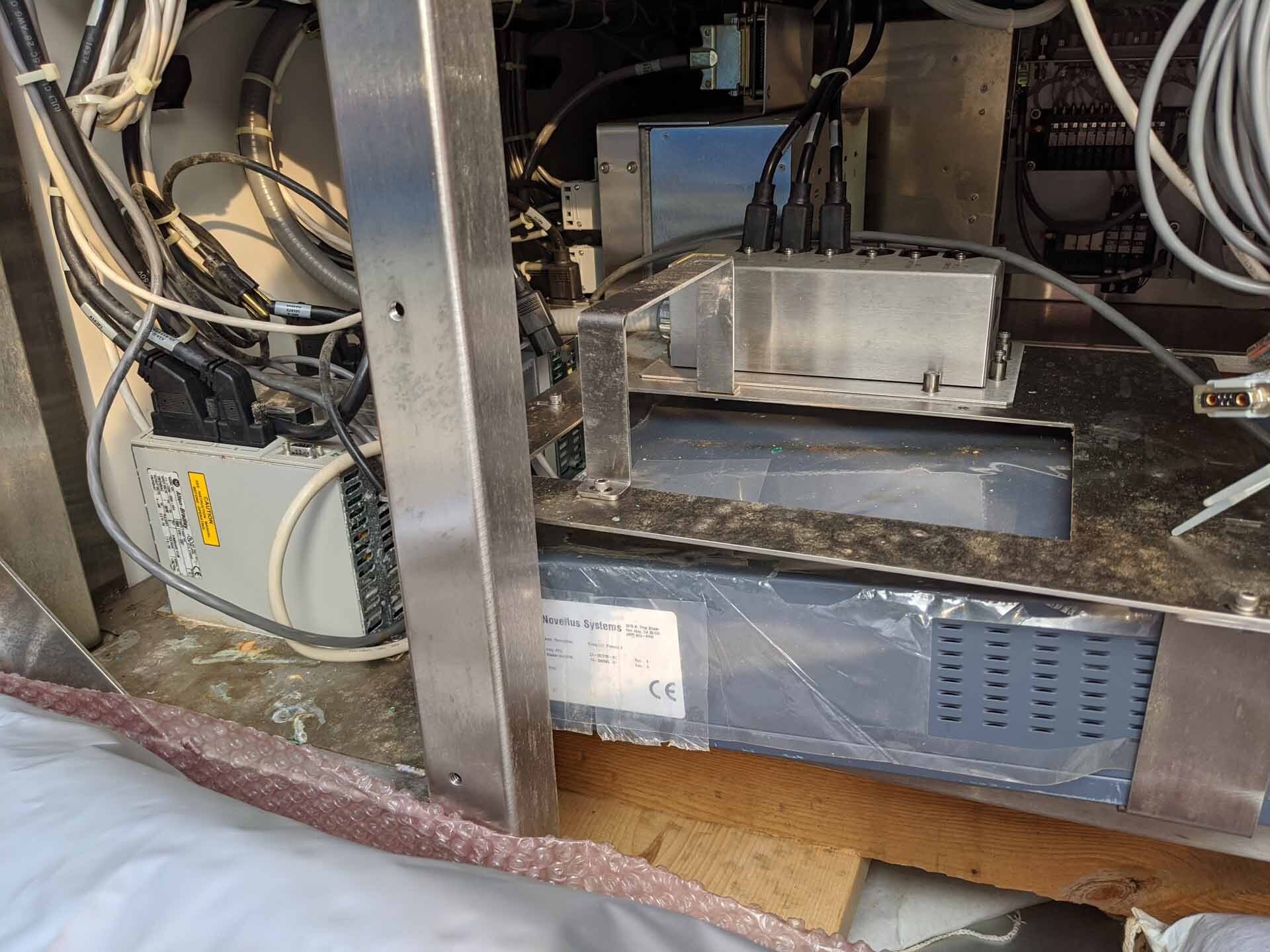

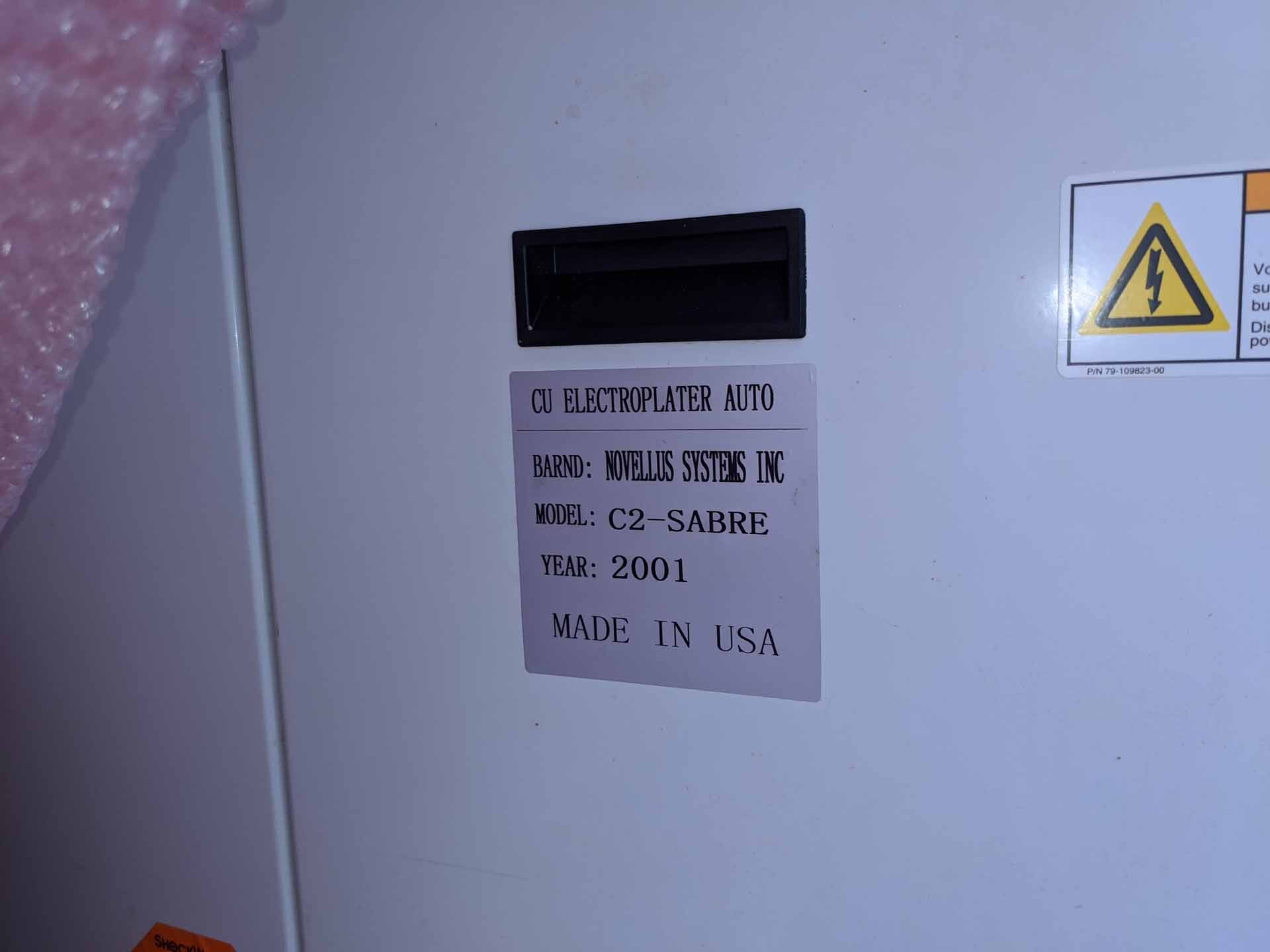

Used NOVELLUS Sabre XT #293610632 for sale

URL successfully copied!

Tap to zoom

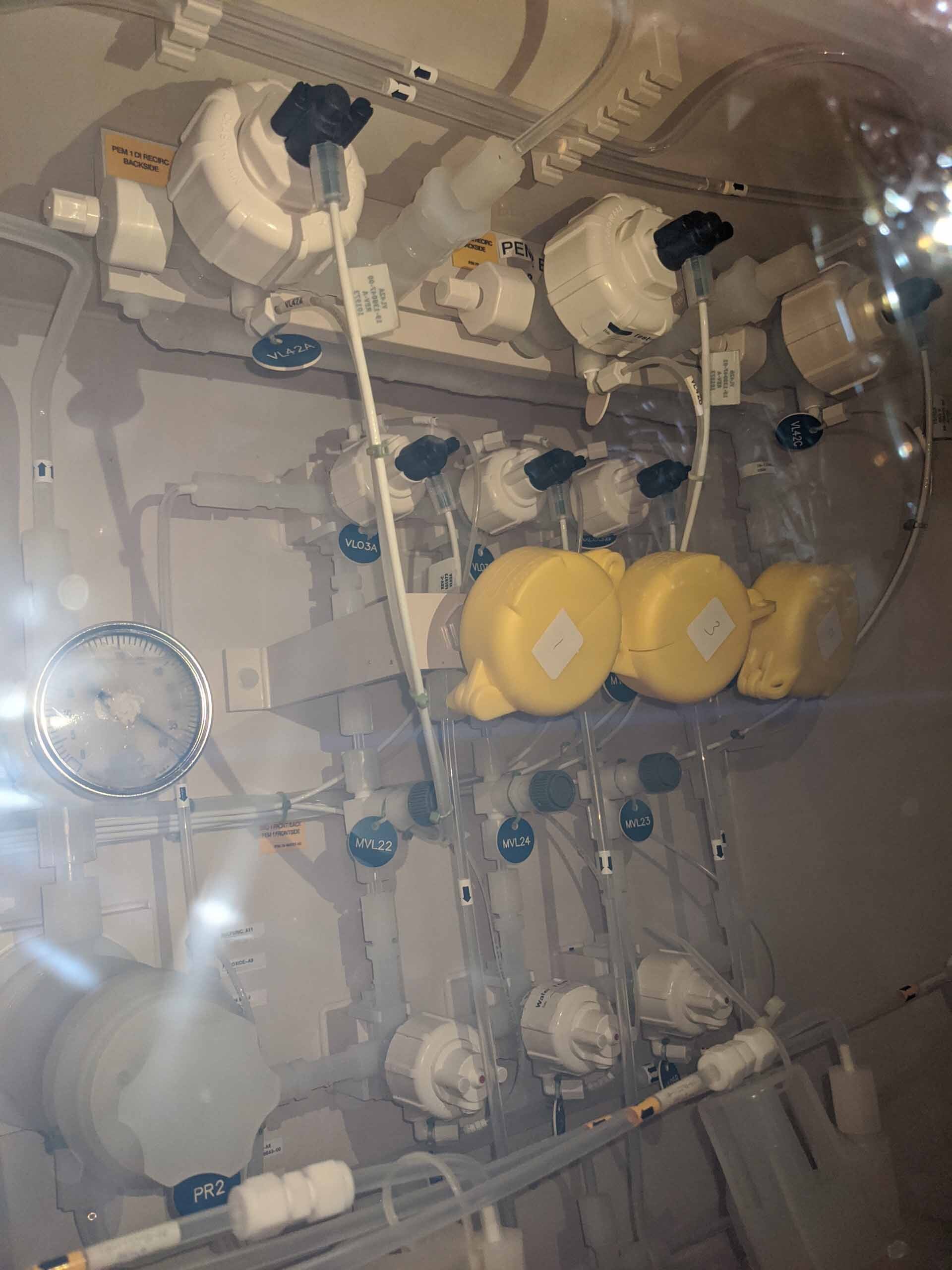

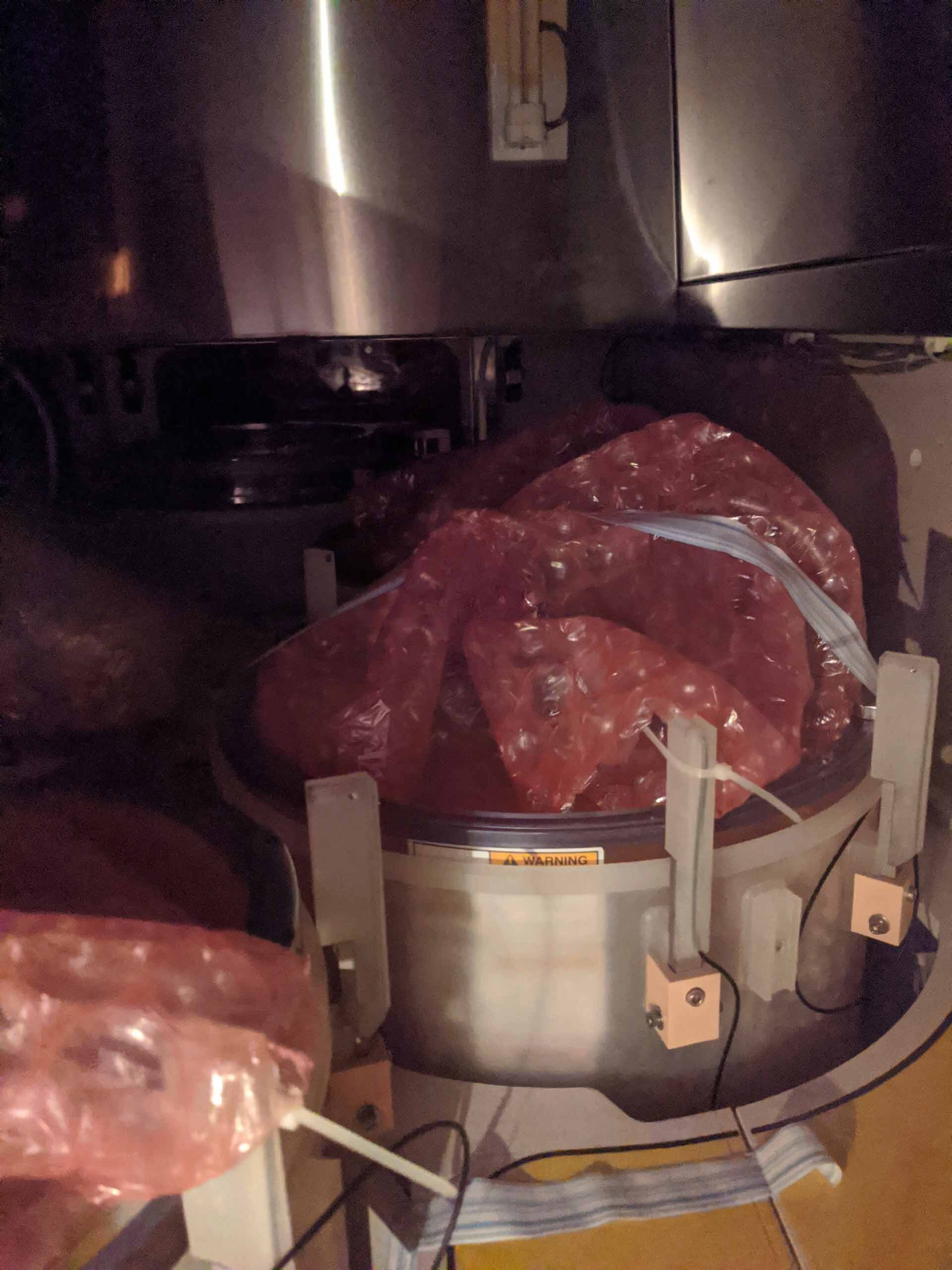

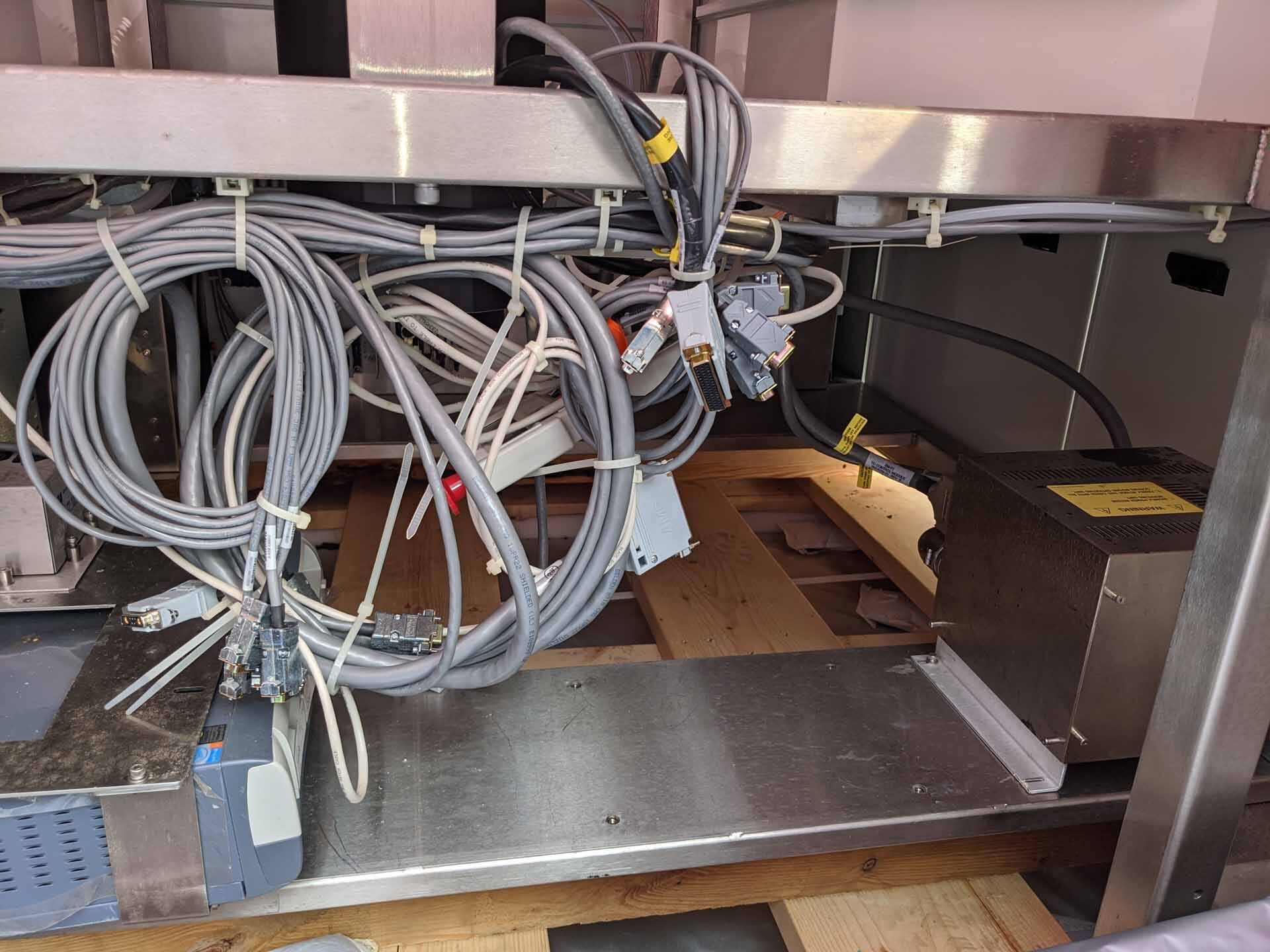

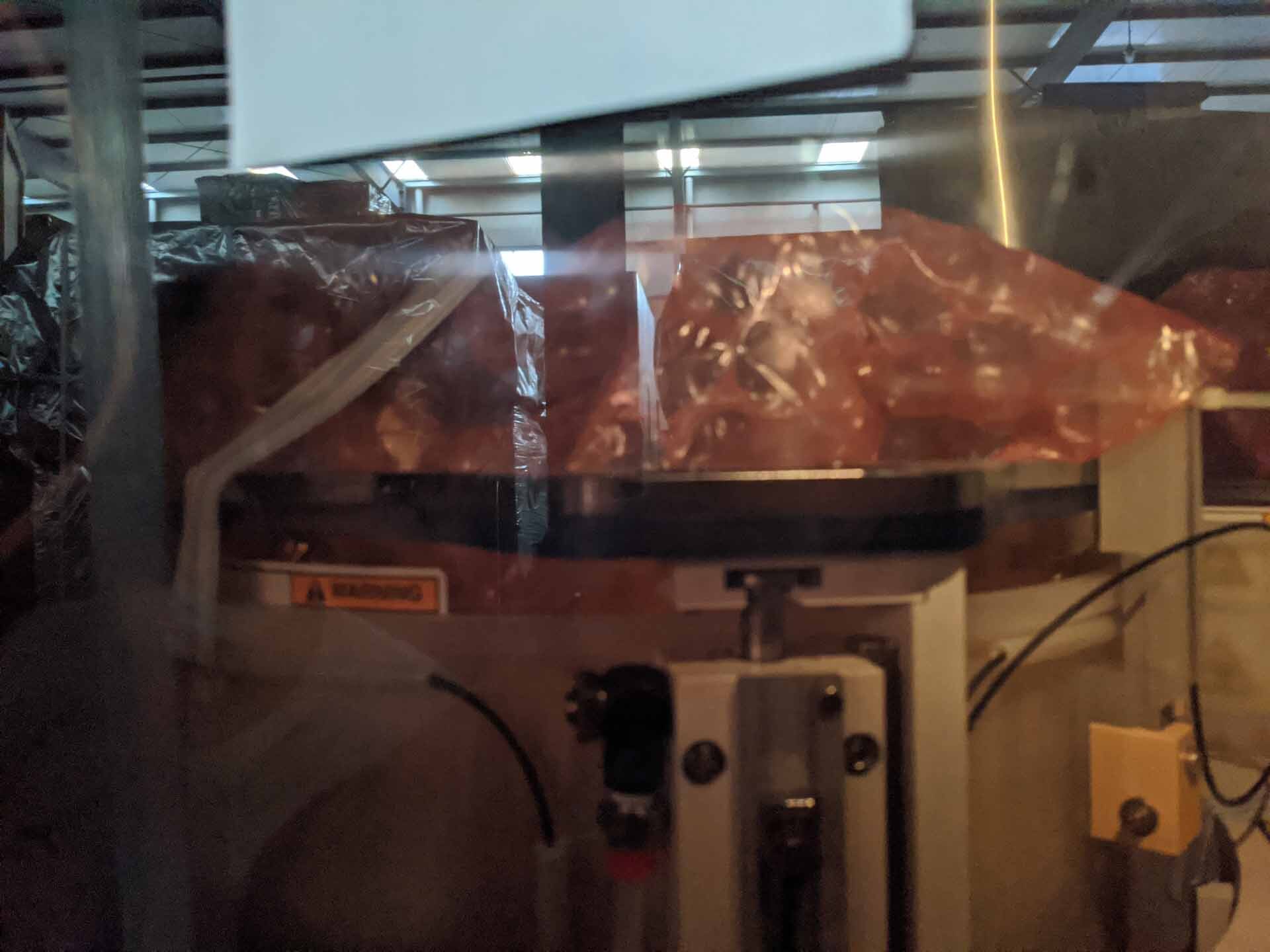

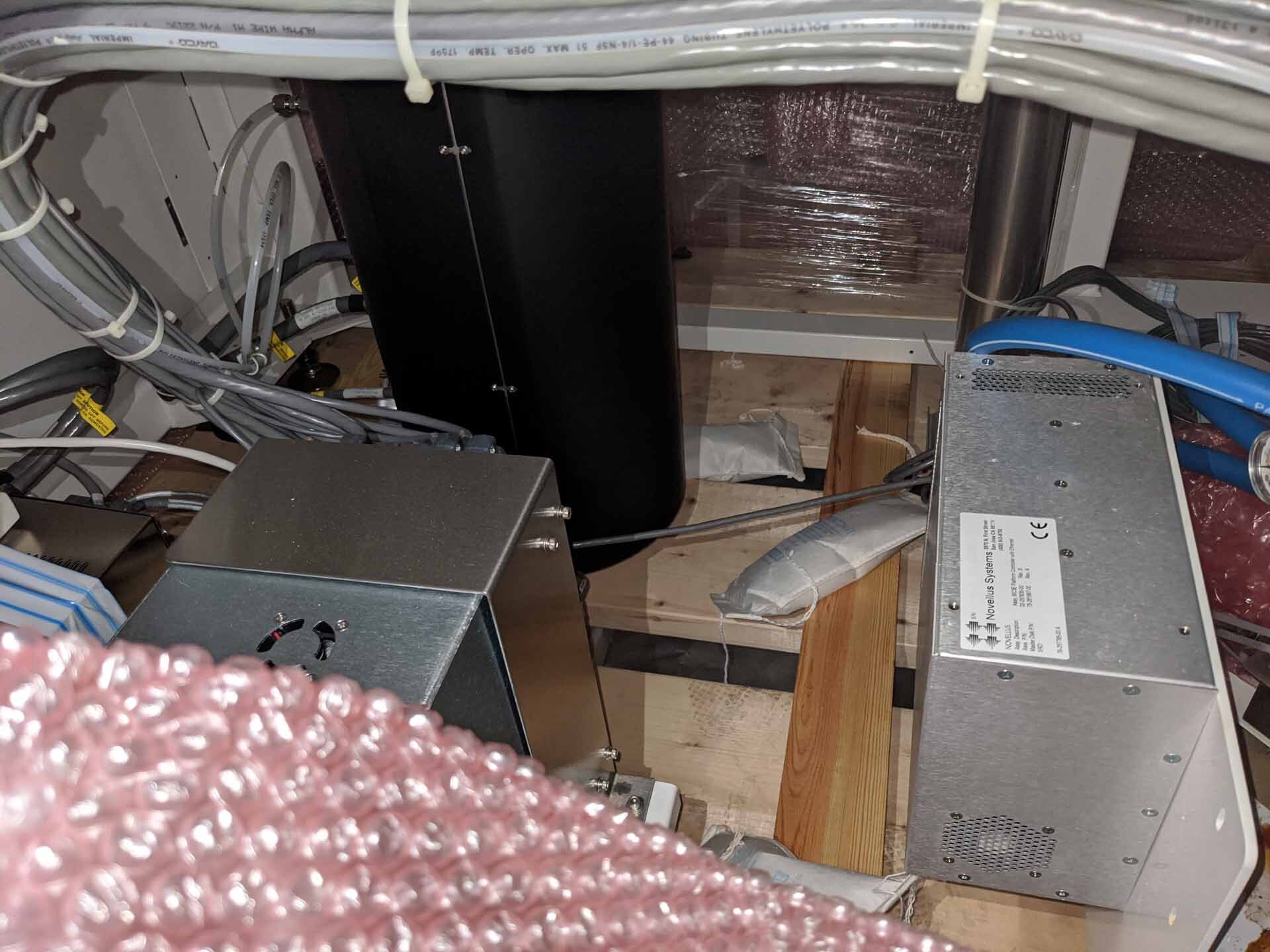

NOVELLUS Sabre XT is an advanced etch reactor that provides manufacturers with the power to create complex patterns with high precision. NOVELLUS SABREXT is equipped with three stages of ion bombardment for maximum control and has a modular construction. It's capable of producing structures with feature sizes from one micron down to 35 nanometers. The tool kits of Sabre XT are designed to help manufacturers achieve higher levels of precision and to perform a variety of intricate etching processes with ease. The first stage of ion bombardment uses a tri-field stepping equipment and targets the desired areas of the substrate. By allowing for specific selection of the area to be etched and for precise realization of feature size and form, this system gives users of SABREXT greater control that lets them create complex patterns with more accurate results time after time. The second stage of ion bombardment etches deep within the material, creating features with widths of between 350 nanometers and 1 micron. This process allows manufacturers to meet the standards of high-volume production while still achieving the desired feature accuracy. The final stage of ion bombardment consists of copper etching and can produce features with a width of less than 35 nanometers. The copper etching offers higher resolution patterns with a reduced time to completion. NOVELLUS Sabre XT is also equipped with an automation workstation and complete software that lets users automatically monitor, analyze and optimize their process for maximum yields and productivity. Its advanced "Robustication" control unit further ensures reliable performance and repeatable results, even when etching multiple layers with different photomasks. Overall, NOVELLUS SABREXT is an advanced etch reactor that delivers precise etching of complex patterns with minimal human intervention. With its three stages of ion bombardment, advanced workstation and "Robustication" control machine, manufacturers can achieve high-resolution patterns in high-volume production.

There are no reviews yet